Abstract

The main objective of the present study was to determine the effect of the distillation technique: (i) fractional column distillation (FCD), (ii) copper alembic distillation (CAD), and (iii) home distillation (HD) on the aroma profile of the distilled spirit “tsipouro”. Volatile compounds were identified and semi-quantified in all above fractions for comparison purposes using Solid Phase Micro-extraction–Gas chromatography/Mass Spectrometry (SPME–GC/MS). Τhe richest (p < 0.05) distillate in volatile compounds was that of the FCD, with a total concentration of 768.38 mg/L followed by the HD (577.79 mg/L) and CAD (315.30 mg/L). The concentrations of the volatiles determined (alcohols, aldehydes, ketones, acetals, esters, organic acids, terpenes, hydrocarbons, and heterocyclic compounds) were found to be similar to those of other Greek and European distilled marc spirits. Ethanol and total volatile compound content were within limits set by Greek and EU legislation. Methanol, a toxic compound of grape marc distillates, was determined only in the entire product of CAD 1st distillation (19.35 mg/L) and the “head + tail” fraction of the CAD 2nd distillation (12.82 mg/L) in amounts well below the EU legal limit of 1000 g/hL of absolute alcohol. A general reducing trend was noted in most volatile compound concentration proceeding from the 1st to the 2nd CAD distillation refining the flavor of tsipouro.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

“Tsipouro” is the Greek alcoholic beverage produced by distillation of the residue grape marc (grape skins, seeds, and stalks) resulting from the crushing of grapes for subsequent must separation. Grape marc is then stored for a period of 2–4 weeks during which it is fermented, usually, on its own [1]. Following this storage period, the grape marc is distilled in copper alembics in smaller or traditional distilleries or in fractional columns in larger, more modern distilleries [2]. In addition to commercial production, home-made tsipouro is produced by small scale vine growers using pilot scale traditional distillation equipment. The distillation procedure as well as the product of distillation are strictly controlled by Greek state authorities in terms of specific amount of time that vine growers are allowed to produce tsipouro and the specifications that the distillate should meet. Similar products in the Mediterranean basin include “grappa” in Italy, “orujo” in Spain, “zivania” in Cyprus, “bagaceira” in Portugal, “eau-de-vie de marc” in France, etc. [3]. All above European distillates have similar chemical composition and sensory properties. Factors which influence the sensory characteristics of distillates include: the raw material (grape variety used i.e. Muscat of Tyrnavos, Malagouzia, Roditis, Debina, etc.), grape ripeness, climatic conditions, date of harvest, viticultural practices, storage method of grape marc, yeast strain used, conditions of fermentation, specific distillation system used (CAD, FCD), and the distillate aging in wooden barrels (when this is practiced) [4,5,6,7]. In case of un-aged distillates, which is a more common practice, flavor compounds are those present in the grapes, those formed during fermentation and those generated during distillation through transformation processes enhanced by high temperatures and alcohol concentration. Also, the winemaking process adopted to obtain the grape marc strongly contributes to aromatic profile, e.g., mild processing conditions (temperature gradients, spirit flow rate) are the best to preserve the sensory properties of the raw material [8].

European Union regulation (EU) 2019/787 [9] has set guidelines on general production procedures including labeling and the protection of geographical indications for all marc distillates and has set common analytical composition limits. Presently, at European level, regarding Greece, the only four tsipouro distilled spirits registered as products of Protected Geographical Indication (PGI) are the tsipouro of Thessaly, Macedonia, Tyrnavos, and Crete known as “tsikoudia”. In addition, at Greek national level, the tsipouro of Mouzaki, Epirus, and Naousa have also been registered as PGI products. According to national Greek legislation [10], tsipouro or tsikoudia, without the addition of alcohol should have an alcohol content 35–86% v/v at 20 °C, a maximum methanol content of 1000 g/hL absolute ethanol, and a total concentration of volatile compounds excluding methanol and ethanol higher than 140 g/hL absolute ethanol.

Compounds responsible for the characteristic flavor of tsipouro include: alcohols, esters, acetals, aldehydes, ketones, terpenes, carboxylic acids, hydrocarbons, and heterocyclic compounds [11]. During slow distillation, the distillate is separated into three fractions: the initial fraction known as “head”, the second fraction known as “heart”, and the third fraction known as “tail”. The “head” is somewhat cloudy and contains undesirable odorous constituents, such as methanol, acetaldehyde, ethyl acetate, 2-butanol, acetic and butyric acids, and long chain fatty acid esters among others, and is usually discarded. The “heart” fraction is of commercial value but contains small amounts of methanol and therefore should be re-distilled. The “tail” fraction has similar properties to those of the “head” fraction and is either discarded or both “head” and “tail” fractions are combined and put back into a second distillation, to get all of the usable alcohol out and to produce a cleaner, finer aroma and taste distillate. The specific times when the distillation fraction cuts are made is still done on an empirical sensory basis according to the particular skills and experience of the distillers. The cut between “head” and “heart” products is typically made between 70 and 80% (v/v) ethanol, whereas the cut between “heart” and “tail” products is typically made between 35 and 50% (v/v) ethanol [12]. A major concern of grape marc distillate producers is that of the presence of methanol in the final product. Methanol is a toxic volatile constituent of fermented must or grape marc produced by the action of the enzyme pectinesterase on grape pectins. It is thus imperative that both distillate producers and state authorities control its concentration in commercial grape marc distillate products [3].

Based on the above, the main objective of the present study was to determine the effect of the distillation technique on the aroma profile of the distilled spirit tsipouro (“heart” fraction of FCD, CAD, and HD). A secondary objective was to determine the volatile profile of (i) the entire product of 1st CAD distillation, (ii) “head + tail” fraction of 2st CAD distillation, and (iii) “heart” fraction of 2nd CAD distillation in an effort to determine the evolution of volatiles during CAD distillation. To the best of our knowledge, both objectives have not been previously investigated in Greek tsipouro, this comprising the novelty of the study.

Materials and methods

Sample collection

Grapes of the Debina variety were used for the commercial production tsipouro in two different local plants: Distillery 1 using the CAD technique and Distillery 2 using the FCD technique, respectively, in the autumn of 2020. Furthermore, HD tsipouro prepared using the same grape variety but at pilot scale using traditional still equipment, was provided by a local vine grower. The CAD equipment consisted of a custom-made 1,200 L copper boiler, a copper still head connected to a copper swan neck, a copper condenser including an immersed coil, and a combustion chamber heated by an open flame using natural gas as fuel. Similarly, the home-made equipment consisted of a 55 L copper boiler, a copper still head connected to a copper swan neck, a steel barrel condenser including an immersed coil, and an open flame burner heated by a natural gas. The FCD equipment consisted of a custom-made 1300 L copper boiler, a copper fractional column including three ball trays, a reflux condenser, and a combustion chamber heated by an open flame using natural gas as fuel. All three distillations were batch processes. Τhe tsipouro flow rate during distillation was adjusted 15–25 mL/min. Actually, the only differences between the CAD and HD setups were (i) the size of the boiler pot, (ii) the specific cut-off points among, “head”, “heart”, and “tail” fractions which are based mainly on the experience of the distillation operator, and (iii) the specific flow rate of the tsipouro effluent always within the range 15–25 mL/min.

All three final distillates were diluted with deionized water to a strength of 42% v/v using an alcoholometer. All Debina, grape samples were collected from the same Zitsa area. Three samples of each distillate were collected for analysis. Debina is a protected designation of origin (PDO) white grape variety cultivated in the areas of Zitsa and Konitsa in Epirus (northwestern Greece). In addition to the above, the following samples were provided by Distillery 1 during the same time period: (i) the entire product of 1st CAD distillation, (ii) the “heart” fraction of 2nd CAD distillation, and (iii) the combined “head + tail” fraction of 2nd CAD distillation. All tsipouro samples analyzed were un-aged. Based on information provided by both distilleries, grape marc was stored in inox tanks of 30-ton capacity at ambient temperature for ca. 3 weeks to ferment by indigenous yeast flora. Grape marc is fermented at temperatures close to 20 °C to preserve the amounts of fermentation esters and limit the formation of excessive levels of fusel alcohols [13].

Semi-quantitative determination of volatile compounds using SPME–GC/MS

SPME of FCD, CAD, and HD distillation fractions

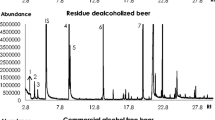

Five mL of sample diluted 1:1 (2.5 mL of sample + 2.5 mL of deionized water) along with 1 g of NaCl, 40 μL of internal standard: 4-methyl-2-pentanone (8 μg/L) and a micro-stirring bar were placed in a 20 mL glass vial and sealed with an aluminum crimp-cap as mentioned above. The vial was placed in a water bath thermostated at 40 °C and stirred at 600 rpm. After allowing 5 min for the sample to equilibrate, the needle of the SPME device (50/30 μm DVB/CAR/PDMS fiber, 50/30 μm, purchased from Supelco Co., Bellefonte, PA., USA) was inserted into the vial through the septum and the fiber was exposed to the headspace of the sample. The DVB/CAR/PDMS fiber was chosen because according to the literature, it combines the characteristics of three different stationary phases being able to adsorb a wide range of volatile compounds with different polarities, such esters, alcohols, aldehydes, ketones, terpenes, and better than other fibers. After 15 min of exposure, the fiber was transferred to the injection port of a gas chromatograph (Agilent Technologies 7890A GC System equipped with an Agilent Technologies 5975C MS System detector, Wilmington, DE, USA) and left in the GC injection port for 10 min for desorption of volatile compounds.

Chromatographic operational conditions were the same as above with the following temperature program used: The column (DB-5 MS column, 60 m × 0.32 mm × 1 μm purchased from J&W Scientific, Folsom, USA) was maintained initially at 40οC for 5 min, then heated to 200 °C at a rate of 8οC/min, and then heated to 260 °C at a rate of 15 °C/min where it was held at 260 °C for 2 min. All above conditions were the result of optimization carried out in preliminary experiments.

The identification of compounds was achieved using the Wiley 7, NIST 2005 (National Institute of Standards and Technology) mass spectral library (J. Wiley & Sons Ltd., West Sussex, England) [14]. For the determination of retention indices, a mixture of n-alkanes (C5–C7 and C8–C20) dissolved in n-hexane, was employed. The mixture was supplied by Fluka, (Buchs, Switzerland). The calculation was carried out for components eluting between n-pentane and n-eicosane. Concentrations were calculated using the following formula:

where Cx = concentration of the unknown compound, Ci = concentration of the internal standard solution, Areax = peak area of the unknown compound, and Areai = peak area of the internal standard solution); results were expressed as mg/L.

Determination of methanol using GC/MS

Samples analyzed for methanol content were: (i) the entire product of CAD 1st distillation, (ii) the “head + tail” fraction of CAD 2nd distillation, (iii) the “heart” fraction of CAD 2nd distillation, (iv) the “heart” fraction of FCD distillation, and (v) the “heart” fraction of HD distillation.

Methanol was extracted from samples as follows: 30 mL of sample along with 2 mL of CH2Cl2 and 1 g NaCl were placed in an Erlenmeyer flask of 100 mL capacity. The flask was placed in a water bath along with crushed ice for 120 min under constant agitation. The solution was then transferred into a separatory funnel where the two phases were separated. The aqueous phase was discarded and Na2SO4 was added to the organic phase to remove any traces of water. The extract was transferred to a glass vial of 5 mL capacity and sealed with a screw type cap. One microliter of the extract was introduced to the injection port of the gas chromatograph. Above conditions were the result of optimization carried out in preliminary experiments.

Standard solutions with a methanol concentration of 2.5, 5, 10, and 20 ppm in dichloromethane were used to construct a standard curve for methanol.

The same GC/MS system was used for the determination of methanol. The column used was a BP20 30 m × 0.32 mm i.d. × 0.25 μm thickness (SGE—Trajan, Victoria, Australia). The column was maintained initially at 40 °C for 5 min, heated to 90οC at a rate of 10οC /min, and then heated to 260 °C at a rate of 35 °C/min where it was held at 260 °C for 2 min. Injection port temperature was 260 °C, transfer line temperature was 260 °C, split ratio was 10:1, and carrier gas flow rate was 1.5 mL/min. MS conditions were as follows: source temperature 230 °C; quadrupole temperature: 150 °C; acquisition was performed in electron impact (EI) mode and the mass/charge was (m/z): 29–300. All determinations were carried out in triplicate (n = 3). Above chromatographic conditions were the result of optimization.

Statistical analysis

Triplicate samples were collected from the two distillation plants and the home distiller. All determinations on each sample were carried out in duplicate (n = 3 × 2 = 6). ANOVA was applied to the results using SPSS software [15]. Tukey’s test was used to assess differences between means and the significance of differences was considered at the level of p < 0.05.

Results and discussion

Effect of distillation technique

The volatile compounds of tsipouro as a function of distillation technique (FCD, CAD, and HD) are given in Table 1 as mean (mg/L) ± standard deviation. A total of 44 volatile compounds were identified and semi-quantified in tsipouro samples. Thirty-four compounds (5 alcohols, 16 esters, 3 aldehydes/ketones/acetals, 3 terpenes, 3 hydrocarbons, and 4 heterocyclic compounds) were determined in the “heart” fraction of FCD; 20 compounds (6 alcohols, 9 esters, 1 ketone, 1 terpene, 2 hydrocarbons, and 1 heterocyclic compound) in the “heart” fraction (2nd distillation) of CAD and 31 compounds (6 alcohols, 17 esters, 1 aldehyde, 1 ketone, 3 terpenes, 2 hydrocarbons, and 1 heterocyclic compound) in the “heart” fraction of HD. The total amount of volatiles was 768.38 mg/L for the FCD distillate, 315.30 mg/L for the CAD distillate, and 577.79 mg/L for the HD distillate. Such values meet the requirements of EU regulation 2019/787 [9] for volatile substances in grape marc spirits (> 140 g/hL of absolute alcohol). It is clear that the “heart” fraction of FCD was the richest in aroma compared to the other two distillates. With the exception of ethanol, esters constituted the group of compounds with the highest concentration in tsipouro, followed by alcohols, both major contributors to the particular aroma of distilled spirits. This holds for both FCD and HD, while the reverse holds for CAD, where alcohols showed a higher contribution to the aromatic character of tsipouro than esters [5]. The two main ester groups identified were fatty acid and acetate esters. The most abundant esters in all three distillates were: ethyl decanoate, ethyl octanoate, ethyl acetate, and ethyl hexanoate. Of these, the amount of ethyl octanoate (39.47–165.97 mg/L) and ethyl decanoate (23.57–219.09 mg/L) was affected (p < 0.05) by method of distillation with FCD showing the highest concentration followed by CAD and HD. Ethyl hexanoate (10.31–25.68 mg/L) recorded similar values (p > 0.05) for FCD and HD, which were higher (p < 0.05) than CAD.

Garcia-Martin et al. [16] reported ethyl octanoate, ethyl decanoate, ethyl dodecanoate, and ethyl lactate to be the most abundant ethyl esters in Spanish orujo spirit. However, quantified amounts of these compounds were considerably lower than those of the present study. A similar trend was reported for Italian grappa by Cortes et al. [2] and Paolini et al. [17]. Likewise, Soufleros et al. [11] reported very low concentrations of ethyl esters in Greek tsipouro and tsikoudia. Ethyl lactate was found at low concentrations only in the product of CAD and HD (0.52–0.55 mg/L). This ester is considered as a “tail” product according to Silva and Malcata [18], indicating that FCD is more successful in separating “heart” from “tail” products compared to CAD and HD. Concentrations of ethyl acetate recorded in the present study (48.71–55.12 mg/L) with no significant differences (p > 0.05) among the three tsipouro samples were lower than those recorded for grappa, bagaceira, and orujo [12, 12, 12] but similar to those of tsipouro and zivania distillates [19]. Apostolopoulou et al. [20] determined the flavor profile of tsipouro samples from various grape varieties and reported ethyl acetate to be the main ester identified followed by ethyl lactate found at considerably lower concentration than ethyl acetate. Ethyl acetate has a significant effect on the sensory characteristics of wines and distillates. Increased ethyl acetate concentrations (> 150 mg/L) are indicative of prolonged storage of the raw material and probable acetic bacterial spoilage. However, lower concentrations contribute with pleasant, “fruity” notes in wine and distilled spirits [21]. Finally, 3-methyl butyl acetate (isoamyl acetate) (4.89–6.18 mg/L) was semi-quantified in all three distillates without significant differences (p > 0.05) among the three.

Esters contribute positively to the flavor of wine and distilled spirits being responsible for fruity and floral odors [22]. However, members of this group, i.e., ethyl acetate, ethyl lactate, and ethyl succinate, at higher concentrations, add an acidic character lowering the quality of distillates [11, 13]. Ethyl hexanoate, ethyl octanoate, and ethyl decanoate contribute to a fine aromatic character to the distillate [23].

Among alcohols, ethanol was the main alcohol in all three “heart” fractions of tsipouro samples at a concentration of 42% v/v. Prior to dilution with water, the alcoholic strength of the “heart” fraction of the FCD distillate was 78.0% v/v; of the respective fraction of the CAD distillate (2nd distillation) was 70.1% v/v and of the HD distillate was 65.5% v/v.

Apostolopoulou et al. [20] reported an ethanol concentration for tsipouro produced using CAD and HD equal to 42.4 and 42.9% v/v, respectively. This is in close agreement to ethanol values in the present work. Cortes et al. [24] reported ethanol concentrations in orujo distilled spirits equal to 63.8 and 52.7% v/v in industrially and home-made product, respectively. Products with such a high alcohol content require dilution with water before they reach the market [25]. It has been shown that alcohol content depends on the grape variety, fermentation conditions, and distillation technique [16]. Apart from ethanol, the predominant alcohols in all three “heart” fraction of distillates were 3-methyl-1-butanol and 2-methyl-1-butanol (amyl alcohols). Both these alcohols quantitatively comprise most of the higher alcohols and are considered predictors of the sensory quality of distilled spirits. 3-methyl-1-butanol ranged between 91.85 and 143.55 mg/L and 2-methyl-1-butanol between 35.57 and 56.82 mg/L in the three distillates. Both alcohols recorded a significantly higher concentration (p < 0.05) in the product of FCD compared to CAD with no significant differences (p > 0.05) recorded between the product of FCD and HD. Concentrations for both alcohols in decreasing order were: HD ≅ FCD > CAD. Cortes et al. [2] reported higher 2-methyl-1-butanol concentrations (200–281 mg/L) for grappa samples and (73.7–234 mg/L) for orujo samples. Respective range values for 3-methyl-1-butanol were 693–1049 and 254–847 mg/L. Likewise, Soufleros et al. [11] reported values in the same range (20.52–138.28 mg/L) for 2-methyl-1-butanol in experimental tsipouro and 10.26–68.21 mg/L in tsikoudia samples. Respective values for 3-methyl-1-butanol were 86.51–264.44 mg/L in tsipouro and 81.94–387.54 mg/L in tsikoudia samples. 1-Propanol was present in all three distillates (3.63–5.59 mg/L) without statistically significant differences (p > 0.05) among them. Cortes et al. [2] reported a significantly higher concentration (p < 0.05) 123–247 mg/L for 1-propanol in grappa and 124–323 mg/L in orujo distilled spirits. High concentrations of 1-propanol are usually indicative of microbiological spoilage of the raw material (grape marc) prior to distillation [26], something not observed in the present study. Cortes et al. [24] reported concentrations for 1-propanol of 146 and 304 mg/L for artisanal and industrially produced orujo, respectively. Finally, Apostolopoulou et al. [20] reported 1-propanol concentrations 15.7–22.7 mg/L for tsipouro samples produced in Epirus, Greece. 1-butanol (22.75 mg/L) was found only in the FCD tsipouro. Silva and Malcata [12] reported a 1-butanol concentration of 61.6 mg/L in marc distillates, significantly higher than that reported in the present study, while Cortes et al. [27] reported a value of 26.8 mg/L for the distilled spirit Aguardiente, similar to that in the present study. Isobutyl alcohol (2-methyl-1-propanol) was identified only in the HD and CAD tsipouro (20.96–34.82 mg/L) recording higher concentration values (p < 0.05) in the former. Silva and Malcata [12] reported isobutyl alcohol concentrations between 280 and 1310 mg/L for marc distillates of various grape varieties. Cortes et al. [24] reported concentrations of 612 mg/L and 328 mg/L for 2-methyl-1-propanol in industrial marc distillate and home-made distillate, respectively, suggesting that the latter was of higher quality, since its presence is the result of microbial contamination of the grape marc raw material. Soufleros et al. [11] reported isobutyl alcohol concentrations 22.52–87.47 mg/L for experimental tsipouro and 10.26–70.37 mg/L for tsikoudia. 1-Hexanol was identified in all three tsipouro “heart” fraction distillates (6.43–8.99 mg/L) recording significantly higher concentrations (p < 0.05) in the “heart” fraction of CAD compared to the respective FCD and HD. At concentrations up to 5 mg/L 1-hexanol contributes positively to the aroma of distillates while at concentrations higher than 200 mg/L it negatively affects the distillate aroma. Soufleros and Bertrand [28] reported concentrations of 1-hexanol between 16 and 43 mg/L for tsipouro produced by CAD. Apostolopoulou et al. [20] reported 1-hexanol concentrations 2.7–3.5 mg/L for bottled and home-made tsipouro produced in Epirus, Greece. Finally, 3-hexen-1-ol was determined in very small amounts only in the “heart” fraction of HD distillate. Similarly, 3-hexen-1-ol was identified at low concentrations in orujo samples from Galicia [29] and in experimental tsipouro and tsikoudia [11]. The lower limit for the content of higher alcohols, ethyl esters, and acetates for grape marc spirits is 140 g/hL of absolute ethanol according to EU regulation 2019/787 [9].

Among aldehydes, large concentrations of acetaldehyde are responsible for flat aroma perception [30]. The sum of acetaldehyde and acetal (1,1-diethoxyethane) comprise more than 90% of aldehydes in grape marc distillates [12]. Acetaldehyde is highly volatile and possesses a pungent irritating odor, but in dilute solutions, it gives a pleasant fruity aroma [31]. It is toxic to humans, especially affecting the cardiac muscle and liver cells [32]. The upper limit set by the EU in distilled spirits is 500 g/hl. As a highly volatile compound, it distills off during the initial stages (‘head’) of the distillation process and is usually discarded [33]. Acetaldehyde was not detected in any of the three distillates. Acetal (1.1-diethoxy-ethane) was determined only in the FCD tsipouro at a concentration of 13.05 mg/L. 1.1-Diethoxy-ethane contributes positively to the fruity aroma of distilled spirits [34]. 1.1-Diethoxy-ethane concentrations 0.41–16.1 mg/L for grappa and 0.0–15.9 mg/L in orujo samples were reported by Cortes et al. [2], 2.77–4.32 mg/L in orujo samples [29], and 8.6–16.6 mg/L and in white and red grape marc [2]. 1,6-Dimethyl-4-heptanone, the only ketone identified in all three distillates, is known for its sweet mint aroma. Its concentration ranged between 1.60 and 2.41 mg/L with non-significant differences (p > 0.05) between FCD and CAD.

At this point, we should note that this work provides a non-exhaustive list of volatiles isolated from a complex matrix such as tsipouro distillate. It is possible that compounds, such as acetaldehyde, present in most grape marc distillates was not identified in the present study. This could be owed to the specific SPME fiber/GC column combination. However, in other relevant studies (Galano et al. [35] on Grappa distilled spirit and Garcia-Martin et al. [16] on orujo distilled spirit), acetaldehyde was also not determined. The same holds for furfural which was not determined in any of the tsipouro samples in agreement with Soufleros et al. [11], Garcia-Martin et al. [16], Galano et al. [35], and Lopez-Vazquez et al. [29]. Regarding the absence of furfural in tsipouro samples analyzed, according to the literature, the concentration of this compound depends, to a large extent, on the degree of toasting of the wood barrels used in the aging process as well as from the time of aging of the spirit (Giannetti et al. [8]). As stated in the Materials and methods section, all tsipouro samples analyzed in the present study were un-aged, a fact partly justifying the absence of furfural in the volatile profile of tsipouro.

Terpenes are another very important group of volatiles contributing to the flavor and aroma of distilled spirits. Four terpenes were identified in distillates: Linalool, dl-limonene, β-myrcene, and the ethyl ether of geraniol. Of these, dl-limonene was the dominant terpene identified in the “heart” fraction of all three distillates in concentrations ranging between 0.80 and 30.84 mg/L. Statistically significant differences (p < 0.05) were recorded in dl-limonene content among all three distillates. Linalool was identified only in the product of FCD and HD. The geraniol ethyl ether was quantified only in the FCD product (1.25 mg/L). d-Limonene and linallol were determined in small amounts in grappa samples [35], while linallol and geraniol were determined in similar amounts in orujo distilled spirit [16].

Of the hydrocarbons, mesitylene (1, 3, 5-trimethylbenzene) and undecane were determined in the “heart” fraction of all three distillates, the former ranging between 12.69 and 18.08 mg/L and the latter ranging between 1.34 and 1.92 mg/L, both recording non-significant differences (p > 0.05) between FCD and CAD distillates. Mesitylene is known for its subtle sweet flavor with only minor contribution to the flavor of distilled spirits. 1,1,6-Trimethyl-1,2,3,4-tetrahydronaphthalene was identified only in the FCD distillate. Both compounds were quantified in very small amounts in grappa samples [35].

Finally, among heterocyclic compounds, vitispirane (2,10,10-trimethyl-6-methylidene-1-oxaspiro [4.5] dec-7-ene) was determined in the “heart” fraction of all three distillates at concentrations ranging between 2.68 and 9.10 mg/L with a significantly higher concentration (p < 0.05) being recorded in the FCD distillate compared to both CAD and HD distillates. Vitispirane has been identified in white and rose grape marc distillates [36].

In contrast to the above findings, Garcia-Martin et al. [16] reported no significant differences in levels of volatiles of orujo distilled spirits obtained from the Albarino grape variety, produced by alembic distillation or steam distillation. Likewise, Cortes et al. [24] and Arrieta-Garay et al. [37] found no differences in most volatile compounds between alembic and packed column pear distillates. On the other hand, Arrieta-Garay et al. [38] reported that copper alembic distillates could be differentiated from packed column distillates of orujo spirits based on the content of linear alcohols, linallol and 1-hexenol. Likewise, Garcıa-Llobodanin et al. [39] reported that the column-distilled pear spirits contained four times more esters and 20% more higher alcohols, than alembic spirits. Finally, according to Matias-Guiu et al. [40], the organoleptic quality of wine distillates depends on raw materials and the distillation process. Comparison between variable reflux packed column and alembic distillations showed that a reduction of the reflux rate at an early stage of the ‘heart’ cut produced a distillate heart sub-fraction with a higher concentration of terpenic compounds and lower levels of negative aroma compounds than alembic distillation.

The main differences between tsipouro FCD and CAD distillation techniques which can be used for the differentiation of the two can be summarized as follows:

-

(i)

The ethanol content of the FCD distillate was higher than that of the CAD distillate (78% v/v versus 70.1%).

-

(ii)

The FCD distillate had a higher linear alcohol content by approximately 21.6% compared to that of the CAD.

-

(iii)

The FCD distillate had a higher ester content by approximately 34.8% compared to CAD. More specifically, among the C6–C12 esters, ethyl hexanoate content was 2 × higher in FCD than the CAD distillate; ethyl octanoate content was 4 × higher in the FCD compared to the CAD, and ethyl decanoate was 9 × higher in the FCD compared to the CAD.

-

(iv)

The FCD distillate had a higher terpene content by approximately 24 × compared to the respective CAD. More specifically, the DL-limonene and linalool content of the CD distillate was 16.30 and 1.82 mg/L, respectively, while both volatiles were not detected in the CAD distillate.

-

(v)

The vitispirane content of the FCD distillate was approximately 5 × higher than that of the CAD distillate.

The main differences in linear alcohols and fatty acid esters in the two distillates are owed to the fact that these compounds show a somewhat different behavior depending on the alcohol content of tsipouro. They will distill following their relationship with alcohol rather than their boiling point [5]. In agreement with results of the present study, working with orujo spirit, Arrieta-Garay et al. [38] reported an ethanol content increase by 12 %, a 25 % increase in C6–C12 esters and a reduction by 21 % in higher alcohols when using packed column versus alembic distillation. In contrast to our overall findings on spirit volatiles, Spaho [5] reported that alembic stills yield better aroma and more characteristic fruity distillates while column still cleans the distillate giving a decent aroma and higher concentration of alcohol.

Determination of volatile compounds in different fractions of the CAD distillation technique

Table 2 shows the volatile profile of (i) the entire product of 1st distillation, (ii) the sum of “head + tail” of 2nd distillation, and (iii) the “heart” fraction of 2nd distillation. A total of 32 volatile compounds were identified and semi-quantified in all tsipouro CAD fractions. Twenty-four compounds (6 alcohols, 11 esters, 2 ketones/acetals, 2 terpenes, 2 hydrocarbons, and 1 heterocyclic compound) were determined in the entire product of 1st distillation; 29 compounds (5 alcohols, 14 esters, 6 aldehydes/ketones/acetals, 1 terpene, 2 hydrocarbons and 1 heterocyclic compound) in the ‘head + tail’ fraction of 2nd distillation and 20 compounds (6 alcohols, 9 esters, 1 ketone, 1 terpene, 2 hydrocarbons, and 1 heterocyclic compound) in the “heart” fraction of the 2nd distillation. The total amount of volatiles was 398.0 mg/L for the entire product of 1st distillation, 374.73 mg/L for the sum of ‘head + tail’ of the 2nd distillation, and 315.3 mg/L for the “heart” fraction of the 2nd distillation. Based on the above, the entire product of 1st distillation followed by the “head + tail” fraction of the 2nd distillation was the richest in aroma compared to the “heart” fraction of 2nd distillation.

Of the volatile compounds, fatty acid ethyl esters and acetic acid esters are produced according to Millicevic et al. [41] during grape marc fermentation through enzymic esterification and further increase in the case of the aging process of spirits [41]. Of all esters, 3-methyl-1-butyl acetate (isoamyl acetate) strongly contributes to the aroma of distilled spirits with fruity banana tones [23] and was determined in the entire product of 1st distillation (11.11 mg/L), in the ‘head + tail’ fraction of 2nd distillation (38.97 mg/L) and in the “heart” fraction of second distillation (4.89 mg/L) recording statistically significant differences among all fractions. Cortes et al. [2] reported an isoamyl acetate concentration of 7.04 and 7.31 mg/L) in grappa and orujo samples, respectively. Ethyl acetate (fruity, sweet odor) was determined in the entire product of 1st distillation (93.30 mg/L), in the ‘head + tail’ fraction of 2nd distillation (80.79 mg/L) and in the “heart” fraction of 2nd distillation (48.71 mg/L) recording statistically significant differences only between the “heart” fraction of 2nd distillation and the entire product of 1st distillation. Apostolopoulou et al. [20] reported ethyl acetate concentrations between 23.5 and 98.7 mg/L for commercial tsipouro samples from Greece while Cortes et al. [2] substantially higher values of 300 and 457 mg/L for grappa and orujo samples. Ethyl esters of C6, C8, and C10 also contribute positively to the aroma of distilled spirits. Ethyl hexanoate (fruity, anise like odor), ethyl octanoate (floral, pineapple, pear odor), and ethyl decanoate (fruity, fatty odor) are formed during alcoholic fermentation and are liberated from the yeast cells during distillation. Ethyl-2-hydroxy propanoate (ethyl lactate) (sweet, acidic, ethereal type odor) also contributes to the aroma of distilled spirits. It was only determined in the entire product of 1st distillation (4.00 mg/L). Ethyl-2-methyl propanoate (ethyl isobutyrate) (fruity, ethereal odor) was determined in the entire product of 1st distillation (1.32 mg/L), in the “head + tail” fraction of 2nd distillation (2.47 mg/L) and in the “heart” fraction of second distillation (0.55 mg/L). It does not contribute essentially to the aroma of distilled spirits with significant differences (p < 0.05) recorded among the three samples. According to Cortes et al. [27] ethyl lactate is found in the ‘tail’ fraction, while according to Apostolopoulou et al. [20], it is found in the “head” fraction. Thus, it is expected to be found at higher concentrations in the “head + tail” fraction compared to the ‘heart’ fraction of distillates. Ethyl butyrate (pineapple like odor) was also determined in the entire product of 1st distillation (0.96 mg/L), in the “head + tail” fraction (1.89 mg/L) of 2nd distillation and in the “heart” fraction of 2nd distillation (0.52 mg/L) with significant differences (p < 0.05) among all samples. Silva et al. [18] reported ethyl butyrate concentrations lower than 10 mg/L in grape marc-distilled spirits.

Regarding ethanol, the alcoholic strength of the entire product of 1st CAD distillation was 39.3% v/v, of the “head + tail” fraction of the 2nd CAD distillation was 25.5% v/v, and of the “heart” fraction of 2nd CAD distillation was 70.1% v/v before dilution with water to 42% v/v.

Soufleros et al. [11] reported ethanol concentrations of 45.79 and 35.54% in tsipouto and tsikoudia samples, respectively. Higher alcohols (C ≥ 4) are formed during the alcoholic fermentation from sugars through the synthesis of α- ketoacids by yeasts. Ketoacids are subsequently decarboxylated and reduced to respective alcohols. They are also formed from amino acids following deamination and decarboxylation [42]. 2-Methyl-1-butanol (amyl alcohol) (pungent, fermented, yeasty, winey odor) and 3-methyl-1-butanol (isoamyl alcohol) (fusel, pungent, ethereal, fruity, and molasses like odor) recorded the highest concentrations (38.72 and 97.09 mg/L, respectively) among all alcohols, with the exception of ethanol, in the entire product of the 1st distillation. These concentration values remained the same (p > 0.05) in the entire product of 1st distillation and “heart” fraction of 2nd distillation. In contrast, their concentration was substantially lower in the “head + tail” fraction of 2nd distillation. 1-Propanol was determined in small amounts in the entire product of 1st and “heart” fraction of 2nd distillation (3.59 and 4.66 mg/L, respectively) and in even lower amounts in the “head + tail” fraction of 2nd distillation. 1-Propanol is formed from the amino acid threonine and has a distinct sweet taste [4]. According to Silva and Malcata [12], the concentration of 1-propanol depends on the variety of grape marc and the specific conditions of fermentation and distillation. 1-Hexanol (pungent, ethereal, fruity, alcoholic odor with a green top tone) was determined in all samples at higher concentrations in the entire product of 1st distillation and “heart” fraction of 2nd distillation (9–10 mg/L) and at a lower concentration (2.96 mg/L) in the “head + tail” fraction of 2nd distillation. 1-Hexanol originates from both crushed grapes [28] and through the reduction of hexanal during vinification [30]. 2-Methyl-1-propanol (isobutanol) (ethereal, winey odor) was determined in the entire product of 1st distillation (22.60 mg/L) and the “heart” fraction of 2nd distillation (20.96 mg/L) and in substantially lower concentrations (p < 0.05) in the “head + tail” fraction of 2nd distillation. It comprises a fermentation metabolite. Soufleros et al. [11] reported a concentration of 518.9 mg/L for tsipouro and 307.4 mg/L for tsikoudia.

Of the aldehydes/acetals, butanal (pungent, musty, green, malty odor), 2-methyl-butanal (musty, nutty, fruity, caramel like odor), and 3-methyl-butanal (ethereal, chocolate, peach, fatty odor) were determined in small amounts (1.01, 0.96, and 0.44 mg/L, respectively) only in the “head + tail” fraction of the 2nd distillation and are formed during fermentation by the action of yeasts [43]. Acetals were the main compounds in this category of volatiles. They are formed from acetaldehyde, originating from fermentation after reaction with alcohols. The main acetal (1,1-diethoxyethane) was determined in the entire product of 1st distillation (2.63 mg/L) and “head + tail” fraction of 2nd distillation (5.92 mg/L). Its odor is described as grassy [44]. 1,1-Diethoxyethane was also determined in grappa and orujo samples by Cortes et al. [2], by Galano et al. [35] in grappa samples and by Cortes et al. [24] in traditional and industrial Orujo spirits. Ketones are formed during fermentation and have a minor contribution to the aroma of distilled spirits. 2,6-Dimethyl-4-heptanone (di-isobutyl ketone or cognac heptanone) having a subtle aroma of sweet mint was determined in the entire product of 1st distillation (2.32 mg/L), the “heart” fraction of 2nd distillation (2.41 mg/L), and the “head + tail” fraction of 2nd distillation (3.21 mg/L) without significant differences (p > 0.05) among them. To the best of our knowledge, this is the first time di-isobutyl ketone is reported in grape marc-distilled spirits.

Terpenes are volatiles deriving from grape skins are often found in the form of monoterpenoid alcohols or their respective oxides. They are also found in the form of glycosides complexed with diols or triols. The latter compounds are non-volatile and thus do not contribute to the aroma of wines and spirit distillates. It is however possible that upon enzymic hydrolysis, terpenes will be liberated and contribute to aroma formation [21]. Terpene content usually decreases with storage type. DL-limonene (orange, citrus to piney odor) was determined in all three distillation samples ranging in amounts from 4.76 to 0.80 mg/L. DL-limonene was also determined in small amounts in grappa samples [35]. Linalool (citrus, orange, floral, terpy, waxy odor) was determined only in the entire product of 1st distillation (0.94 mg/L). It has been found to be a part of the flavor profile of white variety grapes [35, 45, 46].

Hydrocarbons originate from the wax components of grape skins [45]. They contribute very little to the aroma of grapes [42]. The main hydrocarbon determined was mesitylene (sweet aromatic odor) determined in all three distillation samples ranging between 14.25 and 19.08 mg/L) with significant differences (p < 0.05) among samples. Finally, of the heterocyclic compounds, vitispirane (floral, fruity, woody odor reminiscent of eucalyptus) was also determined in all three samples ranging from 2.68 to 7.33 mg/L with significant differences (p < 0.05) among samples. Vitispirane is formed during fermentation from grape precursors (megastigm-4-en-3,6,9-triol 3-O-glucoside and megastigm-4-en-3,6,9-triol 9-O-glucoside [47].

Determination of methanol

Table 3 shows the methanol content of the entire product of CAD 1st distillation, “head + tail” fraction of 2nd CAD distillation, “heart” fraction of 2nd CAD distillation, and “heart” fractions of FCD and HD distillation. It is important to note that methanol was not detected in any of the “heart” fraction distillates destined for consumption. It was only determined in the entire product (1st distillation-19.35 mg/L) and the “head + tail” fraction of 2nd distillation (12.82 mg/L) (CAD). Methanol distills off during the initial stages of the process due to its high volatility (b.p. 64.7 °C) [48] and its concentration decreases steadily as distillation proceeds. Methanol has also been found in the ‘tail’ fraction of distillation. This may be due to the fact that methanol forms hydrogen bonds with water molecules forming clusters of higher molecular weight which, in turn, reduces its volatility [49]. This is in agreement with Cortes et al. [27] and Claus and Berglund [33] who reported higher amounts of methanol in the “head + tail” fraction in Aguardiente and fruit brandy distillates, respectively. Likewise, Apostolopoulou et al. [20] reported higher amounts of methanol in the ‘tail’ fraction of tsipouro in the product of first distillation. Finally, Kana et al. [50] reported concentrations for methanol 700–1770 mg/L in various grape marc distillates. Such higher methanol concentrations may be due to the use of thick skin grape varieties used for the production of distilled spirits or the prolonged keeping of grape marc with wine grape must. Methanol is formed via enzymic hydrolysis of pectic substances which are part of the cellular membranes of grapes. Pectins are polymers of galacturonic acid partially esterified with methanol. Hydrolysis takes place during contact of grape marc with grape must. Apostolopoupou et al. [20] reported a methanol content of 86.1 mg/L in home-made tsipouro prepared from grape marc of the Debina variety. Respective concentrations were 1542 mg/L for grappa and 2635 mg/L for orujo [2], 57.7–79.2 mg/L [29], 18.1 mg/L for tsipouro and 20.8 mg/L for tsikoudia samples [11], and 6390 mg/L for white grape pomace distillates and 4541 mg/L for red grape pomace distillates [2]. On the other hand, methanol was not determined in the study of Galano et al. [35] in grappa distilled spirit samples, Garcia-Martin et al. [16] in orujo distilled spirit samples, and Giannetti et al. [8] in grappa samples.

Conclusions

The present study showed that the specific distillation technique used affected the volatile profile of tsipouro distillate. Fractional column distillation gave the richest volatile profile followed by home distillation and copper alembic distillation. Compounds showing the highest statistical differences among the three distillates included ethyl octanoate, ethyl decanoate, and DL-limonene with FCD recording drastically higher values compared to CAD. All three tsipouro distillates analyzed meet legal requirements [10] regarding ethanol, methanol, and volatile compound content, as well as the absence of furfural [9]. A general reducing trend was noted in most volatile compound concentration proceeding from the 1st to the 2nd CAD distillation refining the flavor of tsipouro.

Data availability

Data supporting reported results are available from the corresponding authors.

References

Bovo B, Andrighetto C, Carlot M et al (2009) Yeast population dynamics during pilot-scale storage of grape marcs for the production of Grappa, a traditional Italian alcoholic beverage. Int J Food Microbiol 129:221–228. https://doi.org/10.1016/j.ijfoodmicro.2008.11.025

Cortés S, Rodríguez R, Salgado JM, Domínguez JM (2011) Comparative study between Italian and Spanish grape marc spirits in terms of major volatile compounds. Food Control 22:673–680. https://doi.org/10.1016/j.foodcont.2010.09.006

Geroyiannaki M, Komaitis ME, Stavrakas DE et al (2007) Evaluation of acetaldehyde and methanol in greek traditional alcoholic beverages from varietal fermented grape pomaces (Vitis vinifera L.). Food Control 18:988–995. https://doi.org/10.1016/j.foodcont.2006.06.005

Silva ML, Macedo AC, Malcata FX (2000) Review: steam distilled spirits from fermented grape pomace Revision: Bebidas destiladas obtenidas de la fermentaci & oacute; n. Food Sci Technol Int 6:285–300. https://doi.org/10.1177/108201320000600403

Spaho N (2017) Distillation techniques in the fruit spirits production. In: Mendes M (ed) Distillation: innovative applications and modeling. IntechOpen, London

Hernández-Gómez LF, Úbeda-Iranzo J, García-Romero E, Briones-Pérez A (2005) Comparative production of different melon distillates: chemical and sensory analyses. Food Chem 90:115–125. https://doi.org/10.1016/j.foodchem.2004.03.033

Biernacka P, Wardencki W (2012) Volatile composition of raw spirits of different botanical origin. J Inst Brew 118:393–400. https://doi.org/10.1002/jib.55

Giannetti V, Mariani MB, Marini F et al (2019) Flavour fingerprint for the differentiation of Grappa from other Italian distillates by GC-MS and chemometrics. Food Control 105:123–130. https://doi.org/10.1016/j.foodcont.2019.05.028

Commission E (2019) Regulation (EU) 2019/787 of the European Parliament and of the Council of 17 April 2019 on the definition, description, presentation and labelling of spirit drinks, the use of the names of spirit drinks in the presentation and labelling of other foodstuff. Off J Eur Union L 130:1–54

Greek Legislation L 2969/2001 (2001) Ethyl alcohol and alcoholic beverages. Off Goverment Gaz 281/A/18–1:1–11

Soufleros EH, Natskoulis P, Mygdalia AS (2005) Discrimination and risk assessment due to the volatile compounds and the inorganic elements present in the Greek marc distillates Tsipouro and Tsikoudia. J Int des Sci la Vigne du Vin 39:31–45. https://doi.org/10.20870/oeno-one.2005.39.1.907

Silva ML, Malcata FX (1999) Effects of time of grape pomace fermentation and distillation cuts on the chemical composition of grape marcs. Z Lebensm Unters Forsch A 208:134–143. https://doi.org/10.1007/s002170050390

Lukić I, Tomas S, Miličević B et al (2011) Behaviour of volatile compounds during traditional alembic distillation of fermented Muscat blanc and Muškat ruža porežki grape marcs. J Inst Brew 117:440–450. https://doi.org/10.1002/j.2050-0416.2011.tb00491.x

Wiley 7 NIST05 (2005) National Institute of Standards and Technology, Mass Spectral Library, Wiley, West Sussex

SPSS (2014) IBM Corp. Released 2014. IBM SPSS statistics for windows, version 23.0 (Computer Software). Armonk, NY, USA. 0:2014

García-Martín S, Herrero C, Peña RM, Barciela J (2010) Solid-phase microextraction gas chromatography-mass spectrometry (HS-SPME-GC-MS) determination of volatile compounds in orujo spirits: multivariate chemometric characterisation. Food Chem 118:456–461. https://doi.org/10.1016/j.foodchem.2009.04.105

Paolini M, Tonidandel L, Larcher R (2022) Development, validation and application of a fast GC-FID method for the analysis of volatile compounds in spirit drinks and wine. Food Control 136:108873. https://doi.org/10.1016/j.foodcont.2022.108873

Silva ML, Malcata FX (1998) Relationships between storage conditions of grape pomace and volatile composition of spirits obtained therefrom. Am J Enol Vitic 49:56–64

Fournaris K (1999) Zivania, the traditional Cyprus alcoholic beverage. In: Greek Chemists’ Association (ed) Proceedings of the 6th Chemistry Conference Greece-Cyprus. Rhodes, Greece, pp 260–265

Apostolopoulou AA, Flouros AI, Demertzis PG, Akrida-Demertzi K (2005) Differences in concentration of principal volatile constituents in traditional Greek distillates. Food Control 16:157–164. https://doi.org/10.1016/j.foodcont.2004.01.005

Zoecklein BW, Marcy JE, Williams JM, Jasinski Y (1997) Effect of native yeasts and selected strains of Saccharomyces cerevisiae on glycosyl glucose, potential volatile terpenes, and selected aglycones of White Riesling (Vitis vinifera L.) wines. J Food Compos Anal 10:55–65. https://doi.org/10.1006/jfca.1996.0518

Etievant PX (1991) Wine. In: Maarse H (ed) Volatile compounds in foods and beverages. New York: Marcel Dekker, New York, USA, pp 483–546

Ferreira V, Hernández-Orte P, Escudero A et al (1999) Semipreparative reversed-phase liquid chromatographic fractionation of aroma extracts from wine and other alcoholic beverages. J Chromatogr A 864:77–88. https://doi.org/10.1016/S0021-9673(99)01004-3

Cortés S, Gil ML, Fernández E (2005) Volatile composition of traditional and industrial Orujo spirits. Food Control 16:383–388. https://doi.org/10.1016/j.foodcont.2004.04.003

Abreu P, Cortes S, Gil ML, Fernandez E (2001) Repercusion de la dilucion en el contenido en esters de un destilado de Orujo monovarietal de jerez. In: Proceedings of the XV Encontro Galego-Portugues de Quimica. Coruna, Spain, pp 185–186

Versini G (1993) Volatile compounds of spirits. In: Doneche B (ed) Les Acwuisitions Recentes en Chromatographie du Vin Cours Europeen de Formation Continue. Paris : Tec & Doc : Lavoisier, Porto, Portugal, pp 189–213

Cortés S, Gil ML, Fernández E (2002) The influence of redistillation in the distribution of volatile components of marc spirit (Aguardiente) and its repercussion on the aromatic quality. Sci Aliments 22:265–275

Soufleros EH, Bertrand A (1987) Etude sur le «Tsipouro», eau-de-vie de marc traditionnelle de Grèce, précurseur de l’ouzo. J Int des Sci la Vigne du Vin 21:93–111. https://doi.org/10.20870/oeno-one.1987.21.2.1280

Lopez-Vazquez C, Bollain MH, Moser S, Orriols I (2010) Characterization and differentiation of monovarietal grape pomace distillate from native varieties of Galicia. J Agric Food Chem 58:9657–9665

Clarke RJ, Bakker J (2004) Wine flavour chemistry. Blackwell Publishing Ltd, Oxford

Liu SQ, Pilone GJ (2000) An overview of formation and roles of acetaldehyde in winemaking with emphasis on microbiological implications. Int J Food Sci Technol 35:49–61. https://doi.org/10.1046/j.1365-2621.2000.00341.x

Kulkarni RD (1992) Alcoholic liver disease. J Gen Med 3:24–32

Claus MJ, Berglund KA (2005) Fruit brandy production by batch column distillation with reflux. J Food Process Eng 28:53–67. https://doi.org/10.1111/j.1745-4530.2005.00377.x

Sun J, Li Q, Luo S et al (2018) Characterization of key aroma compounds in Meilanchun sesame flavor style baijiu by application of aroma extract dilution analysis, quantitative measurements, aroma recombination, and omission/addition experiments. RSC Adv 8:23757–23767. https://doi.org/10.1039/c8ra02727g

Galano E, Imbelloni M, Chambery A et al (2015) Molecular fingerprint of the alcoholic Grappa beverage by mass spectrometry techniques. Food Res Int 72:106–114. https://doi.org/10.1016/j.foodres.2015.03.033

Lukić I, Miličević B, Banović M et al (2011) Secondary aroma compounds in fresh grape marc distillates as a result of variety and corresponding production technology. Food Technol Biotechnol 49:214–227

Arrieta-Garay Y, García-Llobodanin L, Pérez-Correa JR et al (2013) Aromatically Enhanced Pear Distillates from Blanquilla and Conference Varieties Using a Packed Column. J Agric Food Chem 61:4936–4942. https://doi.org/10.1021/jf304619e

Arrieta-Garay Y, Blanco P, Lopez-Vasquez C et al (2014) Effects of distillation system and yeast strain on the aroma profile of Albariño (Vitis vinifera L.) grape pomace spirits. J Agric Food Chem 62:10552–10560. https://doi.org/10.1021/jf502919n

García-Llobodanin L, Roca J, López JR et al (2011) The lack of reproducibility of different distillation techniques and its impact on pear spirit composition. Int J Food Sci Technol 46:1956–1963. https://doi.org/10.1111/j.1365-2621.2011.02707.x

Matias-Guiu P, Rodríguez-Bencomo JJ, Orriols I et al (2016) Floral aroma improvement of Muscat spirits by packed column distillation with variable internal reflux. Food Chem 213:40–48. https://doi.org/10.1016/j.foodchem.2016.06.054

Milicevic B, Banovic M, Kovacevic-Ganic K, Gracin L (2002) Impact of grape varieties on wine distillates flavour. Food Technol Biotechnol 40:227–232

Tsakiris A (2014) Oenology: from grape to wine, 4th edn. Psichalos Publ, Athens

Ndaba B, Chiyanzu I, Marx S (2015) N-butanol derived from biochemical and chemical routes: a review. Biotechnol Rep 8:1–9. https://doi.org/10.1016/j.btre.2015.08.001

Ribéreau-Gayon P, Glories Y, Maujean A, Dubourdieu D (2000) Handbook of Enology. Volume II. The Chemistry of Wine, Stabilization and Treatments. John Wiley & Sons, Ltd, West Sussex

Anonymous (2008) Analysis of grape volatiles by solid phase microextraction and comprehensive two-dimensional gas chromatography with time-of-flight mass spectrometry (GCxGC-TOFMS)

Slegers A, Angers P, Pedneault K (2017) Volatile compounds from must and wines from five white grape varieties. J Food Chem Nanotechnol 3:8–18

Botelho M (2008) Characterization of the aroma components of clonal grapes and wines from Aragonez and Trincadeira Vitis vinifera L. cultivars. PhD Thesis

Botelho G, Anjos O, Estevinho LM, Caldeira I (2020) Methanol in grape derived, fruit and honey spirits: a critical review on source, quality control, and legal limits. Processes 8:1–21. https://doi.org/10.3390/pr8121609

Rodrıguez-Madrera R, Mangas-Alonso JJ (1996) Obtencion de aguardiente de sidra mediante alambique con columna de rectificacion. Alimentaria 277:89–93

Kana K, Kanellaki M, Papadimitriou A, Koutinas AA (1991) Cause of and methods to reduce methanol content of Tsicoudia, Tsipouro and Ouzo. Int J Food Sci Technol 26:241–247

Funding

Open access funding provided by HEAL-Link Greece.

Author information

Authors and Affiliations

Contributions

Conceptualization, MGK; methodology, MGK and AVB; software, ISK; formal analysis, KK and ISK; resources, MGK and AVB; data curation, MGK, AVB, and ISK; writing-original draft preparation, MGK; writing review and editing, MGK, AVB, ISK, and PT; supervision, AVB and MGK; project administration, MGK and AVB. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Compliance with ethics requirements

This article does not contain any studies on human or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kokoti, K., Kosma, I.S., Tataridis, P. et al. Volatile aroma compounds of distilled “tsipouro” spirits: effect of distillation technique. Eur Food Res Technol 249, 1173–1185 (2023). https://doi.org/10.1007/s00217-023-04205-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04205-0