Abstract

The article proposes using Computational Fluid Dynamics to predict protein denaturation and weight loss in pork loin samples during baking. The optimal conditions of heat treatment were determined to be at 181.55℃, 20% humidity, and a fan speed of 639.18 rpm. Following this process, the denaturation of various pork loin proteins was measured, and the weight loss was determined to be 12.21 ± 0.89%. In the laboratory study at the verification stage, it was found that myosin and actin denaturation and body weight loss did not differ significantly from the values predicted on the basis of the response surface model developed using simulation data. However, the degree of sarcoplasmic protein denaturation observed in the laboratory was lower than the model's predictions, while collagen denaturation was higher. The study suggests that computational fluid dynamics can be a useful tool for predicting protein denaturation and weight loss in pork loin samples and could improve product quality and consistency in the food industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

According to the Food and Agriculture Organization of the United Nations (FAO) in 2020, meat consumption in Europe had reached 75.5 kg per person, with pork accounting for 33.7 kg of that amount. Meat is an important source of protein, vitamins, and minerals that are crucial for human health. Meat proteins provide essential amino acids that are used by the body to build proteins and regulate metabolic pathways, which are important for growth and development. Meat also contains minerals, such as selenium, zinc, and heme–iron, derived from hemoglobin and myoglobin, which play vital roles in various bodily processes. Zinc, selenium, and iron are essential minerals with significant roles in the body. Zinc is involved in metabolism, immune response, and human development. Selenium has antioxidant and anti-inflammatory effects and is important for the immune and reproductive systems. Iron is crucial for the development and function of all tissues and plays a crucial role in cellular processes, such as energy metabolism and neurotransmitter synthesis [1,2,3,4,5,6,7,8,9,10].

Nutrients found in meat are essential for the human body, but their content and bioavailability can be reduced during thermal processing. Heat treatment of meat is primarily aimed at improving safety, digestibility, and sensory quality [11]. To ensure the microbiological safety of pork, thermal processing should be carried out to maintain a temperature of 72℃ in the geometric center of the product for at least 2 min [12]. Another crucial aspect of meat processing is the improvement of sensory properties, including aroma and texture. However, heat treatment can also result in weight and water losses, which reduce process efficiency and increase production costs. Excessive water loss and extensive meat proteins denaturation and fats crystallization can negatively impact the product's texture, making it unacceptable to consumers [13]. Denaturation of muscle proteins has a significant impact on meat tenderness, which in turn affects sensory acceptability. Myofibrillar proteins, including myosin and actin, account for 50–60% of the total meat protein and undergo denaturation starting at around 35–40℃, continuing until the temperature reaches about 80℃. This denaturation process causes contraction of muscle fibers and can affect digestibility and functionality. Collagen, the main protein in connective tissue, requires prolonged thermal treatment at a temperature of at least 55 ℃ for hydrolysis to occur, resulting in reduced fiber adhesion and increased meat tenderness [14, 15],

These aspects are particularly important for pork, which is commonly consumed after processing. Some of the more recent or less frequently used methods of processing pork include microwave and Ohmic heating, sous vide cooking, and deep frying. Among the more commonly used methods are roasting, grilling, baking, steam cooking, and stewing [11,12,13]. The most common classification of meat doneness is rare (core temperature 60℃), medium-rare (63℃), medium (71℃), and well-done (77℃) [16]. Numerous studies have shown that meat cooked to lower degrees of doneness (such as 63℃) tends to be more tender, juicy, flavorful, and acceptable compared to meat cooked to higher degrees. It has also been found that the degree of doneness has a greater impact on the sensory quality of meat than the rate of heating, the quality of meat selected, or postmortem packaging alterations. Low-temperature baking (also known as "slow roasting"), within the temperature range of 120–150 °C, is a time-consuming process, but it helps to minimize weight losses and preserve bioactive compounds. On the other hand, high-temperature baking, within the temperature range of 175–220 °C, enables rapid and intensive meat preparation, often resulting in a crispy crust on the surface. However, it is worth noting that during such processing, the cooking loss significantly increases to 13–36%. This is primarily due to the higher loss of juices and intramuscular fat [17,18,19,20,21].

Computational Fluid Dynamics (CFD) is a powerful tool used for process simulation, applicable in various industries, including the food industry. It can be used to analyze heat and mass flow, optimize processes, and improve the nutritional, sensory, and microbiological quality of food products, as well as optimize production processes in terms of cost and equipment utilization. CFD finds applications in simulating thermal processing of foods, such as dehydration, cooking and baking, cooling and freezing, and smoking, as well as mechanical processes, such as mixing, 3D printing, and food packaging, as mentioned by Szpicer et al. [22]. Response Surface Methodology (RSM) is a tool used for optimizing chemical and biochemical processes. It involves building empirical models that consider the single and interactive effects of independent factors on response factors [23]. This allows for the evaluation of synergistic, antagonistic, and/or additive effects of factors on one or multiple responses. RSM is useful for predicting and improving processes, as well as interpreting them. Through its application, process conditions can be optimized before implementation, reducing the number of process repetitions required to obtain the best response parameters [24]. The final step of the RSM method involves experimental verification of the obtained model to confirm its effectiveness [25,26,27,28,29].

Materials and methods

Design of the experiment

The experiment was undertaken in three phases. In the first phase, a simulation model of a combi-steam oven and raw materials was developed, with programmed boundary conditions. The simulation process involved analyzing the temperature distribution during thermal treatment of the raw materials, as well as estimating the impact of protein denaturation (including myosin, collagen, sarcoplasmic proteins, and actin) and weight loss.

In the next phase, the surface response method (RSM) was utilized for optimization purposes. The primary objective of this procedure was to determine the optimal parameters for thermal treatment, namely temperature, humidity, and fan rotation speed, that would result in a product with maximum nutritional value and minimal weight reduction.

The verification stage was the third and last step of the process. During this phase, the anticipated outcomes were evaluated against the results obtained from laboratory examinations. The measurements used included the extent of protein denaturation determined through differential scanning calorimetry, as well as weight loss evaluated using the gravimetric method.

CFD simulation

CFD Description and implementation

A 3D model of the testing apparatus was constructed using Ansys v.19.0 software, which was also employed to simulate thermal treatment. The simulation process adhered to the methodology outlined by Szpicer et al. (2022) with some modifications.

The essential components that dictate the thermal properties of food products are their basic composition, which includes the amount of protein, fat, carbohydrates, and ash. The conduction coefficient (λ) and specific heat (Cp) of the raw material influence the content of these ingredients. The basic composition of pork meat may vary based on factors, such as age, stage of development, and activity, and can contain approximately 72–75% water, 1.5–3.0% fat, 22–23% proteins, 0.5–0.8% collagen, and 1.0–1.2% ash [30]. For the simulation, input data based on the pork loin’s basic composition was used, as determined by Wojtasik-Kalinowska et al. (2016): 72% water, 4% fat, 24% proteins, 0.8% connective tissue (CTP), and 1.5% ash [31]. The objective of the research was to determine the thermal penetration coefficient, which allowed for the calculation of the extent of denaturation of individual proteins and the resulting weight loss. The differential scanning calorimetry (DSC) method was used to obtain data on temperatures and enthalpies of denaturation for each protein type: myosin at 60℃, collagen at 67℃, sarcoplasmic proteins at 72℃, and actin at 80℃, with respective enthalpies of 3.86, 3.92, 3.90, and 3.96 J/gK [32].

To conduct the simulation, a 3D model of a combi steamer (CPE 110, Convect-Air Professional Küppersbusch Germany) was created, with a heat source (heater), fan (Fig. 1), steam generator, and GN container rack. A pork loin was placed on a GN 1/1 tray (530 × 325 × 20 mm) inside the oven. The simulation varied temperature (100–200℃), humidity (0–20%), and fan speed (0–1800 rpm), and the experiment was designed using Design Expert 11 (Stat-Ease, Inc., USA) (Table 1). The simulated baking time was 3600 s, and the pork meat was assumed to have homogeneous microstructure and isotropic properties in terms of mass and heat, without transport and fat loss. Forced convection was described by the global heat transfer coefficient, and water diffusion by Fick's law of diffusion with a global diffusion coefficient. Weight loss due to water squeezing was considered, but thermal contraction and shape changes were omitted, with a constant sample volume assumed during baking [33, 34].

Numerical Model

The analyzed space

The model consisted of three separate domains. The first domain was the fluid domain surrounding the sleeve-shaped rotor, which was set to a specific rotational speed. This enabled the simulation of the rotor's rotation inside the chamber, with the blades being modeled as surfaces. The second domain was the chamber space where air circulation was driven by the rotating rotor. The third domain contained two solids: the sample insert and the support plate.

Mesh

A Hex structural mesh was utilized for the rotor space with surface compaction of the rotor blades to achieve better flow representation. A Tetra/Prism mesh was employed for the chamber, with prismatic elements placed in locations relevant to the analysis, such as the walls of the meat and plate for heat transfer. Hexa mesh was used for the pork meat and plate. The model statistics were as follows: rotor space – 152,880 hexes and 177,702 nodes; chamber – 339,867 tetras, 100,385 prims, and 120,714 nodes; meat and plate – 86,634 hexes and 103,366 nodes.

Materials

For the calculations, the following materials were utilized: a mixture consisting of air and water vapor, pork meat as the user material, and stainless steel (AISI 304). Initial temperature of solids: 20℃.

Material data

-

Longissimus dorsi muscle

The calculation of the conduction coefficient (λ) was based on Eq. (1) as described by Choi and Okos in 1986, taking into account the fundamental composition of the sample [35].

where:

x-mass fraction of the food ingredient,

indexes:

c-carbohydrates,

p-proteins,

f-fat,

a-ash,

w-water.

The calculation of specific heat (Cp) was based on Eq. (2) as described by Singh and Heldman in 2014, taking into account the sample's fundamental composition [36].

where

x—mass fraction of the food ingredient,

indexes:

c—carbohydrates,

p—proteins,

f—fat,

a—ash,

w—water.

-

Stainless steel (AISI 304)

Conduction coefficient (λ)—60.5 W/mK.

Specific heat (Cp)- 434 J/kgK.

-

Air–Air Ideal Gas

The ideal gas equation of state can be used to calculate various properties of the gas Eq. (3).

where

p-the absolute pressure of the gas,

V-the volume of the gas,

n-the amount of substance of gas (also known as number of moles),

R-the ideal, or universal, gas constant, equal to the product of the Boltzmann constant and the Avogadro constant,

T-the absolute temperature of the gas.

Water vapor – Redlich–Kwong Dry Steam:

Properties were calculated from the Redlich–Kwong Eq. (4) [37].

where

p-gas pressure,

R-gas constant,

T-temperature,

Vm-molar volume (V/n),

a-constant that corrects for attractive potential of molecules,

b-constant that corrects for volume.

The gas used in the experiment was a mixture of steam and air, and the composition of the mixture was determined by the mass fractions of the individual components.

-

Humidity

The Goff–Gratch equation (Eq. 5), [38] was used to convert humidity into mass fractions of steam and air at a specific temperature.

where

log refers to the logarithm in base 10.

e*-the saturation water vapor pressure (hPa).

T-the absolute air temperature in Kelvins.

Tst-the steam-point (i.e., boiling point at 1 atm.) temperature (373.15 K).

e*st-e* at the steam-point pressure (1 atm = 1013.25 hPa).

Using Eq. (6), the mass fraction of water vapor in the mixture was determined based on the saturation pressure at the given temperature and specified humidity.

Definition of a solver

The solver definition for the SST turbulence model was set with a convergence criterion of 10e-4 and 600 iterations, and the solver work type was set to Double Precision. The SST turbulence model was chosen because it is flexible, handles the boundary layer well, has relatively low computational complexity, and is commonly used in the field of CFD. In the case of the transient state solver definition, the adaptive time step was set with 2–5 iterations per step and a time step range of 0.1–10 s, and the process duration was set to 3600 s.

Stages of CFD analysis

The CFD analysis was carried out in two stages due to the variability of output parameters during heat treatment and the size of the model. The first stage involved a steady-state analysis that provided actual heat transfer coefficients on the surface of the meat sample and the GN container. In the second stage, the results from the first phase were applied to the solids (meat and GN container), and transient simulations were performed to obtain the temperature changes of the samples over time. The first phase determined the penetration coefficients, while the second phase involved the simulation of protein denaturation and water loss.

RSM analysis and optimization

In this experiment, the impact of three variables on the denaturation of myosin, collagen, sarcoplasmic proteins, and actin, and mass loss due to water evaporation was examined. The variables were the temperature in the furnace, the speed of the air stream (fan speed), and the degree of humidity. Three independent factors were tested at different levels, with temperature ranging from 100 to 200℃, humidity from 0 to 20%, and fan rotation speed from 0 to 1800 rpm. The range of these parameters was established based on literature data and previous pilot studies. Table 1 displays the 21 runs used for computation and optimization utilizing Design Expert software v.11 (Stat-Ease, Inc., USA). A quadratic equation was employed to interpret and describe the relationship between the variables and the measured parameters. The central point was used five times in the model. Based on the model, heat treatment was optimized concerning myosin, collagen, sarcoplasmic proteins, actin denaturation, and weight loss. The final step was to optimize the thermal treatment parameters using a mathematical model and experimental validation of the calculated response values.

The CFD model’s validity was assessed using laboratory techniques

Before verification, a representative sample with basic composition was selected, and its primary composition was measured using NIR spectrometry. Verification of predicted parameters was carried out using thermal analysis (DSC), and gravimetric method was used to determine weight loss. Denaturation levels of proteins (myosin, collagen, sarcoplasmic proteins, and actin) were assessed through differential scanning calorimetry.

Preparation and heat treatment of pork loin muscle

The pork loin muscles (m. Longissimus dorsi) from crossbred pigs Polish Landrace × Polish Large White (PL × PLW) (slaughter weight 100 ± 6 kg; around 160 ± 8 days) were prepared by cleaning and cutting it into samples measuring 15 × 25 cm, sourced from Meat Plant Wierzejki Ltd. in Poland. The raw material underwent basic composition evaluation, including moisture, protein, fat, CTP, and ash, which was performed using near-infrared (NIR) spectrometry based on the method outlined in Stelmasiak, Wyrwisz, and Wierzbicka (2019).

The degree of protein denaturation and weight loss were evaluated in the pork loin. A cylindrical pork meat sample, slightly flattened with a length of 25 cm and a diameter of 15 cm, was used as a whole. The meat samples were then subjected to heat treatment based on optimized RSM method parameters, including temperature, relative humidity, and fan rotation speed, using a Küppersbusch convection steam oven CPE-110 (Küppersbusch Convect-Air Professional; Germany). Throughout the process, wireless temperature and humidity recorders (TrackSense Pro; Ellab, Denmark) were used to monitor the heat treatment parameters of the samples.

Basic composition evaluation

The basic composition of raw meat samples was evaluated following the procedure described by Stelmasiak et al. (2019). Near-infrared (NIR) spectrometry was used to determine the basic composition of the samples. The analysis was conducted using a NIRFlex N-500 spectrometer with a solids module (Büchi Labortechnik AG, Switzerland) in reflectance mode, with a spectral range of 12,500–4000 cm−1 and the application of Büchi Art. N. N555-501. The analysis was carried out at an accredited NIR laboratory (Polish Centre for Accreditation FT-NIR—Accreditation No. AB 1670). Homogenized meat samples of 100 g were placed on a Petri dish and measured six times at 32 scanning rate for each sample. The evaluation of basic composition was performed in triplicate for each sample [39].

The level of protein denaturation evaluated by DSC

The extent of denaturation of pork proteins was determined using differential scanning calorimetry (DSC 1 from Mettler Toledo; Schwerzenbach, Switzerland). Prior to the experiment, the device underwent calibration with pure zinc and indium pellets. Both raw and heat-treated samples were examined to determine the proportion of protein denaturation. A BÜCHI B-400 homogenizer was used to homogenize each sample. Next, 10.0 ± 0.1 mg of meat samples were placed in a standard 40 μL aluminum pan (No: ME-51119870) and hermetically sealed with an aluminum lid (No: ME-51119871) using a Mettler Toledo Crucible Sealing Press. Under an argon atmosphere (100 cm3/min), DSC analysis was conducted at a rate of 10 °C/min (β) from 10 °C to 100 °C. The resulting thermograms were analyzed using STARe Software to determine the start (Ton), maximum (Tmax), and end (Tend) temperatures, as well as the areas under the peaks (ΔH). The denaturation degree of myosin, collagen, sarcoplasmic proteins, and actin was determined based on the thermograms using the method described by Agafonkina et al. (2019). The percentage of denaturation for myosin, collagen, and actin was calculated based on the difference in denaturation enthalpy of individual proteins between the raw sample and the heat-treated sample using Eq. (7). Thermal analysis measurements were performed in triplicate for each sample [32].

where

Hraw—The enthalpy of protein denaturation in raw meat prior to heat treatment (J/g).

Hbaked—The enthalpy of protein denaturation in baked meat following heat treatment (J/g).

Weight loss

To determine the cooking loss, the sample was weighed before being placed in the oven and immediately after being removed. The percentage of weight loss was calculated based on the difference in weight between the raw and heat-treated meat using Eq. (8). Weight loss measurements were taken in triplicate.

where

Mraw – mass of the raw sample prior to heat treatment (g).

Mbaked—mass of the baked sample following heat treatment (g).

Statistics

The experiment was designed using Design Expert v. 11 software (Stat-Ease, Inc., USA) as shown in Table 1. An analysis of the influence of temperature, humidity, and convection intensity on individual responses was performed according to the programmed experimental model. The significant terms in this model were found by the analysis of variance (ANOVA) for each response, the lack of fit, coefficients of determination (R2), and coefficients of variation (CV), which were calculated to check the model accuracy. 3D charts were generated based on the analysis results, and quadratic equations describing the model were used for the studies.

In the prediction analysis using the surface response method (RSM), the maximal desirable degree of denaturation for myosin, collagen, and sarcoplasmic proteins was determined while the minimal actin denaturation and mass loss were selected as parameters.

The last phase of the RSM analysis involved optimizing and verifying the heat treatment technology. The predicted response values were then compared with experimentally determined values. The instrumental technique analyzes were carried out using raw materials from different production batches in three independent biological replicates. After the optimization, Student's t-test at P ≤ 0.05 was used to check differences between two groups of values: predicted and measured properties in laboratory experiments. The statistical analysis were performed using Design Expert software, and the results were presented as mean (X̄) ± standard error (SE).

Results and discussion

Checking the model’s adequacy

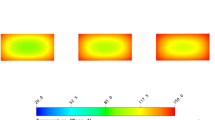

Heat transfer coefficient and temperature distribution in the longitudinal section of meat are presented in Fig. 2. The prediction model's sufficiency has been assessed and confirmed. All R2 values exceeded 0.9 and ranged from 0.921 to 0.998. The most elevated R2 values were achieved by the actin denaturation, collagen, and sarcoplasmic protein denaturation models, which were 0.997, 0.998, and 0.997, respectively. No instances of inadequate model fitting were observed. The weight loss variable had the lowest R2 value of 0.921. The standard error ranged from 1.38 to 3.86. The lowest standard error values were recorded for weight loss, myosin and collagen denaturation and were 1.38, 1.46 and 1.54, respectively. Sarcoplasmic protein denaturation and actin denaturation were characterized by standard errors of 2.05 and 3.86. To optimize the pork loin heat treatment process parameters, three independent variables were considered: temperature, humidity, and fan speed, which represent the air flow speed within the oven chamber. The model's regression coefficients are presented in Table 2. The interactions between variables and responses are presented in linear, intercept, and quadratic terms.

Optimization of heat treatment parameters

In order to evaluate the impact of temperature, humidity, and fan speed on the heat treatment of pork loin (m. Longissimus dorsi), the surface response method (RSM) was employed. The model was used to observe the trends in the results as the independent variables were varied. The regression coefficients presented in Table 2 and the 3D graphs in Fig. 3 showed that all three independent variables had a statistically significant effect on the denaturation levels of individual proteins, including myosin, collagen, sarcoplasmic proteins, actin, and weight loss in the meat samples. The impact varied depending on the response and the level of the independent variable.

The RSM model produced 3D surface plots with actual factor fan rotation set to 900 rpm, depicting the relationship between the samples and the following responses: A—denatured myoglobin [%], B—denatured collagen [%], C—denatured sarcoplasmic proteins [%], D—denatured actin [%], and E—weight loss [%]

The degree of myosin denaturation was observed to be significantly affected by temperature in both linear (P ≤ 0.001) and quadratic (P ≤ 0.001) terms. Similarly, a linear effect was observed for humidity (P ≤ 0.01) on the denaturation degree of myosin. However, there was no significant impact of fan speed, humidity in quadratic terms (P > 0.05), and humidity in linear terms (P > 0.05). The interaction between fan speed, temperature, and humidity did not have a significant influence on myosin denaturation (P ≤ 0.05). Chapwanya and Misra (2015) conducted a study on the mathematical modeling of protein denaturation during double-sided heat treatment of meat [40]. They developed a mathematical model for simultaneous heat and mass transfer based on Fourier conduction and the Flory–Huggins theory. The model was validated through experiments, demonstrating good agreement with results. While it accurately predicts the core temperature of beefsteak, it may have limitations for thicker steaks. The study emphasizes the significance of the initial porosity of the meat for precise predictions. The model can be expanded to various cooking scenarios by adjusting boundary conditions, such as single-sided heating with flipping, oven roasting, or frying. By incorporating equations for microbial inactivation, it could also enable predictions of microbial safety. This model enhances the understanding of protein denaturation in food processing and offers practical applications for optimizing cooking processes and ensuring food safety.

The analysis of collagen denaturation in pork meat revealed similar relationships to those observed for myosin denaturation. The experiment demonstrated that temperature had a statistically significant impact on collagen denaturation in both linear and quadratic terms (P ≤ 0.001). Furthermore, the interaction between temperature and humidity was found to have a significant influence on collagen denaturation. However, the interaction between temperature and fan speed, as well as humidity and fan speed, did not have a statistically significant effect on collagen denaturation during the computer simulation (P > 0.05). Additionally, humidity had a significant effect on collagen denaturation in linear terms (P ≤ 0.05). However, the air movement intensity in the chamber did not have a significant impact on collagen denaturation in quadratic terms (P > 0.05). He et al. (2019) conducted a study focusing on protein denaturation in false abalone during wet heating at temperatures between 95 and 100 °C [41]. They developed a heat transfer model to predict the denaturation of myosin and actin, while also evaluating the effects of cooking time on water mobility, tenderness, and sensory acceptability. The results revealed that muscle proteins were fully denatured within 60–80 s of wet heating, as indicated by 3D finite element heat transfer analysis and reaction kinetics. The use of low field 1H nuclear magnetic resonance (LF-NMR) and magnetic resonance imaging (MRI) demonstrated reduced immobilized water content and decreased shear force with longer cooking times. Additionally, sensory acceptability decreased as cooking time extended. Partial least squares (PLS) analysis highlighted a strong correlation between immobilized water, color, taste, and sensory acceptability. This research provides valuable insights into seafood cooking quality assessment and control. Further studies are required to investigate the connections between cooking parameters and microstructural changes during extended cooking.

The analysis of the degree of denaturation of sarcoplasmic proteins yielded similar results. Similar to collagen, temperature had a significant linear effect (P ≤ 0.001) on the denaturation of sarcoplasmic proteins. Moreover, humidity had a significant linear effect on the level of denaturation of sarcoplasmic proteins. However, the interaction between temperature and humidity, temperature and fan speed, and humidity and fan speed did not significantly affect the degree of denaturation of sarcoplasmic proteins (P > 0.05). Additionally, only temperature had a significant quadratic effect (P ≤ 0.001) on the degree of denaturation of sarcoplasmic proteins. In contrast, humidity and air movement speed in the oven chamber did not have a statistically significant quadratic effect on the denaturation of sarcoplasmic proteins (P > 0.05). Onyeaka et al. [42] conducted a review focusing on the application of mathematical models to understand protein denaturation, particularly in the context of sous vide cooking. Sous vide cooking involves low-temperature cooking of vacuum-sealed foods, offering advantages in terms of product quality and sensory attributes [41, 43]. However, concerns arise due to lower cooking temperatures and their potential impact on microbiological safety and protein denaturation. Mathematical models have been utilized to optimize sous vide processing parameters, aiming to balance quality characteristics while minimizing risks from food pathogens. These models help predict protein stability and design strategies to mitigate denaturation-induced loss of function. Future research in this area should concentrate on optimizing process conditions and cooking methods for different food types and sizes. Additionally, investigating a more comprehensive modeling approach, real-time quality evaluation, and implementing hurdle technology shows promise. In conclusion, mathematical modeling is a valuable tool for understanding protein denaturation during sous vide cooking, enabling the enhancement of food quality and ensuring microbiological safety through the optimization of processing parameters. The continuous advancement of mathematical models will contribute to further improvements in sous vide cooking techniques and their applications across various food preparations.

All the analyzed factors had a statistically significant effect on the dynamics of actin denaturation in linear terms, including temperature (P ≤ 0.001). However, no significant influence was observed for humidity and speed of hot air movement in linear terms (P > 0.05). Similar effects were also observed for quadratic terms. Only temperature had a significant influence on the level of actin denaturation (P ≤ 0.001). Additionally, none of the tested interactions between factors, including temperature × humidity, temperature × fan speed, and humidity × fan speed, had a statistically significant effect on the process of actin denaturation (P > 0.05). Nelson et al. (2020) presented a precise two-dimensional mathematical model for protein denaturation during steak cooking, utilizing the Flory–Rehner theory. This model treats meat as a poro-elastic medium saturated with fluid, considering the impact of heat on protein matrix deformation and moisture loss, leading to shrinkage. Numerical simulations conducted demonstrated excellent agreement with experimental data, validating the model's accuracy. The study also introduced a novel and computationally efficient approach to incorporate shrinkage in the model. This research enhances our understanding of protein denaturation during steak cooking and offers a valuable tool for predicting cooking outcomes [44]. In van der Sman's (2017) research, a model is introduced to predict the electrical conductivity of muscle meat, particularly for assessing Ohmic heating. The model takes into account the meat's composition, temperature, and microstructure, including protein, water, salt, muscle fiber orientation, and the formation of drip channels due to protein denaturation. Additionally, it incorporates protein denaturation kinetics. Validation of the model was carried out on various types of meat with different compositions and heating rates, utilizing DSC measurements to validate the sub-model for protein denaturation. The findings indicate that when meats are heated rapidly, the conductivity increases linearly with temperature, as there is no protein denaturation or drip channel formation. However, for slower heating rates, the conductivity exhibits nonlinear behavior, with a significant decrease at temperatures above 70℃, attributed to complete protein denaturation. The study emphasizes the potential of Ohmic heating at fast rates to preserve moisture in meat during the heating process [45].

The study examined how certain factors affected the mass loss from evaporation and thermal leakage during pork loin baking simulation. Results revealed that temperature and fan movements had a significant linear effect on weight loss (P ≤ 0.001 and P ≤ 0.01, respectively). In contrast, humidity levels in the chamber had no significant effect on pork weight changes during heat treatment (P > 0.05). There was also no significant interaction observed between the factors of temperature × fan speed, temperature × humidity, and humidity × fan speed (P > 0.05). Additionally, all factors, including temperature, humidity, and fan speed, had a significant impact on weight loss during baking when analyzed in quadratic terms (P ≤ 0.05, P ≤ 0.05, and P ≤ 0.01, respectively). Szpicer et al. (2022) conducted a study specifically targeting protein denaturation in beef during heat treatment. The researchers employed CFD simulations to model the extent of denaturation in beef proteins under different processing conditions, including variations in temperature and time. The study's outcomes highlighted the usefulness of CFD simulations as a valuable tool for optimizing beef's heat treatment to achieve desired denaturation levels and overall quality. This showcases the potential of numerical studies in the food industry, enabling a deeper understanding of protein denaturation and the optimization of food processing to enhance product quality.

In conclusion, the study highlights the importance of controlling cooking conditions, such as temperature and humidity, to achieve optimal protein denaturation in meat. Future studies may explore the impact of other cooking variables, such as pH and salinity, on meat protein denaturation and sensory attributes.

Verification of heat treatment parameters

The experiment's final phase involved verifying the RSM model results by comparing them to laboratory tests. The denaturation of myosin, collagen and sarcoplasmic proteins were determined to be maximal desirable, while actin denaturation and mass loss were minimal. The RSM optimization model showed that pork loin samples should be processed at a temperature of 181.55℃, 20% humidity, and with a fan speed set to 639.18 rpm. The predicted output parameters values (X̄ ± SE) were as follows: myosin denaturation at 98.16 ± 0.58%, collagen denaturation at 79.53 ± 0.50%, sarcoplasmic proteins denaturation at 71.06 ± 0.67%, actin denaturation at 62.21 ± 0.66%, and weight loss at 11.86 ± 0.45%. The results of the optimization and verification process can be found in Table 3, showing that the laboratory test results were consistent with the RSM model predictions. No statistically significant differences were found between the analyzed parameters and predicted values.

Following the optimized heat treatment process, the degree of denaturation for various pork loin proteins was as follows: myosin denaturation at 97.74 ± 0.77%, collagen denaturation at 80.21 ± 0.76%, sarcoplasmic protein denaturation at 69.18 ± 0.55%, and actin denaturation at 61.72 ± 0.91%. Additionally, there was a weight loss of 12.21 ± 0.89%. The levels of myosin and actin denaturation, as well as weight loss, did not show any statistically significant differences from the predicted values. However, the degree of sarcoplasmic protein denaturation observed in the laboratory was significantly lower than the values calculated by the model. On the other hand, the degree of collagen denaturation observed in the laboratory was statistically higher than the predicted values by the model.

Conclusions

The results indicate that the combination of computational fluid dynamics (CFD) and response surface methodology (RSM) can be used to determine the optimal heat treatment parameters for pork meat. By properly designing the experiment with RSM, the desired final product parameters were achieved. The study demonstrated that the thermal treatment parameters, including temperature, humidity, and air movement speed, significantly influence the quality of the baked pork meat. The findings suggest that heat treatment parameters and their interactions affect protein denaturation and weight loss in baked pork meat. Based on the optimized model, it was determined that pork meat samples should be processed at a temperature of 181.55℃, 20% humidity, and with a fan speed of 639.18 rpm. After undergoing the optimized heat treatment process, the proteins in pork loin exhibited varying degrees of denaturation. Specifically, the myosin denaturation was 97.74 ± 0.77%, collagen denaturation was 80.21 ± 0.76%, sarcoplasmic protein denaturation was 69.18 ± 0.55%, and actin denaturation was 61.72 ± 0.91%. Additionally, there was a weight loss of 12.21 ± 0.89%. The method presented provides a means to model thermal processes in the food industry. This innovative approach not only enhances the culinary quality and nutritional value of products but also reduces energy consumption and associated costs. The hybrid method of forecasting and optimization utilizing CFD and RSM is not only applicable to thermal processing of pork loin (m. Longissimus dorsi) but also to various food products. A computer simulation-based system using this approach can be used by food technologists in production plants, as well as dieticians who forecast the nutritional value of food products.

Overall, the results from these studies demonstrate that CFD simulations are a valuable tool for understanding the behavior of meat proteins during processing. CFD can be used to optimize processing conditions, predict protein denaturation, and investigate the impact of mechanical processing. However, it is important to note that CFD simulations are limited by the accuracy of the model and the availability of experimental data. In conclusion, the use of CFD simulations in the study of meat protein denaturation has shown promising results. The application of CFD in this field has the potential to improve product quality, reduce processing time, and enhance the overall efficiency of meat processing. Future research should continue to investigate the accuracy and limitations of CFD models to ensure their effectiveness in the food industry.

Data availability

The authors declare availability of data and material.

Code availability

Not Applicable.

Abbreviations

- CTP:

-

Connective tissue protein

- CFD:

-

Computational fluid dynamics

- RSM:

-

Response surface method

- DSC:

-

Differential scanning calorimetry

- FAO:

-

Food and Agriculture Organization

- GLM:

-

General linear model

- Rpm:

-

Revolutions per minute

- λ:

-

Conduction coefficient (W/(m⋅K))

- C p :

-

Specific heat (J/kgK)

- Β:

-

Heating rate (°C/min)

- Ton :

-

Onset temperature (°C)

- Tmax :

-

Maximum peak temperature (°C)

- Tend :

-

End set temperature (°C)

- ΔH:

-

Areas under the peaks (J/g)

- X̄:

-

Mean

- SE:

-

Standard error

References

Guo Q, Kong X, Hu C et al (2019) Fatty acid content, flavor compounds, and sensory quality of pork loin as affected by dietary supplementation with l-arginine and glutamic acid. J Food Sci 84:3445–3453. https://doi.org/10.1111/1750-3841.14959

Menezes EA, Oliveira AF, França CJ et al (2018) Bioaccessibility of Ca, Cu, Fe, Mg, Zn, and crude protein in beef, pork and chicken after thermal processing. Food Chem 240:75–83. https://doi.org/10.1016/j.foodchem.2017.07.090

Bjørklund G, Shanaida M, Lysiuk R et al (2022) Selenium: an antioxidant with a critical role in anti-aging. Molecules 27:1–16. https://doi.org/10.3390/molecules27196613

Chasapis CT, Ntoupa PSA, Spiliopoulou CA, Stefanidou ME (2020) Recent aspects of the effects of zinc on human health. Arch Toxicol 94:1443–1460. https://doi.org/10.1007/s00204-020-02702-9

Donker AE, van der Staaij H, Swinkels DW (2021) The critical roles of iron during the journey from fetus to adolescent: Developmental aspects of iron homeostasis. Blood Rev. https://doi.org/10.1016/j.blre.2021.100866

Guo C, Wang Y, Luan D (2021) Study the synergism of microwave thermal and non-thermal effects on microbial inactivation and fatty acid quality of salmon fillet during pasteurization process. Lwt. https://doi.org/10.1016/j.lwt.2021.112280

Guo Q, Li L, Hou S et al (2021) The role of iron in cancer progression. Front Oncol 11:1–18. https://doi.org/10.3389/fonc.2021.778492

Hariharan S, Dharmaraj S (2020) Selenium and selenoproteins: it’s role in regulation of inflammation. Inflammopharmacology 28:667–695. https://doi.org/10.1007/s10787-020-00690-x

Tamura Y (2021) The role of zinc homeostasis in the prevention of diabetes mellitus and cardiovascular diseases. J Atheroscler Thromb 28:1109–1122. https://doi.org/10.5551/JAT.RV17057

Vickram S, Rohini K, Srinivasan S et al (2021) Role of zinc (Zn) in human reproduction: A journey from initial spermatogenesis to childbirth. Int J Mol Sci 22:1–16. https://doi.org/10.3390/ijms22042188

Hassoun A, Ojha S, Tiwari B et al (2020) Monitoring thermal and non-thermal treatments during processing of muscle foods: a comprehensive review of recent technological advances. Appl Sci. https://doi.org/10.3390/app10196802

Bhat ZF, Morton JD, Bekhit AEDA et al (2021) Thermal processing implications on the digestibility of meat, fish and seafood proteins. Compr Rev Food Sci Food Saf 20:4511–4548. https://doi.org/10.1111/1541-4337.12802

Khalid W, Maggiolino A, Kour J et al (2023) Dynamic alterations in protein, sensory, chemical, and oxidative properties occurring in meat during thermal and non-thermal processing techniques: a comprehensive review. Front Nutr 9:1–19. https://doi.org/10.3389/fnut.2022.1057457

Han Y, Liu H, Li Q et al (2023) The degree of doneness affected molecular changes and protein digestibility of pork. Front Nutr 9:1–14. https://doi.org/10.3389/fnut.2022.1084779

Kurp L, Danowska-Oziewicz M, Kłębukowska L (2022) Sous vide cooking effects on physicochemical microbiological and sensory characteristics of pork loin. Appl Sci. https://doi.org/10.3390/app12052365

Lendzin K, Uścińska G, Rynduch M et al (2015) Wielka Księga Wołowiny, 1st edn. Instytut Badań i Edukacji, Olsztyn

Cassens AM, Ramanathan R, VanOverbeke DL, Mafi GG (2021) Effects of pork quality types packaging, and degree of doneness on trained sensory and instrumental tenderness color and consumer perception. Meat Muscle Biol. https://doi.org/10.22175/mmb.11598

Honegger LT, Bryan EE, Price HE et al (2022) The effect of cooking method and cooked color on consumer acceptability of boneless pork chops. Foods 11:1–13. https://doi.org/10.3390/foods11010106

Jang A, Kim HJ, Kim D et al (2019) Effects of doneness on the microbial, nutritional, and quality properties of pork steak of different thicknesses. Food Sci Anim Resour 39:756–767. https://doi.org/10.5851/kosfa.2019.e63

Klehm BJ, King DA, Dilger AC et al (2018) Effect of packaging type during postmortem aging and degree of doneness on pork chop sensory traits of loins selected to vary in color and marbling. J Anim Sci 96:1736–1744. https://doi.org/10.1093/jas/sky084

Nethery TN, Boler DD, Harsh BN, Dilger AC (2022) Relationship between inherent cooking rate and warner-bratzler shear force of pork chops cooked to two degrees of doneness. Foods. https://doi.org/10.3390/foods11010131

Szpicer A, Bińkowska W, Wojtasik-Kalinowska I et al (2023) Application of computational fluid dynamics simulations in food industry. Eur Food Res Technol. https://doi.org/10.1007/s00217-023-04231-y

Piepiórka-Stepuk J, Mierzejewska S, Sterczyńska M et al (2019) Analysis and modelling of the regeneration process of chemical solutions after brewing equipment cleaning in a cleaning in Place system based on changes in turbidity. J Clean Prod 237:1–9. https://doi.org/10.1016/j.jclepro.2019.117745

Piepiórka-Stepuk J, Sterczyńska M, Kalak T, Jakubowski M (2021) Predictive model for the surface tension changes of chemical solutions used in a clean-in-place system. Materials (Basel) 14:1–13. https://doi.org/10.3390/ma14133479

Bajić M, Oberlintner A, Kõrge K et al (2020) Formulation of active food packaging by design: linking composition of the film-forming solution to properties of the chitosan-based film by response surface methodology (RSM) modelling. Int J Biol Macromol 160:971–978. https://doi.org/10.1016/j.ijbiomac.2020.05.186

Çankırılıgil EC, Berik N, Erbay EA (2020) Optimization of hydrolyzation procedure for amino acid analysis in fish meat with HPLC-DAD by Response Surface Methodology (RSM). Ege J Fish Aquat Sci. https://doi.org/10.12714/egejfas.37.2.01

Szpicer A, Wierzbicka A, Półtorak A (2022) Optimization of beef heat treatment using CFD simulation: Modeling of protein denaturation degree. J Food Process Eng. https://doi.org/10.1111/jfpe.14014

Tirado-Kulieva VA, Sánchez-Chero M, Villegasyarlequé M et al (2021) An overview on the use of response surface methodology to model and optimize Extraction processes in the food industry. Curr Res Nutr Food Sci. https://doi.org/10.12944/CRNFSJ.9.3.03

Piepiórka-Stepuk J, Diakun J, Sterczyńska M et al (2021) Mathematical modeling and analysis of the interaction of parameters in the clean-in-place procedure during the pre-rinsing stage. J Clean Prod 297:1–12. https://doi.org/10.1016/j.jclepro.2021.126484

Choi YS, Lee JK, Jung JT et al (2016) Comparison of meat quality and fatty acid composition of longissimus muscles from purebred pigs and three-way crossbred LYD pigs. Korean J Food Sci Anim Resour 36:689–696. https://doi.org/10.5851/kosfa.2016.36.5.689

Wojtasik-Kalinowska I, Guzek D, Górska-Horczyczak E et al (2016) Volatile compounds and fatty acids profile in Longissimus dorsi muscle from pigs fed with feed containing bioactive components. LWT - Food Sci Technol 67:112–117. https://doi.org/10.1016/j.lwt.2015.11.023

Agafonkina IV, Korolev IA, Sarantsev TA (2019) The study of thermal Denaturation of beef, pork, chicken and turkey muscle proteins using differential scanning calorimetry. Theory Pract meat Process. https://doi.org/10.21323/2414-438x-2019-4-3-19-23

Chhanwal N, Tank A, Raghavarao KSMS, Anandharamakrishnan C (2012) Computational fluid dynamics (CFD) modeling for bread baking process-a review. Food Bioprocess Technol 5:1157–1172. https://doi.org/10.1007/s11947-012-0804-y

Ishiwatari N, Fukuoka M, Sakai N (2013) Effect of protein denaturation degree on texture and water state of cooked meat. J Food Eng 117:361–369. https://doi.org/10.1016/j.jfoodeng.2013.03.013

Choi Y, Okos MR (1986) Thermal Properties of Liquid Foods - Review. ASAE Publ 35–77

Singh RP, Heldman DR (2014) Introduction to food engineering: Fifth edition. Academic Press

Markočič E, Knez Ž (2016) Redlich-Kwong equation of state for modelling the solubility of methane in water over a wide range of pressures and temperatures. Fluid Phase Equilib 408:108–114. https://doi.org/10.1016/j.fluid.2015.08.021

Goff JA, Gratch S, (1946) Low-pressure properties of water from − 160 to 212 F. In: Transactions of the American Society of Heating and Ventilating Engineers presented at the 52nd annual meeting of the American Society of Heating and Ventilating Engineers. New York,

Stelmasiak A, Wyrwisz J, Wierzbicka A (2019) Effect of packaging methods on salt-reduced smoked-steamed ham using herbal extracts. CYTA - J Food 17:834–840. https://doi.org/10.1080/19476337.2019.1660409

Chapwanya M, Misra NN (2015) A mathematical model of meat cooking based on polymer – solvent analogy. Appl Math Model 39:4033–4043. https://doi.org/10.1016/j.apm.2014.12.015

He S, Sun X, Du M et al (2019) Effects of muscle protein denaturation and water distribution on the quality of false abalone (Volutharpa ampullacea perryi) during wet heating. J Food Process Eng 42:1–10. https://doi.org/10.1111/jfpe.12932

Onyeaka H, Nwaizu C-C, Ekaette I (2022) Trends in food science & Technology mathematical modeling for thermally treated vacuum-packaged foods: a review on sous vide processing. Trends Food Sci Technol 126:73–85. https://doi.org/10.1016/j.tifs.2022.06.018

Wojtasik-Kalinowska I, Marcinkowska-Lesiak M, Onopiuk A et al (2021) Geese fillets flavor stability and quality characteristics at different stages of sous-vide cooking. Anim Sci Pap Reports 39:419–435. https://doi.org/10.1016/j.lwt.2022.113849

Nelson H, Deyo S, Puente P et al (2020) A mathematical model for meat cooking. Eur Phys J Plus 135:1–19. https://doi.org/10.1140/epjp/s13360-020-00311-0

van der Sman RGM (2017) Model for electrical conductivity of muscle meat during Ohmic heating. J Food Eng 208:37–47. https://doi.org/10.1016/j.jfoodeng.2017.03.029

Funding

Research financed by Polish Ministry of Science and Higher Education within funds of Faculty of Human Nutrition and Consumer Sciences, Warsaw University of Life Sciences (WULS), for scientific research.

Author information

Authors and Affiliations

Contributions

AS: Conceptualization, Methodology, Software, Validation, Formal analysis, Supervision, Investigation, Resources, Project administration, Data Curation, Writing—Original Draft, Writing—Review and Editing, Visualization, WB: Writing—Original Draft, Writing—Review and Editing, Iwona WK: Writing—Original Draft, Writing—Review and Editing, AP: Software, Funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

Not Applicable.

Consent to participate

Not Applicable.

Consent for publication

Not Applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Szpicer, A., Binkowska, W., Wojtasik-Kalinowska, I. et al. Prediction of protein denaturation and weight loss in pork loin (muscle Longissimus dorsi) using computational fluid dynamics. Eur Food Res Technol 249, 3055–3068 (2023). https://doi.org/10.1007/s00217-023-04348-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04348-0