Abstract

The paper discusses the influence of the oak chips addition on physicochemical properties of beer. The research material consisted of wort and beer after the fermentation, brewed in the English porter style. Medium toasted oak chips, from two varieties of an oak tree (French and American), were used. Variants without the addition of oak chips were used as control samples. The research was conducted for three periods: after 18 days, 2, and 3 months. The samples containing oak chips were characterized by higher fermentation efficiency, compared to beers without the addition of chips. Titratable acidity increased with aging time in beers containing the chips. Alcohol content decreased after 3 months in all samples. Increased amounts of oak chips and aging time, resulted in greater free amino nitrogen utilization. Prolonging the storage time of the beer with the addition of oak chips changed the profile of volatile components in the beverages.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Beer has accompanied mankind since antiquity. Its traces can be found all over the world, from Europe, through the Middle East up to China. The production of this beverage became a part of the culture and tradition in many countries. Prior to the usage of stainless steel, barrels were a typical vessel used for storage and transportation for almost all liquids. Oak was the most common wood species used for their production. Nowadays, they are generally made from French and American oak varieties. They gained appreciation due to their hardness, durability, and waterproofness [1].

The wood aging is an old tradition that currently attracts the attention of brewers looking for new, innovative products. This technique is often used as an attempt to reproduce the original versions of beers [2, 3]. However, it is mainly used to obtain a broad range of aromas and tastes originating from wood. During aging in barrels, compounds extracted from the wood additionally influence the color, they improve the beverage properties and accelerate the aging of beer. However, the production of these tanks is very expensive, and aging requires long periods of time. A more accessible and cost-effective alternative to the usage of oak barrels is to use fragments of oak wood, commonly known as chips. An additional advantage is the usability of the entire surface of the wood, compared to only 40% of the area inside a barrel [4,5,6,7,8].

The aim of the study was to evaluate the influence of the oak chips addition on the physicochemical properties of the beer. For this purpose, medium toasted chips of American and French varieties were used in the study, as they are most commonly used by various branches of the alcohol industry [9, 10]. The research material consisted of English porter style beer, due to its historical relevance to the oak wood.

Materials and methods

Materials

Raw materials

In this study, following malts were used: Pale Ale (Weyermann, Germany), Carahell (Weyermann, Germany), Pale Chocolate (Fawcett, Great Britain), Chocolate Wheat (Weyermann, Germany); Challenger hops (Great Britain); Safale S-04 yeasts (Fermentis, Poland); oak chips (medium toasted): French, American.

Wort preparation

The wort was prepared on a medium scale, by heating up 23.5 L of water to 69 °C. Afterwards, 6.5 kg of Pale Ale malt and 0.3 kg Carahell malt (Weyermann, Germany) were added. The mash was heated to 66 °C, in which it was kept for 60 min, then the temperature was raised to 72 °C. 0.75 kg of Pale Chocolate malt (Fawcett, Great Britain) and 0.4 kg of chocolate wheat malt (Weyermann, Germany) were added to the mash, which was then kept at this temperature for 10 min. After this time, an iodine test was performed, to ensure that all available starch was saccharified. The mash was heated to 78 °C and held for 10 min to terminate the mashing process. Afterwards, it was transferred to a filtration vessel and left for 30 min to allow the grain filtration bed to settle.

The mash was then transferred to a filter tank and left to develop a layer of spent grain. Subsequently the mash was filtered with liquor of 80 °C. 42 L of wort with an extract of 12°P was obtained. To ensure clarity of the wort, the first 1 L of it was returned to the filtration. The wort was boiled for 70 min. 35 g of Challenger hops (Great Britain) was added 10 min after the boiling began. The second addition was 25 g of the same hops, dosed 20 min before the finish, to achieve a low-hopped beer with approximately 30 IBU. After boiling, the wort was cooled down using an immersion chiller to promote hot trub precipitation, from which it was separated. A solution with an extract of 13.5°P was obtained.

Wort inoculation and fermentation

The raw material used for fermentation was a wort (13.5°P extract, 30 IBU). Each of the 500 mL Erlenmeyer flasks was filled with 300 mL of it. Next, the dry yeast after rehydration according to producer (Safale US-04, Fermentis, Poland) was added into such setups in the amount of 0.5 g d.w./L For the time of fermentation, French and American sterile oak chips were added to eighteen flasks, in quantities of 3, 5, or 7 g/L of wort (Fig. 1). After carefully closing the fermentation flasks and fixing fermentation tubes filled with glycerin, the setup was additionally sealed with a parafilm. The fermentation process was carried out for 18 days at 20 °C, in three repetitions. After the fermentation was completed, 21 samples (18 containing oak chips, and 3 control samples—without any additions) were analyzed, while the remaining samples were decanted off the sediment into new 500 mL Erlenmeyer flasks. French and American oak chips were added in amounts of 3, 5, or 7 g/L to beer. The beers prepared this way were aged for 2 and 3 months at 20 °C (each variant at three repetitions) (Fig. 1).

Methods

Determination of fermentation dynamics

The fermentation rate was determined based on a weight loss of samples, weighted every 24 h with 0.01 g accuracy. Results from three independent repetitions were presented as a percentage loss of the fermentation media mass.

Determination of real extract and alcohol content

The alcohol concentration in the final beer was determined using the pycnometric method. For this purpose, the sample after fermentation was distilled. The obtained distillate was filled up to 100 g with distilled water, its density was determined, and the concentration of ethanol was read from the adequate tables (Analytica EBC Methods 9.2.1, Analytica EBC Methods 9.4), (Analytica EBC, European Brewery Convention, 1998).

Determination of sugar content (HPLC)

Analyses were performed using a Shimadzu (Japan) NEXERA XR with an RF-20A refractometric detector. The separation was performed on a Asahipak NH2P-50 250 × 4.6 mm Shodex column (Showa Denko Europe, Germany), thermostated at 30 °C. The mobile phase was an aqueous solution of acetonitrile (70% v/v), while the isocratic elution profile (0.8 mL/min) lasted for 20 min. For quantitative determination, standard curves were prepared for the respective standards: fructose, glucose, sucrose, and maltose.

Determination of titratable acidity

The potentiometric method was applied to determine titratable acidity, titrating a sample with 0.1 M NaOH solution to obtain pH = 8.

Determination of FAN content

Free amino nitrogen (FAN) was measured using ninhydrin-based methods with the use of the absorbance measurement at 570 nm (Beckman DU-650 UV–Vis) according to the method: 8.10 Free Amino Nitrogen in wort by Spectrophotometry (IM) (Analytica EBC, European Brewery Convention, 1998).

Determination of color

The color of the filtered samples was determined spectrophotometrically (Beckman DU-650 UV–Vis) at a wavelength of 430 nm (according to Analytica EBC Methods 8.5 and Analytica EBC Methods 9.6).

Determination of volatile compounds (SPME–GC–MS)

In order to determine the headspace volatile compounds, 1 g of NaCl and 2 mL sample of wort/beer were placed into a 10 mL vial. Next, an internal standard solution was added (0.57 mg/L 4-methyl-2-pentanol, 0.2 mg/L anethol, and 1.48 mg/L ethyl nonanoate, Sigma-Aldrich, St. Louis, MO, USA). The SPME device (Supelco Inc., Bellefonte, PA, USA) coated with PDMS (100 μm) fiber was first conditioned by inserting it into the gas chromatograph injector port at 250 °C for 1 h. For sampling, the fiber was inserted into the headspace under stirring (300 rpm) for 30 min at 60 °C. Subsequently, the SPME device was introduced into the injector port of the Agilent Technologies 7890B chromatograph system equipped with LECO Pegasus High Throughput TOFMS, and kept in the inlet for 3 min. The SPME process was automated using the GERSTEL MultiPurpose Sampler (MPS). The tested components were separated on a Rtx-1 ms capillary column (Crossbond 100% dimethyl polysiloxane, 30 m × 0.53 mm × 0.5 μm). The detector was 250 °C, and the column was heated using the following temperature program: 40 °C for 3 min at an increment of 8 °C/min to 230 °C, then maintaining a constant temperature for 9 min. Carrier: Helium at 1.0 mL/min constant flow. EIMS electron energy 70 eV; ion source temperature and connection parts: 250 °C. The analyte transfer was performed in splitless mode; the MSD was set to scan mode from m/z = 40 to m/z = 400. Compounds were identified using mass spectral libraries and linear retention indices, calculated based on a series of n-alkanes from C6 to C30. The qualitative and quantitative identification of volatile substances (ethyl acetate, ethyl propionate, isobutyl acetate, ethyl butanoate, ethyl isovalerate, isoamyl acetate, ethyl hexanoate, ethyl octanoate, diethyl succinate, 2-phenylethyl acetate, ethyl decanoate, ethyl dodecanoate, ethyl tetradecanoate, ethyl hexadecanoate, ethyl octadecanoate, 2-methyl-1-propanol, 2-methyl-1-butanol, 3-methyl-1-butanol, 1-hexanol, 1-ocatnol, 2-phenylethanol, 1-nonanol, 1-decanol, 1-dodecanol, linalool, caryophyllene, ß-damascenone, humulene, nerolidol, caryophyllene oxide; Sigma-Aldrich) were based on a comparison of retention times and peak surface area reads from samples and standard chromatograms. Other detected components were determined semiquantitatively (μg/L) by measuring the relative peak area of each identified compound according to the National Institute of Standards and Technology (NIST) database (The National Institute of Standards and Technology (NIST)) in relation to that of the internal standard. Each of the tests was performed three times.

Statistical analysis

The results are presented as the means of three independent repetitions with the determination of the standard deviation. In addition, an analysis of variance was applied—ANOVA test with repeated measurements, and a test of the differentiation between means (Duncan’s test), at a significance level of α = 0.05.

Results and discussion

Fermentation dynamics

The fermentation process was monitored based on the created CO2, the production of which resulted in a weight loss of the batches. Figure 2 presents the percentage weight loss of the tested samples. The most intense fermentation took place until the second day of the process (since the yeast inoculation). Subsequently, its rate decreased, and from the seventh day, the differences between the measures were marginal. From the fifteenth day, no changes in flasks masses were noted. No significant differences were noted between the variants with the addition of the oak chips, regardless of their type and quantity. The samples without the dosage of oak chips have shown lower mass loss compared to the variants that contained them (Fig. 2). This could be due to the presence of fermentable ingredients, such as D-glucose, which is produced by the hydrolysis of cellulose [11]. Pérez-Coello et al. [12] demonstrated that the presence of oak chips in the fermentation environment results in a higher fermentation efficiency.

Real extract and alcohol content

Real extract

Table 1 presents the contents of real extract and alcohol in beers after the fermentation and aging, with the addition of American and French oak chips, in doses of 3, 5, and 7 g/L. Control samples did not contain any oak chips. Usually, residual extract content in beers can range from less than 1% v/v in highly attenuated styles, such as lambic, to nearly 10% v/v in a sweet barley wine. The high content of residual sugars adds fullness and often a sweet taste to the beverages, while small ones give the impression of a lighter feeling in a mouth [2]. Significant residual extract in all the analyzed variants may suggest a relatively low content of fermentable sugars in a wort (Table 1).

In both variants of oak chips used, the results of real extract content were comparable. Among tested variants, the highest level of the analyzed parameter was found in beer containing 5 g/L of American oak chips after 3 months of aging (59.77 g/L), and the lowest value was found in beer with the same chips type, but in a dose of 7 g/L after 2 months (43.77 g/L). It was shown that after 60 days of storage, every variant, regardless of the oak chips type, was characterized by a lower extract content in comparison to a control sample. The value of this parameter after 3 months in all the beers did not differ significantly from the control sample. Extract of beers without the chips increased after 2 and 3 months (Table 1).

Considering only the American oak chips variety, it was noted that after fermentation and aging, each variant containing 5 g/L of these chips was characterized by the highest extract, compared to the other beers with a different weight of wood chips dosage. Simultaneously, the value of the extract increased with the longer storage time in contact with chips, regardless of the difference in their content. The only exception to this rule was the sample with the addition of 7 g/L of wood chips, after 2 months of aging, in which the extract amounted to 43.67 g/L. Analyses of beer after the fermentation showed that the amount of chips did not substantially influence the extract level. After 3 months of aging, beers with the American chips addition were characterized by slightly higher extract levels, as compared to the control (Table 1). The growth of this parameter over time may be related to the extraction of compounds from the wood [13]. In the study by Balcerek et al. [8], the aging of plum destillates with oak chips increased overall extract levels, in all tested variants. The highest increase in levels of this parameter took place in the first 3 months of the aging and decreased in the subsequent months. It was concluded that this growth was dependent, among others, on the dosage and type of the oak chips.

In the case of the beers containing the French oak chips, it was found that higher chips content did not cause an increase in extract content. The highest level of this parameter in variants with the aforementioned chips was found in beers with the addition of 3 g/L during fermentation, and the lowest in variants dosed with 7 g/L after 2 months of aging. After 60 days of aging, all the beers were characterized by lower extract levels, as compared to control samples. Although, after 3 months, one beverage with a chips content of 3 g/L was characterized by a higher extract than the control (Table 1).

Alcohol content

The average alcohol level in beers ranges from 4.8 to 5.2% (v/v). There are many beers on the market that have only 3.5% (v/v) of alcohol or less, while some beer styles, such as barley wine usually reach 12% (v/v). It is possible to conduct fermentation in a way that will allow to obtain alcohol levels in beer higher than 20% (v/v), however, special yeast strains and techniques are necessary. Beers intended for long aging should have around 15% (v/v) of alcohol or more [2, 14].

The highest alcohol level was found in beer aged for 2 months with the addition of 7 g/L French chips (6.16% (v/v)), while the lowest was determined in one stored for 3 months with American chips in a content of 5 g/L (4.51% (v/v)), (Table 1). It was noted that control samples were characterized by a decrease in alcohol levels as the aging time was extended. A similar trend was observed in beers with addition of both types of oak chips. Only in three variants analyzed, after 2 months of aging, a higher alcohol levels was observed as compared to the beers from other analyzed periods with the same amount of chips. The first exception was beer with 7 g/L of American chips, the alcohol content of which was 5.96% (v/v). The other two were those with the addition of 3 and 7 g/L of French chips. Mentioned exceptions were characterized by higher alcohol levels than the control sample (Table 1).

All variants tested after the fermentation, including the control, regardless of the type and content of oak chips, contained a similar level of alcohol 5.55–5.73% (v/v). The majority of variants after 2 months of aging were characterized by a higher amount of ethanol than the control. Only the beer with a dose of 5 g/L of American chips contained lower levels of this component. Samples tested after 3 months of aging were in a similar range of 4.51—5.05% (v/v) (Table 1). Wyler et al. [7] assessed the influence of medium toasted French oak on the young beer, over 3 months. They found that the alcohol content increased after 2 months, relative to the results after fermentation. On the other hand, after 3 months, a lower percentage of ethanol was obtained. However, the main trend in the variants analyzed in this paper is the reduction of ethanol content over time (Table 1). This dependence is confirmed by the studies conducted by Balcerek et al. [8] and Madrera et al. [5]. Sorption, esterification, oxidation, and evaporation are among the causes of alcohol loss during aging with oak chips. Sorption is particularly related to the type of chips used and the different porosities of the wood. A lower level of ethanol can be attributed to its infiltration during aging into the porous structure of the oak chips [5, 8].

Sugar content

Table 2 lists the sugars contents in the beers with the addition of French and American oak chips, in three doses (3, 5, 7 g/L), after fermentation, and two periods of aging (2 and 3 months). It also presents the results for the control samples (without the addition of oak chips) and wort. The results are presented as a means of three repetitions.

A significant amount of maltose and minor levels of other sugars were found in the examined wort. It is probably associated with the properties of the malts used and is appropriate for a typical beer wort [15]. Sucrose presence was stated. Whereas lack of this sugar in the beers indicates its complete attenuation (Table 2). Not all the sugars in the wort get fermented. These constituents give the body, and sometimes sweetness to the beer [2, 14].

An interesting study by Dróżdż [16] presented the composition of sugars in oak bark. According to the quoted author’s analysis, free monosaccharides represent about 5% of this material, with glucose (1.5–3.0%) and mannose (1.1–1.7%) being the most abundant, and the galactose (about 0.5%) the least. After hydrolysis, cellulose and hemicellulose decomposes into xylose (12.6%), arabinose (4.0%), glucose (3.0%), galactose (1.7%), mannose (0.8%), and rhamnose (0.8%).

Fructose

The fructose content in the wort, according to Hough and Hough [15] should be in the range of 1.0–1.5 g/L. In the material analyzed, this sugar was found in the amount of 1.45 g/L (Table 2).

The highest content of fructose was found in the variant after 2 months of maturation with the addition of 3 g/L of French oak chips (1.51 g/L), (Table 2). It was distinguished the content of this sugar twice larger than the same beverage after the fermentation. In the case of the American chips batch, the drink with the dosage of 7 g/L was characterized by the highest level of this sugar, also after 2 months of aging. The control sample after 3 months of storage showed the lowest content of fructose (0.65 g/L), and slightly more was found in samples dosed with 3 and 5 g/L of French chips, after fermentation. In all the variants analyzed, the fructose content is within the range in beer (0–5.5 g/L), [17].

Beers after 2 months of aging, apart from the one with the addition of 3 g/L of American chips, were characterized by the greatest fructose content (1.04–1.51 g/L). Beverages tested after fermentation and 3 months of maturation were characterized by a similar range of the sugar analyzed (0.75–1.04 g/L), (Table 2).

Glucose

All the variants contained small amounts of glucose (Table 2). The highest levels (8.62 g/L) were found in the wort, which is consistent with the literature sources, which provide the range of this parameter between 8 and 10 g/L [Hough 1991]. Beer with the addition of French chips in a content of 3 g/L, after 2 months of aging, was characterized by the highest content of glucose among the samples (0.75 g/L). In the case of American oak variety, the greatest quantity of the analyzed sugar was found in the sample dosed with 7 g/L of chips, after 2 months of aging. Whereas the lowest level was determined in beer containing 5 g/L of American oak chips, after 3 months of storage (0.14 g/L). Among the samples with the French version of the chips, the least amount of glucose was found in the sample dosed with 3 g/L, also after 3 months of aging (Table 2). The results obtained from the analysis of the samples are within the range given by the literature data for this sugar (0–8 g/L), in beers after the fermentation [17]. The discrepancy between both oak chips types occurred solely after 2 months, between the trials that contained 3 g/L and 7 g/L, where beverages with the American version of the chips showed the lower content of the analyzed parameter (Table 2).

In control samples, a loss of glucose over time was observed. The greatest loss of this sugar was detected between beers after 18 days, and their equivalents from the subsequent analyzed periods. All beverages fermented with chips were characterized by lower levels of this sugar, compared to the control from the same time. Beers after 2 and 3 months of aging contained similar levels of glucose to the control samples (Table 2). Differences between the beers with the addition of oak chips and the control samples may be caused due to the presence of glucose in oak chips composition. According to Drożdż [2019], the structure of the oak mass may contain even 1.5 to 3% of this sugar. Minor changes in glucose levels during the 3-month aging process are comparable to the results published by Balcerek et al. [8]. The quoted authors examined the influence of the French oak chips on the alcoholic beverage dosed in the amount of 3, 5, and 7 g/L. Significant changes in glucose content occurred only after 9 months.

Maltose

Among the sugars that constitute the composition of the typical wort, maltose is the most abundant [15, 18]. The lowest concentration of that sugar was found in a beer after fermentation with French chips in the amount of 3 g/L. In the case of the American variety, it was a variant with an addition of 5 g/L, after fermentation (Table 2). The highest maltose level was found in the wort, and it exceeded the range stated by literature (33–54 g/L), [15]. Presumably, this was caused by the type of malts used. Among the samples with oak chips added, the greatest value of the analyzed parameter was found in the variant with American chips (3 g/L) after 2 months of aging, and among the French chips samples, in variant with the inclusion of 3 g/L, after 3 months (Table 2). The highest discrepancies between the beers, taking into consideration the same chips type and same analysis time occurred after 90 days in a French type of chips (Table 2). This could be due to the higher yeast activity, resulting from higher amounts of fermentable compounds derived from the oak chips. The maltose content in all the tested beers is within the ranges reported by the literature, i.e., 0–2 g/L [17]. The results of the maltose level analyses represented in Table 2 showed similar values in all variants (including control samples), and they did not indicate a significant influence of oak chips on the content of this sugar in a beer.

Titratable acidity and pH

Titratable acidity

The highest titratable acidity level was found in beers with the addition of French chips in the amount of 7 g/L, after 2 and 3 months of aging (Table 1). A similar dependency was found in samples with American chips. Meanwhile, the lowest value of this parameter was found in the wort (1.32 mL 1 M NaOH/100 mL of beer), and among samples with oak chips addition, in those with the content of 3 and 5 g/L of American and French chips after the fermentation (2.12–2.14 mL 1 M NaOH/100 mL of beer). It was found that oak chips showed no significant effect on the acidity levels in beers during the fermentation (Table 1).

In comparison to the control samples after 2 and 3 months, all the variants with the addition of oak chips showed significantly higher acidity (Table 1). Oliver [2] and Bamforth [17] reported the acidity range in the extent from 0.1% to 0.3%. Most of the beers analyzed are within these ranges (Table 1). It is worth to note that a significant part of the beers with the oak chips addition was in the upper range presented by Oliver [2] and Bamforth [17]. Variants with the addition of French oak chips in amounts of 5 and 7 g/L, after 60 and 90 days, even slightly exceeded mentioned acidity range (Table 1).

In all beers containing chips, there was a noticeable growth in acidity over time. The most prominent discrepancies were found between samples after the fermentation and those after 2 months of aging. The titratable acidities of beverages with identical chips amount, after 60 and 90 days of storage were similar. American chips in a dose of 3 g/L did not show any significant effect on the acidity growth in the beer. A considerable differences occurred only among samples with the addition of 5 and 7 g/L of these chips, after 2 and 3 months. However, in the case of French variant, all types of quantities showed a substantial increase in this parameter, between the measurements after 18 days, and those after 60 and 90 days of aging. The greatest differences in the titratable acidity between both types of chips, in the same doses by weight, were found in the samples containing 7 g/L of chips after 2 months, and after 3 months in those with doses of 3 and 7 g/L. In all cases, beers with the French variant of chips were characterized by a higher acidity (Table 1). Presumably, it is caused by a higher porosity of French oak, compared to American one [2]. A greater wood porosity promotes enhanced oxygen diffusion, which in turn may contribute to the growth of acetic bacteria. It was concluded that the mass of the added oak chips (especially in the French variety) strongly influenced the acidity rise during the 3-month aging process [2]. This dependence confirms the research conducted by García and Gonzalez-Mendoza [19]. The quoted authors investigated, among other parameters, the change in the acidity levels of alcoholic beverages during 21 months of aging, in French and American oak barrels. In both cases, the most intense acidity growth occurred in the first 90 days. The mean growth in the samples was about 0.7%. An increment of acidity indicated an extraction of carboxylic, phenolic, and volatile acids from the wood [20]. Moreover, this initial significant increase is consistent with previous studies [21, 22]. It was concluded that the extraction of wood compounds is higher during the first aging stage. Comparison of the alcoholic beverage aging with the oak chips to aging in barrels is reasonable. The effect of the oak wood on the drink could be even more intense in the version with oak chips. The first method is characterized by a greater contact surface between the wood pieces and the beer. Simultaneously, in both methods, the same wood types are used.

pH

The wort was characterized by the highest pH among the samples (5.48), which is consistent with the literature data (5.0–5.6) [15]. Nowak et al. [23] showed that wort pH level affects the color and frothiness of the resulting beer. The pH levels of the tested samples remained at similar levels (4.44–4.69), (Table 1). Thus, the values of the tested parameter were within the range stated in the literature data [2, 24, 25]. Among the variants, the highest pH was determined in the control sample after the fermentation (4.69). However, it is worth to note that the other samples without the addition of the chips, from other periods, differed only slightly from this value. The lowest pH levels among the beverages were found in variants with a dosage of 7 g/L of French chips, aged for 2 and 3 months (Table 1). In most of these beers, a decrease in pH was noted, as the time from the application of oak chips passed. After 2 and 3 months, a significant drop of pH in those beers was observed, as compared to the samples tested after the fermentation. On the contrary, in beverages with the same amounts of chips, but American ones, the pH was kept on the same level (4.57–4.64). It should be assumed that this discrepancy was caused by the usage of different oak varieties (Table 1).

Free amino nitrogen (FAN)

Different concentrations of nitrogen in the wort can be found in literature. Minimal value is from 100 to 140 mg/L, and optimal one 200–250 mg/L. This optimum is considered as appropriate for the standard beers with extract levels of about 12 °P [26,27,28]. However, Hough and Hough [15] indicated that the FAN content of the wort should be in the range of 160—300 mg/L. As illustrated in Table 1, the unfermented sample (150.75 mg/L) meets the minimal ranges reported by sources. The lowest consumption was found in the control sample after 3 months of aging. Among the beers with the addition of oak chips, highest levels of FAN was noted in the one with the addition of French oak chips in a dose of 3 g/L, after 2 months of aging (109.56 mg/L). In the American oak variant, it was a sample in which quantity was also 3 g/L, but after 90 days of storage (Table 1).

The highest consumption of Free Amino Nitrogen was observed in beers containing French oak chips, in doses of 7 g/L, after 2 and 3 months of aging. All the results of the beers after fermentation were similar. A significant difference from the control was found in beer with the French chips addition of 7 g/L, after 2 months of fermentation. It was concluded that the increased amount of oak chips, as well as prolonged aging time, elevates the utilization of free amino nitrogen (Table 1). Only the lowest tested dosage of wood chips (3 g/L) did not show a decrease in FAN content over time (Table 1).

Color

The examined wort was characterized by the intense, dark color, amounting to 79.3 EBC. All the analyzed samples lightened up after the fermentation process relative to the wort, and their color was within the range of 61.8–75.7 EBC (Table 3). These results are distinctive to the color of the English porter (37–98.5 EBC), according to Daniels [29]. The greatest loss of color was found in beer containing American chips in the amount of 7 g/L, after 3 months of aging (61.8 EBC). In the case of samples with French variety addition, the respective drop was found in beer with the chips content of 3 g/L, after 2 months of aging (64.8 EBC). The lowest color loss was observed in beer with the French chips in a quantity of 7 g/L, after 60 days of storage (75.7 EBC), (Table 3).

It was observed that oak chips had no influence on beer color during fermentation. A different situation took place after 2 and 3 months of aging. Sample dosed with 3 g/L of French chips, after 60 days of storage showed significantly brighter color, as compared to the control. Whereas after 90 days of aging, the beers aged with addition of 5 and 7 g/L American chips were the ones that showed a significantly lower value of the tested parameter, comparatively to the control sample from that time (Table 3). After 3 months of aging, the highest number of samples that differed in color from the control was found. This dependence confirms the results obtained in the study conducted by Wyler et al. [7], where a significant color difference was also observed after this period.

The color enhancement during the storage is caused by Maillard reactions and oxidation of polyphenols. A slightly greater increase in color can be observed in samples with a darker color, or higher alcohol content [30]. A similar relation resulting in an intensification of the color during the aging time was found in variants with the addition of 5 and 7 g/L of French oak chips (Table 3). Wyler et al. [7] found an increase in the color intensity during 3 months of beer aging with the addition of medium toasted oak chips. The most relevant differences between oak chips varieties were found between the samples with their dosage of 5 and 7 g/L after 60 days of storage, and 5 and 7 g/L after 90 days. In the case of beers after 2 months, those seasoned with 3 g/L of American chips had a darker color compared to the French equivalent in the same amount. An inverse relationship was found in samples with a dosage of 7 g/L. After 3 months of aging, both of the listed variants with the American chips dosage (samples with 5 and 7 g/L) distinguished with a lighter color (Table 3).

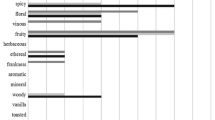

Volatile compounds

Table 4 present the profile of esters, higher alcohols, and terpenes formed in beers with the addition of oak chips, after the fermentation process and two periods of aging. The highest levels of the analyzed compounds are marked in red, while the lowest—in green.

The compounds forming beer aroma include mainly higher alcohols and esters, which are produced by the yeast’s secondary metabolism. Even in low amounts, they have a major influence on the taste and aroma of the beer [7, 31]. Volatile compounds (aldehydes, esters, higher alcohols) typically undergo changes during storage when in contact with oak.

Relatively high contents of ethyl acetate, ethyl propionate, 3-methylbutyl acetate, 2-methylbutyl acetate, and ethyl octanoate were found in beers analyzed. In the case of those compounds, significantly higher amounts of them were detected in beers that had French chips added on the fermentation stage. It was observed that the greater addition of chips resulted in a higher amount of components detected in a beer. The exception was 2-methylbutyl acetate, higher levels of which were found in beers without the addition of oak chips, both on fermentation stage as well as after 3 months of aging (Table 4). Ethyl esters (hexanoate, octanoate, and decanoate) and acetates were found to be absorbed in wood. Ramirez-Ramirez et al. [32] reported wood sorption of ethyl octanoate and isoamyl acetate from synthetic wine matrices, which increased for higher wood concentrations. Results obtained by quoted authors were not fully reflected in our experiments. Only in the case of ethyl 9-decenoate, ethyl decanoate, and propyl nonanoate, higher levels were found in beers without the addition of chips (Table 4). Interestingly, concentrations of some esters (such as isobutyl octanoate, ethyl 9-decenoate, ethyl decanoate) in beers with the addition of French oak chips decreased with an extended aging period. This could be due to the adsorption of these compounds by the wood. The obtained results are confirmed by the literature [33, 34]. Lower amounts of diethyl succinate and ethyl E-11-hexadecenoate were found in the beverages analyzed. Their content was higher in beers made with the addition of French chips compared to American ones. In opposite, the highest levels of ethyl dodecanoate, 3-methylbutyl decanoate, and ethyl tetradecanoate were found in beers that had American chips added (7 g/L). Higher quantities of propyl nonanoate and ethyl decanoate have been detected in beers without the application of chips (Table 4).

The highest quantities of analyzed higher alcohols were detected in beers made with the addition of French oak chips (Table 4). In the case of 2-methyl-1-propanol, 3-methyl-1-butanol, and 2-methyl-1-butanol, the greatest quantities of these compounds were found in beers made with 7 g/L of French chips, after 3 months of aging. A similar dependency was observed for 2-phenylethanol. 1-nonanol, 2-[(2-Ethylhexyl)oxy]-ethanol, 1-decanol, and 1-undecanol occurred in the highest levels in beers aged with French chips in the amount of 3 g/L. All the analyzed beers with the dosage of French chips were characterized by a greater level of higher alcohols, as compared to beverages with American chips (Table 4). Significantly lower amounts of these compounds were found in beverages without chips use (control). The only exceptions were 2-methyl-1-octanol, 1-nonanol, 1-decanol, and 1-undecanol (in beers after fermentation).

Terpenes are the main components of hops essential oils and contribute to the unique sensory attributes of the beer. More than 90% of hop oil volatilizes during boiling [35]. The greatest levels of caryophyllene, humulene, β-helmiscapene, α-calamenene, caryophyllene oxide, humulene epoxide II, patchulane, and τ-muurolol were found in the wort (Table 4). The obtained results are consistent with the literature data. Del Almeida et al. [36] showed that the main ingredients of hops oil are β-myrcene, α-humulene, β-caryophyllene, and β-farnesene, while the dominant ingredients of the finished beers are terpene alcohols, especially linalool and geraniol. Linalool was found in our beers, and its highest quantities were found in beverages without the addition of oak chips, after 2 and 3 months of aging (Table 4). Relatively high levels of this compound were found in beers made with the addition of French chips (added in an amount of 5 g/L). Abundant amounts of β- damascenone were found in beers without the addition of oak chips, after the fermentation process. Its comparable amounts were found in beverages with the addition of French chips (3 g/L), after 2 and 3 months of aging (Table 4).

Conclusions

The samples containing oak chips were characterized by a higher fermentation efficiency than those without such addition. In all the samples analyzed, the alcohol content decreased after 3 months. In both oak varieties investigated, only larger additions of chips resulted in a pH drop, which became apparent after 2 months of aging. The titratable acidity of beers containing oak chips increased with the aging time. It was found that the most significant acidity growth occurred after 2 months of storage. Furthermore, it was found that the increase in the weight of the oak chips (especially in the French variety) intensively influenced the acidity growth during the 3-month aging process. The increased addition of oak chips, as well as prolonged aging time, elevates the utilization of free amino nitrogen. Prolonging the beer aging time in contact with oak chips changed the profile of volatile components in beverages. In the beers analyzed, relatively high levels of ethyl acetate, ethyl propionate, 3-methylbutyl acetate, and ethyl octanoate were detected. Significantly higher amounts of these components were found in beers with the addition of French chips, added on the fermentation stage. Higher amount of chips resulted in an increased amount of compounds obtained in beer. The concentration of some esters (e.g., isobutyl octanoate, ethyl-9-decenoate, and ethyl decanoate) in beers with the addition of French oak chips decreased as the aging period extended. This could be due to the adsorption of the aforementioned compounds by the wood. All the analyzed beers with the addition of French chips were characterized by a higher amount of higher alcohols compared to drinks with American chips.

The addition of wood chips is a potentially good substitute for barrels. In addition to the attractive color (in wines, distillates), the wood chips also provide a wide bouquet of aromas that could encourage alcohol producers to invest in a more economical and ecological alternative to barrels. The conducted research provides a lot of new information on beers with the addition of oak chips. However, more research is needed to better understand the biochemical changes that occur during alcohol maturation.

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

Foster T (1998) Porter. Brewers Publications

Oliver G, Colicchio T (2011) The Oxford companion to beer. Oxford University Press, New York

Palmer JJ (2017) How to brew: everything you need to know to brew great beer every time. Brewers Publications, Colorado

Arapitsas P, Antonopoulos A, Stefanou E, Dourtoglou VG (2004) Artificial aging of wines using oak chips. Food Chem 86:563–570. https://doi.org/10.1016/j.foodchem.2003.10.003

Madrera RR, Hevia AG, Valles BS (2013) Comparative study of two aging systems for cider brandy making. Changes in chemical composition. LWT-Food Sci Technol 54:513–520. https://doi.org/10.1016/j.lwt.2013.05.037

Robinson J, Harding J (2015) The Oxford companion to wine. American Chemical Society, Oxford

Wyler P, Angeloni LHP, Alcarde AR, Da Cruz SH (2015) Effect of oak wood on the quality of beer. J Inst Brew 121:62–69. https://doi.org/10.1002/jib.190

Balcerek M, Pielech-Przybylska K, Dziekońska-Kubczak U, et al (2017) Changes in the chemical composition of plum distillate during maturation with oak chips under different conditions. Food Technol Biotechnol 55:333–359. https://doi.org/10.17113/ftb.55.03.17.5145

Rodríguez-Bencomo JJ, Ortega-Heras M, Perez-Magarino S, Gonzalez-Huerta C (2009) Volatile compounds of red wines macerated with Spanish, American, and French oak chips. J Agric Food Chem 57:6383–6391. https://doi.org/10.1021/jf900739k

Canas S, Caldeira I, Belchior AP, et al (2018) Chestnut Wooden Barrels for the Ageing of Wine Spirits. Organ Int la Vigne du Vin

Fleet GH (1993) Wine microbiology and biotechnology. CRC Press

Pérez-Coello MS, Sánchez MA, García E et al (2000) Fermentation of white wines in the presence of wood chips of American and French oak. J Agric Food Chem 48:885–889

Lyons TP (1999) Production of Scotch and Irish whiskies: Their history and evolution. The Alcohol Textbook. Nottingham University Press Nottingham, UK, pp 137–164

Briggs DE, Brookes PA, Stevens R, Boulton CA (2004) Brewing: science and practice. Woodhead Publishing Limited Cambridge London

Hough JS, Hough JS (1991) The biotechnology of malting and brewing. Cambridge University Press

Dróżdż P (2019) Badanie możliwości wykorzystania produktów ubocznego użytkowania lasu jako źródła antyutleniaczy

Bamforth CW (2005) Beer, carbohydrates and diet. J Inst Brew 111:259–264

Serrano R (1977) Energy requirements for maltose transport in yeast. Eur J Biochem 80:97–102

García MP, González-Mendoza LA (2001) Changes in composition and sensory quality of red wine aged in American and French oak barrels. OENO One 35:41–48

Aiken JW, Noble AC (2016) Composition and sensory properties of Cabernet Sauvignon wine aged in French versus American oak barrels. VITIS-Journal Grapevine Res 23:27

Singleton VL, Draper DE (1961) Wood chips and wine treatment; the nature of aqueous alcohol extracts. Am J Enol Vitic 12:152–158

Nykanen L, Nykanen I, Moring M (1985) Aroma compounds dissolved from oak chips by alcohol. Dev food Sci

Nowak D, Nowak A (2009) Kinetyka wzrostu biomasy oraz biosyntezy enzymów amylolitycznych przez drożdże Saccharomycopsis fibuligera podczas hodowli w bioreaktorze. Żywność Nauk Technol Jakość 16

Bamforth CW (2001) pH in brewing: an overview. Tech quarterly-Master Brew Assoc Am 38:1–9

Menz G, Aldred P, Vriesekoop F (2009) Pathogens in beer. In: Beer in health and disease prevention. Elsevier, pp 403–413

Bisson LF, Kunkee RE (1991) Microbial interactions during wine production. Mix Cult Biotechnol 37–68

Fix G (1999) Principles of brewing science: A study of serious brewing issues. Brewers Publications

Hill AE, Stewart GG (2019) Free Amino Nitrogen in Brewing Fermentation 5:22. https://doi.org/10.3390/fermentation5010022

Daniels R (1998) Designing great beers: The ultimate guide to brewing classic beer styles. Brewers Publications

Vanderhaegen B, Delvaux F, Daenen L et al (2007) Aging characteristics of different beer types. Food Chem 103:404–412. https://doi.org/10.1016/j.foodchem.2006.07.062

Renger RS, van Hateren SH, Luyben KCAM (1992) The formation of esters and higher alcohols during brewery fermentation; the effect of carbon dioxide pressure. J Inst Brew 98:509–513

Ramirez-Ramirez G, Chassagne D, Feuillat M et al (2004) Effect of wine constituents on aroma compound sorption by oak wood in a model system. Am J Enol Vitic 55:22–26

Coelho E, Teixeira JA, Domingues L et al (2019) Factors affecting extraction of adsorbed wine volatile compounds and wood extractives from used oak wood. Food Chem 295:156–164

Coelho E, Teixeira JA, Tavares T et al (2021) Reuse of oak chips for modification of the volatile fraction of alcoholic beverages. LWT 135:110046

Rybacek V (2012) Hop production. Elsevier

de Almeida NEC, de Aguiar I, Cardoso DR (2015) Mechanism of hop-derived terpenes oxidation in beer. J Braz Chem Soc 26:2362–2368

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

M.C.-S.: conceptualization, methodology, and validation; S.S.: software; M.C.-S., M.B., K.K.: formal analysis and investigation; M.C.-S., M.B.: original draft preparation; M.C.-S., S.S. and P.S.: review and editing; M.C.-S., S.S.: visualization. All the authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contribution for the Special Issue: The chemistry behind malt and beer production – from raw material to product quality.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cioch-Skoneczny, M., Bajerski, M., Klimczak, K. et al. Influence of oak chips addition on the physicochemical properties of beer. Eur Food Res Technol 249, 183–197 (2023). https://doi.org/10.1007/s00217-022-04143-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-022-04143-3