Abstract

In recent years, global warming, climate change, and carbon emissions have emerged due to the uncontrolled use of fossil fuels and the lack of widespread use of renewable energy sources on a global scale. This research investigated specific energy consumption (SEC) and greenhouse gases (GHG) emissions (carbon dioxide [CO2] and nitrogen oxides [NOX]) during the drying of pear samples by five different types of dryers, namely, convective (CV), infrared (IR), microwave (MW), combined IR/CV, and MW/CV. Moreover, the quality properties of dried pears, such as shrinkage, rehydration (RR), and color change were determined. The results showed that the highest shrinkage (72.53%) and color change (ΔE = 33.41) values were obtained in CV drying at 50 °C and thickness of 2 mm and IR dryer 1000 W and thickness of 6 mm, respectively. The greatest rehydration rate (4.25) was also determined in MW/CV drying at 450 W and an air temperature of 60 °C. The lowest SEC was observed for the MW/CV dryer with a power of 630 W and air temperature 70 °C (20.25 MJ/kg), while the highest SEC (267.61 MJ/kg) was obtained in the CV drying (50 °C, sample thickness of 6 mm). The highest CO2 and NOX emissions (GT-GO power plant) were 280.45 and 1.55 kg/kg water in the CV dryer at 50 °C and a thickness of 6 mm. In conclusion, the increases in IR and MW power and temperatures led to reduced CO2 and NOX emissions, while the increases in sample thickness led to increase CO2 and NOX emissions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pear (Pyrus communis) is a widely cultivated fruit in temperate regions, especially in Europe. Pears are highly appreciated by consumers due to their good taste and low calories, and high nutritional properties, such as dietary antioxidants, vitamins, minerals, and fiber. Generally, pears can be consumed fresh, as well as canned, yogurt, nectar, and syrup used in purees after processing and drying, which are widely used [1].

Drying processing reduces the water content in the product to safe levels, preventing microbial growth and enzymatic modifications [2]. In addition, it eliminates the use of expensive cooling systems for the enclosure and simplifies transportation and storage. Most importantly, it offers products with new tastes, textures, and flavors [3]. However, drying is one of the most extensive processes in energy use (12–25% of the total energy) in industrial processing [4]. Ekka et al. [5] stated that about 30% of the total energy consumed in the world is consumed by the agricultural sector, of which about 3.62% is related to the drying of agricultural products in different dryers. A large number of industrial processes directly or indirectly involve the drying process. The energy used to dry agricultural products is more than fossil fuels, which can create significant greenhouse gases [5]. These results show that the drying of agricultural products is associated with high energy consumption, but it also has high industrial importance. These results show that the drying of agricultural products is associated with high energy consumption, but it also has high industrial importance. Due to the high energy consumption in the drying of agricultural products, the production of greenhouse gases and its environmental effects also become very important [6]. The increase in the emission of greenhouse gases in the world due to the excessive consumption of fossil fuels has brought negative consequences such as global warming, the expansion of desert areas, climate changes, and the increase in the level of open water for the environment [7]. Therefore, energy and greenhouse gas analysis of dryers is very important to improve design and technical sustainability [8]. For example, drying in power plants that use lignite and sub-bituminous coal to generate electricity generation requires a much energy (about 7%) to evaporate the moisture from the coals [7, 9]

In the past decades, some researchers conducted SEC and GHG analyses for drying process of different products using various drying systems such as Seyfi et al. [10] for refractance window, convective and solar refractance window drying of aloe vera, Karimi et al. [11] for fluidized bed drying of canola seeds, Pérez-Won et al. [12] for vacuum microwave drying; freeze drying; and hot air drying and pulsed electric fields as pretreatment of Chilean Abalone, Taghinezhad et al. [13] hot air-infrared dryer with ultrasound pretreatment of blackberry, Ashtiani et al. [14] for ultrasound-assisted convective drying with Cold plasma pretreatment of goldenberry, Wang et al. [15] for solar-electric hybrid drying setup of lotus bee pollen, Fang et al. [16] for solar-electric hybrid drying of lotus seeds, and Hadibi et al. [17] for solar dryer drying of onion slices.

The most preferred method for drying agricultural products is hot air drying [18]. However, high temperature, microwave power, sample thickness, and long drying time cause adverse effects on quality parameters, such as nutritional values, shrinkage [19], color [20], and rehydration capacity of the products [21]. New drying technologies have been developed to energy consumption reduce and environmental influence [22]. Combined drying (infrared-hot air and microwave-hot air) are relatively new methods in which heat transfer is done through hot air flow and infrared or microwave radiation. In this way, these dryers have the merits of both individual methods and usually reduce the drying duration and SEC and increase the quality of the final product [23].

Several research has been done on determining the functional characteristics of different dryers and the effect of these parameters on the quality properties, drying time and energy consumption of agricultural products, such as moisture content (MC), color and RR for ‘Ankara’ pear in an electrohydrodynamic-hot air [18], MC and bulk density for pear in a ventilated drying chamber [24], drying time and SEC for soybean in a fluidized bed drying [25], drying time and SEC for cherry fruits in an air convective [26], MC, color, and water activity for pear in an air convective [27], moisture ratio, water activity, color, antioxidant activity and total phenolic content for “Rocha” pear in a tray dryer with MW and ultrasound pre-treatments [28], MC, color, SEC, RR for pear in an MW-vacuum [29], moisture ratio, RR, SEC, water activity, antioxidant activity, color, and total phenolic content for pear in an IR and mid- IR-freeze [30], and drying time and SEC for peppermint leaves in MW, IR and CV dryers [31], drying time, SEC and GHG for dog-rose [32] and Pistacia Atlantica [33] in hybrid drying, including MW, IR and CV. However, few studies have investigated the influence of simultaneous microwave and infrared powers, drying temperatures, and sample thickness on specific energy consumption (SEC), color change, rehydration, shrinkage, and GHG. In this study, (I) pear samples were dried in five different drying systems at different sample thicknesses, temperatures, microwave and infrared powers, (II) vital quality properties, such as color change, shrinkage, and rehydration of the dried pears were determined, (III) drying time, SEC and greenhouse gas emission products were obtained according to different types, and (IV) determined properties were comparatively evaluated in detail.

Materials and methods

Sample preparation

Pear fruits (Pyrus communis L.) were hand-picked from an orchard located in Sardasht City, West Azerbaijan Province, Iran. All pear samples were regularly stored in the refrigerator at a temperature of 3–5 °C to reduce the rate of respiration and physiological and chemical changes. The large size of this figure made it possible to prepare cubic samples with almost the same quality. Prototypes were prepared to measure initial moisture content (MC) with dimensions of 0.4 × 3 × 3 cm. These samples had no core and, skin. Forty g of samples with three repetitions were used to determine the initial MC. Pear samples were placed in an oven (Memmert, UFB 500, Germany) to measure initial MC. The initial MC was measured by the standard [34] method (24 h at 70 °C) and using Eq. (1) [18]. The initial MC of pear slices was 6.11 on a dry basis. Before performing the drying test, the samples were placed at a temperature of 23 °C and a relative humidity of 30% for one hour to reach the same equilibrium conditions [17, 35].

Dryers

To perform the experiments, the laboratory dryers available in the department mechanical engineering of biosystem of Mohaghegh Ardabili University, Iran, which were previously designed and built by the research team, were used. For more access to the details of these dryers, refer to their main sources [36, 37]. Dryers have sections of airflow generation (fan), hot air temperature control system, microwave power control system, and infrared lamp control. The air passes through 3 heating elements before entering the dryer compartment for heating. 2 thermostats were applied to control the temperature of the hot air entering the dryer compartment in the hot air flow path in the dryers. Also, two magnetrons (LG2M246, China) were used to generate microwaves and 4 lamps were used to generate infrared power. Of course, it should be mentioned that the rotary part of the dryers was not used in this research. After applying the desired settings on each dryer in each experiment, 100 g of prepared samples were placed in a thin layer on the mesh tray inside the dryer. The tray was connected to a digital scale (GF-600, Japan) that took the mass data of the drying samples at 3 min intervals, which was used to draw the kinetic curves of moisture loss and drying time. The dryers were turned on for about an hour before drying experiments to achieve stable conditions before each drying period.

Convective dryer

To investigate the effect of dryer air temperature on the product, three temperatures, and three thicknesses were selected to dry pears in a convective air dryer. According to the conducted studies, the air temperature of the dryer was 50, 60, and 70 °C [38, 39]. The thickness of the samples used for drying pears were 2, 4, and 6 mm. This thickness range has been used and suggested in past studies [40, 41]. Also, the air velocity in these experiments was chosen as 1 m/s.

Infrared dryer

A total of 100 g of sliced pear samples were placed on a perforated tray (30 × 30 cm) inside an IR dryer containing four 250 W IR lamps. In this research, the IR power was chosen at three levels of 500, 750, and 1000 W, and the thickness of the samples was 2, 4, and 6 mm. Also, the distance of the sample from the lamp was kept constant at 10 cm. Then the mass and time data were measured during the drying process until reaching the final moisture content.

Microwave dryer

A microwave device (Sharp R-I96T, Thailand) was used, and after placing the samples in it at powers of 270, 450, and 630 W and thicknesses of 2, 4, and 6 mm, they were dried until reaching a specific weight. During the process of changing the weight of the samples, it was recorded every 30 s through a digital scale (GF-600, Japan). This device has an internal chamber with dimensions of 54 × 34 × 45 cm3 cubic and is made of a rotating glass plate with a diameter of 28 cm. The microwave power can be changed in the range of 90–900 W.

Combined microwave-convective (MW/CV) dryer

To perform experiments on drying pears in MW/CV and IR/CV methods, first, the samples were cut into pieces of 3 × 3 cm and 4 mm thickness. After preparing the dryer and adjusting it to the desired temperature and microwave powers, pear pieces were placed in a special tray and placed in the dryer chamber. Pear samples of 100 g were spread evenly on the tray to absorb microwave energy uniformly. Experiments were performed at three temperature levels of 50, 60 and 70 °C and three MW power levels of 270, 450, and 630 W.

Combined infrared-convective (IR/CV) dryer

Pear slices were used for irradiation by IR/CV system immediately after cutting. In this dryer, it is possible to change the airflow speed, air temperature, distance, and lamp power. The speed of the airflow was 1 m/s and the distance of the samples from the lamp was 10 cm. To dry the cut samples for the IR/CV system, variables, including hot air temperature at three levels of 50, 60, and 70 °C and infrared lamp powers at three levels of 500, and 750, and 1000 W were used.

Drying time

The time taken to reduce the MC of pear pieces during the drying process with different dryers from the initial moisture content [6.11 (d.b.)] to the final MC of 0.11 (d.b.) was known as the drying period [42].

Shrinkage (SR)

The amount of shrinkage of the samples was measured by the liquid displacement method (toluene). First, 10 dried pear samples were randomly selected and placed inside a glass pycnometer containing toluene, and the amount of fluid displacement, which is the volume of the pieces, was recorded [43]. This process was done in 3 repetitions for each test. Finally, the shrinkage rate of the product was obtained from Eq. (2) [44, 45].

Rehydration ratio

One of the quality indicators used to evaluate the dried product is the rehydration ability. After finishing the drying process of pear slices, 4 samples were taken out of the dryer and immersed in 100 mL of distilled water at 20 °C for one hour [34]. The rehydration ratio of dried samples is obtained from Eq. (3) [46]:

Color properties

The drying process affects the surface properties of food and as a result changes the ability to reflect light and the color of food [47]. The drying temperature has a significant effect on the color of agricultural products. Measurement of color changes is used to predict chemical changes and product quality [48]. A calorimeter (HP–200, China) was used to check the color of the dried samples. Fresh and dried pear slices were randomly measured from different parts (5 points). The measurement results were expressed based on L*, a*, and b* indices. The following equation was used to determine the color difference created from the fresh pear sample (ΔE) during the drying process [49].

where, the subscripts o and t correspond to the color of fresh pear and the color of dried pear, respectively. L*, a*, and b* indicate brightness (0 ~ 100), red/green (−60 ~ + 60), and yellow/blue (−60 ~ + 60), respectively [50, 51]. Fresh pear tissue was used as a reference. An increase in the value of ΔE indicates more color changes between the reference sample and the dried sample.

Specific energy consumption

The energy used in the drying process is vital for production processes in the industrial and domestic sectors. SEC represents the specific energy consumption (J) to remove one kilogram of water from the product. SEC during drying using CV (SECCV) is obtained by Eq. (5) [52]:

To calculate the SEC in the drying methods using MW (SECMw) and IR (SECIR), Eqs. (6) and (7) were used, respectively [53].

Energy consumption in combined methods of MW/CV (SECMW/CV) and IR/CV (SECIR/CV) was obtained from Eqs. (8) and (9), respectively [32].

Greenhouse gases

Energy is used in various forms in industries, one of the most common types of which is heat energy, which requires a lot of money to provide. One of the main uses of thermal energy is to use it to dry agricultural products. The main source of energy used in industrial dryers is fossil fuels, which are a crucial source of energy in the world. In addition, these fuels are the main cause of the world’s environmental problems, including atmospheric pollution and global warming. To calculate the number of greenhouse gases and pollutants per kilowatt of electricity produced in different power plants, the coefficients related to the production of different gases were used, which were obtained by certified organizations [54]. Figure 1 shows the average coefficients per kilowatt of electricity production in Iran’s power plants and different fuels [55].

Statistical analysis

Statistical analysis of the data obtained from the effect of drying temperature, MW power, IR power, and thickness of pear slices on drying time, color, shrinkage and RR, SEC, and GHG using a factorial experiment in the form of a Tukey HSD (honestly significant difference) multiple comparison tests were performed SPSS software v20.0. In order to test the significant differences in the present study, the Post Hoc test was performed with the Tukey HSD test at a 95% confidence interval. Significant differences are shown here for both between and within groups.

Results and discussion

Drying time and SEC

Table 1 presents drying time and SEC. Effects of drying temperature and thickness on drying time (DT) and SEC were highly significant (P ≤ 0.01). The shortest drying time among groups for different thicknesses and drying conditions was determined from 70°C for CV, 1000 W for IR, 630 W for MW, 1000 W and 70 °C for IR/CV, 630 W and 70 °C for MW/CV. In addition, the shortest drying time among all dryers was 35.00 min in 70 °C air temperature at MIC 630 W. The longest drying time was obtained at 6 mm thickness at CV 50 °C with values of 618.33 min. It was about 13.25 times among the systems. It was determined that the shortest DT was in the MW/CV system and the longest DT was in the CV system.

The highest SEC values for CV, IR, and MW were at 50 °C, 500 W, and 270 W at 6 mm thickness, with values of 267.61, 204.64, and 87.03 MJ/kg, while the lowest SEC values were 94.54, 85.36, and 28.33 MJ/kg at 70 °C, 1000 W, and 630 W at a sample thickness of 2 mm, respectively. EL-Mesery and Elabd [53] compared CV, MW and IR dryers to calculate the drying energy of okra. They found values that ranged from 2.75 (in MW dryer) to 56.93 MJ/kg (in CV dryer) while drying okra and their values showed a decreasing trend with an increase in air temperature, MW power and IR power within the range of 40–60 °C, 200–600 W, 1000–4000 W/m2. The MW energy penetrates into the pear samples. Then it produces a polarity in water molecules of the material and heats it up. As a result, it significantly improves the heating rate and uniform heat distribution of the material. Consequently, it reduces the required time and energy of the process [56]. Moreover, the increasing IR power, reasons a rise in evaporation rate while the drying time and the SEC decreased for the drying of pear [57]. Abbasi et al. [58] used different levels of MW power 450, 600 and 750W and with thicknesses (5, 7, 9, and 11 mm) for drying of Myrtus communis L. in an MW dryer and found that the SEC values varied between 6.98 and 18.13 MJ/kg for all the drying conditions. They stated that by increasing the MW power and decreasing the thickness of the samples, the SEC decreased. They pointed out that the transfer of moisture from the inside to the surface of thinner samples will be done faster, which will reduce the drying time and specific energy consumption.

Çetin and Sağlam [23] reported similar drying times for apple drying at 200 W (27 min) microwave, 70 °C convective (480 min), 100 W + 60 °C (120 min) hybrid (MW + CV) dryers. Polat and İzli [18] indicated drying time for 'Ankara' pear samples at different air velocities, voltages, and constant temperatures in electrohydrodynamic-hot air between 90 and 150 min at 1.5 m/s, and between 80 and 130 min at 2.5 m/s, respectively. The moisture firstly removes away from the surface of the sample and secondly towards the surface (rest of the moisture). Araujo et al. [59] reported SEC values of pear drying between 10.28 and 20.79 kWh/kg, at IR dryer. Taskin et al. [29] found SEC values for “Deveci” pear between 1 and 1.9 MJ/kg in hybrid (MW- vacuum). Antal et al. [30] Calculated SEC value for pear drying 4.5 and 339.3 MJ/kg in hybrid dryer. The present findings are also consistent with the values of 6.68 to 55.93 kWh/kg applied for edamame [60], 2.75–6.83 MJ/kg in an MW dryer and 15.9–56.93 MJ/kg CV dryer for okra [53] and 4.32–318.42 MJ/kg for Roman chamomile [61].

In the hybrid systems, the highest SEC values for IR/CV and MW/CV were 119.02 and 67.35 MJ/kg at 500 W –50 °C and 270 W –50 °C, and the lowest values were 45.71 and 20.25 MJ/kg at 1000 W –70 °C and 630 W –70 °C, respectively. Higher SEC is directly related to longer drying times, temperatures, and powers. The present findings showed that combined (MW/CV and IR/CV) drying consumes less energy than single (MW, IR and CV) drying methods. Such a case was attributed combined energy consumption of both temperature and microwave power outputs [62]. Many authors, including EL-Mesery and El-khawaga [63], Kaveh et al. [64], Wang et al. [65] and Ye et al. [57] for drying tomato, green pea, chrysanthemum, and mint showed that combined drying requires less energy consumption compared to single dryers, which is consistent with the results of this research.

Shrinkage, rehydration ratio (RR) and color properties

Table 2 presents the shrinkage, rehydration, and color properties of the dried pear. The effects of drying temperature and thickness on shrinkage were significant (P ≤ 0.01). The highest shrinkage values of CV, IR, and MW were in 2 mm thicknesses, and 50 °C (72.53%), 500 W (68.63%), and 270 W (66.21%), while the lowest values were in 4 mm thicknesses and 60 °C (54.49%), 750 W (53.05%) and 450 W (49.79%), respectively. The results showed that when the thickness of the samples increased from 2 to 4 mm, the shrinkage decreased, but when the thickness of the samples increased from 4 to 6 mm, the shrinkage increased, which means that the thickness of 4 mm had the lowest amount of shrinkage in all conditions. Also, according to the results, the thickness of 2 mm had the highest amount of shrinkage because the difference in water content between the center and its surface is less. Therefore, the shrinkage of the material is more intense [58]. Also, crust development, which hinders moisture loss, occurs slower at lower thicknesses and has a greater impact on the pear sample shrinkage.

The lowest shrinkage among the individual dryers (CV, IR, and MW) appeared to occur under MW drying. The lower shrinkage of pears during the MW drying process may be due to radio frequency drying, which causes higher internal pressure at the beginning of the drying stage and faster evaporation, resulting in cell swelling [53]. Similar results were obtained by Kaveh et al. [66] for green pea. EL-Mesery and Elabd [53] reported that shrinkage of MW samples was found to be significantly less than CV and IR dried samples.

In the hybrid systems, the highest shrinkage values for IR/CV and MW/CV dryers were obtained as 63.47% and 60.50% at 500 W –50 °C and 270 W –50 °C, respectively. The lowest values were obtained as 47.39 and 45.34% at 750 W –60 °C and 450 W –60 °C, respectively. Similar to the present study, Guiné [24] stated the shrinkage value of small slices of pear pulp with the value of 75.00% in a ventilated drying chamber. Differences may vary depending on the drying system and product shape [54, 67]. This result agrees with Witrowa-Rajchert and Rzaca [68] in drying of apples using, CV, IR/CV, and MW/CV. An et al. [60] observed that the shrinkage of the edamame dried with MW/CV was lower than CV and MW, which was consistent with the conclusion of this study.

Rehydration is associated with changes in the structure of plant cells and tissues, resulting in collapse and shrinkage during drying [69]. In this study, the lowest RR for non-hybrid systems was recorded in the samples dried at 2 mm thickness and 50 °C (2.80), 500 W (2.97), and 270 W (2.85), while the highest values were in 4 mm thicknesses and 60 °C (3.54), 750 W(3.66) and 450 W (3.77), respectively. Liu et al. [70] reported the RR values of pear slices as 2.66 in single hot air drying at 45 °C. Antal et al. [30] stated that the RR values of pears dried in mid-IR- freeze dryer were between 2.48 and 3.47. According to the results obtained in all thicknesses, the RR in the CV dryer was less than other dryers (MW and IR). EL-Mesery and Elabd [53] reported that MW dried okra pods had the best rehydration property. CV samples formed a sealed structure, and the RR of the sample is weak [71]. The reason may be that the longtime of exposure to heat in CV destroyed the inherent elasticity of cells, thus decreasing the RR. Similarly, the inferiority of CV in improving the RR was also reported in dried sweet corn [71] and taro slices [72]. In addition, by increasing of thickness from 2 to 4 mm and temperature from 50 to 60 °C, the RR increased, but by increasing of thickness from 4 to 6 mm and temperature from 60 to 70 °C, the RR decreased.

In the hybrid systems, the lowest shrinkage values for IR/CV and MW/CV dryers were 2.95 and 3.08 at 500 W –70 °C and 270 W –70 °C. The highest values were 3.88 and 4.25 at 750 W –60 °C and 450 W –60 °C. In the present study, the RR of the dried products decreased at higher temperatures. The reason for this is the collapse of the cellular structure through the drying process and the prevention of water diffusion during the rehydration process [73]. Using a hybrid dryer has a better absorption coefficient compared to all single dryers. EL-Mesery et al. [74] and Nalawade et al. [75] also obtained similar results for garlic and spearmint.

Color is a critical qualitative attribute of foods and is related to internal characteristics and product development [76]. Total color change (ΔE) is an attribute frequently used to measure color in the drying processes of foodstuffs. The highest ΔE color change value was obtained from 6 mm thicknesses and 50 °C (29.35), 1000 W (33.41), and 270 W (32.30), while the lowest value was obtained from 4 mm thicknesses and 60 °C (18.29), 750 W (23.02) and 450 W (18.16), respectively. Consistent with the present findings, Polat and İzli [18] reported ΔE values between 19.06 and 21.12 for dried ‘Ankara’ pear samples in electrohydrodynamic-hot air. Önal et al. [28] reported the ΔE color change values for 'Rocha' pears dried at the microwave (MW) at 50–60 °C between 3.86 and 23.41, respectively. In contrast to the present study, Domínguez-Niño et al. [27] found color change ΔE values for pear in CV drying at different conditions ranged from 6.36 to 15.00. By observing Table 2, it can be seen that the color of the sample CV dryer is lower than IR and MW. Because enzymatic browning reactions and non-enzymatic browning reactions were significantly weakened in CV [77]. Ismail et al. [78] used vacuum sun, MW, IR and CV to dry fresh okra and found HA-processed okra had lower color changes compared to vacuum sun, MW, and IR processed samples also reported similar results. The results of our study were consistent with the study of Osae et al. [79] who found that color change of CV dried ginger slices was less than Freeze, IR, and MW dried ones.

The highest color change values in IR/CV and MW/CV hybrid dryers were 31.14 and 24.02 at 2 mm thickness at 500 W –50 °C and 270 W –50 °C. The lowest values were 17.64 and 15.51 at 750 W –60 °C and 450 W –60 °C at 4 mm thickness. The changes in color during drying can be attributed to Maillard reactions, color pigment degradation, and enzymatic browning [80]. From the total color difference ΔE, the MW/CV group had the lowest ΔE value, followed by CV, and MW, IR/CV and IR had the largest ΔE values. This indicates that MW/IR was closest to the color of fresh pear slices. Although MW/IR used microwaves and air temperature as the heat source, continuous microwave heating may lead to a large diffusion of internal moisture to the surface, However, due to the short drying time and physiological and biochemical reaction time [81], the color difference between the dried sample and fresh pear slices was small.

Greenhouse gases for CV, IR, and MW dryers

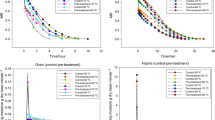

Figure 2 shows the results of GHG emissions during the drying of pear samples using CV. The maximum value of CO2 was determined with the value of 280.45 kg/kg water from the GT-GO power plant at 50 °C (6 mm thickness). Moreover, the lowest amount (42.54 kg/kg water) was achieved from the CC-NG power plant at 70 °C (2 mm thickness). The GT-GO power plant (1.55 kg/kg water) had the highest amount of NOx (50 °C and 6 mm thickness), and the GT-NG power plant (0.18 kg/kg water) released the lowest NOX emissions (70 °C and 2 mm thickness).

GHG (CO2 and NOx) of dried samples at higher drying temperatures were less than those dried at lower drying temperatures. At higher temperatures, due to the higher thermal gradient, the rate of moisture evaporation from the product increases and the product dries in a shorter period of time [10]. Many researchers have shown that the GHG decrease with increasing air temperature, among them Beigi et al. [82] for drying paddy, Fabani et al. [83] for drying onions, Taghinezhad et al. [13] for drying blackberry and Karimi et al. [11] for drying canola seeds. CO2 and NOX emissions decreased proportionally with an increase in Rehydration decreased proportionally with an increase in thickness samples from 2 to 6 mm. Seyfi et al. [10] a comparison between GHG of Aloe vera gel drying at different drying thicknesses (1 to 3 mm) investigated which the results showed a downward trend with decreasing thickness.

As shown in Fig. 3, the GHG formed by an IR dryer decreases with increasing IR power and with decreasing sample thickness. The GT-GO (214.46 kg/kg water) and SP-HO (209.75 kg/kg water) power plants for 500 W and 6 mm thickness had the highest CO2. The minimum value of CO2 (38.14 kg/kg water) was when NG was used as fuel in the CC at an IR power of 1000 W and a product thickness of 2 mm. The maximum of NOX was 1.18 kg/kg water in a dryer working at IR power 500 W and 6 mm thickness when powered by a GT-GO. The minimum NOX was 0.16 kg/kg water from a GT-NG power plant with a dryer operating at 1000 W and 2 mm thickness. Any increment in infrared power resulted in a reduction in GHG. The rise in IR power reasons an increase in the temperature of the pear sample and then the rate of evaporation [84]. The increasing of rate evaporation causes a decrease in the drying period and energy consumption ultimately GHG (CO2 and NOX) emissions [32]. Similar findings were reported by Kaveh et al. [64] for green peas and Motevali et al. [85] for Aloe vera. Motevali and Koloor [32] concluded that increasing IR power reduces SEC and GHG (CO2 and NOX) emissions. They also stated that IR waves can penetrate the sample and cause an increase in the temperature of the product and more evaporation of its moisture [32, 86].

Figure 4 shows GHG levels for MW treatment. As shown, the greatest CO2 levels were recorded for the SP-HO (89.21 kg/kg water) and GT- GO (91.21 kg/kg water) power plants when drying at 270 W with a sample thickness of 6 mm. The lowest CO2 level was 12.75 kg/kg water in the CC-NG power plant at 630 W MW power with a sample thickness of 2 mm. The highest NOX emissions (0.50 kg/kg water) were found for the GT- GO at 270 W and 6 mm thickness. The lowest NOx (0.05 kg/kg water) belonged to the GT- NG for drying at 630 W and a sample thickness of 2 mm. Additionally, the increments in MW power led to reduced CO2 and NOX emissions, while the increases in sample thickness led to increasing CO2 and NOX emissions. This indicates that the high MW power results in less energy required for moisture removal of the pear samples leading to a decline in GHG emission [33]. Petković et al. [87] also showed that reducing thickness and increasing MW power and leads to decreased CO2.

Greenhouse gases for IR/CV and MW/CV dryers

Figure 5 shows the emission levels of GHG for a hybrid IR/CV dryer. The maximum amount of CO2 emissions was from the SP- HO (121.99 kg/kg water) and GT-GO (124.73 kg/kg water) power plants for drying with an IR power of 500 W at 50 °C, while the minimum result (20.57 kg/kg water) was observed in the CC- NG for drying at 70 °C using 1000 W. The GT-GO had the maximum NOX of 0.69 kg/kg water when drying at 50 °C and 500 W, while the GT- NG power plant had a minimum NOX of 0.08 kg/kg water at 70 °C and 1000 W. The lowest CO2 and NOx was obtained for blackberry drying in combined IR/CV dryer 42.53 kg/kg water and 0.18 kg/kg water [13], which was higher than the values of this study because pear drying requires less drying time and less energy for drying. However, the lowest CO2 for Aloe vera [85] and green peas [64] was 4.72 and 16.5 kg/kg water, respectively, which was lower than this study due to less time and less energy for drying them.

Figure 6 shows the GHG [CO2 and NOX] emissions for using the MW/CV dryer to dry 1 kg of the pear sample. It presents that the CO2 is reduced with rising MW power and air temperature. Accordingly, its maximum CO2 in ST-HO power plant (69.03 kg/kg water) was at 50 °C and 270 W, and its minimum values in CC-NG power plant (9.11 kg/kg water) were at 70 °C and 630 W. The GT-GO released its greatest quantities of NOX (0.39 kg/kg water) when drying at 50 °C and 270 W. As a result, the GT-NG provided the lowest amount (0.04 kg/kg water) for drying at 70 °C and 630 W. Considering that the energy consumption at 630 W and 70 °C was lower than the other drying conditions, this led to a reduction in greenhouse gas emissions. As the drying temperature increases and MW power, the thermal gradient will increase, which can improve the moisture released from pears and reduce the drying time. Hence, GHG emissions will be lower [61]. In the study of Kaveh et al. [33] the amount of CO, and NOx in the drying of the Pistacia Atlantica in an MW/CV dryer was between 2.70 and 29.68 kg/kg water and 0.01–0.16 kg/kg water, respectively. Motevali and Koloor [32] showed that the amount of CO2 (from 0.09 to 2.91 kg/kg water) and NOx (from 0.002 to 0.016 kg/kg water) decreased by increasing drying temperature and MW power for drying dog rose by MW/CV dryer. At higher temperatures and IR power, the GHG emission decreased due to the heating effect of IR radiation, as the increase in IR power reduces energy consumption; this, in turn, shortened the drying time [32, 33, 74]. In addition, rapid evaporation reduces drying time and SEC, which in turn decreases GHG emissions [31, 32].

Compared with other fossil fuels, NG is a cleaner and less polluting resource. The results of burning NG, GO, and HO as fuel in various power plants are analyzed. It has been shown that NG could significantly decrease GHG (CO2 and NOx) emissions from power plants. According to Figs. 2–6, the highest emission production of the GT power plant under all conditions was due to burning diesel fuel. Results from GHG (CO2 and NOx) emissions of the CC power plant (Figs. 2–6) revealed that, compared to other power plants, this plant has lower GHG (CO2 and NOx) emissions. In all dryers, the highest pollution level was at the lowest temperature, MW power and IR power. The highest emissions in the CV dryers occurred at 50 °C. The reason for the high CO2 and NOx emission in CV dryer is the need for high energy due to the use of both conduction and convection heat transfer [64, 84]. The study results showed that the MW/CV dryers could have the lowest energy consumption and GHG (CO2 and NOx) emissions. The microwave penetrates the product in an MW and MW/CV dryer, polarizing the moisture content. This causes a rapid rise in temperature and a rapid fall in humidity, which lowers SEC and GHG emissions [64].

Conclusion

The present study investigated the drying time, energy, shrinkage, rehydration, color, and greenhouse gas emission parameters of pear drying in five various dryers, CV, IR, MW, IR/CV, and MW/CV. Based on the study, it was obtained that the SEC showed a decreasing trend at increasing temperature-power and decreasing sample thickness. It was found that shrinkage values were higher at low sample thicknesses and temperature powers. It was also determined that the rehydration rate of the mid-drying parameters was higher, and the color change was less in the groups. The CV dryer operating at 50 °C with a sample thickness of 6 mm produced the highest GHG emissions, specifically CO2 and NOX. Using a higher sample thickness can increase greenhouse gas emissions. In conclusion, SEC and GHG emissions can be minimized when the MW dryer operates at 630 W power. The present findings can be used in dryer design and to produce quality products. It can be seen from the experimental observations that compared with MW/CV and CV, MW, IR and IR/CV equipment operating at MW/CV-630 W –70 °C brought relatively lower energy consumption and less greenhouses gas (CO2 and NOx) emissions on the basis of faster drying rate and higher drying efficiency. The results of the current study corroborate that MW/CV equipment is a more suitable choice for energy saving, emission reduction and quality assurance of food processing.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Abbreviations

- A:

-

Area of the sample container (m2)

- Ca :

-

Specific heat capacity of the drying air (kJ/kg °C)

- MCd.b. :

-

Moisture content of dry basis at time t,

- mIR :

-

Amount of moisture removed from the sample in the IR drying method (kg)

- mMW :

-

Amount of moisture removed from the sample in MW drying (kg)

- mt :

-

Mass of pear slices at time t, (g)

- mCV :

-

Amount of moisture removed from the sample in CV drying (kg)

- m:

-

Dry mass of pear slices, (g)

- PMW :

-

MW power (W)

- PIR :

-

Power of IR lamps (W)

- Rr :

-

Weight of the rehydrate sample (g)

- Rd :

-

Weight of the dry sample (g)

- SECIR :

-

Energy consumption in the IR (kJ/kg)

- SR:

-

Shrinkage (%)

- SECMW :

-

Energy consumption in the MW (kJ/kg)

- SECCV :

-

Energy consumption in the CV dryer (kJ/kg)

- SECMW/CV :

-

Energy consumption in the MW/CV (kJ/kg)

- SECIR/CV :

-

Energy consumption in the IR/CV (kJ/kg)

- tIR :

-

Drying time of the sample with IR (s)

- tCV :

-

Drying time of CV dryer (s)

- tMW :

-

Sample drying time with MW (s)

- Vi :

-

Initial volume of the sample (cm3)

- Vf :

-

Volume of the sample at the end of the process (cm3)

- Va:

-

Velocity of incoming air (m/s)

- ΔT:

-

Temperature difference (°C)

- ΔE:

-

Color change

- ρa :

-

Mass density of air (kg/m3)

References

Proietti N, Adiletta G, Russo P, Buonocore R, Mannina L, Crescitelli A, Capitani D (2018) Evolution of physicochemical properties of pear during drying by conventional techniques, portable-NMR, and modelling. J Food Eng 230:82–98

Bonazzi C, Dumoulin E (2011) Quality changes in food materials as influenced by drying processes. Mod Drying Technol 3:1–20

Guiné RP, Rodrigues AE, Figueiredo MM (2007) Modelling and simulation of pear drying. Appl Math Comp 1921:69–77

Amantéa RP, Fortes M, Ferreira WR, Santos GT (2018) Energy and exergy efficiencies as design criteria for grain dryers. Drying Technol 36(4):491–507

Ekka JP, Bala K, Muthukumar P, Kanaujiya DK (2020) Performance analysis of a forced convection mixed mode horizontal solar cabinet dryer for drying of black ginger (Kaempferia parviflora) using two successive air mass flow rates. Renew Ener 152:55–66

Dincer I (2000) Thermodynamics, exergy and environmental impact. Ener Sour 22(8):723–732

Xiao HW (2015) Guest editorial: some mitigation strategies for climate change. Drying Technol 33(14):1679–1680

César LVE, Lilia CMA, Octavio GV, Orlando SS, Alfredo DN (2021) Energy and exergy analyses of a mixed-mode solar dryer of pear slices (Pyrus communis L). Energy 220:119740

Bullinger C, Ness M, Sarunac N, Levy EK (2002) Coal drying improves performance and reduces emissions. Presented at the 27th International technical Conference on Coal Utilization & Fuel Systems, Clearwater, FL, Mar

Seyfi A, Asl AR, Motevali A (2021) Comparison of the energy and pollution parameters in solar refractance window (photovoltaic-thermal), conventional refractance window, and hot air dryer. Sol Energy 229:162–173

Karimi M, Moradi M, Niakousari M, Karparvarfard SH (2022) Application of heat carrier particles in a fluidized bed dryer: dimensionless modeling and GHG emissions. J Food Process Eng 45(9):e14071

Pérez-Won M, González-Cavieres L, Palma-Acevedo A, Tabilo-Munizaga G, Jara-Quijada E, Lemus-Mondaca R (2023) Pulsed electric fields as pretreatment for different drying methods in chilean abalone (Concholepas concholepas) Mollusk: effects on product physical properties and drying methods sustainability. Food Bioprocess Technol. https://doi.org/10.1007/s11947-023-03102-4

Taghinezhad E, Kaveh M, Khalife E, Chen G (2021) Drying of organic blackberry in combined hot airinfrared dryer with ultrasound pretreatment. Drying Technol 39(14):2075–2791

Ashtiani SHM, Rafiee M, Mohebi Morad M, Martynenko A (2022) Cold plasma pretreatment improves the quality and nutritional value of ultrasound-assisted convective drying: the case of goldenberry. Drying Technol 40(8):1639–1657

Wang H, Torki M, Xiao HW, Orsat V, Raghavan GS, Liu ZL, Peng WJ, Fang XM (2022) Multi-objective analysis of evacuated tube solar-electric hybrid drying setup for drying lotus bee pollen. Renew Sustain Energy Rev 168:112822

Fang XM, Liu ZL, Xiao HM, Torki M, Orsat V, Raghavan GSV, Xiao HW, Wang H (2023) Performance assessment of an evacuated tube solar-electric hybrid dryer for lotus seeds drying: Moisture removal behavior, GHG emission and thermodynamic analysis. J Clean Prod 406:136972

Hadibi T, Boubekri A, Mennouche D, Benhamza A, Kumar A, Bensaci C, Xiao HW (2022) Effect of ventilated solar-geothermal drying on 3E (exergy, energy, and economic analysis), and quality attributes of tomato paste. Energy 243:122764

Polat A, Izli N (2022) Drying characteristics and quality evaluation of ‘Ankara’pear dried by electrohydrodynamic-hot air (EHD) method. Food Cont 134:108774

Çetin N (2022) Prediction of moisture ratio and drying rate of orange slices using machine learning approaches. J Food Proc Preserv 4611:e17011

Darvishi H (2017) Quality, performance analysis, mass transfer parameters and modeling of drying kinetics of soybean. Brazilian J Chem Eng 34:143–158

Izli N, Polat A (2019) Effect of convective and microwave methods on drying characteristics, color, rehydration and microstructure properties of ginger. Food Sci Technol 39:652–659

Silva V, Costa JJ, Figueiredo AR, Nunes J, Nunes C, Ribeiro TI, Pereira B (2016) Study of three-stage intermittent drying of pears considering shrinkage and variable diffusion coefficient. J Food Eng 180:77–86

Çetin N, Sağlam C (2022) Effects of ultrasound pretreatment assisted drying methods on drying characteristics, physical and bioactive properties of windfall apples. J Sci Food Agric 103(2):534–547

Guiné RP (2006) Influence of drying method on density and porosity of pears. Food Bioprod Proc 84(3):179–185

Darvishi H, Khoshtaghaza MH, Minaee S (2014) Fluidized bed drying characteristics of soybeans. J Agr Sci Technol 16(5):1017–1031

Ozgen F (2015) Experimental investigation of drying characteristics of cornelian cherry fruits (Cornus mas L.). Heat Mass Tran 51(3):343–352

Domínguez-Niño A, Salgado-Sandoval O, López-Vidaña EC, César-Munguía AL, Pilatowsky-Figueroa I, García-Valladares O (2021) Influence of process variables on the drying kinetics and color properties of pear slices (Pyrus communis). Color Res Appl 46(5):1128–1141

Önal B, Adiletta G, Di Matteo M, Russo P, Ramos IN, Silva CL (2021) Microwave and ultrasound pre-treatments for drying of the “Rocha” pear: Impact on phytochemical parameters, color changes and drying kinetics. Foods 10(4):853

Taskin O, Polat A, Izli N, Asik BB (2019) Intermittent microwave-vacuum drying effects on pears. Polish J Food Nutr Sci 691:101–108

Antal T, Tarek-Tilistyák J, Cziáky Z, Sinka L (2017) Comparison of drying and quality characteristics of pear (Pyrus communis L.) using mid-infrared-freeze drying and single stage of freeze drying. Int J Food Eng 13(4):20160294

Torki-Harchegani M, Ghanbarian D, Pirbalouti AG, Sadeghi M (2016) Dehydration behaviour, mathematical modelling, energy efficiency and essential oil yield of peppermint leaves undergoing microwave and hot air treatments. Renew Sust Ener Rev 58:407–418

Motevali A, Koloor RT (2017) A comparison between pollutants and greenhouse gas emissions from operation of different dryers based on energy consumption of power plants. J Clean Prod 154:445–461

Kaveh M, Chayjan RA, Taghinezhad E, Sharabiani VR, Motevali A (2020) Evaluation of specific energy consumption and GHG emissions for different drying methods (Case study: Pistacia Atlantica). J Clean Prod 259:120963

AOAC (1990) Official method of analysis. Association of Official Analytical Chemists, Arlington

Meng Z, Cui X, Zhang H, Liu Y, Wang Z, Zhang F (2023) Study on drying characteristics of yam slices under heat pump-electrohydrodynamics combined drying. Case Stud Therm Eng 41:102601

Kaveh M, Abbaspour-Gilandeh Y (2020) Impacts of hybrid (convective-infrared-rotary drum) drying on the quality attributes of green pea. J Food Process Eng 2020:e13424

Kaveh M, Abbaspour-Gilandeh Y (2022) Drying characteristics, specific energy consumption, qualitative properties, total phenol compounds, and antioxidant activity during hybrid hot air-microwave- rotary drum drying of green pea. Iran J Chem Eng 402:655–672

Chikpah SK, Korese JK, Sturm B, Hensel O (2022) Colour change kinetics of pumpkin (Cucurbita moschata) slices during convective air drying and bioactive compounds of the dried products. J Agric Food Res 10:100409

Kadir N, Yeasmen N, Bhuiyan MHR, Khan MJ, Iqbal A (2022) Osmotic and convective hot air drying of sweet gourd. Food Sci Biotech. https://doi.org/10.1007/s10068-022-01193-x

Fealekari M, Chayjan RA (2014) Optimization of convective drying process for Persian shallot using response surface method (RSM). Agric Eng Int CIGR J 162:157–166

Mahdad A, Laidi M, Hanini S, Hentabli M, Benhelal M (2021) Modelling the drying kinetics of apple (Golab Variety): fractional calculus vs semi-empirical models. Kem Ind 70(5/6):251–262

Rifna EJ, Dwivedi M (2021) Optimization and validation of microwave–vacuum drying process variables for recovery of quality attribute and phytochemical properties in pomegranate peels (Punica granatum L. cv. Kabul). J Food Meas Charac 15:4446–4464

Dehghannya J, Seyed-Tabatabaei SR, Khakbaz Heshmati M, Ghanbarzadeh B (2021) Influence of three stage ultrasound-intermittent microwave-hot air drying of carrot on physical properties and energy consumption. Heat Mass Tran 5712:1893–1907

Bao X, Min R, Zhou K, Traffano-Schiffo MV, Dong Q, Luo W (2023) Effects of vacuum drying assisted with condensation on drying characteristics and quality of apple slices. J Food Eng 340:111286

Gharkhloo ZR, Sharifian F, Rahimi AA, Yamchi A (2022) Influence of high wave sound pretreatment on drying quality parameters of Echinacea root with infrared drying. J Sci Food Agr 102(5):2153–2164

Malakar SD, Arora PV (2022) Modeling and optimization of osmo-sonicated dehydration of garlic slices in a novel infrared dryer using artificial neural network and response surface methodology. J Food Proc Eng 46:e14261

Belwal T, Cravotto C, Prieto MA, Venskutonis PR, Daglia M, Devkota HP, Baldi A, Ezzat SM, Gómez-Gómez L, Salama MM, Campone L (2022) Effects of different drying techniques on the quality and bioactive compounds of plant-based products: a critical review on current trends. Drying Technol. https://doi.org/10.1080/07373937.2022.2068028

Nowacka M, Dadan M, Janowicz M, Wiktor A, Witrowa-Rajchert D, Mandal R, Janiszewska-Turak E (2021) Effect of nonthermal treatments on selected natural food pigments and color changes in plant material. Compr Rev Food Sci Food Saf 20(5):5097–5144

Chen BL, Lin GS, Amani M, Yan WM (2023) Microwave-assisted freeze drying of pineapple: kinetic, product quality, and energy consumption. Case Stud Ther M Eng 41:102682

Bai JW, Zhang L, Aheto JH, Cai JR, Wang YC, Sun L, Tian XY (2023) Effects of different pretreatment methods on drying kinetics, three-dimensional deformation, quality characteristics and microstructure of dried apple slices. Innov Food Sci Emer Technol 83:103216

Sharifian F, Gharkhloo ZR, Yamchi AA, Kaveh M (2023) Infrared and hot drying of saffron petal (Crocus sativus L.): Effect on drying, energy, color, and rehydration. Journal of Food Process Engineering. 46(7):e14342

Kumar A, Kandasamy P, Chakraborty I, Hangshing, (2022) Analysis of energy consumption, heat and mass Tran., drying kinetics and effective moisture diffusivity during foam-mat drying of mango in a convective hot-air dryer. Biosyst Eng 219:85–102

EL-Mesery, H S, Elabd, M A, (2021) Effect of microwave, infrared, and convection hot-air on drying kinetics and quality properties of okra pods. Int J Food Eng 1711:909–926

Iran Energy Balance-Sheet (201) Available from: URL: http://pep.moe.gov.ir/

Nazari S, Shahhoseini O, Sohrabi-Kashani A, Davari S, Paydar R, Delavar-Moghadam Z (2010) Experimental determination and analysis of CO2, SO2 and NOx emission factors in Iran’s thermal power plants. Energy 35:2992–2998

Çetin N (2022) Comparative assessment of energy analysis, drying kinetics, and biochemical composition of tomato waste under different drying conditions. Scientia Hortic 305:111405

Ye L, EL-Mesery HS, Ashfaq MM, Shi Y, Zicheng H, Alshaer WG (2021) Analysis of energy and specific energy requirements in various drying process of mint leaves. Case Stud Therm Eng 26:101113

Abbasi H, Layeghiniya N, Mohammadi S, Karimi S (2022) Effect of fruit thickness on microwave drying characteristics of Myrtus communis L. Iranian J Chem Chem Eng. pp.222–236

Araujo MEV, Barbosa EG, Lopes RP, Corrêa PC, Barbosa EG (2021) Infrared drying of pear slices: drying kinetics, energy, and exergy analysis. J Food Proc Eng 44(12):e13915

An N, Sun W, Li B, Wang Y, Shang N, Lv W, Li D, Wang L (2022) Effect of different drying techniques on drying kinetics, nutritional components, antioxidant capacity, physical properties and microstructure of edamame. Food Chem 373:131412

Motevali A, Minaei S, Banakar A, Ghobadian B, Khoshtaghaza MH (2014) Comparison of energy parameters in various dryers. Ener Conv Manag 87:711–725

Horuz E, Bozkurt H, Karataş H, Maskan M (2018) Comparison of quality, bioactive compounds, textural and sensorial properties of hybrid and convection-dried apricots. J Food Meas Charac 121:243–256

EL-Mesery HS, El-Khawaga SE (2022) Drying process on biomass: evaluation of the drying performance and energy analysis of different dryers. Case Stud Therm Eng 33:101953

Kaveh M, Abbaspour-Gilandeh Y, Nowacka M (2021) Comparison of different drying techniques and their carbon emissions in green peas. Chem Eng Proc Proc Intens 160:108274

Wang Y, Li X, Chen X, Li BO, Mao X, Miao J, Zhao C, Huang L, Gao W (2018) Effects of hot air and microwave-assisted drying on drying kinetics, physicochemical properties, and energy consumption of chrysanthemum. Chem Eng Process-Process Int 129:84–94

Kaveh M, Abbaspour-Gilandeh Y, Fatemi H, Chen G (2021) Impact of different drying methods on the drying time, energy, and quality of green peas. J Food Process Preserv 45(6):e15503

Samimi-Akhijahani H, Arabhosseini A (2018) Accelerating drying process of tomato slices in a PV-assisted solar dryer using a sun tracking system. Renew Energy 123:428–438

Witrowa-Rajchert D, Rząca M (2009) Effect of drying method on the microstructure and physical properties of dried apples. Drying Technol 27(7–8):903–909

Kaymak-Ertekin F (2002) Drying and rehydrating kinetics of green and red peppers. J Food Sci 671:168–175

Liu Y, Zeng Y, Wang Q, Sun C, Xi H (2019) Drying characteristics, microstructure, glass transition temperature, and quality of ultrasound-strengthened hot air drying on pear slices. J Food Proc Preserv 43(3):e13899

Yao L, Zhang Y, Qiao Y, Wang C, Wang X, Chen B, Kang J, Cheng Z, Jiang Y (2022) A comparative evaluation of nutritional characteristics, physical properties, and volatile profiles of sweet corn subjected to different drying methods. Cereal Chem 99(2):405–420

Yang Y, Liang D, Wang X, Li F, Fan X, Liu Y (2022) Effects of contact ultrasound & far-infrared radiation strengthening drying on water migration and quality characteristics of taro slices. J Food Process Preserv 46(11):e17030

Saengrayap R, Tansakul A, Mittal GS (2015) Effect of far-infrared radiation assisted microwave-vacuum drying on drying characteristics and quality of red chilli. J Food Sci Technol 52(5):2610–2621

EL-Mesery HS, Sarpong F, Xu W, Elabd MA (2022) Design of low-energy consumption hybrid dryer: a case study of garlic (Allium sativum) drying process. Case Stud Therm Eng 33:101929

Nalawade SA, Ghiwari GK, Hebbar HU (2019) Process efficiency of electromagnetic radiation (EMR)-assisted hybrid drying in spearmint (Mentha spicata L.). J Food Proc Preserv. 4311:e14190

Cetin N, Yaman M, Karaman K, Demir B (2020) Determination of some physicomechanical and biochemical parameters of hazelnut (Corylus avellana L.) cultivars. Turkish J Agr Forestry 44(5):439–450

Bai JW, Wang YC, Cai JR, Zhang L, Dai Y, Tian XY, Xiao HW (2023) Three-dimensional appearance and physicochemical properties of Pleurotus Eyngii under different drying methods. Foods 12(10):1999

Ismail O, Kipcak AS, Doymaz I (2019) Drying of okra by different drying methods: comparison of drying time, product color quality, energy consumption and rehydration. Athens J Sci 6:155–168

Osae R, Essilfie G, Alolga RN, Bonah E, Ma H, Zhou C (2020) Drying of ginger slices—evaluation of quality attributes, energy consumption, and kinetics study. J Food Process Eng 43(2):e13348

Pinar H, Çetin N, Ciftci B, Karaman K, Kaplan M (2021) Biochemical composition, drying kinetics and chromatic parameters of red pepper as affected by cultivars and drying methods. J Food Compos Anal 102:103976

Li C, Ren G, Zhang L, Duan X, Wang Z, Ren X, Chu Q, He T (2023) Effects of different drying methods on the drying characteristics and drying quality of Cistanche deserticola. LWT. https://doi.org/10.1016/j.lwt.2023.115000

Beigi M, Torki M, Khoshnam F, Tohidi M (2021) Thermodynamic and environmental analyses for paddy drying in a semi-industrial dryer. J Therm Analysis Calor 146:393–401

Fabani MP, Román MC, Rodriguez R, Mazza G (2020) Minimization of the adverse environmental effects of discarded onions by avoiding disposal through dehydration and food-use. J Environm Manage 271:110947

Aboud SA, Altemimi AB, Al-Hilphy AR, Watson DG (2020) Effect of batch infrared extraction pasteurizer (BIREP)-based processing on the quality preservation of dried lime juice. J Food Process Preserv 44(10):e14759

Motevali A, Jafari H, Molkabadi EZ, Zhu S, Koloor RT, Taghizadeh-Alisaraei A (2020) Comparison of environmental pollution and social cost analyses in different drying technologies. Int J Glob Warm 221:1–29

Salarikia A, Miraei Ashtiani SH, Golzarian MR (2017) Comparison of drying characteristics and quality of peppermint leaves using different drying methods. J Food Proc Preserv 41(3):e12930

Petković M, Miletić N, Kurćubić V, Lukyanov A, Đurović I, Filipović V, Mladenovic V (2022) Energy consumption and dehydration parameters of microwave drying of carrot. Acta Agri Serbica 27(54):137–142

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

MK: conceptualization, formal analysis, methodology, computation, and writing; NÇ: software, validation, data curation, visualization, and writing; YA-G: conceptualization, supervision, writing and editing; FS: investigation, formal analysis, writing, and editing; MS: Writing—review and editing, Formal analysis.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kaveh, M., Çetin, N., Gilandeh, Y.A. et al. Comparative evaluation of greenhouse gas emissions and specific energy consumption of different drying techniques in pear slices. Eur Food Res Technol 249, 3027–3041 (2023). https://doi.org/10.1007/s00217-023-04346-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04346-2