Abstract

Furan and alkylfurans are a group of contaminants formed through thermal processing. For breakfast cereals, this includes processing steps like extrusion cooking, roasting, puffing or baking. Furan was classified as possibly carcinogenic to humans (Group 2B) and, therefore, monitoring of this contaminant including other furans is of great interest. Breakfast cereals have been part of previous studies, but only few publications provided data regarding furan or alkylfuran levels in different groups of breakfast cereals. In this study, the furan and alkylfuran levels of over 70 samples have been analyzed and interpreted for 4 groups of breakfast cereals, namely flakes and cornflakes, extruded cereals, puffed grains and granolas. In this study, a solid phase microextraction method was established to extract the analytes from the headspace of the samples followed by gas chromatography–mass spectrometry analysis. In addition to furan, the alkylfurans 2-methylfuran, 3-methylfuran, 2,5-dimethylfuran, 2-ethylfuran and 2-pentylfuran were quantitated and levels up to 230 µg/kg furan and almost 200 µg/kg 2-pentylfuran were detected. The samples were also analyzed for acrylamide and in most cases no correlation with furan/alkylfurans was observed. Furthermore, during storage of the samples, the furan and methylfuran levels were stable but a rise of the levels of 2-ethylfuran and 2-pentylfuran was observed which is potentially linked to lipid oxidation.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The production of breakfast cereals involves different thermal processing steps such as baking, toasting, extrusion cooking, roasting or steam treatment. These processes create the wanted sensory properties and increase digestibility as well as microbiological safety [1, 2]. In addition to the desired changes in the product, the thermal processes may also lead to undesirable process related contaminants [3]. Among others, furan, alkylfurans and acrylamide belong to these process contaminants and are of particular relevance for human health [4,5,6]. Furan, and the alkylfurans 2-methylfuran (2-MF), 3-methylfuran (3-MF), 2,5-dimethylfuran (2,5-DF), 2-ethylfuran (2-EF) and 2-pentylfuran (2-PF) are shown in Fig. 1.

All of these compounds have been described as constituents of the volatile fraction of coffee for more than 50 years and historically, they solely were considered as part of the coffee flavor [7]. However, since the latest evaluation by the International Agency for Research on Cancer (IARC), which classified furan as possibly carcinogenic to humans (Group 2B), its relevance as a food contaminant is undisputed [8]. The carcinogenic effect of furan is primarily based on the highly reactive metabolite cis-2-butene-1,4-dial (BDA), which is formed by cytochrome P450 enzymes and can lead to alkylation of proteins and DNA as well as protein–protein, protein–DNA and DNA–DNA crosslinks. For proteins, reactions with cysteine and lysine are favored, DNA-adducts are described in vitro for the nucleosides deoxycytidine (dCyd) and deoxyadenosine (dAdo) as summarized by the Joint FAO/WHO Expert Committee on Food Additives (JECFA) [9]. Safety evaluation by the JECFA included the evaluation of hepatocellular adenoma and carcinoma as well as leukemia in rats and mice of both sexes [10, 11]. Based on these data, a benchmark dose lower confidence limit for 10% increase (BMDL10) of 0.96 mg/kg bw per day for neoplastic effects was determined [9]. The Panel on Contaminants in the Food Chain (CONTAM panel) of the European Food Safety Authority (EFSA) confirmed this BMDL10 for neoplastic effects and selected a BMDL10 of 0.064 mg/kg bw per day for non-neoplastic effects based on the induction of cholangiofibrosis in male rats as reference point [6].

The alkylfurans are less well studied toxicologically, but it is assumed that they are subject to similar metabolism and, for instance, 2-MF is metabolized to 2-methyl-BDA. Consequently, the CONTAM panel proposes to apply the sum of furan, 2-MF and 3-MF for risk assessment. Concerning the other abovementioned alkylfurans, no evaluation has been made by the CONTAM panel thus far [6]. In contrast, 2-pentylfuran as a flavoring compound is generally recognized as safe (GRAS) according to the GRAS 5 report of the Flavor and Extract Manufacturers Association (FEMA), as well as the update to chewing gum in GRAS report 25 [12, 13]. A recent evaluation by the EFSA considered the use of 2-PF as flavoring compound also as save, calculating a BMDL of 8.51 mg/kg bw per day [14].

A wide range of potential precursors have been described for furan and alkylfurans based on experiments in model systems. This includes, in particular, reducing sugars, ascorbic acid/dehydroascorbic acid, starch, carotenoids, polyunsaturated fatty acids (PUFA), and the amino acids serine, alanine and aspartic acid [15,16,17]. Many reaction conditions applied in model experiments focus on the roasting processes of coffee production [18, 19]. In other cases, the focus is on the thermal preservation of baby food or its storage [20,21,22]. Thermal processes corresponding to the production of breakfast cereals have not yet been mapped experimentally.

In addition to furans other process contaminants such as acrylamide are also relevant for breakfast cereal. The toxicity of acrylamide has been extensively studied and was summarized by the EFSA CONTAM Panel [5]. Neurotoxicity was assigned as reference point for non-neoplastic effects and for neoplastic effects, the results of a 2-year carcinogenicity study in mice by the US National Toxicology Program was considered [23]. Based on these data, a MOE between < 100 and 500 was calculated, indicating an urgent need for exposure reduction [5]. However, more recently, the genotoxicity of acrylamide and especially the toxicological relevance for humans was discussed critically [24, 25].

The formation of acrylamide, on the other hand, is widely understood. Reducing sugars as well as aspartic acid are well known precursors of acrylamide [26, 27]. Additionally, temperatures above 130 °C are known to accelerate the formation of acrylamide. Based on an extensive data set on acrylamide levels in various foods, an acrylamide toolbox has been developed which allows producers to significantly lower acrylamide levels in food [28].

Both groups of contaminants, furan, alkylfurans as well as acrylamide can be found in breakfast cereals of different origin. In the supplement of the EFSA CONTAM Panel report [6], mean furan levels of approx. 30 µg/kg and levels for the 95th percentile of 118 µg/kg have been reported for a total number of 542 breakfast cereals with about 30% being below the LOQ (left-censored). For eleven breakfast cereals analyzed in a study published in 2014, furan levels from < 2.4 to 387 µg/kg and a mean concentration of 57.4 µg/kg were determined. The authors observed particularly high furan levels in honey-coated cereals [29]. Additional data on the occurrence of breakfast cereals was provided by Hamlet et al. [30] who analyzed 32 breakfast cereals and determined mean levels of 23 µg/kg for furan and 18 µg/kg for 2-MF. Maximum levels were 94 µg/kg and 70 µg/kg for furan and 2-MF, respectively. No 3-MF was detected in the samples (LOD 10 µg/kg). Kettlitz et al. analyzed 95 samples of breakfast cereals with furan levels between 1 and 140 µg/kg and an average furan level of 27 µg/kg. In this study no 2-MF and 3-MF could be detected [4].

In none of the abovementioned studies, both furan and acrylamide levels were given. Additionally, information on the manufacturing processes or ingredients in breakfast cereals were not provided. Only Hamlet et al. [30] reported some basic descriptions (name, description of material) of the individual breakfast cereals analyzed in their study. Regarding the contaminants 3-MF, 2-EF or other alkylfurans, even less information is available, which has led EFSA, among others, to issue a call for more data for this food group.

Compared to acrylamide analysis, the determination of furan and alkylfurans is significantly more error-prone and official analytical methods are lacking. Methods published employ headspace (HS) or solid phase microextraction (SPME) followed by gas chromatography–mass spectrometry (GC–MS) using isotopically labeled standards. Samples were analyzed in a linear range of 5–500 µg/kg [4, 31, 32]. Nevertheless, difficulties in the reproducibility of some results may be associated with the high volatility of furan and the methylfurans in particular as well as the high water-binding capacity of ground breakfast cereals which pose a further hurdle.

Here, we present the development of an optimized SPME-GC/MS method for the determination of low levels of furan and alkylfurans in breakfast cereals and its application for the analysis of furan, 2-MF, 3-MF, 2,5-DF, 2-EF and 2-PF in 76 samples of breakfast cereals from the European market. The results were correlated with determined acrylamide levels, processing techniques, and ingredients. Moreover, the change in furan and alkylfuran levels during storage over a period of 3–6 months was investigated.

Materials and methods

Chemicals and reagents

Furan (≥ 99% purity), 2-MF (99% purity), 3-MF (98% purity), 2,5-DF (99% purity), 2-EF (≥ 98%% purity) were purchased from Sigma-Aldrich (Taufkirchen, Germany). 2-PF (98% purity) was purchased by Fisher Scientific (Schwerte, Germany). Furan-d4 (> 98% purity) was purchased from Sigma-Aldrich. 2-MF-d6 (98% purity), 3-MF-d3 (96% purity), and 2,5-DF-d3 (95% purity) were from Toronto Research Chemicals and purchased via LGC standards (LGC GmbH, Luckenwalde, Germany). 2-PF-d3 was synthesized in the laboratory based on the procedure by Kobayashi et al. with slight modifications using d4-furan and 1-bromopentane as starting materials [33]. Methanol was of LC–MS grade quality (Fisher Scientific, Schwerte, Germany) and water was of ASTM Type 1 quality and prepared inhouse using a Purelab flex 2 system (Veolia Water Solutions & Technologies, Celle, Germany). Acrylamide (analytical standard), d3-acrylamide (standard solution of 500 mg/L in acetonitrile), Na2Hcitrate * 1.5 H2O was purchased from Sigma-Aldrich, sodium chloride (p.A.), MgSO4 (pure) and cyclohexane were purchased from Carl Roth (Karlsruhe, Germany), Na3citrate * 2 H2O from VWR International LLC (Darmstadt, Germany) and Bondesil PSA (40 µm) from Agilent Technologies (Santa Clara, USA).

Samples

Breakfast cereal samples were provided by several German and European food companies or purchased from local supermarkets. They cover the categories multigrain flakes and cornflakes, granola, extruded cereals and puffed cereals. The samples were stored in their original packaging at room temperature without direct exposure to light and opened directly before each analysis. The samples were analyzed when they were received and after three and 6 months with all samples of a product coming from the same batch.

Furan and alkylfuran analysis

Standard and working solutions

Due to the high volatility of furan, all solutions were kept at a temperature of 4 °C or below. Stock solutions were prepared in methanol and stored at −18 °C. Pipetting was performed using a gas-tight electrical syringe, Trajan eVol XR (Sigma-Aldrich, Taufkirchen, Germany) and the substance was pipetted below the surface of the liquid (this pipetting step was identified as rather critical and the use of an electrical syringe substantially lowered the relative standard deviation). A merged stock solution was prepared by combining defined amounts of the individual stock solutions of all analytes and appropriate dilution.

Working solutions were prepared on a daily basis by dilution of an aliquot of the merged stock solution in water. The working solution was kept at 4 °C and used on the same day. A seven-point calibration curve was prepared in water, covering the following analyte ranges: 0.19–18.5 ng/ml for furan (R2 = 0.9998), 0.14–14.0 ng/ml for 2-MF (R2 = 0.9999), 0.05–5.45 ng/ml for 3-MF (R2 = 0.9998), 0.09–8.9 ng/ml for 2-EF (R2 = 0.9970), 0.06–5.88 ng/ml for 2,5-DF (R2 = 0.9998) and 0.23–23.47 ng/ml for 2-PF (R2 = 0.9996). The concentration of the internal standards in the calibration curve was 3.4 ng/ml for furan-d4, 2.5 ng/ml for 2-MF-d6, 1.0 ng/ml for 3-MF-d3, 0.5 ng/ml for 2,5-DF-d3 and 1.5 ng/ml for 2-PF-d3. 2-EF was quantified using 2,5-DF-d3 as internal standard.

Sample preparation

Approximately 5–20 g of sample were homogenized using an M20 universal mill (IKA, Staufen, Germany) with water cooling to prevent loss of furan. Immediately after grinding, 0.5 g of the ground material were quickly weighed into a cold 20 ml-screw-cap headspace vial followed by immediate addition of 10 ml of cold water (4 °C). Subsequently, 50 µL of pre-cooled internal standard solution were added and the sample vigorously shaken to avoid clumping and achieve homogenous suspension. After shaking, the cap was replaced to ensure that the septum surface was free of particles or droplets.

Quality control

A set of quality control samples was prepared by homogenization of 500 g of a furan containing breakfast cereal followed by division into eight subsamples of 60 g each. Analysis of five randomly selected subsamples resulted in levels of 65.0 ± 6.5 µg/kg furan, 58.7 ± 6.7 µg/kg 2-methylfuran, 3.75 ± 0.47 µg/kg 3-methylfuran, 5.08 ± 0.79 µg/kg 2-ethylfuran, 1.54 ± 0.39 µg/kg 2,5-dimethylfuran and 25.4 ± 6.1 µg/kg 2-pentylfuran. The remaining subsamples were stored at −18 °C and used as quality control samples during analysis.

Recovery

For the determination of the recovery rates, a breakfast cereal sample was spiked with volumes corresponding to the calibration levels 1, 2, 3, 6 and 7. The concentrations of the levels can be found in the Supplementary Information.

GC–MS analysis

The analysis was performed on a GC 7890A and MS 5975C from Agilent coupled with a Gerstel Multi-Purpose Sampler MPS 2XL equipped with a SPME analysis unit. A carboxen/PDMS fiber (NIT, 75 µm, 23 ga, Supelco) was used. The S/SL injector contained an ultra-inert liner (straight, SPME taper, 0.75 mm, Agilent) as well as a Merlin microseal SPME septum (Sigma-Aldrich). The sample was incubated at 50 °C for 20 min with 250 rpm agitator speed and subsequently the gas phase was extracted without agitation with the abovementioned SPME fiber for 20 min. Desorption in the injector was achieved within 1 min at 250 °C. Carryover was avoided by heating the fiber at 280 °C for 2 min before extraction and 8 min post-injection of each sample using a PAL-xt SPME fiber conditioning module (CTC Analytics AG, Zwingen, Switzerland). Separation was performed on a HP-PLOT Q column (30 m × 320 µm × 20 µm) with a temperature gradient. Injection started at 50 °C for 1.7 min, followed by an increase of 8 °C/min to 150 °C, by 1.8 °C/min to 180 °C, by 22 °C/min to 270° and 7 min hold at 270 °C with a helium carrier gas flow rate of 1.7 ml/min. The MS was performed in Scan and SIM modes. The SIM parameters for the analysis are shown in Table 1. Further details and instrumental parameters can be found in the Supplementary Information.

Acrylamide analysis

A homogenized and milled breakfast cereal sample was extracted using a QuEChERS sample preparation. 1 g of the sample was weighed into a vial and 10 ml of water as well as 200 µL of a solution of the internal standard d3-acrylamide (1 µg/mL) were added. For samples with higher fat content (> 5%), fat was then removed by addition of 5 mL cyclohexane followed by shaking for one minute, centrifugation (3200 g; 10 °C; 5 min) and removal of the upper layer. Clean up of the samples was performed by extraction with 10 mL acetonitrile followed by quick addition of a salt mixture (4 g MgSO4; 1 g NaCl; 0.5 g Na2Hcitrate * 1.5 H2O; 1 g Na3citrate * 2 H2O) and vigorous shaking for 1 min to obtain a phase separation. Subsequently the sample was cooled down to RT in an ice bath followed by centrifugation (3200 g; 4 °C; 3 min). 3 mL of the acetonitrile-phase were transferred into a 15 mL-PP tube and the second clean-up-mix (0.6 g MgSO4, 0.2 g Bondesil PSA) was added followed by shaking and cooling down in an ice bath. Additional centrifugation (3200 g; 4 °C; 5 min) was applied to obtain a clear solution of which 1 mL was transferred in a 2 mL PP tube. Solvent was removed using a RVC 2–33 CDplus IR vacuum concentration (Martin Christ Gefriertrocknungsanlagen GmbH, Osterode am Harz, Germany) (10 mbar; 40 °C; 60 min). The obtained residue was redissolved in 500 µL mobile phase (water + 0.1% formic acid) and centrifuged (20.000 g; 10 °C; 5 min) before injection into the UHPLC-system. Separation was achieved by HPLC on a hypercarb column (50 mm × 2.1 mm; 5 µm, Thermo Scientific, Schwerte, Germany) with acetonitrile and water as eluents and analyzed by mass spectrometry (MS/MS) using a QTrap 5500 mass spectrometer (Sciex, Darmstadt, Germany). 10 µl of the sample were injected, followed by isocratic elution with water + 0.1% formic acid at 0.4 ml/min and 40 °C. Between samples a flush method with a gradient from 0 to 100% acetonitrile + 0.1% formic acid was employed. Quantitative determination was performed using acrylamide-d3 as an internal standard and an external calibration in solvent (ranging from 1 to 750 ng/ml, R2 = 0.9941). MS/MS-conditions were as follows: ESI in positive ion mode, ionspray voltage 5500 V, declustering potential 32 V, cell exit potential 11 V, and the following MRM transitions were used for quantitation (with varying collision energy potential): acrylamide quantifier m/z 72.1 > 55.0 (16 V), qualifier 72.1 > 44.1 (25 V), acrylamide-d3 quantifier m/z 75.1 > 58.0 (16 V), qualifier 75.1 > 47.1 (25 V). As quality control, European Reference Material ERM-BD272 (BAM, Berlin, Germany) was analyzed with every sample batch.

Results and discussion

Furan and alkylfuran analysis

Analytical method

In the first step, an analytical method for the analysis of furan and alkylfurans in breakfast cereals was developed and established based on published methods described above [4, 31]. Briefly samples were chilled, finely ground, and weighed into a headspace vial followed by the addition of water and isotope labeled furans as internal standards. Analysis of furans was done by GC–MS after SPME-sampling as this turned out being more sensitive. A detailed method description can be found in the Materials and Methods section.

While the general workflow of furan analysis appeared straightforward, there were some pitfalls during sample handling and treatment. For breakfast cereal samples, clumping of the material resulting in an incomplete solubilization and irreproducible results were observed. Improvement of the extraction was achieved by reducing the sample weight from 1.0 to 0.5 g. Another factor for reproducibility appeared to be the handling of standard solutions with manual syringes. The application of an electronic syringe improved standardization of liquid handling and thus repeatability. The combination of both factors as well as generally quick sample handling allowed the reduction of the relative standard deviation (RSD) of the quality control sample to 10.6% for furan over a time period of 6 months and to 0.5–2% for duplicate analysis on each day. For the other analytes, RSDs between 12 and 18% were recorded over the time period of 6 months, with RSD of the duplicate analysis ranging from 0.5 to 9%.

Validation

Limits of quantitation were set at the lowest validated calibration level. The lowest calibration level corresponds to 3.7 µg/kg for furan, 2.8 µg/kg for 2-MF, 1.1 µg/kg for 3-MF, 1.2 µg/kg for 2,5-DF and 4.7 µg/kg for 2-PF while for 2-EF, the limit of quantitation was set at the second calibration level (3.6 µg/kg). The repeatability in the quality control sample was mostly within the limits of the commission recommendation (EU) 2022/495 (criterion for repeatability is 0.66 times RSDR as derived from (modified) Horwitz equation, namely 15% at the level of 5 µg/kg). This applied to furan, 2-MF, 3-MF and 2-EF. Only 2,5-DF and 2-PF showed higher relative standard deviations. In addition to the monitoring of the repeatability in the quality control sample, samples were spiked to obtain recovery rates. Spiking of samples was done at several calibration levels. Recovery rates were between 70 and 130% for all analytes. Recovery rates for furan were between 70 and 105%. Mainly 2-PF showed higher recovery rates.

Acrylamide

Acrylamide analysis was done using a QuEChERS-based sample preparation and HPLC–MS/MS analysis with internal standard as described in the methods section. Acrylamide levels could be quantitated with an LOQ of 23 µg/kg. When applied to breakfast cereals, the method showed an inter-day repeatability of 15% among the different matrices and a recovery between 68 and 113% at spiking levels of 10 µg/kg, 100 µg/kg and 500 µg/kg and with a certified reference material.

Furan and alkylfuran levels in breakfast cereals

Within this study, 76 different breakfast cereal products were analyzed for the occurrence of furan, 2-MF, 3-MF, 2,5-DF, 2-EF, and 2-PF as well as their acrylamide content. With the applied method, only trace amounts of 2-propylfuran and 2-butylfuran could be detected compared to furan, methylfurans, 2-EF and 2-PF (data not shown). Thus, 2-propylfuran and 2-butylfuran were not further considered for quantitation and subsequent data analysis.

The samples covered a broad range of breakfast cereals which were manufactured using one or more of the following processes: Baking, extrusion cooking, steam cooking, flaking, and puffing.

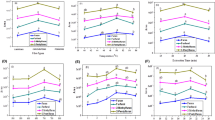

Flakes

Fourteen products were categorized as flakes, among which eleven products were cornflakes and five were different kinds of multigrain flakes, containing whole wheat, oats, spelt, and/or rice. Generally, two different procedures for cornflake production are applied in industry: (1) cooking of the broken kernels of corn or other grain kernels, followed by rolling into thin flakes and toasting in a hot airstream, (2) extrusion cooking of a flour mixture, followed by pelleting, rolling and toasting [34]. However, cornflakes are mostly produced with the first procedure and extruded cornflakes are hardly present on the market. Furthermore, multigrain flakes are produced by a variant of procedure (2), as broken grains are cooked and then pressed to pellets in an extruder, followed by the rolling and toasting steps. The results of the furan analysis of flakes are shown in Fig. 2.

Flakes showed furan levels with a range of 7.91–74.4 µg/kg and a mean of 35.0 µg/kg. The 2-PF levels were comparable to furan and ranged between 9.36 and 140 µg/kg with a mean of 42.6 µg/kg. 2-MF levels were lower with a range of 3.76–29.5 µg/kg (mean 13.9 µg/kg). 3-MF was generally observed in lower concentrations (mean: 6.58 µg/kg) with a maximum of 18.0 µg/kg in one cornflakes sample, while the other cornflakes samples showed levels from < LOQ to 10.8 µg/kg. For all multigrain flakes, 3-MF values below 2 µg/kg were recorded. 2-EF levels were observed in concentrations between < LOQ (< 3.6 µg/kg) and 9.11 µg/kg (mean 6.03 µg/kg) with no clear difference between corn and multigrain flakes.

In direct comparison with multigrain flakes, cornflakes showed higher furan and 2-MF levels, as well as higher 2-PF levels. The observation that the 3-MF levels are higher in cornflakes compared to other cereal flakes is in good agreement with the hypothesis that 3-MF formation is related to carotenoids, which can be found in five to twenty times higher concentration in corn compared to wheat or other cereal grains [35]. The observation that wholemeal multigrain flakes show higher levels of acrylamide compared to cornflakes is in good agreement with data from previous studies on biscuit manufacturing, where also more acrylamide formation was observed in these materials compared to biscuits made of refined flour or corn flour [36].

A comparison of the two production procedures shows similar trends, as all cornflakes in this study except for the cornflakes with 7.91 µg/kg furan were produced with the batch-cooking procedure. This cornflakes sample and the multigrain flakes were extruded and then rolled into flakes. These extruded flakes also show lower furan, 2-MF, 3-MF and 2-PF levels but this is mainly due to the raw materials as the multigrain flakes consist of different grains in comparison to cornflakes.

In this category, acrylamide levels between 23.3 to 259 µg/kg were determined (mean 118 µg/kg). Even though the formation pathways of acrylamide and furan are different, both process contaminants are generated by thermal processing, so that the monitoring and comparison of the levels of furan and acrylamide is of high relevance, as mitigation strategies may have an influence on both contaminants. A look at the acrylamide levels in these samples show low correlations with the furan levels (r = 0.312, p = 0.278) as well as low correlations with the other alkylfurans (see Supplementary Information for values and graphs).

Puffed cereal products

26 samples were categorized as puffed cereals and the determined levels of furans are reported in Fig. 3. For puffing, whole kernels are steam cooked at temperatures up to 160 °C and puffed by a sudden drop in pressure [34]. Puffing temperature and pressure correlate with expansion of the product and are adjusted to meet the intended sensory properties of the specific breakfast cereals product.

In most puffed samples, comparably high levels of furan were detected with a range of 13.0–231 µg/kg and a mean of 69.3 µg/kg. Interestingly, the five products with the highest furan levels were all made of different cereals (barley, wheat, oats, amaranth, quinoa) indicating that furan formation could be more related to the process parameters than the grain type.

2-MF was found in levels from 6.4 to 252 µg/kg (mean 52.8 µg/kg), so the level was slightly lower than furan in most of the samples. The five samples with the highest furan levels were also those with the highest 2-MF levels, suggesting a correlation between furan and 2-MF levels. Indeed, correlation analysis among the puffed cereals showed a high Pearson correlation coefficient of 0.869 (see Supplementary Information).

3-MF and 2,5-DF were found only in smaller amounts with a mean of 5.60 µg/kg for 3-MF and a mean of 5.28 µg/kg for 2,5-DF. Four samples showed higher 3-MF levels with the highest level of 15.9 µg/kg being found in a puffed corn samples with low furan and 2-MF levels, indicating a mild puffing. On the other hand, further samples with comparably high 3-MF levels were the barley and amaranth sample with the highest furan levels as well as lentils, which are naturally rich in carotenoids. In summary this indicates that besides carotenoids, rather strong puffing conditions also result in elevated 3-MF levels. The highest 2,5-DF-level of 20.7 µg/kg could also be assigned to the amaranth sample with high furan and 2-MF levels.

2-EF levels were observed with a range of 5.01–20.6 µg/kg (mean 10,4 µg/kg) and are only around one fifth of the furan levels. 2-PF in comparison was quantified in comparable levels to furan with a range of 18.6–195 µg/kg and a mean value of 60.7 µg/kg. For both compounds, only comparably low Pearson correlation coefficients of 0.303 (2-EF) and 0.463 (2-PF) were calculated with no significance on the 0.01 level.

Interestingly for quinoa, the ratio between the levels of furan and the individual alkylfurans appeared constant despite different absolute concentrations. These four quinoa products were whole puffed grain products without further ingredients, so a change in furan levels (31.0–93.8 µg/kg) was most probably caused by different parameters in the production process, specifically during the puffing or drying steps. However, the grains could also have had differences in their nutrient composition as they originated from different countries with likely different growing conditions. For two puffed spelt products, the ratio of furan and alkylfurans were similar to each other but differed more than observed within the quinoa products. This could also have been influenced by the addition of honey to these two products. The large range of furan and 2-MF concentrations, observed for the same cereal such as wheat, in this category, indicates that the puffing conditions are a critical factor for furan and 2-MF formation. Adjustment of puffing temperature and water content might be a valuable tool for the reduction of furan and 2-MF levels. However, these parameters are also crucial for the specific sensory properties which are characteristic for the individual products.

Acrylamide and furan/alkylfuran levels showed low correlations within the data (see Supplementary Information). The furan and acrylamide correlation in puffed products was r = 0.289 (p = 0.170) while the correlation with other furans is even lower. If the puffed products are split by grain type, the five puffed wheat products show a strong correlation of furan and acrylamide (r = 0.866, p = 0.058), as well as a strong correlation of the other methyl- and alkylfurans with acrylamide (except for 2-PF). The same was not observed for the six puffed spelt products (correlation of furan and acrylamide: r = 0.083, p = 0.875). Grain as a raw material seems to be an important factor in the optimization of the puffing process.

Extruded cereals

The 21 extruded cereals analyzed in this study were direct-expanded, extruded cereals based on a mixture of flour, water, and additives such as cocoa, honey or malt extract. They were cooked in an extruder under high pressure and shear forces and expanded immediately by passing through the exit die to atmospheric pressure, where moisture was released. The levels of furan and alkylfurans are reported in Fig. 4.

Extruded products showed levels of furan with a range of 7.83–49.5 µg/kg and a mean of 19.8 µg/kg. In comparison to furan, 2-MF levels were at most half as high (3.84–16.0 µg/kg) with a mean of 9.72 µg/kg. With a Pearson correlation coefficient of 0.707, both values show a strong correlation, even though less 2-MF is generally formed (see Supplementary Information).

The range of 2-EF levels (< LOQ (< 3.6)-34.1 µg/kg, mean 12.6 µg/kg) was comparable to that of 2-MF 3.84–16.0 µg/kg, mean 9.72 µg/kg), though only low correlation between 2-MF and 2-EF was observed (r = 0.209, p = 0.363). In five samples, only very low levels of 2-EF below 3.7 µg/kg were detected. As ω-3 fatty acids are described as efficient precursors for 2-EF, the relationship between the declared group of unsaturated fatty acids (which include ω-3 fatty acids) and 2-EF was investigated [37, 38]. Based on nutrient labeling, these five samples contained unsaturated fatty acid in levels of 1.5 g/100 g or below. In the 16 remaining samples, 2-EF was comparably higher with 2-EF levels > 7.5 µg/kg. 13 of these samples had levels of unsaturated fatty acids with concentrations between > 1.5 g and 12 g/100 g. Another three of these samples had 2-EF concentrations > 7.5 mg/kg despite low declared unsaturated fatty acid values of 0.7–1.5 g/100 g. In these cases, the unsaturated fatty acids originated from grain flour or cocoa as no oil ingredient was part of the recipe. Nevertheless, a correlation analysis between the level of unsaturated fatty acids and 2-EF in all extruded samples resulted in a low correlation coefficient of r = 0.170 (p = 0.485).

Strikingly, the 3-MF levels detected after extrusion cooking were higher compared to the other categories of breakfast cereal manufacturing with a range of 1.42–24.9 µg/kg and a mean of 5.22 µg/kg. In detail all products with a higher percentage of 3-MF consisted of grain mixtures with a portion of corn. In one sample 3-MF levels were twice as high as furan levels (24.9 µg/kg 3-MF to 11.8 µg/kg furan). It was a pure corn product without other grains contributing to the mixture. A similar trend was observed with one cornflakes product which was extruded as well (see Fig. 2: 18.0 µg/kg 3-MF to 7.91 µg/kg furan). Unfortunately, the amount of corn in the multigrain products was not declared on the products, allowing now further investigation of the relationship between corn content and 3-MF. As discussed above, carotenoids in corn are most probably responsible for the elevated 3-MF levels.

Some samples contained high amounts of 2-EF and 2-PF simultaneously but other samples had a different ratio of 2-EF to 2-PF. This discrepancy, that was to a lesser extend also observed for puffed and toasted cereals, indicates that the quality of the raw materials, namely the lipid oxidation status, has a strong effect on the determined 2-EF and 2-PF concentrations. In future studies, the pattern of unsaturated fatty acids as well as lipid oxidation products should be analyzed in greater detail to monitor a potential correlation of the formation of 2-EF and 2-PF and different unsaturated fatty acids.

Interestingly, a high correlation (r = 0.686, p < 0.01) of furan and acrylamide levels for extruded products was observed in comparison to the other categories, as well as a high correlation of 2-MF and acrylamide (r = 0.590, p < 0.01).

Muesli and granola samples

Fifteen samples were assigned to muesli/granola with the latter one being manufactured by baking of a mixture containing grains, vegetable oil, sugar, and water. Different ingredients such as nuts, dried fruits or cocoa, as well as extruded pieces can be added, resulting in partially heterogenous mixtures [34].

Baked granola samples in general showed low levels of furan and only traces of 3-MF and 2,5-DF as reported in Fig. 5. The 2-PF content was higher than the furan content with a mean of 34.5 µg/kg. The low furan and alkylfuran levels can be explained by the comparably low temperature inside the products during baking which remains mostly at around 100 °C [39], indicating that muesli and granola are of low relevance for exposure to these compounds. However, 2-PF levels should be considered for these foods. As polyunsaturated fatty acids such as ω-6 fatty acids are known precursors of 2-PF [15, 40], the presence of this compound in granola is not surprising as fat like sunflower oil is commonly used to form the agglomerated particles. For example, a very high 2-PF level of 120 µg/kg was observed for an oat-based granola containing 5.5 g/100 g fat from which 4.5 g/100 g were unsaturated fatty acids.

Similar to flakes and puffed products the acrylamide levels show almost no correlation with the furan levels (r = 0.145, p = 0.607). The correlation with 2-MF is stronger, but could be coincidental (r = 0.505, p = 0.055).

In a direct comparison of the furan levels in the four categories of breakfast cereals, puffed products showed the highest furan levels. Flakes and cornflakes had slightly lower furan levels, followed by the extruded products. Granola showed lower levels of furan in all products of this category. A one-way MANOVA showed a statistically significant difference between the four categories on the combined dependent variables (F(18, 136) = 2.289, p = 0.004, partial η2 = 0.221, Wilk’s Λ = 0.474). Post hoc univariate ANOVAs were conducted for every dependent variable. Results show a statistically significant difference between the categories for furan, 2-MF, 3-MF, 2-EF and 2,5-DF but not for 2-PF (F(3, 53) = 2.208, p = 0.098, partial η2 = 0.111). Games-Howell post hoc analysis on furan levels revealed a significant difference between granola on one hand and all three other categories as well as between puffed products and extruded products. No significant difference between flakes and puffed products or extruded products was observed. Further details of the statistical analysis can be found in the Supplementary Information. In summary, these data demonstrate that furan and the methyl furans are exclusively process induced contaminants while 2-PF is strongly affected by lipid oxidation during processing as well as post-harvest.

The overall results are summarized in Fig. 6. The mean furan levels of the four groups of breakfast cereals analyzed in this study varied from 10.3 µg/kg furan and 6.55 µg/kg 2-MF in muesli and granola to 69.3 µg/kg furan and 52.8 µg/kg 2-MF in puffed grains. The highest observed furan levels were 231 µg/kg and 252 µg/kg for 2-MF in puffed barley and puffed oat, respectively. This is comparable to the data described in literature. Fromberg et al. observed furan levels up to 387 µg/kg in breakfast cereals but no details about the products were given by the authors. Hamlet et al. observed furan levels up to 94 µg/kg and 2-MF levels up to 69 µg/kg in puffed grains [4, 6, 29, 30].

Storage experiments

53 samples of the project were analyzed at three different time points over a period of 6 months. For this, the closed original package was stored at room temperature and directly opened before analysis. Furan, 2-MF, 3-MF showed almost no differences over this period (Fig. 7). Furan decreased 7% with a mean of 22.5 µg/kg in the initial analysis and a mean of 20.9 µg/kg in the analysis 6 months later. 2,5-DF was only found in traces in most of the samples, therefore, no relevant effect could be observed. Interestingly, the concentrations of the alkylfurans 2-EF and 2-PF increased remarkably during storage. 2-EF levels increased by 19% with a high increase for extruded samples and granola samples. 2-PF increased in these samples, too, as well as in puffed products. The mean level of 2-PF increased by 25%. Statistical analysis of the datasets by paired T-test revealed a difference between the levels in the initial analysis and in analysis after 6 months at a significance level of p < 0.001 for 2-PF while for furan decrease and 2-EF increase, no sufficient significance could be determined. An increase for 2-PF and 2-EF can be explained by the ongoing lipid oxidation: Unsaturated fatty acids can be degraded into aldehydes such as 2-nonenal and further oxidized to 2-alkylfuranes [15]. However, further studies performing model experiments are needed to support this hypothesis.

Acrylamide analysis

Acrylamide levels varied in the different products between < LOQ and 556 µg/kg. The highest levels were found in puffed products, while the lowest levels were found in extruded products. Levels in puffed products varied between 32 and 556 µg/kg. In extruded products acrylamide levels between < LOQ and 354 µg/kg were detected. Flakes showed acrylamide levels from 23 to 259 µg/kg and cornflakes from < LOQ to 198 µg/kg. In the flakes category, most cornflakes showed lower levels of acrylamide, especially when there was also a lower level of sugar in the product. Granola products showed acrylamide levels from < LOQ to 121 µg/kg (see Figs. 2–5 above and Table 2–5 in the Supplementary Information).

When compared by grain type, the highest levels of acrylamide were found in wheat products with a mean of 171 µg/kg followed by oat products with a mean of 93 µg/kg. Products with corn showed acrylamide levels with a mean of 60 µg/kg and rice with an average of 41 µg/kg with the highest level being 74 µg/kg. Detailed information on the acrylamide levels in the analyzed samples can be found in the Supplementary Information.

Conclusion

In this project, 76 samples of breakfast cereals were analyzed for their furan, 2-MF, 3-MF, 2-EF, 2,5-DF, and 2-PF content using an optimized GC–MS analysis based on solid phase microextraction. Furthermore, acrylamide levels were determined using an HPLC–MS/MS method.

The screening of breakfast cereals showed that furan levels stayed almost constant over a 6 months storage period, as long as the samples remained in the original packaging and were opened directly before analysis. 2-EF and 2-PF increased over the storage period which is most probably due to fat oxidation mechanisms.

Granola samples showed the lowest levels of furan and alkylfurans while the highest levels were observed in puffed cereals. Furan and 2-MF-levels were found to be the most abundant in all of the samples with levels up to 231 µg/kg furan and 252 µg/kg 2-MF and a mean of 39.2 µg/kg for furan and 26.6 µg/kg for 2-MF. 2-PF was observed with levels up to 195 µg/kg and a mean of 49.8 µg/kg. Compared to the other analytes, 2-PF was present in all samples with levels of at least 9.36 µg/kg and was the most abundant analyte in the granola samples. To further substantiate the data on the products and process categories, it is useful to examine multiple batches of the same products in future studies to include process variability.

Only in corn-based cereals, especially after extrusion cooking or toasting, 3-MF was found as a relevant alkylfuran contaminant with levels of up to 24.9 µg/kg. A possible explanation could be the higher levels of carotenoids in corn compared to other cereals. 3-MF was not found in high levels in any non-corn-based breakfast cereal and the same was observed for 2,5-DF which was only found in traces in almost all kind of cereal samples.

Furan and alkylfuran formation follows different chemical pathway than acrylamide formation. While the data showed a correlation of furan and acrylamide in puffed wheat, no strong correlation between the furan and acrylamide levels was observed in the other products and procedures for acrylamide reduction not necessarily support the reduction of furan and alkylfuran formation. Instead, our results show that furan formation in cereal production needs to be monitored in addition to the already existing monitoring of acrylamide. Similar to the process contaminant acrylamide, the creation of a toolbox for mitigation strategies would be useful for manufactures to manage furan and alkylfurans in food.

Data availability

Online Resource 1 includes all relevant additional data which are not shown in the publication.

References

Ali S, Singh B, Sharma S (2017) Development of high-quality weaning food based on maize and chickpea by twin-screw extrusion process for low-income populations. J Food Process Eng 40:e12500. https://doi.org/10.1111/jfpe.12500

Singh S, Gamlath S, Wakeling L (2007) Nutritional aspects of food extrusion: a review. Int J Food Sci Tech 42:916–929. https://doi.org/10.1111/j.1365-2621.2006.01309.x

Capuano E, Fogliano V (2011) Acrylamide and 5-hydroxymethylfurfural (HMF): a review on metabolism, toxicity, occurrence in food and mitigation strategies. LWT Food Sci Technol 44:793–810. https://doi.org/10.1016/j.lwt.2010.11.002

Kettlitz B, Scholz G, Theurillat V et al (2019) Furan and methylfurans in foods: an update on occurrence, mitigation, and risk assessment. Compr Rev Food Sci Food Saf 18:738–752. https://doi.org/10.1111/1541-4337.12433

EFSA Panel on Contaminants in the Food Chain (2015) Scientific opinion on acrylamide in food. EFSA J. https://doi.org/10.2903/j.efsa.2015.4104

Knutsen HK, Alexander J et al (2017) Scientific opinion on the risks for public health related to the presence of furan and methylfurans in food. EFSA J 15:e05005. https://doi.org/10.2903/j.efsa.2017.5005

Maga JA (1979) Furans in foods. CRC Crit Rev Food Sci Nutr 11:355–400. https://doi.org/10.1080/10408397909527268

IARC Working Group on the Evaluation of Carcinogenic Risks to Humans (1995) Dry cleaning, some chlorinated solvents and other industrial chemicals: monographs on the evaluation of carcinogenic risks to humans, No. 63. International Agency for Research on Cancer, Lyon

Joint Expert Committee on Food Additives (2011) Safety evaluation of certain contaminants in food. World Health Organization, Geneva

Moser GJ, Foley J, Burnett M et al (2009) Furan-induced dose-response relationships for liver cytotoxicity, cell proliferation, and tumorigenicity (furan-induced liver tumorigenicity). Exp Toxicol Pathol 61:101–111. https://doi.org/10.1016/j.etp.2008.06.006

NTP (1993) Toxicology and carcinogenesis studies of furan (CAS No. 110–00-9) in F344 rats and B6C3F1 mice(Gavage Studies). Natl Toxicol Program Tech Rep Ser 402:1–286

Oser B, Hall R (1972) 5. GRAS substances: recent progress in the consideration of flavoring ingredients under the food additives amendment. Food Technol 26:35–42

Smith RL, Waddell WJ, Cohen SM et al (2011) GRAS flavoring substances 25: the 25th publication by the expert panel of the flavor and extract manufacturers association provides an update on recent progress in the consideration of flavoring ingredients generally recognized as safe under the food additives amendment. Food Technol 65:44–75

Younes M, Aquilina G et al (2021) Scientific opinion on flavouring group evaluation 67, revision 3 (FGE.67Rev3): consideration of 23 furan-substituted compounds evaluated by JECFA at the 55th, 65th, 69th and 86th meetings. EFSA J 19:e06362. https://doi.org/10.2903/j.efsa.2021.6362

Perez Locas C, Yaylayan VA (2004) Origin and mechanistic pathways of formation of the parent furan–a food toxicant. J Agric Food Chem 52:6830–6836. https://doi.org/10.1021/jf0490403

Limacher A, Kerler J, Davidek T et al (2008) Formation of furan and methylfuran by maillard-type reactions in model systems and food. J Agric Food Chem 56:3639–3647. https://doi.org/10.1021/jf800268t

Becalski A, Seaman S (2005) Furan precursors in food: a model study and development of a simple headspace method for determination of furan. J AOAC Int 88:102–106. https://doi.org/10.1093/jaoac/88.1.102

Lachenmeier DW, Schwarz S, Teipel J et al (2018) Potential antagonistic effects of acrylamide mitigation during coffee roasting on furfuryl alcohol, furan and 5-hydroxymethylfurfural. Toxics. https://doi.org/10.3390/toxics7010001

Arisseto AP, Vicente E, Ueno MS et al (2011) Furan levels in coffee as influenced by species, roast degree, and brewing procedures. J Agric Food Chem 59:3118–3124. https://doi.org/10.1021/jf104868g

Javed F, Shahbaz HM, Nawaz A et al (2021) Formation of furan in baby food products: identification and technical challenges. Compr Rev Food Sci Food Saf 20:2699–2715. https://doi.org/10.1111/1541-4337.12732

van Lancker F, Adams A, Owczarek A et al (2009) Impact of various food ingredients on the retention of furan in foods. Mol Nutr Food Res 53:1505–1511. https://doi.org/10.1002/mnfr.200800565

Palmers S, Grauwet T, Buvé C et al (2015) Furan formation during storage and reheating of sterilised vegetable purées. Food Addit Contam Part A Chem Anal Control Expo Risk Assess 32:161–169. https://doi.org/10.1080/19440049.2014.999720

NTP (2012) Toxicology and carcinogenesis studies of acrylamide (CASRN 79–06–1) in F344/N rats and B6C3F1 mice (feed and drinking water studies). Natl Toxicol Program Tech Rep Ser:1–234

Eisenbrand G (2020) Revisiting the evidence for genotoxicity of acrylamide (AA), key to risk assessment of dietary AA exposure. Arch Toxicol 94:2939–2950. https://doi.org/10.1007/s00204-020-02794-3

Guth S, Baum M, Cartus AT et al (2023) Evaluation of the genotoxic potential of acrylamide: arguments for the derivation of a tolerable daily intake (TDI value). Food Chem Toxicol 173:113632. https://doi.org/10.1016/j.fct.2023.113632

Lineback DR, Coughlin JR, Stadler RH (2012) Acrylamide in foods: a review of the science and future considerations. Annu Rev Food Sci Technol 3:15–35. https://doi.org/10.1146/annurev-food-022811-101114

Mottram DS, Wedzicha BL, Dodson AT (2002) Acrylamide is formed in the Maillard reaction. Nature 419:448–449. https://doi.org/10.1038/419448a

Food Drink Europe (2019) Acrylamide Toolbox, 15th edn., Brussel

Fromberg A, Mariotti MS, Pedreschi F et al (2014) Furan and alkylated furans in heat processed food, including home cooked products. Czech J Food Sci 32:443–448. https://doi.org/10.1722/341/2013-CJFS

Hamlet CG, Liang L, Baxter B et al. (2019) Survey of Acrylamide and Furans in UK Retail Products: Results for Samples Purchased Between January 2018 and November 2018: A Report Prepared for the Food Standards Agency. UK

Frank N, Dubois M, Huertas Pérez JF (2020) Detection of furan and five alkylfurans, including 2-pentylfuran, in various food matrices. J Chromatogr A 1622:461119. https://doi.org/10.1016/j.chroma.2020.461119

Becalski A, Forsyth D, Casey V et al (2005) Development and validation of a headspace method for determination of furan in food. Food Addit Contam 22:535–540. https://doi.org/10.1080/02652030500129170

Kobayashi Y, Nakano M, Kumar GB et al (1998) Efficient conditions for conversion of 2-substituted furans into 4-oxygenated 2-enoic acids and its application to synthesis of (+)-aspicilin, (+)-patulolide a, and (-)-pyrenophorin. J Org Chem. https://doi.org/10.1021/jo980942a

Perdon AA, Schonauer SL, Poutanen KS (eds) (2020) Breakfast cereals and how they are made: raw materials, processing, and production, 3rd edn. Woodhead Publishing; Cereals & Grains Association, Cambridge

Trono D (2019) Carotenoids in cereal food crops: composition and retention throughout grain storage and food processing. Plants. https://doi.org/10.3390/plants8120551

Žilić S, Aktağ IG, Dodig D et al (2020) Acrylamide formation in biscuits made of different wholegrain flours depending on their free asparagine content and baking conditions. Food Res Int 132:109109. https://doi.org/10.1016/j.foodres.2020.109109

Adams A, Bouckaert C, van Lancker F et al (2011) Amino acid catalysis of 2-alkylfuran formation from lipid oxidation-derived α, β-unsaturated aldehydes. J Agric Food Chem 59:11058–11062. https://doi.org/10.1021/jf202448v

Fratini G, Lois S, Pazos M et al (2012) Volatile profile of Atlantic shellfish species by HS-SPME GC/MS. Food Res Int 48:856–865. https://doi.org/10.1016/j.foodres.2012.06.033

Kuchenbuch HS, Becker S, Schulz M et al (2018) Thermal stability of T-2 and HT-2 toxins during biscuit- and crunchy muesli-making and roasting. Food Addit Contam Part A Chem Anal Control Expo Risk Assess 35:2158–2167. https://doi.org/10.1080/19440049.2018.1530456

Min DB, Callison AL, Lee HO (2003) Singlet oxygen oxidation for 2-pentylfuran and 2-pentenyfuran formation in soybean oil. J Food Sci 68:1175–1178. https://doi.org/10.1111/j.1365-2621.2003.tb09620.x

Acknowledgements

We thank all members and the chairperson Jens Meyer of the project monitoring committee of FEI for support and discussion as well as Christine Nowakowski for proofreading. The authors thank Lina Schürmann for assistance during the analysis of the samples.

Funding

Open Access funding enabled and organized by Projekt DEAL. This IGF project of the FEI was supported via AiF within the program for promoting the Industrial Collective Research (IGF) of the German Ministry of Economics and Climate Action (BMWK), based on a resolution of the German Parliament. Project AiF 21305 N.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors have no conflict of interest to declare.

Compliance with ethics requirements

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lipinski, S., Lindekamp, N., Funck, N. et al. Determination of furan and alkylfuran in breakfast cereals from the European market and their correlation with acrylamide levels. Eur Food Res Technol 250, 167–180 (2024). https://doi.org/10.1007/s00217-023-04374-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04374-y