Abstract

The Maillard reaction products (MRPs) 3-deoxyglucosone (3-DG) and 5-hydroxymethylfurfural (HMF), which are formed during the thermal processing and storage of food, come into contact with technologically used yeasts during the fermentation of beer and wine. In order for the yeast cells to work efficiently, handling of the stress-inducing carbonyl compounds is essential. In the present study, the utilization of 3-DG and HMF by 13 Saccharomyces yeast strains (7 brewer’s yeast strains, 1 wine yeast strain, 6 yeast strains isolated from natural habitats) was investigated. All yeast strains studied were able to metabolize 3-DG and HMF. 3-DG is mainly reduced to 3-deoxyfructose (3-DF) and HMF is completely converted to 2,5-bishydroxymethylfuran (BHMF) and 5-formyl-2-furancarboxylic acid (FFCA). The ratio of conversion of HMF to BHMF and FFCA was found to be yeast strain-specific and no differences in the HMF stress tolerance of the yeast strains and species were observed. After incubation with 3-DG, varying amounts of intra- and extracellular 3-DF were found, pointing to a faster transport of 3-DG into the cells in the case of brewer’s yeast strains. Furthermore, the brewer’s yeast strains showed a significantly higher 3-DG stress resistance than the investigated yeast strains isolated from natural habitats. Thus, it can be shown for the first time that Saccharomyces yeast strains differ in their interaction of 3-DG induced carbonyl stress.

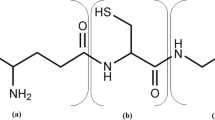

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The term “Maillard reaction” or “glycation” describes a series of reactions between reducing carbohydrates and amino compounds. Maillard reaction products (MRPs) include 1,2-dicarbonyl compounds such as 3-deoxyglucosone (3-DG), 3-deoxygalactosone (3-DGal), methylglyoxal (MGO) and glyoxal (GO), which are formed in the advanced phase of the reaction from the previously formed Amadori or Heyns products (AP, HP) [1]. 1,2-Dicarbonyl compounds are also formed from reducing carbohydrates in the absence of amino compounds during intense heating of carbohydrate-rich foods (“caramelization”). These compounds are highly reactive and thus represent precursors for many subsequent reactions and products [2,3,4]. For example, reactions with protein side chains give rise to advanced glycation endproducts (AGEs), and dehydration reactions can form MRPs such as 5-hydroxymethylfurfural (HMF, from 3-DG) or furfural [FF, from 3-deoxypentosone (3-DP)] [5]. The reaction named after Louis Camille Maillard also occurs endogenously in the human body. In this process, the 1,2-dicarbonyl compounds react with endogenous proteins such as enzymes to form peptide-bound glycation products [2, 3, 6]. The consequences for the body induced by this carbonyl stress are intensively discussed in the literature. For example, diseases such as uremia, Alzheimer’s disease, and diabetes have been linked to carbonyl stress and the resulting glycation products [1,2,3, 6, 7]. In addition to endogenous formation, MRPs present in heat-treated food such as milk and bakery products, pasta, coffee and beer, are consumed with the daily diet [2, 4, 8, 9]. In a conventional diet based on 1 L milk, 500 g baked goods and 400 mL coffee, an average daily intake of 0.5–1.2 g AP and 25–75 mg AGEs was estimated [10]. Furthermore, depending on the diet, between 20 and 160 mg of 3-DG, 2 and 16 mg of HMF as well as 5 and 20 mg of MGO are ingested [8]. High levels of 1,2-dicarbonyl compounds are found primarily in high-sugar and/or heat-treated products such as fruit juices, honey, beer, and baked goods [8, 11,12,13,14]. Certain MRPs are decisive for the taste, color and technological properties of foods [15]. In the production of some foods, microorganisms are specifically used, which have a significant influence on the quality of the respective product. For example, yeasts are used as a leavening agent in bread baking due to their production of carbon dioxide, and their use is essential in beer and wine production because of their ethanol generation [16]. Through the metabolization of some food ingredients, yeasts are also relevant to the flavor profile of the food product [15].

MRPs are of particular importance during beer and wine production. In beer production, MRPs are introduced into the wort by the kilned malt during the mashing process and are additionally formed during wort boiling. The levels of MRPs in wort are, therefore, highly dependent on the degree of heating or roasting of the malt used, with 3-DG being the main component of the 1,2-dicarbonyl compounds and pyrraline being the main representative of products from advanced Maillard reactions [8, 17, 18]. Concentrations of 732 µmol/kg of 3-DG and 3.8 µmol/kg of pyrraline were found in lightly roasted malt and 3266 µmol/kg of 3-DG and 33.2 µmol/kg of pyrraline in dark/caramel malt. HMF is also present in the malt. The contents range between 19 µmol/kg (lightly roasted malt) and 446 µmol/kg (dark/caramel malt) [18]. In wine production, dicarbonyl compounds may play a role due to the high-sugar content of the grapes. At present, only limited information is available concerning the formation of dicarbonyls in must. In dried fruits, including raisins, up to 1300 mg/kg of 3-DG, 8 mg/kg of MGO, 5 mg/kg of GO and 28 mg/kg of HMF can be formed [12]. Technologically used yeast strains should come into contact with MRPs during fermentation, exposing them to increased carbonyl stress. Due to a high plasticity of the yeast genome and the associated rapid adaptation to environmental conditions, an adjustment to higher dicarbonyl concentrations can be assumed [19]. This adaptation to the respective habitat has already been observed for some food constituents. For example, brewer’s yeast strains are able to utilize maltotriose and maltose, as these are the main carbon sources in beer wort [20]. Wine yeast strains, on the other hand, are more resistant to sulfite, which is used as a preservative and antioxidant in wine production [21]. In technologically used Saccharomyces cerevisiae yeast strains, a gene was identified that is responsible for a high resistance to toxic compounds to the yeast cells, such as MGO and heavy metal ions. This gene called pYMG14 could not be found in the wild-type species studied [22].

Previous studies in our and other laboratories have shown that yeasts of the genus Saccharomyces cerevisiae are able to metabolize MRPs [23,24,25,26,27]. Yeasts possess effective detoxification mechanisms to convert reactive carbonyl compounds into less toxic substrates. Since yeasts have a glyoxalase system, it can be assumed that MGO can be metabolized to d-lactate via this metabolic pathway [22, 25]. HMF and furfural are reduced to BHMF and to furfuryl alcohol, respectively, in the presence of S. cerevisiae yeast strains and are additionally oxidized to FFCA and 2-furancarboxylic acid in small amounts [26, 28, 29]. Moreover, it is known that different yeast species show different HMF and furfural stress resistance during bioethanol production [28, 30, 31]. Furthermore, it has already been demonstrated in previous studies that 3-DG is reduced to 3-DF during beer fermentation [24]. In summary, a wide variety of publications show that yeasts mainly reduce carbonyl compounds, which are cytotoxic for them, to less toxic substrates. A possible formation of the MRPs 3-DG and HMF and their metabolization by S. cerevisiae is shown in Fig. 1. However, it is not yet known whether other Saccharomyces species also have the ability to metabolize MRPs and whether this is equally expressed in all strains. Research to understand the metabolism of S. cerevisiae and its regulation is relevant because yeasts are used as a model organism to elucidate fundamental biological processes [19]. Furthermore, the more detailed phenotypic characterization is essential to select yeast strains for specific applications.

Therefore, in this study, we wanted to clarify whether yeast strains commercialized as brewer's yeasts or wine yeasts as well as yeast strains isolated from natural habitats of the Saccharomyces genus differ in their HMF and 3-DG metabolization. For this purpose, different Saccharomyces strains were cultured and incubated with the MRPs in model experiments. The stability and metabolization of the substrates in the presence of different strains were investigated by HPLC–UV and GC–MS, and the toxicity of the MRPs on yeast cells was analyzed. The metabolites identified were 3-DF, BHMF and FFCA in all yeasts. It was demonstrated for the first time that brewer’s yeast strains and yeast strains isolated from natural habitats differ in both their 3-DG metabolism and carbonyl stress resistance.

Materials and methods

Chemicals

The following substances were purchased from commercial suppliers: 2,5-bis(hydroxymethyl)furan (BHMF, ABCR, Karlsruhe, Germany); 5-formyl-2-furancarboxylic acid (FFCA, ChemCollect GmbH, Wuppertal, Germany); 5-hydroxymethylfurfural (HMF), the yeast extract for microbiology, peptone from soy bean meal (enzymatically digested), malt extract for microbiology, and ortho-phenylenediamine (OPD) from Sigma Aldrich, Steinheim, Germany; acetonitrile HPLC grade (Fisher Chemical, Loughborough, UK); agar for microbiology (Marcor, Carlstadt, USA); formic acid as well as pyridine (Acros Organics, New Jersey, USA); ammonium formate, di-sodium hydrogen phosphate dihydrate, hydroxylamine hydrochloride, potassium dihydrogen phosphate and sodium dihydrogen phosphate monohydrate from Grüssing GmbH, Filsum, Germany; d-(+)-glucose, d-(+)-sucrose as well as acetic acid from Carl Roth GmbH & Co KG, Karlsruhe, Germany; heptafluorobutyric acid (HFBA, Alfa Aesar, Kandel, Germany); methanol HPLC grade, sodium chloride, n-hexane as well as hydrochloric acid from VWR Chemicals, Fontenay-sous-Bois, France; methylene blue (Merck, Darmstadt, Germany); N,O-bis-(trimethylsilyl)-trifluoroacetamide (BSTFA) with 1% trimethylchlorosilane (TMCS) (Supelco, Bellefonte, USA); ultrapure water for the preparation of solutions and HPLC eluents was produced in-house with the Destamat Bi 18E apparatus, QCS GmbH, Maintal, Germany; tri-sodium citrate dihydrate (VEB Jenapharm-Laborchemie Apolda, Germany); tris-(hydroxymethyl)-aminomethane (AppliChem GmbH, Darmstadt, Germany). 3-Deoxyglucosone (3-DG) [32], 3-deoxyfructose (3-DF) [33], and [13C]3-deoxyglucosone ([13C]3-DG) [34] were synthesized according to mentioned literature methods and were used for the incubation experiments and measurements.

Yeast strains

The yeast strains used were Saccharomyces species. They belonged to S. cerevisiae (DSM 1848, DSM 70449, SafAle T-58, SafAle WB-06, SafAle BE-256, all commercialized as brewer’s yeast strains; Kitzinger Reinhefe Steinberg, commercialized as wine yeast strain; S402-OA, isolated from natural habitats), S. uvarum (S648-OA, S91-OA, both isolated from natural habitats), S. paradoxus (S96-OA, S466-OA, S445-OA, all isolated from natural habitats), and S. pastorianus (SafLager W34/70, commercialized as brewer’s yeast strain). Further details about the yeast strains used are given in Table 1.

Yeast propagation and cultivation

All media and solutions described were autoclaved (121 °C, 20 min) before use. For propagation, dry yeasts were added to YMPD liquid medium (DSM Universal Medium #186: 10 g/L glucose, 5 g/L peptone from soybean, 3 g/L yeast extract, and 3 g/L malt extract) [36] and shaken at 30 °C and 125 rpm for 24 h using the HT Multitron Standard incubator shaker (Infors, Böttmingen, Switzerland). Subsequently, 50 mL of the suspension was centrifuged (4880×g, 10 min, 4 °C), the supernatant was removed, and the residue was resuspended with 0.9% NaCl. From this suspension, 50 µL was added onto YMPD agar plates (YMPD medium as described above plus 15 g/L agar) and incubated for 48 h at 30 °C. Glycerol cultures were added directly to the agar plates and also incubated. The yeast strains isolated from natural habitats were already present on agar plates and could be used directly. For the subsequent colony cultivation, some of the incubated cultures was taken with an inoculation loop (sterile, polystyrene, VWR, Darmstadt, Germany) and fractionally streaked out on a new plate each. These were incubated again under the same conditions and stored at 5 °C in the refrigerator during use. Yeast strains were propagated every 2 weeks by taking a single colony with an inoculation loop and streaking it out on a new plate.

Incubation experiments—metabolization of 3-DG and HMF by Saccharomyces strains

For each experiment, the yeasts were cultured in a standardized procedure: single colonies were taken from the plates with an inoculation loop and transferred into 20 mL of YMPD medium. The liquid culture was shaken at 30 °C and 125 rpm (preculture). After 24 h, 1 mL of each suspension was transferred into 175 mL of YMPD medium and shaken again for 24 h under the same conditions (main culture). Subsequently, a sample of the yeast suspension was diluted 1:25 with the YMPD medium and OD was measured at a wavelength of 600 nm using the Ultrospec 2100 pro spectrometer (Biochrom, Cambridge, UK) in disposable cuvettes (semi-micro made of PMMA, d = 1 cm, BRAND, Wertheim, Germany). Based on this, the total yeast suspensions were set at a calculated OD of 5. Therefore, the yeast cells were harvested by centrifugation (4880×g, 10 min, 4 °C), the supernatant was removed, and the resulting yeast pellets were slurried with a sucrose minimal medium (10 g/L sucrose, 2.72 g/L potassium dihydrogen phosphate, and 1.96 g/L tri-sodium citrate dihydrate with a pH of 5.5 adjusted by 3 M HCl [37]). To ensure standardization of the experimental conditions for all yeast strains, the exact cell numbers of the strains at OD 5 were determined before the start of the experiment. For this purpose, yeast pellets were slurried with 0.9% NaCl rather than minimal medium and counted using the Thoma counting chamber (depth 0.1 mm, 1/400 mm2, Fein-Optik, Bad Blankenburg, Germany) after appropriate dilution (1:25) on the Axiovert 40 microscope (Carl Zeiss Microscopy, Jena, Germany) at 40 × magnification.

For the metabolization experiments, 900 µL of each yeast suspensions slurried in minimal medium was transferred to 2 mL Eppendorf tubes (Eppendorf, Hamburg, Germany) and incubated for 30 min in the shaking water bath (Thermobad 1083, GFL, Burgwedel, Germany) at 30 °C. Subsequently, 100 µL of each of the sterile filtered (0.2 µm) standard solutions (individually for each sample) was added. The concentrations of MRP solutions used were determined using a preliminary experiment on the stress resistance of selected yeast strains (see Supplements Fig. S1) and were 2.5 mM for 3-DG (final concentration: 0.25 mM) and 10 mM for the HMF solution (final concentration: 1 mM). In addition, a yeast blank (YB) was carried, consisting of 900 µL of the yeast suspension and 100 µL of the minimal medium. Furthermore, a substance blank (SB) was included in order to be able to document the stability of the standards in the medium used. Here, 900 µL of the minimal medium was mixed with 100 µL of the corresponding standard solution (HMF: 10 mM, 3-DG: 2.5 mM). The two blank solutions were treated in exactly the same way as the metabolization solutions. Immediately after substance addition, the first sampling (0 h, 100 µL) was performed after shaking and the collected samples were stored directly on ice. The remaining incubation mixture was resealed and further incubated. Further sampling took place after 3 h (HMF samples) and after 24 h (3-DG and HMF samples). After incubation, the OD of the 24 h samples was measured again to be able to document an influence of the added substances on the growth of the yeast strains. Samples were stored at − 80 °C until analysis. Incubations were performed twice with yeast cells from two independent main cultures, each in triplicate. For the determination of an adsorption of the MRPs to the yeast cell, the experiment was repeated with previously autoclaved main cultures (121 °C, 20 min) as described above.

Dead/live-cell experiments

To evaluate the toxicity of the MRPs 3-DG and HMF on the yeast strains, the percentages of dead cells in the sample solutions were determined after the 24 h incubations. For this purpose, the 24 h solutions were diluted 1:25 with 0.9% NaCl solution in a new tube (60 µL sample solution and 1440 µL NaCl) and 300 µL of a methylene blue solution (100 mg methylene blue in 100 mL ultrapure water) were added. The mixtures were shaken and then incubated for 10 min for staining. Samples were then shaken again and counted using the Thoma counting chamber on the microscope at 40 × magnification. In each case, the total cell number and the number of dead cells in the suspensions (blue colored cells) were determined. For a quantitative evaluation of the toxicity of the substrates, the determined proportion of dead cells in the YBs (incubation without the addition of MRPs) was subtracted from the respective proportion of dead cells in the samples.

Analysis of HMF and its metabolites

The measurements were performed on an HPLC system with UV detection. A low-pressure gradient system consisting of a mixing chamber (K-1500; Knauer, Berlin, Germany), an autosampler (Basic Marathon, Spark Holland, Emmen, The Netherlands), a pump (Smartline 1000), an online degasser and a diode array detector DAD 2.1L (all from Knauer, Berlin, Germany) was used. Data analysis was performed using ClarityChrom version 6.1.0.130 software (Chrom Tech Inc., Apple Valley, MN). The measurement system used was a stainless steel column (250 mm × 4.6 mm, 5 µm) filled with Eurospher-100 RP-18 material and an integrated precolumn (5 mm × 4 mm) with the same material (Knauer, Berlin, Germany) at room temperature. Analysis was performed using a gradient elution. A solution of 5 mM ammonium formate in ultrapure water, adjusted to a pH of 4.0 with formic acid, to which 5 mM heptafluorobutyric acid (HFBA) was added, was used as eluent A. A mixture of eluent A and acetonitrile (v/v, 40/60) was used as eluent B. The eluents were pumped at a flow rate of 1 mL/min in a gradient system (0 min, 3% B; 15 min, 60% B; 18 min, 80% B; 21 min, 3% B; 27 min, 3% B). The injection volume was 20 µL. Absorbance was measured simultaneously at 220 nm as well as 280 nm. UV spectra were recorded between 190 and 400 nm throughout the run. Prior to analysis, 50 µL of each sample were diluted with 150 µL ultrapure water, centrifuged (10,000×g, 10 min, RT), and the supernatants were transferred to HPLC vials (1.5 mL, glass, VWR, Darmstadt, Germany) with inserts (5 mm × 31 mm, Macherey-Nagel, Düren, Germany). Concentration determinations were carried out by external calibrations in ultrapure water of HMF, BHMF and FFCA from five calibration points each, covering the concentration range from 1.0 to 300 µM.

Analysis of 3-deoxyglucosone

The analysis was performed using the same instrument as described above with the measurement system and the gradient elution according to Degen et al. [8]. The injection volume was 20 µL. Absorbance was measured at 312 nm and UV spectra were recorded between 190 and 400 nm throughout the run. Prior to analysis, samples were centrifuged (10,000×g, 10 min, RT) and then derivatized. For this purpose, 50 µL of each of the sample supernatants was diluted with 200 µL of ultrapure water and 150 µL of a 0.5 M sodium phosphate buffer (pH 6.5) and 150 µL of a 0.2% solution of o-phenylenediamine (OPD) were added. The mixtures were stored overnight in the dark and transferred to HPLC vials with inserts the next day. Concentrations of 3-DG as its quinoxaline were determined by external calibration in ultrapure water of a quinoxaline standard mix containing the quinoxalines of 3-DG, 3-DGal, 3-deoxypentosulose (3-DPs), GO and MGO from 5 calibration points each covering the concentration range from 1.0 to 100 µM. Quinoxalines were synthesized according to Hellwig et al. [38].

Gas chromatography with mass spectrometric detection (GC–MS)

Analysis of potential 3-DG metabolites was based on previous work [4, 24] using an HP 6890A gas chromatograph with an HP 7683 automated liquid sampler and an HP 5973 mass spectrometer (Agilent, Waldbronn, Germany). The analysis was performed using the MSD ChemStation software from Agilent Technologies. The column type was an HP-5 MS UI capillary column (30 m, 0.25 mm diameter, 0.25 µm film thickness, Agilent, Germany). Helium was used as the carrier gas at a constant flow rate of 1.0 mL/min. The injection temperature was 250 °C and 2 µL of samples were injected in pulsed splitless mode. The oven temperature program started at 70 °C (hold time: 2 min), was increased to 260 °C (7 °C/min), and finally heated to 300 °C (20 °C/min). The run was followed by the post-run with a duration of 9 min. The mass spectrometer was used with electron ionization (70 eV) in Scan and SIM modes with the parameters listed in Table 2. In the analytical runs of the samples, mass spectra were recorded with the same gradient in the m/z range between 70 and 700.

Sample preparation followed corresponding publications [4, 24, 34]. Initially, samples were diluted 1:10 with ultrapure water (100 µL sample and 900 µL RW). Then, 25 µL of each sample were taken and mixed with 5 µL IS [13C]3-DG and 15 µL ultrapure water in a new tube. Then, 265 µL each of an acetonitrile/methanol mixture (v/v, 70/30) was added for protein precipitation and the solutions were shaken and stored at 4 °C for 1 h. After centrifugation (10,000×g, 10 min, 4 °C), 200 µL of the supernatant were transferred to a new tube and concentrated to dryness overnight using nitrogen in the Turbo VAP LV evaporator (Zymark, Idstein, Germany). Subsequently, samples were mixed with 100 µL hydroxylamine hydrochloride (10 mg/mL in dry pyridine), shaken, and incubated at 80 °C for 30 min in a water bath. After subsequent centrifugation (2000×g, 2 min, RT), the solutions were evaporated again. Then, 50 µL of BSTFA/TCMS was added to each sample, shaken, and incubated for 2 h at RT. Prior to measurement, 250 µL of cold n-hexane was added to each sample, centrifuged again (10,000×g, 10 min, RT), and finally 80 µL of the supernatant was transferred to a GC vial (Merck, Darmstadt, Germany) with insert. For quantification, an external calibration spiked with IS was carried along. This was processed analogously to the samples from the precipitation step with the acetonitrile/methanol mixture and covered a calibration range of 1.0–20 µM (3-DG) and 0.33–2 µM (3-DF and 3-deoxy-2-ketogluconic acid (3-DGA)) consisting of 7 calibration points. Oximation leads to the formation of syn- and anti-isomers. In the evaluation, the areas of both isomers of 3-DF were considered for quantification.

Cell disruption for analysis of internalized MRPs

For accounting the recovery of 3-DG and HMF by the yeast strains, cell disruption of the samples after 24 h incubation was performed. For this, the suspensions were centrifuged (10,000×g, 10 min, 4 °C), the supernatant was removed, and 200 µL of a 20 mM Tris–HCl buffer with an adjusted pH of 7.5 and glass beads (diameter: 0.5 mm, FR0603, Retsch, Haan, Germany) were added to the residue. Samples were then shaken in a vortex mixer (Minishaker MS-1 Ika, Bandelin, Berlin, Germany) for 1 min and then placed on ice for 1 min. This procedure was repeated a total of 5 times. The supernatant was then pipetted off and centrifuged again (10,000×g, 10 min, RT). For samples incubated with HMF, the supernatant was transferred directly to an HPLC vial with insert and measured. For the samples incubated with 3-DG, the procedure for GC–MS measurement was continued in the same way as described above. For this purpose, the supernatants were used without prior 1:10 dilution.

Results and discussion

Degradation of 3-DG and HMF by Saccharomyces strains

Previous studies have demonstrated that yeasts are able to metabolize various MRPs, such as glycated dipeptides or HMF [23, 24, 26, 28, 29]. Furthermore, model studies have recently demonstrated for the first time that 3-DG and other 1,2-dicarbonyl compounds are reduced by a strain of brewer's yeast (S. cerevisiae DSM 1848) [24]. Here, we investigated whether different Saccharomyces yeast strains, which are commercialized as beer or wine yeast strains or which originate from natural habitats are also able to utilize MRPs and whether there are differences between yeast strains and/or yeast species in terms of the metabolization. Therefore, the aim of the present study was to investigate the stability and metabolization of 3-DG and HMF in the presence of different species of the genus Saccharomyces. For a better comparability of the results generated in the current study with those described in the literature the frequently investigated Saccharomyces cerevisiae strain DSM 1848 was included. In addition, the top-fermenting S. cerevisiae brewer's yeast strain DSM 70449, commercially available brewer’s yeast strains of the species S. cerevisiae and S. pastorianus, the S. cerevisiae wine yeast strain KRS, and various strains of the species S. cerevisiae, S. uvarum, and S. paradoxus isolated from natural habitats were investigated. Incubations were performed at 30 °C in a minimal medium in order to compare the results with previous studies [24]. As brewer’s yeast strains in wort normally operate at 8–14 °C (bottom-fermenting strains) and 18–24 °C (top-fermenting strains), and wine yeast strains in grape must at 15–25 °C, this study has to be considered a model study [39, 40].

To ensure that the degradation and metabolization rates of the Saccharomyces strains were comparable, yeast cells were counted at a calculated OD (optical density) of 5. The cell counts of the studied yeast strains obtained in this process were on average 5.7 × 107 cells/mL. The yeast strains isolated from natural habitats had smaller cells than the brewer's yeast strains, but the cell numbers were still in a similar range. Therefore, the starting incubation conditions of the yeasts can be considered comparable. To investigate the stability of the MRPs in minimal medium, a substance blank (SB) without yeasts was included in each incubation. It was found that both 3-DG and HMF were not chemically degraded with a stability of 99.1 ± 1.2% and 102.8 ± 6.0% (n = 6), respectively. Therefore, the degradation of the compounds in the incubated samples can be completely attributed to the yeast cells. With the aim of documenting potential growth-influencing effects of 3-DG and HMF on the yeast cells, OD600 was measured from the yeast samples after the 24 h incubations and related to the respective OD600 of the yeast blanks (YB). It was found that at the concentrations of 3-DG (0.25 mM) and HMF (1 mM) present in the samples there was no growth inhibitory effect except for the yeast strain S91-OA, isolated from natural habitats. Some brewer’s yeast strains even showed slightly increased growth in the presence of 3-DG. Overall, this supports the statement that the toxicological effects of the MRPs and, therefore, the degradation and metabolization performances of the yeast strains are comparable. The results of the cell counts at OD = 5 and the calculated cell densities after incubation can be found in the supplement (Table S1). Figure 2 shows the degradation of 3-DG after 24 h as well as of HMF after 3 h and 24 h incubation. Since the measured values at 0 h were comparable for all yeast strains, the percentages were related to the respective blank sample (SB). Figure 3 shows chromatograms obtained for the supernatants of two selected yeast strains following HPLC with UV detection at 312 nm. As a representative of brewer's yeasts, S. cerevisiae strain SafAle T-58 (Fig. 3A) showed an increased 3-DG degradation after 24 h incubation compared to S. uvarum strain S91-OA, a representative of the yeast strains isolated from natural habitats (Fig. 3B). All yeast strains examined were able to degrade 3-DG within 24 h, however, to a different extent. While for four of the six brewer’s yeast strains degradation rates ranging between 50 and 60% were observed, the strains isolated from natural habitats and the wine yeast strain were only able to degrade 10–30% of 3-DG (Fig. 2A). For the bottom-fermenting S. pastorianus brewer's yeast strain SafLager W34/70 as well as the top-fermenting S. cerevisiae brewer’s yeast strain BE-256, a low degradation capacity similar to the S. cerevisiae wine yeast strain and strains isolated from natural habitats was observed. In the case of the yeast strain W34/70, the high incubation temperature could be a reason for the slow degradation of 3-DG, since the normal operating temperature of this bottom-fermenting yeast in technological applications is about 10 °C. No differences in degradation capacity were observed when comparing the strains or the species S. cerevisiae, S. uvarum and S. paradoxus, which had been isolated from natural habitats.

Relative amount of 3-DG or HMF, respectively, in the extracellular supernatant of yeast samples (divided into brewer’s yeast strains, wine yeast strain, and yeast strains isolated from a natural habitat), following incubation in minimal medium at 30 °C. A 3-DG, 0.25 mM initial concentration, 24 h incubation; B HMF, 1 mM initial concentration, 3 h incubation; C HMF, 1 mM initial concentration, 24 h incubation. Data are given as percentage of concentration relative to the non-inoculated sample (substance blank) as mean value ± SD (n = 6)

RP-HPLC with UV detection at 312 nm of the supernatants of A Saccharomyces cerevisiae brewer’s yeast strain SafAle T-58 and B Saccharomyces uvarum yeast strain S91-OA, isolated from a natural habitat, comparing yeast blank (YB, 0 h), and the incubation sample consisting of yeast suspension and added 3-DG (0.25 mM) at the beginning of the experiment (0 h) and after 24 h of incubation (gray traces). The used 3-DG standard in minimal medium is represented as a black line

Under comparable conditions, HMF (1 mM) was degraded faster than 3-DG. After 3 h of incubation, the degradation rate was already at 19–32% (Fig. 2B). At this point in time, no pronounced differences between the yeast strains were observed. After 24 h, residual amounts ranging between 10 and 31% of HMF were measured in the extracellular supernatant (Fig. 2C), corresponding to an average degradation rate of 80%. It is notable that the five investigated yeast strains of the species S. uvarum and S. paradoxus that had been isolated from natural habitats showed almost identical degradation rates (77–79%) with little variation. For both sampling times, the yeast strains of S. cerevisiae DSM 70449, SafAle WB-06, KRS as well as S402-OA were slightly more efficient in HMF degradation, but no markable differences between brewer’s yeast strains and strains isolated from natural habitats were observed.

Metabolization of 3-DG and HMF by Saccharomyces yeasts

In a previous study, the S. cerevisiae brewer’s yeast strain DSM 1848, also used here, was shown to reduce 3-DG to 3-DF [24]. This could be confirmed in this study for all yeast strains of different Saccharomyces species by GC measurement after 24 h incubation at 30 °C in a minimal medium containing 0.25 mM 3-DG. The 3-DF formation is shown exemplarily in the chromatograms in Fig. 4 for two selected yeast strains (gray lines). Thereby, the brewer’s yeast strain S. cerevisiae SafAle T-58 (Fig. 4A) showed an increased 3-DF formation when compared with the yeast strain S. uvarum S91-OA, which had been isolated from a natural habitat (Fig. 4B). The relative amounts of 3-DG and 3-DF after 24 h incubation in the extracellular supernatant of all yeasts examined are shown in Fig. 5A. The 3-DF formation ranged from 1 to 17% (mean 9.4%) with S. cerevisiae wine yeast strain KRS showing the lowest and S. cerevisiae brewer’s yeast strain SafAle WB-06 the highest formation of 3-DF. No general differences between the group of brewer’s yeast strains and the group of strains isolated from natural habitats regarding the 3-DF formation were observed. It is notable that the sum of 3-DF and residual 3-DG in the extracellular supernatant of four brewer’s yeast strains, ranging from 56 to 65% (mean 60.8%), is considerably lower when compared with the other yeast strains (79–94%, mean 85.7%). This indicates differences in the metabolism of these S. cerevisiae brewer’s yeast strains. Another possible metabolite of 3-DG, namely 3-DGA, which is formed from 3-DG by oxidation via the aldehyde dehydrogenase ALDH1A1 and present in human erythrocytes [34, 41, 42], was not detected in the extracellular supernatant of the yeast samples.

GC with mass spectrometric detection (selected ion monitoring at m/z 214 and 347) of the supernatants of A Saccharomyces cerevisiae brewer’s yeast strain SafAle T-58 and B Saccharomyces uvarum yeast strain S91-OA, isolated from a natural habitat. Shown are the yeast blank samples (YB) and the incubation sample consisting of yeast suspension and added 3-DG (0.25 mM) after 24 h incubation (gray lines) and after cell disruption (CD, blue lines). Samples were prepared for measurement by oximation and silylation. 3-DG and 3-DF in ultrapure water were used as standards (black lines)

Relative amount of 3-DG, HMF and the metabolites 3-DF, BHMF and FFCA in the extracellular supernatant of yeast samples (divided into brewer’s yeast stains, wine yeast strain, and yeast strains isolated from a natural habitat), following incubation in minimal medium at 30 °C. A 3-DG, 0.25 mM initial concentration, 24 h incubation; B HMF, 1 mM initial concentration, 3 h incubation; C HMF, 1 mM initial concentration, 24 h incubation. Data are given as percentage of concentration relative to the non-inoculated sample (substance blank) as mean value (n = 3 for 3-DG, n = 6 for HMF)

RP-HPLC chromatograms for the incubation experiments with HMF are shown in Fig. 5. In parallel with the decrease of HMF, two peaks detectable only at 220 nm and eluting before HMF were observed after 3 h of incubation. Their peak areas increased with incubation time, while the peak of HMF decreased. By comparison with an authentic standard, this peak could be assigned to 2,5-bishydroxymethylfuran (BHMF). 11–23% of HMF were recovered as BHMF after 3 h of incubation, which increased to 46–70% BHMF after 24 h of incubation. The reduction of HMF to BHMF by yeast cells has been described in the literature [26, 28, 29, 43]. For eight of the investigated yeast strains, a second peak could be detected after 3 h and 24 h of incubation at both wavelengths of 220 nm and 280 nm, which eluted before BHMF and had a much lower intensity. By comparison with an authentic standard, this peak could be identified as 5-formyl-2-furancarboxylic acid (FFCA). Oxidation of HMF to FFCA has also been reported in the literature as another, less pronounced metabolic pathway in yeast cells [28, 44]. The top-fermenting S. cerevisiae brewer's yeast strain SafAle WB-06 showed an increased FFCA formation of 5% compared to the other yeasts. The strains isolated from natural habitats showed overall no FFCA formation after 3 h. The relative amounts of HMF, BHMF and FFCA found extracellularly after 3 h incubation for each yeast strain are shown in the supplement (Table S2). After 24 h, both BHMF and FFCA were found in all yeast samples except for S. paradoxus yeast strain S466-OA, with BHMF as the major metabolite. The extracellular fraction of BHMF determined after 24 h was 46–70%, and the formation of FFCA was 2–10% of the initial amount of HMF (Fig. 5C). In addition, after 24 h, the top-fermenting brewer’s yeast strain SafAle WB-06 showed the most pronounced FFCA formation. No trends were identified in terms of metabolite formation or metabolite pattern between technologically relevant yeast strains and yeast strains isolated from natural habitats plus species. Furthermore, it is remarkable that with the exception of the bottom-fermenting brewer’s yeast strain SafLager W34/70, the amount of extracellular quantifiable HMF-derivatives after 24 h is not sufficient to outweigh and fully explain the HMF degradation. The sum of residual HMF and formed metabolites was 70–90%.

Measurement of intracellular compounds and possible adsorption of 3-DG and HMF to the yeast cell

In Fig. 7, the intra- and extracellular concentrations as well as the adsorbed amounts of 3-DG, HMF and the corresponding metabolites are shown. Since 3-DG is highly reactive due to its dicarbonyl structure, reactions with the yeast cell, whose outer layer consists mainly of mannoproteins, is conceivable [45, 46]. After 24 h incubation of autoclaved yeast cells with 3-DG followed by removal of the cells by centrifugation, a markable decrease of the 3-DG amount in the supernatant was observed. This ranged from 1 to 28% of the initial amount of 3-DG, with the bottom-fermenting brewer’s yeast strain W34/70 showing the lowest (1.4 ± 0.3%) adsorption and nature-isolated yeast strain S466-OA the highest (28.2 ± 8.4%). These differences might be due to the fact that yeast strains differ in their cell wall structure and thus in the content of potential nucleophilic groups, which can attach to the carbonyl groups of the 3-DG [47]. Since the adsorption to the yeast cell could not fully explain the metabolization gap, especially for the strains of brewer's yeasts, an additional cell disruption was performed and the intracellular content of all yeast samples was measured. Figure 4 shows the chromatograms of corresponding sample of two selected yeast strains measured by RP-HPLC and GC–MS. While 3-DG or 3-DF, respectively, were not detected in the disrupted yeast cells derived from cultures which were isolated from natural habitats (example in Fig. 4B, blue lines), both 3-DG and 3-DF could be detected in 5 strains of brewer’s yeasts examined (example in Fig. 4A, blue lines). The intracellular amount of 3-DG accounted for 6–12% and of 3-DF for 1–4% of the initial amount of 3-DG. 3-DGA was not detected in the intracellular supernatants either. The relative amounts of 3-DG and 3-DF found extracellularly and intracellularly in each yeast strain, as well as adsorption to the cell, are shown in the supplement (Table S3). Taking together the intracellular and extracellular present amounts of 3-DG and 3-DF and considering the adsorption of 3-DG to the yeast cell, a good recovery of the initially applied amount of 3-DG was found, ranging between 81 and 113% (Fig. 7A). However, it cannot be ruled out that further, currently unknown metabolites are present or that the yeasts have used 3-DG in small amounts as a carbon source. Furthermore, it is conceivable that the 3-DG taken up into the cells partially adsorbs to intracellular proteins or other components of the yeast cell. Particularly noteworthy was the observation that only for the brewer’s yeast strains (with BE-256 being an exception) a substantial amount of intracellular 3-DG and 3-DF was measured, indicating that the brewer’s yeast strains might differ from the strains isolated from natural habitats in terms of 3-DG metabolism in their enzyme or transport systems.

Since HMF also has a carbonyl group, adsorption to the yeast cell is also possible. Following incubation of HMF with autoclaved yeast cells for 24 h, some yeast strains showed a slight but negligible adsorption to the yeast cell of 0.5–3%. Only for the bottom-fermenting brewer’s yeast strain SafLager W34/70 an adsorption of 7.2% was observed. In order to further elucidate the metabolization of HMF by the Saccharomyces yeasts, cell disruption was also performed for the same samples and the supernatants were subsequently measured by RP-HPLC-UV. Figure 6 shows the corresponding chromatograms using two yeast strains as examples (cell disruption, CD). Amounts of BHMF ranging between 6.5 and 18.5% of the initial amount of HMF and small amounts of HMF with 1–6% were found in the supernatants after cell disruption of all yeast strains examined. Intracellular FFCA (1–5%) was also found in all yeasts except the top-fermenting yeast strain DSM 70449. Again, the top-fermenting brewer's yeast strain SafAle WB-06 showed, as already after the 3 h incubation, a particularly pronounced FFCA formation. The relative amounts of HMF, BHMF, and FFCA found extracellularly and intracellularly of each yeast strain, as well as the amounts adsorbed to the cells, are shown in the supplement (Table S4). Regarding the degradation of HMF and formation of its metabolites, no pronounced differences between brewer’s yeast strains, yeast strains from natural habitats and yeast species were found. The metabolization proceeds yeast-specifically. By accounting the intracellularly and extracellularly quantified relative amounts of HMF and the metabolites BHMF and FFCA formed by reduction and oxidation, the HMF metabolism can be almost completely elucidated in all yeast strains studied, as the total recovery was 90–120% (Fig. 7B). It would be conceivable that additional small amounts of HMF and/or its metabolites are attached to amino groups of proteins or to other yeast components inside the cell.

RP-HPLC with UV detection of the supernatants of A Saccharomyces cerevisiae brewer’s yeast strain SafAle T-58 and B Saccharomyces uvarum yeast strain S91-OA isolated from a natural habitat. Shown are the yeast blank (YB, 0 h), the incubation sample consisting of yeast suspension and added HMF (1 mM) at the beginning of the experiment (0 h), after 3 h and after 24 h of incubation, and the yeast blank (YB) and incubation sample after cell disruption (CD). HMF, BHMF and FFCA in ultrapure water were used as standards. The black lines were recorded at 280 nm and used for HMF evaluation. The gray lines were recorded at 220 nm and used for metabolite evaluation

Accounting of the degradation of carbonyl compounds and the formation of metabolites following incubation of yeast strains for 24 h in minimal medium at 30 °C. A 3-DG, initial concentration 0.25 mM, and B HMF, initial concentration 1 mM. extra extracellular amount, intra intracellular amount measured after cell disruption, ads amount adsorbed/bound to cells. Data are given as a percentage of the applied concentration of 3-DG or HMF, respectively, relative to the non-inoculated sample (substance blank) as mean value (n = 3 for 3-DG, n = 6 for HMF)

Dead/live-cell experiments

Here, we investigated whether 3-DG and HMF are cytotoxic compounds for yeast cells in the concentrations used for our incubation experiments. While 3-DG irreversibly modifies free amino groups in lipids, nucleic acids as well as proteins with the highly reactive carbonyl groups contained in its structure [5], HMF is known to influence yeast growth as well as protein and RNA syntheses and thus leads to a reduction in the efficiency of fermentation capacity [26, 28]. Both substrates thus may lead to cell death at higher concentrations. After 24 h of incubation in the presence of 1 mM HMF or 0.25 mM 3-DG, the OD600 of the yeast samples and the yeast blanks (YB) were determined. No growth inhibitory effect was observed here (Supplements Table S1). However, when measuring the OD, it is not possible to differentiate between dead and living cells; only the biomass or the turbidity of the cell suspension is determined here. In order to actually assess the influence of 3-DG and HMF on the cell viability of the investigated yeast strains, the percentage of dead cells within the total cell number of the yeast samples and the YBs without substrate addition were determined before and after 24 h incubation at 30 °C in minimal medium. The concentrations of MRPs in the incubation solutions were 0.25 mM for 3-DG and 1 mM for HMF. Using methylene blue staining, it was found that prior to incubation, no dead cells were present in any of the yeast strains examined. In contrast, after the 24 h incubations, dead cells were found in all yeast samples following incubation in the presence of 3-DG as well as HMF (Fig. 8). After incubation with 3-DG, the percentage of dead cells among all yeasts after subtracting YBs was 0.1–19.6% (mean 12.0 ± 1.0%), while for HMF incubation it was between 6.4 and 17.5% (mean 10.1 ± 2.8%). Thus, the inhibitions of the yeast strains by the MRPs are in a comparable range. Since a concentration of 0.25 mM was used for 3-DG and a concentration of 1 mM for HMF, 3-DG appears to have a higher average toxicity for the yeast strains tested. Comparing the investigated brewer's yeast strains with the strains isolated from natural habitats as well as the wine yeast strain, no differences regarding the percentage of dead cells following incubation in the presence of HMF was found (Fig. 8B). However, beer yeast strains and strains isolated from natural habitats clearly differed in their viability during incubation with 3-DG (Fig. 8A). While for the brewer’s yeast strains, only between 0 and 10% (mean 4.3 ± 3.5%) dead cells were found, significantly (ρ < 0.0005) higher relative amounts of dead cells, ranging between 16.3 and 19.6% (mean 18.0 ± 1.1%), were observed for the yeast strains isolated from natural habitats and the wine yeast strain. For HMF incubation, the range of inhibition for both brewer’s yeast strains and strains isolated from natural habitats was approximately 7–17%, with nature-isolated strain S96-OA showing the lowest inhibition at 6.4% and top-fermenting brewer’s yeast strain DSM 70449 showing the highest inhibition at 17.5%. The individually determined percentages of dead cells after 24 h incubations of the samples with spiked MRPs as well as the YBs of all yeast strains are listed in the supplements (Table S5).

A Dead/live assay of the Saccharomyces yeast strains, divided into brewer's yeast strains (beer) and yeast strains isolated from natural habitats (nature-isolated), after 24 h incubation in minimal medium at 30 °C with A 0.25 mM 3-DG or B 1 mM HMF. Shown are the mean values of the percentages of dead cells in the incubation mixtures after subtraction of dead cells in the yeast blanks without substrate addition (n = 6). Data are presented as box plots. The square indicates the mean value and the line indicates the median. Significance: ***ρ < 0.0005

Conclusion

In conclusion, we show that the MRPs 3-DG and HMF are metabolized by yeast strains of the Saccharomyces genus with differences between them. HMF is degraded and metabolized to BHMF as the major metabolite and FFCA formed in small amounts by each strain. The rate of metabolization, the distribution of HMF and the metabolites inside and outside the yeast cells and the HMF stress resistance are yeast-specific. In the metabolism and stress resistance of 3-DG, differences between the brewer's yeast strains and strains isolated from natural habitats were shown. All yeast strains are able to reduce 3-DG to 3-DF. We have found evidence that the transport of 3-DG into the yeast cells occurs faster for some beer yeast strains when compared with strains isolated from natural habitats and the wine yeast strain. Furthermore, only in brewer’s yeast strains, 3-DG and 3-DF can be detected in the cells after cell disruption. To what extent these properties have consequences for the yeast cells or whether the yeasts draw a benefit for themselves, cannot be answered in the course of this work. From the Dead/Live Assay can be inferred, that all examined beer yeast strains exhibit a clearly higher 3-DG stress resistance than the yeast strains isolated from natural habitats. Due to selective breeding and selection of technologically suitable yeasts by humans and the high plasticity of the yeast genome, this adaptation could be an indication of domestication [19]. Approximately 10 times more 3-DG is found in beer wort than HMF [17, 18], which could explain why no difference between brewer’s yeast strains and yeast strains isolated from natural habitats is evident in HMF utilization. That the wine yeast strain acts similarly to strains isolated from natural habitats with respect to 3-DG metabolization and stress resistance, although high levels of 3-DG may be present in wine [8, 14, 48], is possibly due to their technological use. While wine is produced seasonally and wine yeasts are in constant contact with “natural” strains of the grape microbiota, brewer’s yeasts are grown as pure cultures throughout the year and re-used in the brewing process. As a result, they lose contact with their natural niches and adapt to the substrates of the beer wort (e.g., maltotriose and maltose as carbon sources) to survive and work efficiently [16]. Linking the differences in metabolization of 3-DG between the beer yeast strains and strains from natural habitats to the 3-DG toxicity studies is not possible here.

It must be emphasized that this study is a model study because the incubations were performed at 30 °C in a minimal medium with continuous shaking. In technological applications, fermentation experiments in wine and beer production take place at lower temperatures. Whether and to what extent 3-DG and HMF present in wort or must have an influence on the fermentation behavior of technologically relevant yeast can not be assessed yet. Based on the data found for malt, contents of approximately 200 µM 3-DG and 3 µM HMF might be found in the wort. The 3-DG concentrations used in our study were only slightly higher than those possible in wort and, therefore, 3-DG, but not HMF, may have an influence on the fermentation process. This will be considered in our further fermentation experiments with the different Saccharomyces yeast strains in wort and must, spiked with different concentrations of MRPs, under technologically relevant conditions. In addition, it will be interesting to investigate other MRPs such as MGO or furfural, since these compounds are also cytotoxic for yeast cells and a comparison of yeast strains with regard to their metabolization and stress resistance is still pending [22, 28, 49,50,51,52]. Studies on this are already being carried out in our laboratory.

Abbreviations

- 3-DF:

-

3-Deoxyfructose

- 3-DG:

-

3-Deoxyglucosone

- 3-DGA:

-

3-Deoxy-2-ketogluconic acid

- 3-DGal:

-

3-Deoxygalactosone

- 3-DP:

-

3-Deoxypentosone

- 3-DPs:

-

3-Deoxypentosulose

- AGEs:

-

Advanced glycation endproducts

- BHMF:

-

2,5-Bis-(hydroxymethyl)furfural

- BSTFA:

-

N,O-Bis-(trimethylsilyl)-trifluoroacetamide

- CD:

-

Cell disruption

- DNA:

-

Deoxyribonucleic acid

- DSMZ:

-

Collection of Microorganisms and Cell Cultures

- EZ:

-

Extracellular

- FF:

-

Furfural

- FFCA:

-

5-Formyl-2-furancarboxylic acid

- GC:

-

Gas chromatography

- GO:

-

Glyoxal

- HFBA:

-

Heptafluorobutyric acid

- HMF:

-

5-Hydroxymethylfurfural

- HP:

-

Heyns products

- HPLC:

-

High-performance liquid chromatography

- IS:

-

Internal standard

- IZ:

-

Intracellular

- m/z :

-

Mass/number of charge

- MGO:

-

Methylglyoxal

- MRPs:

-

Maillard reaction products

- MS:

-

Mass spectrometer

- OD:

-

Optical density

- OPD:

-

Ortho-phenylenediamine

- RT:

-

Room temperature

- SB:

-

Substance blank

- SIM:

-

Selected ion monitoring

- TMCS:

-

Trimethylchlorsilane

- UV:

-

Ultraviolet

- YB:

-

Yeast blank

- YMPD:

-

Yeast extract-malt extract-peptone-dextrose

References

Hellwig M, Henle T (2014) Baking, ageing, diabetes: a short history of the Maillard reaction. Angew Chem Int Ed 53:10316–10329. https://doi.org/10.1002/anie.201308808

Hellwig M, Gensberger-Reigl S, Henle T, Pischetsrieder M (2018) Food-derived 1,2-dicarbonyl compounds and their role in diseases. Semin Cancer Biol 49:1–8. https://doi.org/10.1016/j.semcancer.2017.11.014

Turk Z (2010) Glycotoxines, carbonyl stress and relevance to diabetes and its complications. Physiol Res 59:147–156. https://doi.org/10.33549/physiolres.931585

Degen J, Beyer H, Heymann B, Hellwig M, Henle T (2014) Dietary influence on urinary excretion of 3-deoxyglucosone and its metabolite 3-deoxyfructose. J Agric Food Chem 62:2449–2456. https://doi.org/10.1021/jf405546q

Belitz D, Grosch W, Schieberle P (2008) Lehrbuch Der Lebensmittelchemie, 6th edn. Springer, Berlin

Suzuki D, Miyata T, Kurokawa K (2001) Carbonyl stress. Contrib Nephrol 134:36–45. https://doi.org/10.1159/000060151

Niwa T (1999) 3-Deoxyglucosone: metabolism, analysis, biological activity, and clinical implication. J Chromatogr B 731:23–36. https://doi.org/10.1016/S0378-4347(99)00113-9

Degen J, Hellwig M, Henle T (2012) 1,2-Dicarbonyl compounds in commonly consumed foods. J Agric Food Chem 60:7071–7079. https://doi.org/10.1021/jf301306g

Maillard LC (1912) Action des acides aminés sur les sucres. Formation des mélanoidines par voie méthodique. Acad Sci Ser 145:66–68

Henle T (2003) AGEs in foods: do they play a role in uremia? Kidney Int Suppl 84:145–147. https://doi.org/10.1046/j.1523-1755.63.s84.16.x

Gensberger S, Glomb MA, Pischetsrieder M (2013) Analysis of sugar degradation products with α-dicarbonyl structure in carbonated soft drinks by UHPLC-DAD-MS/MS. J Agric Food Chem 61:10238–10245. https://doi.org/10.1021/jf3048466

Aktag I, Gökmen V (2020) A survey of the occurrence of α-dicarbonyl compounds and 5-hydroxymethylfurfural in dried fruits, fruit juices, puree and concentrates. J Food Compos Anal 91:103523. https://doi.org/10.1016/j.jfca.2020.103523

Mavric E, Wittmann S, Barth G, Henle T (2008) Identification and quantification of methylglyoxal as the dominant antibacterial constituent of Manuka (Leptospermum scoparium) honeys from New Zealand. Mol Nutr Food Res 52:483–489. https://doi.org/10.1002/mnfr.200700282

Hellwig M, Nobis A, Witte S, Henle T (2016) Occurrence of (Z)-3,4-dideoxyglucoson-3-ene in different types of beer and malt beer as a result of 3-deoxyhexosone interconversion. J Agric Food Chem 64:2746–2753. https://doi.org/10.1021/acs.jafc.6b00468

Pires EJ, Teixeira JA, Brányik T (2014) Yeast: the soul of beer’s aroma—a review of flavour-active esters and higher alcohols produced by the brewing yeast. Appl Microbiol Biotechnol 98:1937–1949. https://doi.org/10.1007/s00253-013-5470-0

Gallone B, Steensels J, Prahl T, Soriaga L, Saels V, Herrera-Malaver B, Merlevede A, Roncoroni M, Voordeckers K, Miraglia L, Teiling C, Steffy B, Taylor M, Schwartz A, Richardson T, White C, Baele G, Maere S, Verstepen KJ (2016) Domestication and divergence of Saccharomyces cerevisiae beer yeasts. Cell 166:1397–1410. https://doi.org/10.1016/j.cell.2016.08.020

Nobis A, Röhrig A, Hellwig M, Henle T, Becker T, Gastl M (2019) Formation of 3-deoxyglucosone in the malting process. Food Chem 290:187–195. https://doi.org/10.1016/j.foodchem.2019.03.144

Hellwig M, Henle T (2020) Maillard reaction products in different types of brewing malt. J Agric Food Chem 68:14274–14285. https://doi.org/10.1021/acs.jafc.0c06193

Legras JL, Galeote V, Bigey F, Camarasa C, Marsit S, Nidelet T, Sanchez I, Couloux A, Guy J, Franco-Duarte R, Marcet-Houben M, Gabaldon T, Schuller D, Sampaio JP, Dequin S (2018) Adaptation of S. cerevisiae to fermented food environments reveals remarkable genome plasticity and the footprints of domestication. Mol Biol Evol 35:1712–1727. https://doi.org/10.1093/molbev/msy066

Gallone B, Mertens S, Gordon JL, Maere S, Verstrepen KJ, Steensels J (2018) Origins, evolution, domestication and diversity of Saccharomyces beer yeasts. Curr Opin Biotechnol 49:148–155. https://doi.org/10.1016/j.copbio.2017.08.005

Querol A, Fernandez-Espinar MT, Del Olmo M, Barrio E (2003) Adaptive evolution of wine yeast. Int J Food Microbiol 86:3–10. https://doi.org/10.1016/S0168-1605(03)00244-7

Murata K, Fukuda Y, Shimosaka M, Watanabe K, Saikusa S, Kimura A (1985) Phenotypic character of the methylglyoxal resistance gene in Saccharomyces cerevisiae: expression in Escherichia coli and application to breeding wild-type yeast strains. Appl Environ Microbiol 50:1200–1207. https://doi.org/10.1128/aem.50.5.1200-1207.1985

Hellwig M, Börner M, Beer F, Van Pée KH, Henle T (2017) Transformation of free and dipeptide-bound glycated amino acids by two strains of Saccharomyces cerevisiae. ChemBioChem 18:266–275. https://doi.org/10.1002/cbic.201600486

Hellwig M, Börner M, Henle T (2021) Reduction of 5-hydroxymethylfurfural and 1,2-dicarbonyl compounds by Saccharomyces cerevisiae in model systems and beer. J Agric Food Chem 69:12807–12817. https://doi.org/10.1021/acs.jafc.1c04760

Martins A, Cordeiro C, Ponces Freire A (2001) In situ analysis of methylglyoxal metabolism in Saccharomyces cerevisiae. FEBS Lett 499:41–44. https://doi.org/10.1016/S0014-5793(01)02519-4

Almeida JRM, Röder A, Modig T, Laadan B, Lidén G, Gorwa-Grauslund MF (2008) NADH- vs NADPH-coupled reduction of 5-hydroxymethyl furfural (HMF) and its implications on product distribution in Saccharomyces cerevisiae. Appl Microbiol Biotechnol 78:939–945. https://doi.org/10.1007/s00253-008-1364-y

Van Bergen B, Cyr N, Strasser R, Blanchette M, Sheppard JD, Jardim A (2016) α, β-Dicarbonyl reduction is mediated by the Saccharomyces old yellow enzyme. FEMS Yeast Res 16:1–12. https://doi.org/10.1093/femsyr/fow059

Liu ZL, Slininger PJ, Dien BS, Berhow MA, Kurtzman CP, Gorsich SW (2004) Adaptive response of yeasts to furfural and 5-hydroxymethylfurfural and new chemical evidence for HMF conversion to 2,5-bis-hydroxymethylfuran. J Ind Microbiol Biotechnol 31:345–352. https://doi.org/10.1007/s10295-004-0148-3

Akillioglu HG, Mogol BA, Gökmen V (2011) Degradation of 5-hydroxymethylfurfural during yeast fermentation. Food Addit Contam 28:1629–1635. https://doi.org/10.1080/19440049.2011.609491

Ruyters S, Mukherjee V, Verstrepen KJ, Thevelein JM, Willems KA, Lievens B (2015) Assessing the potential of wild yeasts for bioethanol production. J Ind Microbiol Biotechnol 42:39–48. https://doi.org/10.1007/s10295-014-1544-y

Liu ZL (2011) Molecular mechanisms of yeast tolerance and in situ detoxification of lignocellulose hydrolysates. Appl Microbiol Biotechnol 90:809–825. https://doi.org/10.1007/s00253-011-3167-9

Henle T, Bachmann A (1996) Synthesis of pyrraline reference material. Z Lebensm Unters Forsch 202:72–74. https://doi.org/10.1007/BF01229689

Mutz YS, Rosario DKA, Conte-Junior CA (2020) Insights into chemical and sensorial aspects to understand and manage beer aging using chemometrics. Compr Rev Food Sci Food Saf. https://doi.org/10.1111/1541-4337.12642

Rückriemen J, Hellwig A, Schultes S, Hellwig M, Hahne F, Henle T (2018) Studies on the influence of dietary 3-deoxyglucosone on the urinary excretion of 2-keto-3-deoxygluconic acid. Eur Food Res Technol 244:1389–1396. https://doi.org/10.1007/s00217-018-3052-1

Brysch-Herzberg M, Seidel M (2017) Distribution patterns of Saccharomyces species in cultural landscapes of Germany. FEMS Yeast Res 17:1–10. https://doi.org/10.1093/femsyr/fox033

DSMZ (2007) 186. Universalmedium for yeast (YM). http://www.dsmz.de/microorganisms/medium/pdf/DSMZ_Medium186.pdf

Island MD, Perry JR, Naider F, Becker JM (1991) Isolation and characterization of S. cerevisiae mutants deficient in amino acid-includible peptide transport. Curr Genet 20:457–463. https://doi.org/10.1007/BF00334772

Hellwig M, Degen J, Henle T (2010) 3-Deoxygalactosone, a “new” 1,2-dicarbonyl compound in milk products. J Agric Food Chem 58:10752–10760. https://doi.org/10.1021/jf102388v

Lodolo EJ, Kock JLF, Axcell BC, Brooks M (2008) The yeast Saccharomyces cerevisiae—the main character in beer brewing. FEMS Yeast Res 8:1018–1036. https://doi.org/10.1111/j.1567-1364.2008.00433.x

Pagliarini E, Tomaselli N, Brenna OV (2004) Study on sensory and composition changes in Italian Amarone Valpolicella red wine during aging. J Sens Stud 19:422–432. https://doi.org/10.1111/j.1745-459x.2004.122303.x

Collard F, Vertommen D, Fortpied J, Duester G, Van Schaftlingen E (2007) Identification of 3-desoxyglucosone dehydrogenase as aldehyde dehydrogenase 1A1 (retinaldehyde dehydrogenase 1). Biochimie 89:369–373. https://doi.org/10.1016/j.biochi.2006.11.005

Fujii E, Iwase H, Ishii-Karakasa I, Yajima Y, Hotta K (1995) The presence of 2-keto-3-deoxygluconic acid and oxoaldehyde dehydrogenase activity in human erythrocytes. Biochem Biophys Res Commun 210:852–857. https://doi.org/10.1016/j.bbrc.2004.03.164

Taherzadeh MJ, Gustafsson L, Niklasson C, Lidén G (2000) Physiological effects of 5-hydroxymethylfurfural on Saccharomyces cerevisiae. Appl Microbiol Biotechnol 53:701–708. https://doi.org/10.1007/s002530000328

Nemirovskii VD, Kostenko VK (1991) Transformation of yeast growth inhibitors, which occurs during biochemical processing of wood hydrolysates. Gidroliz Lesokhim Prom-st 1:16–17

Stewart G (2016) Saccharomyces species in the production of beer. Beverages 2:34. https://doi.org/10.3390/beverages2040034

Walker GM (1998) Yeast physiology and biotechnology. Wiley, Chichester

Park JK, Lee JW, Jung JY (2003) Cadmium uptake capacity of two strains of Saccharomyces cerevisiae cells. Enzyme Microb Technol 33:371–378. https://doi.org/10.1016/S0141-0229(03)00133-9

Oliveira CM, Santos SAO, Silvestre AJD, Barros AS, Ferreira ACS, Silva AMS (2016) Quantification of 3-deoxyglucosone (3DG) as an aging marker in natural and forced aged wines. J Food Compos Anal 50:70–76. https://doi.org/10.1016/j.jfca.2016.05.009

Aguilera J, Prieto JA (2001) The Saccharomyces cerevisiae aldose reductase is implied in the metabolism of methylglyoxal in response to stress conditions. Curr Genet 39:273–283. https://doi.org/10.1007/s002940100213

Gomes RA, Vicente Miranda H, Sousa Silva M, Graca G, Coelho AV, Ferreira AE, Cordeiro C, Ponces Freire A (2006) Yeast protein glycation in vivo by methylglyoxal: molecular modification of glycolytic enzymes and heat shock proteins. FEBS J 273:5273–5287. https://doi.org/10.1111/j.1742-4658.2006.05520.x

Banerjee N, Bhatnagar R, Viswanathan L (1981) Inhibition of glycolysis by furfural in Saccharomyces cerevisiae. Eur J Appl Microbiol Biotechnol 11:226–228. https://doi.org/10.1007/BF00505872

Abalos D, Vejarano R, Morata A, González C, Suárez-Lepe JA (2011) The use of furfural as a metabolic inhibitor for reducing the alcohol content of model wines. Eur Food Res Technol 232:663–669. https://doi.org/10.1007/s00217-011-1433-9

Acknowledgements

We want to thank Dr. Anne Hellwig for providing the [13C]3-DG standard and Tom Teichert for synthesizing the product.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Compliance with ethics requirements

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contribution for the Special Issue: The chemistry behind malt and beer production – from raw material to product quality.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kertsch, AL., Brysch-Herzberg, M., Hellwig, M. et al. Metabolization of the glycation compounds 3-deoxyglucosone and 5-hydroxymethylfurfural by Saccharomyces yeasts. Eur Food Res Technol 249, 103–118 (2023). https://doi.org/10.1007/s00217-022-04137-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-022-04137-1