Abstract

This study examined the influence of ground coffee granulometry and particle distribution on extraction parameters. They have been investigated the physicochemical properties, and the bioactive and volatile compound content in coffee obtained by a conventional filter method, the French Press, as a function of particle size and distribution. Some samples have been used for the extraction the directly the grinding machine, set at different grinding grade, and other samples have been seed before the usage in order to reproduce samples at different particle size class very homogeneous. The results showed that bioactive and volatile compounds are released differently in the beverages depending on the specific particle size. The results have been demonstrated that a homogeneous grind was more deficient in bioactive compounds and total dissolved solids than a classical, bimodal grind. Moreover, extraction from a very fine homogeneous grind was poorest with respect to these compounds, despite the greater surface in contact with the solvent. Conversely, bimodal grinds obtained conventional by the grinding machine, which were more heterogeneous from a granulometric point of view, were found to be richer in volatile organic and bioactive compounds. The study highlights that the grind plays a key role in producing well-extracted coffee and, therefore, in making the most of the potential inherent in the roasted bean.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Coffee is one of the most liked and appreciated beverages, being consumed for its stimulating and hedonistic properties, which are dependent on the green beans' composition and changes occurring during the process of transformation from beans to beverages [1].

Coffee brewing combines two extraction steps. During the first phase, namely washing phase, free solubles are rapidly extracted from the particle surface, while in the second phase, the diffusion phase, internal solubles are extracted from the matrix [2]. Extraction capacity is reported to be a function of the total particle surface, and is closely correlated to particle size [3].

Normally, for every brewing coffee technique is necessary to adopt a specific protocol of extraction. In particular, beans should be ground into particles with a consistent size, and extraction studies prove that various methods (e.g. espresso, French Press, or other filter methods) require a specifical particle size distribution [4]. If the particle size is too coarse, water can flow through large channels, resulting in a low extraction yield (under-extraction). On the other hand, if the powder is too fine, the ground coffee powder cake becomes very compressed and generates a resistance to the passage of the water, that increases the contact time between water and powder and produced an over-extracted coffee [5].

The food powders are widely used food materials, both in industry and households. They have several physical properties, larger studied, and that change of importance in function of the foods considered. Particle size distribution represents one of the most important identifiers of powders physical properties [6, 7]. Ground coffee is characterized by particles or granules that have a theoretical size. The powder may be indicated as a profile, named particle size curve, often with a bimodal distribution. The particle diameter can range from a few micrometres up to 1000 μm. After grounding step, volatile compounds are released, and chemical compounds are quickly dissolved in hot water, giving coffee its particular aroma [8].

It is well studied that variation in factors connected to coffee preparation (e.g. the blend composition, roast grade, grind, water temperature and pressure, percolation time and/ or beverage volume) can specially diversify the ‘cup result’, not only in terms of the flavour, aroma and chemical compounds, but also in terms of the characteristics of the different chemo-physical phases present in the beverage (foam, emulsion, suspension and solution) and in consequence their properties [9,10,11].

Typically, the grind used to make coffee beverage has a bimodal particle size distribution, where the coarse fraction ensures correct water percolation and provides the skeleton of the coffee cake, while finer particles ensure a high diffusion rate [12]. Consequently, the resulting powder is not entirely homogenous, although a coffee grinder can produce precise and repeatable results, it will always produce two fractions, regardless of the chosen setting (the distance between the rotating parts).

Several authors have studied the relation between particle size distribution and the quality of the coffee. These studies have been focused on the impact of grinding step on the physical (pH, total solids), chemical (kinetics and mechanism of Caffeine and CGAs infusion) [2, 13]

Particularly, Severini and co-authors [14] showed that a highly significant source of variation in espresso coffee quality was the grinding class, and demonstrated that this factor accounted for at least 80% of variation. Another study [15] investigated the influence of three grinding levels (fine, medium, coarse) on the aromatic profile of Espresso coffee. However, a major problem occurred, notably that it was difficult to differentiate the effects of percolation time and grinding grade.

In fact, as demonstrated by several studies, there is an immediate relationship between the flow rate and the size distribution of coffee particles. A higher amount of fine particles involve a slower flow rate and at the consequence the coffee that is ‘shorter’ compared to a beverage obtained from a powder where is present a major number of large particles, considering the same extraction time [16, 17]. Too-fine powder reduces the flow rate and products in over-extracted coffee, while a too-coarse grind increases the flow rate, resulting in under-extracted coffee [9]. Finally, other studies have evaluated the effects of classes of ground coffee particle size on espresso coffee quality,[17, 18]. Particularly, these authors reported that Arabica EC prepared using coffee particle sizes ranging between 300 and 425 μm exhibited the highest concentration of volatile compounds, among the different particle size distributions analysed. On the contrary, another study [19] has demonstrated that extracting with smaller particles increases the concentration of bioactive compounds in cup increased moving from 500–1000 µm to 200–300 µm particle size.

To avoid the uncontrollable effect of the flow rate/contact time between powder and water, and search to understand better the influence of grinding method and also the extraction capability of the different coffee powder particle size classes, it has been proposed this study in which has been consider a static extraction process, the French Press method. The static French Press method overcomes the problem of the influences of percolation time and flow rate.

Thus, the study has been focused on highlights the differences between homogeneous grinds, where the particle size (more fine or more coarse) has been controlled after grinding by sieving operation (S), and between conventional, heterogenous-sized coffee particles, which are affected by the grinder (G) setting and used directly for the extraction without the sieving step.

Materials and methods

Sample preparation: grinding, separation and extraction

The same batch of 100% Arabica coffee (Fazenda Baianeira Brasil, roasted by D612, Firenze, Italy) was used for all extractions. Each pack of beans (250 g) was opened immediately before grinding to avoid oxidative damage. The coffee beans have been ground with a professional grinder (EK43 Mahlkönig AG, Switzerland). Approximately 2500 g of ground coffee was used for the experiment. One first part, around 500 g of powders were produced by the grinder and directly used for the extraction. The three conventional grinding settings chosen were: G2 (fine), G6 (medium), and G11 (coarse). Part of the powder ground at each setting was used for the construction of another powder puck, that consisted of an equal proportion of each of the three settings (G2 + G6 + G11), as reported in recent research [20]. This configuration was previously tested for espresso extraction but was adopted here for the French Press extraction.

The other part of powder coffee was used to test the samples that beyond the grinding step had a sieved operation before the extraction phase. Thus, approximately 2000 g of ground coffee was used to ensure the minimum amount of 25 g of fine ground belonging to the class S2, including its replicates.

The powders were sieved through six sieves (Endecotts, Endecotts Ltd, 9 Lombard Rd, London, SW19 3TZ, UK) to obtain 6 homogenous particle size classes. Each of the six sieves had a different mesh size (Table 1), and samples were obtained using a 30 min shaking cycle on a vibratory sifter. This procedure was performed two times to recover the necessary quantity of ground coffee, while checking that the weight of the sieves was constant. In order to separate agglomerates and to facilitate detachment of the fine particles adhering to the sieves, a brush was used. Collected fractions are described as: S1 related to a sieving range < 124 µm, S2 to 125–249 µm, S3 to 250–399 µm, S4 to 400–599 µm, S5 to 600–799 µm, and S6 > 800 µm.

Only the powders from sieves S2 (125 < X < 249 µm), S4 (400 < X < 599 µm) and S5 (600 < X < 799 µm) were used to brew of the beverages. S2 particles were the finest, while S4 and S5 were larger, and more comparable to the particle size typically used in French Press extraction.

The experiment was designed to highlight differences between grinding methods in terms of the physicochemical characteristics of brewed coffee, and its aromatic aspects.

The grinding phase was the factor tested in the experimental plan, for this reason, standardized procedures were used to produce the beverage, changing only the grind conditions. Five replicates were performed for each condition. The sequence of coffee preparation was entirely randomized. Thus, on the overall, seven powder distributions were tested. Three corresponded to the three different grinder settings (G2, G6, G11), one consisting of the recombination of G2 + G6 + G11, and the last three distributions corresponding to the sieved powders (S2, S4, S5).

The same mass of coffee powder was used to prepare the coffee beverages. Thus, 25 g of ground coffee and 250 g at 95 °C of hot water were mixed in a brewer fitted with a mesh plunger (a French Press). The beverage was brewed for 5 min, then the piston was pushed to stop the coffee ground at the bottom of the vessel, following the SCAA procedure [21]. With the mesh inside the plunger beverage was immediately separated and filtered after the plunger is pushed down. As water plays a crucial role in coffee quality, the samples were prepared using a commercial brand of mineral water (Acqua Levissima, TDS 80 mg/L, calcium hardness 57 mg/L, alkalinity 32 mg/L, pH 7.8).

Physicochemical analyses

Physical analyses

All samples were brought to 20 °C before selected parameters were analysed and evaluated. A portable digital multiparameter instrument (PH7200, ORMA srl Via Catone, 19–20158 Milano, Italy) was used to determine pH and conductivity. Total dissolved solids (TDS) were determined with a refractometer (VST LAB Coffee Refractometer, USA). The dissolved solids concentration has been calculated as a total percentage of ground dissolved in the coffee beverage: Total Coffee Brewed (g) * TDS % / powder used (g).

Analyses of caffeine and chlorogenic acids (CGAs)

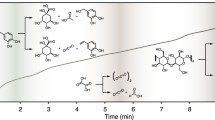

Coffee samples were diluted 1:10 with distilled water, and then centrifuged at 16,900×g for 5 min before HPLC–DAD analysis. The HPLC determination was realized by an Agilent HP 1100 system equipped with a column heater module, an autosampler, and a quaternary pump coupled to a diode array detector (DAD) all from Agilent Technologies (Palo Alto, CA, USA). A 150 mm × 3 mm i.d., 2.7 μm Poroshell 120, ECC18 column (Agilent Technologies) was used, equipped with a precolumn of the same phase, and maintained at room temperature. Analysis conditions were the same as reported in previous work [22]; elution was performed at a flow rate of 0.4 mL/min using water at pH 3.2 by formic acid and acetonitrile and applied a multistep linear solvent gradient. Chromatograms were registered at 278 for caffeine and 330 nm for the CGAs. Caffeine and CGAs were identified by comparing their retention times and UV–Vis spectra to those of the respective standards when possible, otherwise with our previous data. CGAs were evaluated by HPLC–DAD using, for 5-O-caffeoylquinic acid (purity 99%) (Extrasynthèse, Genay, France), a six-point calibration curve at 330 nm (0–1.509 μg; R2 = 0.9991), while caffeine content was measured using a six-point calibration curve (purity 95%) at 278 nm (0–0.7575 μg; R2 = 0.9993). Quantitative data were expressed as mg/mL of coffee.

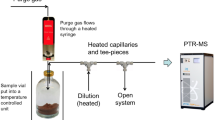

HS–SPME–GC–MS analysis

The concentration of a number of volatile organic compounds (VOCs) was defined by HS–SPME–GC–MS, as described in other work [23]. An Agilent 7820 gas chromatograph, equipped with a 5977 MSD detector with electron ionization (Agilent, Santa Clara, CA, USA) was used for the determination. A DVB/CAR/PDMS 50/30 μm-2 cm fibre (Supelco, Sigma, Darmstadt, Germany) was used for headspace sampling. The system was provided with a Gerstel MPS2 XT (Gerstel GmbH & Co, KG, Germany) autosampler for SPME analysis. Analyses were carried out by pipetting 5 mL of each specimen, 50 μL of an internal standard mixture (ISTD MIX), and 2 g of sodium chloride into 20 mL screw-cap vials fitted with a PTFE/silicone septum.

VOC determination was performed by a comparison of retention times and mass spectra with those of the standard added for calibration. To create the calibration lines, a standard solution was prepared, containing the 17 selected analytes. Every compound was diluted in a water/acetone solution 50/50 to a concentration of 10,000 mg/L (1:100 dilution), parts of these solution were added in a 50 mL volumetric flask and brought to volume with distilled water so as to obtain the maximum level of concentration on the calibration scale. All other calibration levels were obtained by dilution (2, 4, 8, 16, 32 times) of this STD MIX solution. Finally, 5 mL of each calibration level was pipetted into 20 mL headspace vials and analysed.

Statistical analysis

The analysis of variance (ANOVA) was applied to confront the different samples. The factors were considered significantly different at p < 0.05. The post hoc Tukey honestly significant difference (HSD) test was applied to assess differences among mean values of variables where appropriate with a level of significance of 95%. The statistical analyses were conducted with the R software (version 3.4.0 for Windows).

Principal component analysis (PCA) was applied using XLSTAT 2020, to describe the effect of granulometric distribution on the physical and chemical properties of the coffee beverage.

Results and discussion

Physical analyses

The physical characterization of the coffee beverages produced using the different preparation methods is shown in Table 2. This analysis highlighted significant differences between grinding grades for TDS %, extraction %, conductivity and pH (p < 0.001).

Beginning with TDS %, highest values were found for beverages prepared using powder obtained directly after grinding, while values were lowest for all beverages obtained with sieved powder. The highest value was registered for the G2 sample, followed by our new method to prepare coffee powder puck, that is composed of equal parts of G2 + G6 + G11. TDS were lowest in samples obtained using the homogeneous/ sieved finest powder (particle size ranging between 125 and 249 um).

Averagely the TDS% reported in previous research [24] related to the French press extraction system was around 1.4%, very similar value is observed for the samples obtained with G6 and G11 grinding mode, that represent the grinding grade more similar to the French press standard. TDS % directly correlates with coffee strength: high values are consistent with a strong brew and reflect the extraction level. It is well known that TDS % affects the sensory property described as ‘body’ [4]; it seems to be related to the coffee/ water ratio [9], and the brewing procedure [25].

Although the literature contains no data related to TDS, this factor is employed by baristas, and is recommended by SCAA to assess the correct degree of extraction.

Regarding extraction %, the same trend was observed. The highest value was found for the G2 sample (21.4 ± 0.9%), followed by the mixed grind (G2 + G6 + G11), while the lowest value was for S2. Percentages were similar for S4 and S5, but always low. SCAA guidelines state that extraction % should be in the range 14–23%. Averagely the extraction % reported in previous research [24] related to the French press extraction system was around 18%. Our data are generally consistent with this range, except for coffees produced with the sieved powder (S2, S4 and S5), which appear to be under-extracted. Data for TDS and extraction % were confirmed by measurements of conductivity. In fact, results were closely related. Electrical conductivity depends upon the concentration, mutual interactions and mobility of ions [26]; here again, values were highest for G2 and G2 + G6 + G11 samples, and the lowest value was observed for S2.

The initial analysis of these parameters revealed a significant effect of particle size/ composition. In particular, there was a clear effect of sieving; homogenous particle size classes appear to have a reduced capability to extract available solutes. Unsieved powders obtained by conventional grinding were better able to extract solutes, as was the mixed coffee powder puck, (G2 + G6 + G11), which represent the most heterogeneous powder tested in terms of both composition and particle size.

Significant differences were also observed for pH values (p < 0.001). G2 and G6 were the most acidic brews (pH 5.6), and acidity decreased (pH increased) up to a value of 6.8 for sample S2.

Evaluation of caffeine and CGAs

Figure 1 shows that there was a significant difference in caffeine and CGAs concentrations for the tested grinding methods (p ≤ 0.05). For caffeine, values were highest for G2 (1.23 ± 0.01), while lowest concentrations were observed for S2 (0.49 ± 0.05). Significant differences were also found between these two samples and other grinding grades. Concentrations were similar in G6 and G11 samples (0.77 ± 0.01, 0.85 ± 0.08, respectively) and the mixed grind (G2 + G6 + G11). Although the mixed sample contained about 33% of each grinding grade, the caffeine concentration was more similar to G6 or G11 than G2. Intermediate values were registered for S4 and S5.

Caffeine content (mg/ mL of extract) and the sum of CGAs. Letters indicate statistically significant differences between particle size classes. Capital letters indicate differences in CGAs, while lowercase letters indicate differences in caffeine. Error bars correspond to the standard deviation (95%)

Several studies have indicated that caffeine content ranges from 2.4 to 4.5 mg/mL for EC (25 mL), from 0.4 to 1.4 mg/mL for American or filtered methods (200 mL), from 0.2 to 0.5 for French Press or Plunger (100 mL), and from 0.7 to 5.4 mg/mL for Moka (30 mL) [25, 27]. A recent study [13] investigated Arabica coffee extracted with the French Press system, and found values ranging from 1.03 ± 0.04 to 1.09 ± 0.06 mg/mL of caffeine, depending on the degree of roasting. However, a research [24] obtained significantly lower results for Arabica coffee (0.52 ± 0.06 mg/mL). The main differences in the latter two studies were related to the origin of the coffee and the grinding grade.

In our study, grinding grade G2 corresponds to the particle distribution reported in Table 1. Notably, in this case, particle size is more widely distributed across the different size classes, and more caffeine and CGAs were extracted. Our result is in agreement with the findings of other studies [28, 15], which found that caffeine content increased significantly as particle size decreased. The latter authors concluded that smaller particle size was consistent with a significant increase in caffeine content. Our study confirms this observation for finely ground powder that is used directly after grinding. Conversely, homogeneous, sieved powder of the same grade results in lower overall extraction of compounds. This is especially true for S2 distribution. This occurrence is of difficult explanation. The authors can only suppose that there is a different repartition of bioactive compounds inside the coffee beans, and this could determine different concentrations of the same compounds in powders of different size.

Earlier work suggests that a plurimodal particle size distribution is optimal, as coarse particles establish a structure that ensures the correct flow of water through the cake, while finer particles facilitate the extraction of large amounts of emulsifiable soluble substances [12]. Our results partly confirmed this assumption, as best performance was obtained with the pluri-bimodal particle size, notably samples G2 and the recombined sample G2 + G6 + G11, where the highest concentrations of compounds were extracted.

A recent study observed that differences in brewing time were not great enough to be the cause of an up to twofold difference in caffeine content, and that it was more likely that other factors such as bean variety and grinding grade affected the final caffeine content [29]. Our experiment confirms the findings of other studies of espresso extraction [15, 18]. It confirms that it is possible to obtain different concentrations of caffeine in beverages made with the same coffee batch and the same standard extraction procedure, simply by modifying the grinding grade.

Volatile organic compounds

Coffee is mostly consumed for its flavour and aroma; these key attributes define the quality of the product. Over 1000 VOC have been identified in roasted coffee, although only around 5% may be responsible for the aroma, i.e., about 50 compounds [30, 31]. The main classes of relevant compounds are furans, pyrazines, aldehydes and ketones [22, 32]. Table 3 reports the concentration of each compound evaluated in our study, and shows that furans and ketones were most prevalent. This finding is in accordance with Cordoba et al. [33] and other studies [31, 34]. Furans are responsible for a malty and sweet roasted aroma, with a relatively high sensory threshold compared to other volatile groups found in coffee [35, 36]. Furan concentrations were highest in our G6 grind, while values were lowest for beverages produced with sieved powder.

According to López-Galilea [32], ketones are one of the most abundant compounds in filtered coffee, and have been described as having buttery, caramel-like, musty, mushroom-like or fruity odour notes. Three ketones were identified in our samples (2,3-pentanedione, 2,3-butanedione and 2-butanone), but no difference was observed in their concentrations as a function of particle size. The exception was 2-butanone, where concentrations were higher for samples obtained with coarse-ground powder.

Two aldehydes were identified in our samples; these compounds have been related to chocolate and malty odours in coffee [37]. Concentrations were highest for 2-methylbutanal (564.23 µg/L), but no statistically significant differences were observed between samples. Pyrazines were also detected in our samples. These compounds have been described as having nutty, earthy, roasty and green aromas [33], and are reported to be most noticeable at higher serving temperatures [32]. Our analyses identified that the total content of these compounds ranged from 1060 to 1500 µg/L, and those concentrations varied significantly among the various particle size classes (Table 3). Pyrazine concentrations were highest in samples obtained with conventional ground powder used directly after grinding (and, thus, with a bimodal distribution). Lower concentrations were registered for beverages obtained with homogenous, sieved powders (S2, S4, S5).

Pyrroles are another VOC class found in coffee beverages. Flament [38] describes them as furan degradation products and amino acid derivatives. Our experiment identified different trends. The concentration of 1-furfurylpyrrole was highest in samples obtained with a homogenous distribution and was lowest for unsieved samples with a bimodal distribution. Although this could suggest that a main effect could be attributed to the type of distribution (homogenous or bimodal) rather than particle size, in fact, no significant differences emerged between the same type of distribution (homogenous or bimodal).

Phenols are said to be responsible for the smoky phenolic odour notes in roasted coffee [39]. In our experiment, phenols followed the same trend as pyrazines—concentrations were highest in samples produced with the bimodal distribution.

To summarise our results, the particle distribution (homogenous or bimodal) affected the VOC composition of coffee for some classes of compounds. On one hand, the analysis of grinding grades found that coffee obtained with samples ground at G6 (used without sieving operation) were richer in VOCs. On the other hand, sieved coffee composed by the finer powder (S2) was poorest in VOCs.

The decrease of volatile compounds during coffee grinding was expected because as reported in other research the crushed of the inside structures of the beans could consent a higher release of the residual levels of volatile compounds [40].

Moreover, based on the previous studies, [18, 19] a greatest impact concerning the chemical compounds concentration and VOCs is imputable to the roasting step, thus the differences emerged could be due both to the different internal distribution of compounds and both the non-homogenous roasting grade between inside and outside part of the bean. The presence of these variables certainly has implications on the quality of the grinding, but currently is not clear which part of the coffee bean to associate a specific granulometry of the powder, precisely because grinding is a very hard process to control.

Correlations between parameters and samples

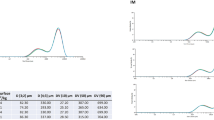

A PCA was applied to summarize differences related to the physical and chemical parameters of the different samples. The outcome is shown in Fig. 2, which summarises the contribution of VOCs, caffeine, CGAs and physicochemical properties to coffee sample characteristics, as a function of granulometry and the type of distribution (homogenous or bimodal). Our analysis confirmed that 79.05% of total variance in the original dataset was explained by the first (61.9%) and second (17.2%) principal components.

Figure 2 is a useful approximation of the relationships between variables. The angle between vectors approximates the correlation between variables. A small angle indicates variables that are positively correlated, an angle of 90° indicates that they are not correlated, and an angle close to 180° indicates a negative correlation (see, for example, caffeine and CGA concentration, or CGA concentration and TDS).

Multivariate analyses identified different groups of samples. Beverages with the smallest bimodal particle size distribution (G2) lie on the right-hand side of Fig. 2, while beverages with the smallest homogenous particle size (S2) lie on the left-hand side. This result confirmed the other findings of our study, namely that, while in general, the finest powder results in better solute extraction, the fine-grained bimodal grind (G2) seems to be richer in bioactive compounds and have better physical properties than beverages obtained with a homogenous fine-grained powder (S2), when both beverages are extracted in the same manner. Plots for the mixed coffee powder puck samples, (G2 + G6 + G11) lie close to those for G2. Samples located on the right-hand side of the plot are characterized by higher values of bioactive compounds, TDS %, the sum of CGAs, extraction %, and conductivity. However, it should be noted that these samples also lie closer to G11 samples. We can, therefore, conclude that their performance lies somewhere between samples with a classical bimodal distribution, even though they themselves do not have this distribution. It could be said that they have a multimodal distribution, as a result of the three grinding grades.

While all of the sieved samples lie on the left-hand side of the PCA, S2 is somewhat different, and closely correlated to the pH measurement. All of these variables are explained by the first component of the PCA plot. The second component is explained by the total VOC concentration, and here samples G6, G11, and S4 are characterized by higher values. Compared to G2, G6 and G11 had a higher contribution of S4 particles, and this could explain their similarity. Hence, the PCA analysis was of particular interest, since it allowed us to identify the variables that resulted in differences between the produced coffee.

Conclusions

This study confirmed that granulometry can influence the physicochemical properties of a coffee beverage. In fact, the results showed that bioactive and volatile compounds are released differently in the beverages depending on the specific particle size.

Our results indicate that a homogeneous grind (mono-dimensional powder) results in a lack of bioactive compounds, and low levels of other chemical properties that characterize the coffee beverage. In particular, the finest homogeneous grind (obtained by sieving), which could be expected to have maximum extraction capacity, proved to be the least powerful from an extractive point of view. On the other hand, more heterogeneous grinds, which included varying percentages of granulometries, were found to be richer in VOC and bioactive compounds.

The results have two important implications. The first concerns the superior extractive power of powder with a bimodal/plurimodal distribution and, therefore, a more heterogeneous particle size. The second concerns the key influence of the fine-grained fraction in the extraction process, which has a greater impact in conditions of granulometric variability than in the homogenous grind condition.

In conclusion, our study confirms that the grind plays a key role in producing well-extracted coffee and, therefore, in making the most of the qualitative potential inherent in the roasted bean. Furthermore, the correct choice of the degree of grinding can improve the management of the raw material and obtain a coffee that is richer in selected compounds, as a function of the desired beverage. Considering the results obtained a good compromise to highlight the bioactive characteristics and the aromatic aspects of the beverages, could be achieved using the powder distribution G2 + G6 + G11, which include more levels of grinding and, therefore, a greater particle size distribution.

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

Ballesteros LF, Teixeira JA, Mussatto SI (2014) Chemical, functional, and structural properties of spent coffee grounds and coffee silverskin. Food Bioprocess Technol 7:3493–3503. https://doi.org/10.1007/s11947-014-1349-z

Spiro M (1993) Modelling the aqueous extraction of soluble substances from ground roast coffee. J Sci Food Agric 61:371–372. https://doi.org/10.1002/JSFA.2740610314

Derossi A, Ricci I, Caporizzi R, Fiore A, Severini C (2018) How grinding level and brewing method (Espresso, American, Turkish) could affect the antioxidant activity and bioactive compounds in a coffee cup. J Sci Food Agric. https://doi.org/10.1002/jsfa.8826

Gloess AN, Schönbächler B, Klopprogge B et al (2013) Comparison of nine common coffee extraction methods: instrumental and sensory analysis. Eur Food Res Technol 236:607–627. https://doi.org/10.1007/s00217-013-1917-x

Andueza S, Maeztu L, Pascual L, Ibáñez C, de Paz Peña M, Cid C (2003) Influence of extraction temperature on the final quality of espresso coffee. J Sci Food Agric 83:240–248

Benković M, Srečec S, Špoljarić I et al (2013) Flow properties of commonly used food powders and their mixtures. Food Bioprocess Technol 6:2525–2537. https://doi.org/10.1007/s11947-012-0925-3

Benković M, Belščak-Cvitanović A, Komes D, Bauman I (2013) Physical properties of non-agglomerated cocoa drink powder mixtures containing various types of sugar and sweetener. Food Bioprocess Technol 6:1044–1058. https://doi.org/10.1007/s11947-011-0742-0

Wang X, Lim LT (2014) Effect of roasting conditions on carbon dioxide degassing behavior in coffee. Food Res Int 61:144–151

Andueza, S., Maeztu, L., Dean, B., De Peña, M.P., Bello, J., Cid C (2002) Influence of water pressure on the final quality of arabica espresso coffee. Application of multivariate analysis. J Agric Food Chem 50 (25):7426–7431

Masella P, Guerrini L, Spinelli S et al (2015) A new espresso brewing method. J Food Eng 146:204–208. https://doi.org/10.1016/j.jfoodeng.2014.09.001

Bilge G, Yurdakul M, Buzrul S, Bulut O (2022) Evaluation of the effect of pulsed electric field on coffee arabica beans. Food Bioprocess Technol 15:1073–1081. https://doi.org/10.1007/s11947-022-02802-7

Illy A, Viani R (1995) Espresso coffee: the chemistry of quality. Academic Press, London

Rao NZ, Fuller M, Grim MD (2020) Physiochemical characteristics of hot and cold brew coffee chemistry: the effects of roast level and brewing temperature on compound extraction. Foods 9:1–13. https://doi.org/10.3390/foods9070902

Severini C, Derossi A, Fiore AG et al (2016) How the variance of some extraction variables may affect the quality of espresso coffees served in coffee shops. J Sci Food Agric 96:3023–3031. https://doi.org/10.1002/jsfa.7472

Andueza S, Paz De Peña M, Cid C (2003) Chemical and sensorial characteristics of espresso coffee as affected by grinding and torrefacto roast. J Agric Food Chem 51:7034–7039. https://doi.org/10.1021/jf034628f

Uman E, Colonna-Dashwood M, Colonna-Dashwood L et al (2016) The effect of bean origin and temperature on grinding roasted coffee. Sci Rep 6:1–8. https://doi.org/10.1038/srep24483

Kuhn M, Lang S, Bezold F et al (2017) Time-resolved extraction of caffeine and trigonelline from fi nely-ground espresso coffee with varying particle sizes and tamping pressures. J Food Eng 206:37–47. https://doi.org/10.1016/j.jfoodeng.2017.03.002

De Vivo A, Tricarico MC, Sarghini F (2019) Espresso coffee design based on non-monotonic granulometric distribution of aromatic profile. Food Res Int 123:650–661. https://doi.org/10.1016/J.FOODRES.2019.05.027

Khamitova G, Angeloni S, Borsetta G et al (2020) Optimization of espresso coffee extraction through variation of particle sizes, perforated disk height and filter basket aimed at lowering the amount of ground coffee used. Food Chem 314:126220. https://doi.org/10.1016/j.foodchem.2020.126220

Angeloni G, Guerrini L, Masella P et al (2021) Test of an innovative method to prepare coffee powder puck, improving espresso extraction reliability. Eur Food Res Technol. https://doi.org/10.1007/s00217-021-03868-x

SCAA. Specialty Coffee Association of America (2016). http://www.scaa.org/PDF/resources/best-practices. Accessed 11 Dec 2021

Angeloni G, Masella P, Guerrini L et al (2019) Application of a screening design to recover phytochemicals from spent coffee grounds. Food Bioprod Process. https://doi.org/10.1016/j.fbp.2019.08.017

Bellumori M, Angeloni G, Guerrini L et al (2021) Effects of different stabilization techniques on the shelf life of cold brew coffee: chemical composition, flavor profile and microbiological analysis. LWT. https://doi.org/10.1016/j.lwt.2021.111043

Angeloni G, Guerrini L, Masella P et al (2019) What kind of coffee do you drink? An investigation on effects of eight different extraction methods. Food Res Int. https://doi.org/10.1016/j.foodres.2018.10.022

López-Galilea I, De Peña MP, Cid C (2007) Correlation of selected constituents with the total antioxidant capacity of coffee beverages: Influence of the brewing procedure. J Agric Food Chem 55:6110–6117. https://doi.org/10.1021/jf070779x

Sobolík V, Žitný R, Tovcigrecko V et al (2002) Viscosity and electrical conductivity of concentrated solutions of soluble coffee. J Food Eng 51:93–98. https://doi.org/10.1016/S0260-8774(01)00042-5

Caporaso N, Genovese A, Canela MD et al (2014) Neapolitan coffee brew chemical analysis in comparison to espresso, moka and American brews. Food Res Int 61:152–160. https://doi.org/10.1016/j.foodres.2014.01.020

Bell LN, Wetzel CR, Grand AN (1996) Caffeine content in coffee as influenced by grinding and brewing techniques. Food Res Int 29:785–789. https://doi.org/10.1016/S0963-9969(97)00002-1

Olechno E, Puścion-Jakubik A, Zujko ME, Socha K (2021) Influence of various factors on caffeine content in coffee brews. Foods 10(6):1208. https://doi.org/10.3390/foods10061208

Akiyama M, Murakami K, Ikeda M et al (2007) Analysis of the headspace volatiles of freshly brewed arabica coffee using solid-phase microextraction. J Food Sci. https://doi.org/10.1111/j.1750-3841.2007.00447.x

Toledo PRAB, Pezza L, Pezza HR, Toci AT (2016) Relationship between the different aspects related to coffee quality and their volatile compounds. Compr Rev Food Sci Food Saf 15:705–719. https://doi.org/10.1111/1541-4337.12205

López-Galilea I, Fournier N, Cid C, Guichard E (2006) Changes in headspace volatile concentrations of coffee brews caused by the roasting process and the brewing procedure. J Agric Food Chem 54:8560–8566. https://doi.org/10.1021/jf061178t

Cordoba N, Fernandez-Alduenda M, Moreno FL, Ruiz Y (2020) Coffee extraction: a review of parameters and their influence on the physicochemical characteristics and flavour of coffee brews. Trends Food Sci Technol 96:45–60. https://doi.org/10.1016/j.tifs.2019.12.004

Amanpour A, Selli S (2016) Differentiation of volatile profiles and odor activity values of turkish coffee and french press coffee. J Food Process Preserv 40:1116–1124. https://doi.org/10.1111/jfpp.12692

Petracco M (2008) Technology IV: beverage preparation: brewing trends for the new millennium. Coffee Recent Dev. https://doi.org/10.1002/9780470690499.ch7

Sunarharum WB, Williams DJ, Smyth HE (2014) Complexity of coffee flavor: a compositional and sensory perspective. Food Res Int 62:315–325. https://doi.org/10.1016/j.foodres.2014.02.030

Sánchez JA, Wellinger M, Gloess AN et al (2016) International journal of mass spectrometry extraction kinetics of coffee aroma compounds using a semi-automatic machine : on-line analysis by PTR-ToF-MS. Int J Mass Spectrom 401:22–30. https://doi.org/10.1016/j.ijms.2016.02.015

Flament I (2001) Coffee flavor chemistry. John Wiley & Sons.

Grosch W (1998) Reviews-flavor of coffee. A review. Nahrung-food 42(6):344–350

Opitz SEW, Goodman BA, Keller M et al (2017) Understanding the effects of roasting on antioxidant components of coffee brews by coupling on-line ABTS assay to high performance size exclusion chromatography. Phytochem Anal 28:106–114. https://doi.org/10.1002/PCA.2661

Acknowledgements

The authors would like to thank Mr. Lucian Trapanese of the D612 coffee roastery (Florence, Italy) for providing the ground coffee used in this study. Thanks also to Simone Niccolai for his contribution. This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Funding

Open access funding provided by Università degli Studi di Firenze within the CRUI-CARE Agreement. This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

AG: conceptualization, formal analysis, investigation, data curation, writing—original draft, writing—review and editing. PM: conceptualization, methodology, formal analysis, investigation, data curation, writing—original draft, review and editing. AS: formal analysis, investigation, data curation. lorenzo guerrini: investigation. ferdinando corti: formal analysis, investigation. MB: formal analysis, data curation. luca calamai: methodology, data curation. MI: investigation, data curation. AP: conceptualization, resources, writing—review and editing, data curation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Angeloni, G., Masella, P., Spadi, A. et al. Using ground coffee particle size and distribution to remodel beverage properties. Eur Food Res Technol 249, 1247–1256 (2023). https://doi.org/10.1007/s00217-023-04210-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04210-3