Abstract

The aims of the present study are: (i) to verify the influence of different flour extraction rates and milling procedures on bread quality, (ii) to optimize the bread-making process by using different percentage and time of fermentation of three spontaneously developed type I sourdoughs. These latter were prepared with a whole-meal wheat flour blend (SA), a type 0 wheat flour blend (SB) both obtained by steel roll milling, and a type 2 wheat flour blend obtained by stone grinding (SC). The pH, total titratable acidity (TTA), and stability of the microbiota of the three sourdoughs were assessed before baking trials. TTA, specific volume, weight, crumb core moisture, texture, and global liking of sourdough bread, in comparison to control bread made with commercial baker’s yeast, were determined. Moisture, texture, and global liking of bread were also evaluated during 6 days of storage. SA was characterized by a significantly higher pH and TTA values than SB and SC. Differences in the LAB-to-yeast ratio were registered among the three sourdoughs although no differences were seen in terms of the dominant microbial community. Concerning breads, although the type 0 roll-milled wheat flour showed better dough rheological performance compared to whole-meal wheat flour and stone-ground wheat flour, sourdough fermentation positively affected the specific volume, texture, and global liking of bread manufactured with stone-ground wheat flour. Overall, for an efficient use of sourdough and bread quality improvement, optimal conditions need to be found by tailoring sourdough to the type of flour used.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bread-making is mainly based on the use of low-extraction-rate soft wheat (Triticum aestivum) flour, from which, during milling, bran and germ are progressively excluded, thus leading to flour and leavened baked products that are poorer in terms of nutrients compared to goods manufactured with whole-meal flour [1,2,3]. More specifically, the modern grain milling process is a highly efficient process performed with steel rolls: the grain is scraped by high-speed rollers layer upon layer and then the flour released from the endosperm is separated by sifters into different grades or streams based on fineness, whereas the bran and germ are completely removed [2,3,4]. The various sieved components can be subsequently re-integrated to enable the production of a variety of flours to be sold for diverse baking purposes [5, 6]. In the last several decades, grain milling with steel rolls has almost completely replaced the ancient milling method, relying on use of millstones [3, 4]. In stone grinding, all whole-grain components (bran, germ, and the amidaceous endosperm) are ground in a single pass through and between two horizontal, round millstones, retaining and integrating wheat germ oil [4]. If conditions of slow grinding and low temperature are applied, the wheat germ is not exposed to overheating, hence being preserved from the consequent oxidation of the fat from the germ and the destruction of vitamins, polyphenols, total fiber, and carotenoids [4, 7, 8]. Furthermore, stone grinding of small amounts of grain enables a better distribution of fat, resulting in a minimization of flour spoilage [9], whereas the larger particle size of stone-ground flour limits nutritive losses due to oxygen exposure [10]. Stone grinding can be followed by refining, but the latter process never produces refined type 00 flour and always type 0, 1, or 2 flour. Stone-ground flour is also believed by some bakers to be nutritionally superior to steel roll-milled flour and to have a better baking capacity, being characterized by an irregular granulometry, an ivory-hued color with flecks of cream and beige, and a sweet, nutty flavor [3, 4, 7, 11]. To the best of our knowledge, published studies that analytically compared the bread-making potential of flour blends milled with these two methods are, to date, very limited [4].

Concerning leavening agents, the use of commercial baker’s yeast, at least at an industrial level, has almost replaced the traditional use of sourdough. Sourdough bread has a wider range of properties compared to most commercially available yeast-started bread, such as a prolonged shelf-life [12], a lower glycemic index [1], higher contents of B vitamins, essential minerals, and bioactive compounds, uniquely balanced protein and fatty acid contents [1, 13], easier digestion [1, 14], a higher mold resistance [3, 15], and a tangy and distinctive flavor [3, 13, 16]. Though sourdough undoubtedly represents a valid alternative to baker’s yeast for manufacturing high-quality bread and other leavened products [13, 16,17,18,19], its successful large-scale utilization still presents technical difficulties, such as the careful control of both the amount of sourdough to be used (to limit excessive bread acidity and sour flavor formation) and the fermentation time required for optimal increases in dough volume [29]. In line with this, the leavening strategy applied is crucial for the optimization of bread dough formulations and bread-making processes as recently reported by Verdonck et al. [21]. Overall, as major consequences of the large-scale use of low-extraction-rate flours and baker’s yeast, the shelf-life, nutritional value, and organoleptic properties of bread have decreased dramatically, with considerable implications in terms of product waste and, hence, economic losses [22]. To the author’s knowledge, up until now, very few studies have investigated the baking capacity of stone-ground vs. roll-milled soft wheat flour [4, 23] and the use of sourdough as a leavening agent of stone-ground wheat flour is still very limited [8].

In a previous study, three mature firm sourdoughs were spontaneously developed by using wheat flour with different extraction rates and milling procedures at an artisan bakery and they were mainly characterized from a microbiological point of view [2]. Based on the above premises, in the present study, the same sourdoughs are used to optimize the sourdough bread-making process with the final aim of improving bread quality. The pH, TTA, and stability of the microbiota of the three long-term-propagated sourdoughs are also assessed before baking trials. Finally, total titratable acidity (TTA), specific volume, weight, crumb core moisture, texture, and global liking of sourdough bread, in comparison to control bread produced with commercial bakers’ yeast, are determined. Moisture, texture, and global liking of bread were also evaluated during 6 days of storage.

Materials and methods

Flours

Two batches of three soft wheat (Triticum aestivum) flours from modern Italian varieties (Bolero, Sagittario, Taylor, and Bologna) designed for bread making, referred to as “FA”, “FB”, and “FC”, were used in this study. Whole-meal flour blend FA and type 0 flour blend FB were obtained by steel roll milling as has previously been elucidated by Taccari et al. [2], whereas type 2 flour blend FC was obtained by stone grinding using a Type A1200 commercial stone mill (Osttiroler Getreidemühlen Green, Austria) as detailed by Cardinali et al. [8]. Flours underwent chemical, farinograph, alveograph, and micro-visco-amylograph tests as reported by Taccari et al. [2]. The flours’ phytate contents were determined as previously described [2].

Sourdough preparation, maintenance, and chemical and microbiological analyses

Three type I sourdoughs (namely “SA-b”, “SB-b”, and “SC-b”) were previously prepared and propagated daily for 20 days (mature sourdoughs) with three flours FA, FB, and FC, respectively, at an artisan bakery as described by Taccari et al. [2]. The sourdoughs were maintained in sealed glass bottles at low temperature (4 °C) and refreshed weekly following the formula and the back-slopping procedure reported by Taccari et al. [2] for approximately 120 days (long-term propagated sourdoughs). One week before the bread-making trials, the three sourdoughs were refreshed daily using the back-slopping procedure [2].

At the end of the 120 days’ propagation, the sourdoughs (hereafter referred to as “SA”, “SB”, and “SC”) were subjected to chemical and microbiological analyses to check their stability, namely through the (i) measurement of pH and TTA; (ii) enumeration of presumptive lactic acid bacteria and yeasts; and (iii) PCR-DGGE profiling using the methods proposed by Taccari et al. [2].

Bread-making trials

Sourdough bread was manufactured at a local artisan bakery (“Il Biroccio”, Filottrano, Italy) according to the formulations and fermentation times reported in Table 1 and chosen on the basis of the results of previous laboratory tests in terms of dough volume increase on a graduated cylinder (data not shown) following the procedure proposed by Zannini et al. [24]. Control bread was prepared by adding 2% (w/w) baker’s yeast (“Maestro®, Lievito”, AB Mauri Italy S.p.A) to reach a final yeast cell density of ca. 108 cfu g−1 for the bread dough [25]. Sourdough and control bread loaves were manufactured by mixing all the ingredients for 7 min with a spiral mixer. Bread dough was divided into 500 g loaves and placed in bread molds and allowed to ferment again for 60 min at 35 °C. The bread dough was baked in an electric oven (Mod. Ecomondial, Mondial Forni, Verona, Italy) at 220 °C for an initial 10 min and at 200 °C for another 35 min. Sourdough and control bread loaves were prepared in triplicate. They were left to cool at room temperature and further subjected to physico-chemical, textural, and sensory analyses.

Determination of bread weight, specific volume, and TTA

After 30 min of cooling, sourdough and control bread loaves were weighed and subjected to volume determination by rapeseed displacement method AACC 10–05.01 [26]. For each bread loaf, specific volume was calculated as the ratio between loaf volume and weight. TTA was determined as previously described [2].

Determination of bread moisture and texture

Cooled experimental and control bread loaves were packaged in sealed polyethylene bags and evaluated for moisture content and crumb texture at regular intervals (5, 24, and 96 h after baking) while in storage at room temperature.

Moisture content was assessed following the procedure detailed by Mariotti, Pagani, and Lucisano [27].

The crumb texture was measured according to AACC method 74–09.01 [28] using a CT3-4500 texture analyzer (Brookfield Engineering Laboratories INC, Middleboro MA, USA) equipped with a 36 mm diameter bread probe (mod. TA-AACC36). Briefly, bread loaves were center sliced (25 mm thick) with an electric bread knife. Bread slices were positioned between the load cell and the base table fixture of the instrument. A 4500 g load cell was used. The probe compressed the crumb to a 40% compression limit (10 mm compression depth) at a speed of 100 mm min−1. The analysis was performed in triplicate.

Bread sensory analyses

The sensory analysis of bread loaves was carried out 5, 24, and 96 h after baking by performing a small-scale consumer sensory test as proposed by Svensson [29] and applied by Mariotti et al. [30] and Cardinali et al. [8]. Briefly, nine non-trained panelists (four males and five females, non-smokers, age: 30–55) were chosen among the personnel of the bakery where the experimental bread was produced. The sensory evaluation was performed as proposed by Resurreccion [31]. The degree of global liking was ranked using a 9-point hedonic scale, ranging from 1 (dislike extremely) to 9 (like extremely) [32]. Results were expressed as the means of three independent experiments (n = 3).

Statistical analysis

All the data referring to the chemical and rheological properties of flours, long-term propagated sourdoughs (pH, TTA, microbial counts), and bread just after baking (TTA, weight, specific volume) were analyzed by one-way ANOVA. When the ANOVA indicated a significant difference, a Tukey's HSD test at a 95% confidence level was performed for mean separation. Data assessed during the bread’s shelf-life (crumb core moisture, crumb texture, and global liking) were analyzed using multivariate analysis of variance (MANOVA) for repeated measures according to the Wilks’ lambda test to determine the effect of flour over time. Statistical analysis was performed using JMP 9 (SAS Institute Inc., Cary, NC).

Results and discussion

Flour analyses

The results of chemical and conventional rheological analyses of flours FA, FB, FC used for the propagation of sourdoughs, leavening, and bread-making trials are shown in Table 2. FA showed a significantly higher ash content and a greatly longer dough development time while both FA and FC showed higher water absorption. These features may be linked to the higher wheat fiber content of whole-meal wheat flour (FA) and of stone-ground wheat flour (FC) that may be detrimental to gluten networks and, thus, bread quality [2, 3, 33]. The values of water absorption were in accordance with those already reported for stone-ground wheat flour by Cardinali et al. [8] (63.75% ± 2.9) and for roll-milled whole-meal flour reported by Kihlberg et al. [34] (62.5%). The ash content value of FC was in accordance with Italian legislation for type 2 flour that indicates a maximum ash content of 0.95 100 g−1 flour, while the higher ash content value of FA was in line with those reported by Prabhasankar and Rao [35] for whole-wheat flour and ranged from 1.5 ± 0.03 and 1.6 ± 0.02. The longer dough development time of FA was in line with a study by Kihlberg et al. [35], reporting a value of 15.0 min for roll-milled whole-meal flour. All of the flours showed high protein content, indicating a good bread-making capacity [8, 25]. The content of phytic acid, which acts as an antinutritional factor by reducing mineral bioavailability, was also estimated for the studied flours and progressively increased in the order from FB to FC and, finally, to FA as also previously reported [2]. These data were expected since phytic acid content is higher in whole-meal flour compared to low-extraction-rate (refined) flour. Indeed, in refined flours, the milling of grain removes nutrients and phytate as well. By contrast, in whole-meal flour (FA), the external part of the endosperm, the aleurone, which retains the majority of nutrients and phytic acid, is not removed [3, 33, 36, 37].

Chemical and microbiological traits of the long-term propagated sourdough

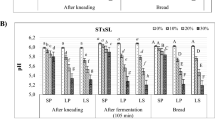

Before bread-making trials, the three sourdoughs were maintained in laboratory conditions by using the back-slopping technique for 120 days. Therefore, pH, TTA, and viable counts of presumptive lactic acid bacteria and yeasts of the three long-term propagated sourdoughs were assayed in order to verify the sourdoughs’ stability (Table 3). By comparing these data with those previously obtained by Taccari et al. [2] on mature sourdough propagated for 20 days, some evidence emerged. pH and TTA levels measured after 120 days of sourdough maintenance were stabilized around the values encountered at the end of the 20th day of continuous sourdough propagation [2], with SA characterized by a significantly higher pH value and higher TTA than SB and SC. These data were previously attributed to the higher ash content of FA compared to the other two flours under study, which affected the sourdoughs’ buffering capacity [2, 30]. Furthermore, it has been reported that excessive acidity levels in sourdough and bread dough (higher than 6.7 ± 0.58 mL when 30% sourdough is used) may decrease the gas retention capacity of dough and, consequently, bread volume and crumb softness due to the degradation of gluten proteins [3, 20, 21, 38, 39].

Changes in the LAB-to-yeast ratio were also seen, passing from ca. 100:1 to 10:1 in SB and, in SA, passing from ca. 10:1 to 1:1 whereas, in SC, this parameter remained stable at ca. 100:1. LAB-to-yeast ratios of 100:1 and 10:1 have already been found in 19 Italian sourdoughs used for traditional/typical breads and reported as common for sourdoughs; the only exception (with a ratio of 1:1) was recorded for Pane Casereccio di Genzano PGI sourdough [40]. The results of PCR-DGGE analysis are shown in Tables S1 and S2. By comparing the compositions of the microbiota of the three mature sourdoughs at the end of the 20 days of continuous propagation and after 120 days of maintenance, a slight evolution in the composition of both bacterial and yeast communities was seen, with the disappearance of a few species (Weissella confusa/cibaria in SB; Pediococcus pentosaceus in SC; Pichia kudriavzevii in SA; Kazachstania unispora/servazzii/aerobia in both SA and SC) and the establishment of a core collection of species shared among all sourdoughs, stably detected in the bulks at both the highest and lowest dilutions and consisting in Levilactobacillus brevis (basonym Lactobacillus brevis), Companilactobacillus alimentarius/paralimentarius (basonym Lactobacillus alimentarius/paralimentarius), Lactiplantibacillus plantarum/paraplantarum/pentosus (basonym Lactobacillus plantarum/paraplantarum/pentosus), and Saccharomyces cerevisiae. Specifically, Lpb. plantarum/paraplantarum/pentosus became dominant after 120 propagation cycles in SA and it replaced Weissella confusa/cibaria in SB and Pediococcus pentosaceus in SC, thus indicating the great competitiveness and adaptation to sourdough environments of strains of the Lpb. plantarum sensu latu group. The species C. alimentarius and C. paralimentarius as well as Lpb. plantarum, Lpb. paraplantarum, and Lpb. pentosus are phylogenetically closely related; therefore, apposite molecular identification methods are needed [19]. The facultatively heterofermentative C. alimentarius/paralimentarius is typically associated with the sourdough environment while the obligately heterofermentative Lev. brevis and Lpb. plantarum (facultatively heterofermentative) often occur in other food ecosystems, although they have been commonly identified in sourdoughs as well [19, 21]. Indeed, Lpb. plantarum was reported to be a LAB species characterized by a metabolic flexibility and a high tolerance towards low pH [41]. This latter consideration may also explain the feasible coexistence of Lpb. plantarum (which utilize all four flour carbohydrates but have a preference for glucose and fructose) and S. cerevisiae (maltose-positive), which was the only yeast species detected in the three long-term propagated sourdoughs under study, suggesting a stable, non-competitive association among these two species, as is often reported in the literature [19, 21]. S. cerevisiae is a yeast species tolerant to low pH and high osmolality; therefore, its stable persistence in the sourdoughs under study is not unusual and may also be attributed to the robustness of the autochthonous strains of S. cerevisiae as has also been documented by several authors [18, 19, 42].

It is well known that the stability of a sourdough over time is influenced by several ecological and process parameters that quantitatively and qualitatively affect the sourdough microflora and, among these factors, flour, which acts as a source of nutrients and microorganisms, is not fully controlled during sourdough maintenance [43]. Only the intrinsically robust and most competitive microorganisms can persist within sourdough during its propagation over time despite the changing of flour batches that may introduce different autochthonous strains and nutrients depending on seasonality characterizing crops [30, 43]. It is interesting to note that no differences were seen in terms of the dominant microbial community among the three long-term propagated sourdoughs under study based on the different kinds of wheat flours obtained with different extraction rates and milling procedures. This result is in line with what was reported by Ercolini et al. [44] who found that the initial differences in microbiota among sourdoughs developed with different flours, namely rye, durum, and soft wheat flours, tend to decrease towards the establishment of a common core microbiota by increasing the number of refreshing steps, irrespective of the type of flour.

Bread characterization

Bread TTA, weight, and specific volume

Results related to TTA, weight, and specific volume of the bread formulations are shown in Table 4.

In the control group (without sourdough), loaves of bread showed the lowest TTA values. On the other hand, the addition of sourdough caused an increase in TTA values to a greater extent for bread formulations BA and BC, thus showing an influence of both sourdough fermentation and the different ash contents of the flours.

An increased addition of sourdough (30% versus 10%) did not lead to significantly higher TTA values for the BA and BC bread loaves, thus indicating that a longer fermentation time applied to bread dough with 10% sourdough may lead to the same performance as that of the 30% sourdough bread formula, in terms of bread TTA. The 20% replacement of SB produced bread loaves BB with not significant differences among sourdough bread loaves and control bread loaves in terms of TTA values, irrespective of whether a long or short fermentation time was used. More specifically, the TTA values of the experimental sourdough bread loaves BB were lower than that reported by Crowley et al. [45] for wheat bread containing 20% sourdough and corresponding to 5.2 mL. In contrast, the TTA values of the sourdough bread BC and control bread were in line with those of bread produced with stone-ground flour and 25% type I sourdough (7.25 ± 1.33) and baker’s yeast (2.20 ± 0.20), respectively [8]. It has also been stated that other elements may influence bread TTA values such as different flours (type and batch) as well as different microbiota in terms of species and strains developed within sourdoughs [30]. TTA was not correlated with the specific volume of bread (correlation coefficient = -0.33 p = 0.294) nor with bread weight (correlation coefficient = 0.445 p = 0.147) or crumb texture (Table 6) (correlation coefficient = 0.226 p = 0.481).

Concerning weight, all the bread formulations showed a weight reduction after baking and cooling, although a higher level of weight reduction was generally seen in BB formulations compared to BA and BC formulations. This result was expected since bread formulations enriched with fibers due to the presence of whole-wheat meal flour or type 2 stone-ground wheat flour are able to retain greater amounts of water as shown by analysis of flour water absorption (Table 2) and as reported by Mariotti et al. [30] and Ktenioudaki and Gallagher [33].

The positive role of sourdough on bread volume has been reported to be mainly caused by the improved gas-holding ability of gluten in mildly acidic environments, the solubilization of flour starch and pentosans, the formation of exopolysaccharides during fermentation, and the commensalism of LAB and yeasts that cause faster yeast metabolism and, thus, improve leavening when in coexistence with LAB [3, 20, 21]. Cappelli et al. [23] underlined that the specific volume of bread is the quintessential attribute of bread quality since higher values are related to greater bread quality. It is also well known that bread volume remains low in yeast-leavened whole-meal wheat bread while the addition of sourdough generally improves the specific volume of bread [3, 21]. In the present study, the specific volume of BB bread formulations was significantly higher than those of bread formulations BA and BC. These data confirm the strong influence of milling properties and extraction rates on the physical features of bread [4, 30, 46]. More specifically, sourdough formulations showed specific volumes comparable to (BA formulas I and II), higher than (BB formula II and BC formulas I, II, and III), or lower than (BA formula III and BB formulas I and III) that of control breads (baker's yeast breads). It is interesting to note that all the sourdough formulations using stone-ground flour enhanced the bread-specific volume at either 10% (long fermentation time) or 30% (short fermentation time) compared to the control bread, thus indicating that lactic acid fermentation may be a valid tool for improving the baking capacity of stone-ground flour. Specifically, the 30% addition of solely sourdough SC produced bread with significantly higher specific volume among BC formulations and a slightly lower numerical difference compared to BB formulations prepared with refined wheat flour and 20% sourdough with either short or long fermentation time. On the other hand, sourdough fermentation did not improve the specific volume of BA compared to the use of baker’s yeasts, thus indicating the stronger effect of whole-meal flour fiber content that negatively influenced bread quality in terms of reduction in bread volume as already reported by Katina et al. [38]. Indeed, the use of whole-meal flour in bread making has been reported to decrease bread volume mainly due to the presence of fibers that may have a detrimental effect on the gluten network, thus decreasing gas-holding ability [30, 38]. This observation in the present study is also in line with the study of Verdonck et al. [21] that confirmed the theory that type I sourdough, containing a microbial inoculum of Lev. brevis, Lpb. plantarum, and S. cerevisiae, either alone or in combination with baker’s yeast, cannot improve the specific volume of whole-meal bread. Concerning BB formulations, the addition of baker’s yeast to 20% sourdough SB greatly improved BB specific volume thus demonstrating the usefulness of combining these leavening agents for this parameter of bread quality. Indeed, baker’s yeast is generally used in addition to sourdough to accelerate leavening during bread making due to its fast and strong CO2 production ability [21]. Furthermore, the specific volume of bread was negatively correlated with weight (correlation coefficient = – 0.75, p = 0.0009) and with crumb texture (hardness) (Table 6) (correlation coefficient = – 0.83). This latter finding was confirmed (correlation coefficient = – 0.88, data not shown) even after 96 h of storage, thus indicating that a higher specific volume is also correlated with a reduction in the hardness of the bread during its shelf-life as previously reported [45].

Bread crumb core moisture and texture

The evolution of the bread formulations during 96 h of storage was estimated in terms of crumb core moisture and bread firmness (hardness of bread crumb).

The crumb moisture of bread formulations 5 h after baking and during storage is reported in Table 5. Multivariate analysis of variance showed that flour type had a significant effect on the moisture content of bread loaves. Although it has been reported that a higher fiber content within flour may lead to moister dough and bread [30, 38], a generally similar trend in terms of bread moisture was observed in the present study irrespective of the type of flour or the leavening agents used both 5 h after baking and during storage. Indeed, during the bread’s shelf-life, significant differences in crumb core moisture were found only for BB formula III and BC formula I where a slight decrease and an increase in moisture were observed, respectively.

Results for crumb texture analyses of the bread formulations 5 h after baking and during storage are presented in Table 6. Multivariate analysis of variance highlighted a significant effect of flour type and time on crumb texture of all bread formulations. After baking (5 h), the softness of BA formulations differs significantly from that of BB and BC formulations, with BB formula II showing the lowest firmness (highest softness) and BA formula III showing the highest firmness (lowest softness). Overall, the highest ash content and typically high fiber content of whole-meal flour (and, to a lesser extent, of type 2 stone-ground flour) may have played a major role in increasing bread hardness being responsible for the non-elastic crumb and denser texture of bread as already reported [3, 30, 33, 38, 47]. Textural analyses highlighted the same trend already observed for the specific volume of bread: the bread that exhibited the highest softness was also characterized by the highest specific volume and the effect of sourdough on improved bread softness seems to be at least in part imputable to higher bread volume (specific volume and crumb texture are negatively correlated, correlation coefficient = – 0.83 p = 0.0009). More specifically, within BC formulations, the hardness was the highest for bread leavened with baker’s yeast alone (BC control). Indeed, the BC control exhibited a significantly higher firmness compared to all sourdough bread loaves made with roll-milled flour, which showed no significant differences among each other, irrespective of fermentation time or percentage of sourdough inoculum. This result confirms again the positive effect of sourdough on the baking capacity of stone-ground wheat flour in terms of textural improvement of bread, in addition to improvements in specific volume as detailed above. Concerning BB formulations, formulation II (baker’s yeast added with 20% sourdough SB), as indicated above for bread volume, showed the highest improvement in terms of softness. These data are also in line with the study of Cappelli et al. [4] reporting roll milling as among the wheat-milling methods that ensure better dough rheological performance. Furthermore, BB formula II remained the softest bread even during storage, significantly showing the lowest crumb hardness both 24 h and 96 h after baking. As was expected, all breads showed an increasing trend in hardness during storage, but different staling rates were observed and the tendency to remain soft was observed for bread loaves with higher specific volume and softness 5 h after baking.

It has been reported that generally long fermentation times are responsible for the softest bread textures [38]. However, this assumption did not seem to be confirmed by the present data, thus indicating that for an efficient use of sourdough, optimal conditions have to be found by tailoring sourdough to the type of flour used.

Bread sensory analyses

As reported by Svensson [29], the small-scale sensory test, as that applied in the present study, is a cheap way to get indications and significant differences in liking of a product. The test groups of such sensory test involve only ten participants chosen among the regular employees of a company that are representative of the consuming population and regular users of the tested product, or at least familiar with similar products [27, 29]. Hence, this method allows the company to identify promising products in need of further evaluation [29]. Similarly to the small-scale internal consumer tests performed by Svensson [29], the nine untrained panelists involved in the present study were chosen among the employees of the bakery where the bread-making trials were performed, as also previously reported by Cardinali et al. [8] and Mariotti et al. [27]. The small-scale consumer test used was aimed at gaining insight into the experimental breads thus providing a preliminary exploration of the consumer acceptance of the sourdough bread performed by using roll-milled or stone-ground soft wheat flours milled to different extraction rates.

The global liking of bread formulations during storage is reported in Table 7. Multivariate analysis of variance showed that flour type had a significant effect on the global liking of bread loaves. To the authors’ knowledge, data regarding the features of bread made with stone-ground soft wheat flour are very limited. The consumer acceptance of BC made with 10% sourdough and 6 h of fermentation (formula III) was in line with the study of Cardinali et al. [8] using 25% type I sourdough and 5 h of fermentation (6.22 ± 0.75), thus obtaining a medium/high score of global liking and confirming the suitability of type I sourdough in bread making with stone-ground wheat flour. However, during the bread’s shelf-life, a significant decrease in global liking over time was found only for BC formula III and for BA formulas I and III and control. Interestingly, BB formula II (found as the bread with the highest volume and softness even during shelf-life) was also the most appreciated bread according to taste tests 5 h after baking and during the bread’s shelf-life. Global liking and crumb texture (hardness) are negatively correlated (correction coefficient = – 0.64 p < 0.0001), thus indicating that the softness of the bread is preferred by consumers and this parameter positively influences consumer acceptance. In contrast, crumb core moisture and acidity (TTA) do not influence global liking (p = 0.48) (see Table 8).

Conclusion

In conclusion, the data of the present study confirmed that roll milling is a wheat-milling method that ensures better dough rheological performance compared to stone-grinding methods, although sourdough fermentation may be a valid tool for improving the baking capacity of stone-ground flour. Indeed, sourdough fermentation positively affected the specific volume, texture, and global liking of bread manufactured with stone-ground wheat flour. Overall, the highest ash and fiber contents of whole-meal flour (followed by those of stone-ground wheat flour) may have played a major role in increasing bread hardness and reducing volume. The effect of sourdough on improved softness seems to be at least in part imputable to a higher specific volume of bread. The present study confirmed that for an efficient use of sourdough, optimal conditions need to be found by tailoring sourdough to the type of flour used with the final aim of improving bread quality.

Data availability

Data are available upon request from the corresponding author.

References

Gobbetti M, Rizzello CG, Di Cagno R, De Angelis M (2014) How the sourdough may affect the functional features of leavened baked goods. Food Microbiol 37:30–40

Taccari M, Aquilanti L, Polverigiani S, Osimani A, Garofalo C, Milanović V, Clementi F (2016) Microbial diversity of type i sourdoughs prepared and back-slopped with wholemeal and refined soft (Triticum aestivum) wheat flours. J Food Sci 81(8):M1996-2005

Ma S, Wang Z, Guo X, Wang F, Huang J, Sun B, Wang X (2021) Sourdough improves the quality of whole-wheat flour products: mechanisms and challenges—a review. Food Chem 360:130038

Cappelli A, Oliva N, Cini E (2020) Stone milling versus roller milling: a systematic review of the effects on wheat flour quality, dough rheology, and bread characteristics. Trends Food Sci Technol 97:147–155

Jenkins S (1975) Bakerv technology-book 1-bread. Lester & Orpen Ltd, Toronto (Chapter 1: Flour)

Davis DR (1981) Wheat and Nutrition - Part 1. Nutr Today 16(4):16–21

Di Silvestro R, Di Loreto A, Marotti I, Bosi S, Bregola V, Gianotti A, Quinn R, Dinelli G (2014) Effects of flour storage and heat generated during milling on starch, dietary fibre and polyphenols in stoneground flours from two durum-type wheats. Int J Food Sci Technol 49(10):2230–2236

Cardinali F, Garofalo C, Reale A, Boscaino F, Osimani A, Milanović V, Taccari M, Aquilanti L (2022) Liquid sourdough from stone-ground soft wheat (Triticum aestivum) flour: development and exploitation in the breadmaking process. Food Res Int 161:111796

Mount JL (1975) The Food and Health of Western Man. Charles Knight & Co., Ltd, London

Thomas B (1976) Unverdauliche Stoffe im Brot. Brotindustrie 19:340–346

Leonard T (1990) The bread book: a natural, whole grain seed-to-loaf approach to real bread. East-West Health Books, Brookline

Arendt EK, Ryan LA, Dal Bello F (2007) Impact of sourdough on the texture of bread. Food Microbiol 24(2):165–174

Arora K, Ameur H, Polo A, Di Cagno R, Rizzello CG, Gobbetti M (2021) Thirty years of knowledge on sourdough fermentation: a systematic review. Trends Food Sci Technol 108:71–83

Arendt EK, Moroni AV (2013) Sourdough and gluten-free products. In: Gobbetti M, Gänzle M (eds) Handbook on sourdough biotechnology. Springer, New York

Garofalo C, Zannini E, Aquilanti L, Silvestri G, Fierro O, Picariello G, Clementi F (2012) Selection of sourdough lactobacilli with antifungal activity for use as biopreservatives in bakery products. J Agric Food Chem 60:7719–7728

Corsetti A, Settanni L (2007) Lactobacilli in sourdough fermentation. Food Res Int 40:539–558

Garofalo C, Silvestri G, Aquilanti L, Clementi F (2008) PCR-DGGE analysis of lactic acid bacteria and yeast dynamics during the production processes of three varieties of Panettone. J Appl Microbiol 105:243–254

Garofalo C, Aquilanti L, Clementi F (2011) The biodiversity of the microbiota of traditional Italian sourdoughs. In: Almeida MT (ed) Wheat: genetics. Crops and Food Production, Nova Science Publishers Inc, New York, pp 366–392

De Vuyst L, Van Kerrebroeck S, Harth H, Huys G, Daniel HM, Weckx S (2014) Microbial ecology of sourdough fermentations: diverse or uniform? Food Microbiol 37:11–29

Katina K, Heiniö R-L, Autio K, Poutanen K (2006) Optimization of sourdough process for improved sensory profile and texture of wheat bread. LWT 39(10):1189–1202

Verdonck C, De Bondt Y, Pradal I, Bautil A, Langenaeken NA, Brijs K, Goos P, De Vuyst L, Courtin CM (2023) Impact of process parameters on the specific volume of wholemeal wheat bread made using sourdough- and baker’s yeast-based leavening strategies. Int J Food Microbiol 396:110193

Gray JA, Bemiller JN (2003) Bread staling, molecular basis and control. Comp Rev Food Sci Food Saf 2(1):1–21

Cappelli A, Guerrini L, Parenti A, Palladino G, Cini E (2020) Effects of wheat tempering and stone rotational speed on particle size, dough rheology and bread characteristics for a stone-milled weak flour. J Cereal Sci 91:102879

Zannini E, Garofalo C, Aquilanti L, Santarelli S, Silvestri G, Clementi F (2009) Microbiological and technological characterization of sourdoughs destined for bread-making with barley flour. Food Microbiol 26:744–775

Pontonio E, Nionelli L, Curiel JA, Sadeghi A, Di Cagno R, Gobbetti M, Rizzello CG (2015) Iranian wheat flours from rural and industrial mills: Exploitation of the chemical and technology features, and selection of autochthonous sourdough starters for making breads. Food Microbiol 47:99–110

AACC, Method 10-05.01. Guidelines for measurement of volume by rapeseed displacement. Approved Methods of Analysis, 11th edition. St. Paul, MN: AACC International.

Mariotti M, Pagani MA, Lucisano M (2013) The role of buckwheat and HPMC on the bread making properties of some commercial gluten-free bread mixtures. Food Hydrocolloids 30:393–400

AACCI Method 74-09.01 Measurement of Bread Firmness by Universal Testing Machine. Approved Methods of Analysis, 11th edition. St. Paul, MN: AACC International

Svensson L (2012) Design and performance of small scale sensory consumer tests. Master’s thesis, 30hec, Second cycle, A2E. Publikation/Sveriges Iantbruksuniversitet, Institutionen, for ¨ livsmedelsvetenskap, no. 354. Uppsala: The Faculty of Natural Resources and Agricultural Sciences, Swedish University of Agricultural Sciences

Mariotti M, Garofalo C, Aquilanti L, Osimani A, Fongaro L, Tavoletti S, Hager AS, Clementi F (2014) Barley flour exploitation in sourdough bread-making: a technological, nutritional and sensory evaluation. LWT 59:973–980

Resurreccion AVA (1998) Consumer sensory testing for product development. Aspen Publishers Inc, A Chapman & Hall food science book

Peryam DR, Pilgrim FJ (1957) Hedonic scale method of measuring food preferences. Food Technol 11:9–14

Ktenioudaki A, Gallagher E (2012) Recent advances in the development of high-fibre baked products. Trends Food Sci Technol 28:4–14

Kihlberg I, Johansson L, Kohler A, Risvik E (2004) Sensory qualities of whole wheat pan bread—influence of farming system, milling and baking technique. J Cereal Sci 39(1):67–84

Prabhasankar P, Rao PH (2001) Effect of different milling methods on chemical composition of whole wheat flour. Eur Food Res Technol 213:465–469

Garcia-Estepa RM, Guerra-Hernandez E, Garcia-Villanova B (1999) Phytic acid content in milled cereal products and breads. Food Res Int 32:217–221

Buddrick O, Jones OAH, Cornell HJ, Small DM (2014) The influence of fermentation processes and cereal grains in wholegrain bread on reducing phytate content. J Cereal Sci 59:3–8

Katina K (2005) Sourdough: A tool for the improved flavour, texture and shelf-life of wheat bread, vol 569. VTT Publications, pp 3–92 (ISSN 14550849)

Torrieri E, Pepe O, Ventorino V, Masi P, Cavella S (2014) Effect of sourdough at different concentrations on quality and shelf life of bread. LWT 56(2):508–516

Minervini F, Di Cagno R, Lattanzi A, De Angelis M, Antonielli L, Cardinali G, Cappelle S, Gobbetti M (2012) Lactic acid bacterium and yeast microbiotas of 19 sourdoughs used for traditional/typical italian breads: interactions between ingredients and microbial species diversity. Appl Env Microbiol 78:1251–1264

Bessmeltseva M, Viiard E, Simm J, Paalme T, Sarand I (2014) Evolution of bacterial consortia in spontaneously started rye sourdoughs during two months of daily propagation. PLoS ONE 9:1–12

De Vuyst L, Vrancken G, Ravyts F, Rimaux T, Weckx S (2009) Biodiversity, ecological determinants, and metabolic exploitation of sourdough microbiota. Food Microbiol 26:666–675

Minervini F, De Angelis M, Di Cagno R, Gobbetti M (2014) Ecological parameters influencing microbial diversity and stability of traditional sourdough. Int J Food Microbiol 171:136–146

Ercolini D, Pontonio E, De Filippis F, Minervini F, La Storia A, Gobbetti M, Di Cagno R (2013) Microbial ecology dynamics during rye and wheat sourdough preparation. Appl Env Microbiol 79(24):7827–7836

Crowley P, Schober TJ, Clarke CI, Arendt E (2002) The effect of storage time on textural and crumb characteristics of sourdough wheat bread. Eur Food Res Technol 214:489–496

Nkhabutlane P, du Rand GE, de Kock HL (2014) Quality characterization of wheat, maize and sorghum steamed breads from Lesotho. J Sci Food Agric 94(10):2104–2117

Kurek MA, Wyrwisz J, Karp S, Brzeska M, Wierzbicka A (2017) Comparative analysis of dough rheology and quality of bread baked from fortified and high-in-fiber flours. J Cereal Sci 74:210–217

Acknowledgements

This study was financially supported by the Regione Marche-Servizio Agricoltura, Forestazione e Pesca, in the context of the project “P.S.R. Marche 2007/2013—Progetti di Macrofiliera, Filiera Locale e Microfiliera-Misura 1.2.4-Cooperazione per lo sviluppo di nuovi prodotti, processi e tecnologie”. The authors wish to thank the farmers’ cooperative “Il Biroccio” (Filottrano, Ancona, Italy) for supplying the soft wheat flour blends and for performing the backing trials. They are also grateful to Dr.ssa Catia Governatori of the “Agenzia Servizi Settore Agroalimentare delle Marche” (ASSAM) for the chemical, farinographic, and alveographic analyses performed on the four blends.

Funding

Open access funding provided by Università Politecnica delle Marche within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subject.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cardinali, F., Garofalo, C., Taccari, M. et al. Development of sourdough bread from roll-milled and stone-ground soft (Triticum aestivum) wheat flours milled to different extraction rates. Eur Food Res Technol 250, 581–591 (2024). https://doi.org/10.1007/s00217-023-04409-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04409-4