Abstract

In this study, the effect of matrix compounds from natural curcuminoid resources on the stability of curcuminoids and emulsions thereof was evaluated. Curcuminoid emulsions were prepared curcuminoid rich sources (curcuminoid extract, an aqueous turmeric concentrate and turmeric powder) with medium-chain triglyceride oil as lipid phase, lecithin, and pectin as emulsifiers. The curcuminoid emulsions were exposed to light in the visible wavelength range (300 nm–800 nm) at the specific energy input of 0.47 kW/m2 for 7 days and to the temperature of 4 °C, 25 °C, 40 °C for 49 days. The total curcuminoid retention (TC), droplet size (DS) change, instability index (InI), and yellowness reduction (YR) was observed during the storage time. The half-life of curcuminoids in emulsions was increased to 21 h, while the half-life of free curcuminoids was 1.3 h in the light exposure test. The co-compounds from the curcuminoid sources contributed to the emulsion stability by increasing the viscosity. In the thermal exposure test, the matrix compound system retained more than 93% curcuminoids after 49 days of storage at 40 °C, whereas the phase separation increased significantly. However, the TC reduction was independent of the InI change and droplet agglomeration. The YR depended on the TC and the amount of co-components in the emulsion.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

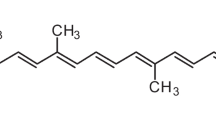

In recent years, the number of publications related to curcuminoid stability enhancement has increased [20]. Curcuminoids are the main bioactive compounds in turmeric [23]. It was found that curcuminoids have various biological activities such as antioxidant, anti-inflammatory, and antimicrobial properties [48], neuroprotective, immunomodulatory, anti-proliferative, and chemically inhibitory effects [38]. Nevertheless, the integration of curcuminoids into functional foods and beverages is often limited due to their low water-solubility, low bioavailability, and poor chemical stability [48]. Curcuminoids decompose quickly under the effect of light [16], temperatures are higher than 70 °C 24, alkaline conditions and aqueous phase [1]. The degradation products of curcuminoids are bicyclopentadione, vanillin, and ferulic acid [41].

In turmeric, curcuminoids are a mixture composed of 75% curcumin (CUR), 20% demethoxycurcumin (DMC), and 5% bisdemethoxycurcumin (BDMC) [3]. In the report of Gordon et al. [11], BDMC and DMC exhibited stabilizing effects in the curcuminoid mixture. Similar findings were reported by Kharat et al. [17], who showed that curcuminoid mixture has better stability than pure curcumin. In Gordon et al. [11] report, it was demonstrated that BDMC and DMC are less prone to oxidation than CUR. The available evidence about stability differences of curcuminoids was the number of methoxy groups attached to the aromatic ring of its molecular structure [2, 25]. Based on the above observations, CUR separation from the curcuminoid mixture is unnecessary. Additionally, BDMC and DMC may enhance the stability of the turmeric extracts [11]. Hence, the natural sources of curcuminoid mixture such as turmeric concentrate or turmeric powder are used in this research. The amount of CUR, DMC, and BDMC in the emulsions is combined and expressed as Total curcuminoid content (TC) throughout the studies.

It is known that curcuminoids are highly sensitive to light and alkaline pH conditions [23]. Pure curcuminoids have low solubility, and limited bioavailability [33]. These properties represent challenges for curcuminoid-based commercial products. Curcuminoid-loaded emulsion enhanced curcuminoid stability, such as physical and chemical stability under the effect of environmental conditions [18]. Plant-based emulsifiers and carriers is an interesting trend for food-functional products. In terms of curcuminoid emulsion, carbohydrates could be an effective carrier to enhance curcuminoid protection, e.g., gum arabic [8], maltodextrins, modified starch, and pectin [5], methylcellulose [51]. These findings can help create a matrix compounds system to enhance curcuminoid dispersion and stability.

According to a recent study by Peng et al. [35], lecithin (LEC) was a promising emulsifier for curcuminoids due to its high loading capacity, stability, and commercially potential in the food industry. The effective matrix system could load and protect curcuminoids, then deliver curcuminoids into commercial foods and beverages. In the past few years, some applications of curcuminoid emulsion used the combination of emulsifier with carbohydrate to enhance the process efficiency [4, 28, 33, 46]. Pectin (PEC) was a promising carbohydrate to stabilize curcuminoid emulsion, which could attribute hydrogen bonds in the system [13]. Besides, pectin enhances the viscosity of the continuous phase and reduces droplet movement during the storage period [39].

In the current work, different curcuminoid sources, such as pure curcuminoid powder, turmeric concentrate, and turmeric powder, with varying levels of curcuminoid purity, were used to assess the impact of the curcuminoid source on the total curcuminoid retention (TC) in emulsions. The combination of lecithin and pectin was used to generate the emulsions. Curcuminoid degradation, droplet size, instability index, and yellowness reduction were investigated during the storage period. This research aims to evaluate the curcuminoid protection ability in different matrix compound systems; by using natural complex curcuminoid sources familiar to the food industry. Furthermore, besides the effect on curcuminoid stability, the concept of using more complex and less refined ingredients may increase the sustainability of applying plant-derived compounds in the food industry [43].

Materials and methods

Materials

Pure curcuminoid powder (purity > 95%—HPLC), consists of 3.47% BDMC, 12.25% DMC, 84.29% CUR) was obtained from Rüther Gewürze GmbH (Holzwickede, Germany).

Turmeric concentrate: Turmeric concentrate was produced and provided by GNT International B. V. (Netherlands). The curcuminoid content in the concentrate is 5.4 mg/g of dry matter.

Turmeric powder: The fresh rhizomes of C. longa were purchased from a local market in Vienna, Austria. Then, rhizomes of C. longa were dried at 50 °C for 72 h by hot air drying in a drying oven. Dried turmeric was frozen for 5 min in liquid nitrogen, milled to the powder, and sieved with a mesh width of 2 mm. The mean particle size of dried powder was determined by laser diffraction measurement (357.23 ± 12.24 µm). The curcuminoid content in the concentrate is 140 mg/g of dry matter.

The low-HLB emulsifiers, soybean lecithin, (phospholipids ≥ 97.0%, Lysophosphatidylcholine ≤ 10%) was obtained from Carl Roth GmbH, Germany. Pectin from the citrus peel (CP; P9135) and MCT oil (C1758) from Cocos nucifera were purchased from Sigma-Aldrich, Germany.

The BDMC, DMC, and CUR standard from Sigma-Aldrich with purity ≥ 95% (HPLC) was used to build the linear regression for curcuminoids quantification. All solvents and chemicals used in the research were analytical grades and HPLC grades (Merck Specialities Private Limited, Germany).

Analytical methods

Water content

The water content [%] of curcuminoid emulsion was determined according to the method described by Le-Tan et al. [20]. Around 2 g of sample was weighed in an aluminum pan and dried at 103 °C for four hours. The difference in weight before and after the drying was the amount of water in the sample.

Protein measurement

In order to investigate the amount of protein in curcuminoid emulsion, the AOAC Official Method AOAC 991.20 was used with a nitrogen conversion factor of 6.25. The Kjeldahl analysis was carried out by Büchi KjelDigester K-449 (Fawil, Switzerland).

α-glucans measurement

The α-glucans content in the material and emulsion was investigated by Megazyme Total starch assay kit (AOAC method 995.16, Wicklow, Ireland). The measurement would investigate turmeric starch, dextrin, maltodextrins, maltose/isomaltose, and glucose in the materials, which contribute hydrogen bonds to the emulsions.

Droplet size measurement

The droplet size distribution of the emulsion was determined using a laser diffraction system (LA-960, Horiba, Japan). The wet samples were measured in the liquid dispersion system filled with water (150 mL). Agitation was run during the measurement. The span value calculated as (d90 − d10)/d50 indicates how far the 10% and 90% points are apart from the midpoint.

Curcuminoids quantification

The curcuminoids in the emulsions were extracted to DMSO by the method described by Kharat et al. [16] with some modifications: a specific volume of emulsion (250 μL) was added to DMSO (5000 μL), and then the mixture was vortexed for 15 s. Hexane (1 mL) was added to the mixture and vortexed again for 15 s. The bottom layer was withdrawn after centrifugation (1700 RCF for 15 min). Then, the curcuminoids content in DMSO was measured using the high-performance liquid chromatography column (HPLC) as described by Le-Tan et al. [20]. The column used was C18 type with 125 mm × 3.5 mm dimensions. The HPLC column was initially cleaned up by elution, which typically required 30 min by acetonitrile 50%. After the washing step, the column was conditioned by eluting the mobile phase for 10 min simultaneously.

The mobile phase consisted of acetonitrile (A), 2% acetic acid (B), and acetone (C). Quantitative curcuminoids were determined using the above solvents programmed linearly from 45 to 65% of A for 0–15 min. The gradient then went from 65 to 45% of A for 15–20 min, with a constant of 5% C.

The linearity of the method was evaluated by analyzing a series of standard curcuminoids. Six concentrations of each curcuminoid's standard solution were 5, 10, 20, 25, 50, and 100 ppm. The calibration range was chosen to be suitable for average curcuminoids concentrations in the emulsion. Analysis of the calibration curves showed a good correlation between concentration and resulting peak area for CUR (R2 = 0.9998), DMC (R2 = 0.9996), and BDMC (R2 = 0.9967). The ratio of CUR, DMC, and BDMC in three curcuminoid sources was varied in different curcuminoid sources and degraded differently during the storage period. In the current study, total curcuminoid content was calculated as the sum of all three components.

Preparation of curcuminoid emulsions

There are three types of emulsion prepared in the current study; the first type was CUE, the emulsion was prepared from pure curcuminoid powder, the second type was COE, and the emulsion was prepared from turmeric concentrate; the last type was POE, which was prepared from turmeric powder.

All the buffer used for the preparation step was prepared according to the European Pharmacopoeia 7.0 method [9]. The pectin solution was prepared separately by thoroughly adding pectin to acetate buffer (pH 5.0) and mixing by vortex for 10 min at 60 °C. The lecithin solution was obtained independently by adding lecithin to acetate buffer (pH 4.0) and vortexed for 5 min. The oil phase was prepared by adding curcuminoid sources to MCT oil and then stirring the mixture at 60 °C for 30 min in dark conditions. After that, the LEC and PEC solution was added to the mixture; then, the mixture was treated by ultrasonic bath for 15 min. Finally, the mixture was stirred at 60 °C for 30 min by vortex (Vortex-Genie 2, Chicago, USA).

The amount of curcuminoid source was calculated to achieve a constant curcuminoid content in the final emulsion of 1 mg/gemulsion. In the case of POE preparation, before adding LEC and PEC solutions, the turmeric powder was removed by a 250 μm filter. Besides curcuminoids from the powder, a fraction of turmeric α-glucans and protein was extracted to the oil phase (see Table 1).

All solutions were mixed and adjusted to pH 4.0 by acetate buffer. The mixture was homogenized using Ultra-Turrax (IKA T25-Digital Ultra Turrax, Staufen, Germany) for 5 min. Then, the final emulsion was passed through EmulsiFlex-C5 (Avestin, Ottawa, ON, Canada) at 1000 bar for 3 passes. The final composition of the stock emulsion produced was 35% oil phase, 2% LEC, 1% PEC, and the pH of the solution was adjusted to 4.0. Then, the emulsion was filled in a flask bottle and ready for pasteurization. The detailed composition of the different emulsions is shown in Table 1. The preliminary tests (microscopy and droplet size distribution measurement) were carried out to ensure that droplet agglomeration did not occur after the pasteurization. The morphology of the curcuminoid droplet is shown in Fig. 1; a few curcuminoids could be seen on the droplet's surface.

Pasteurization of the emulsions

After adjusting the emulsion pH to 4.0, the emulsion was filled in flask bottles (10 mL). In order to avoid the growth of microorganisms during the storage period, the curcuminoid emulsion was pasteurized at 80 °C for 120 s holding time in a water bath.

Instability index measurement

The instability index of the emulsion was investigated by the optical centrifuge LUMifuge (LUM GmbH, Berlin, Germany). The LUMifuge instrument exposes the emulsions to a centrifugal force, which promotes the movement of the large or aggregated droplets [29]. The operating parameters of the instrument used were: 0.35 mL of sample, 2000 rpm; interval of time: 30 s, temperature: 25 °C, total scanning time: 2 h.

To evaluate the accelerated centrifugal stability, the transmission measurements were performed in the middle region of the tubes between 106 and 130 mm. The Instability index is a dimensionless number ranging from 0 (very stable) to 1 (very unstable).

Light exposure test (LET)

In order to investigate the effect of light on curcuminoid oxidative ability, the emulsion was exposed to SunTest XLS (Atlas MTS, Chicago, IL, USA) cabinet. The input energy was 0.47 kW/m2, wavelength from 300–800 nm, and the temperature kept stable at 20 °C. The conversion parameter for the light accelerated test is shown in Table 2. Control samples were prepared by dissolving pure curcuminoid powder into MCT oil; the curcuminoid content in the control sample was adjusted equally to the curcuminoid content in the emulsion (1 mg/mL).

The conversion of storage time at high-intensity light conditions into actual days of ambient light exposure was performed based on the recommendation from SunTest XLS manufacturer, Ametek. The corresponding storage time of 30 min under 0.47 kW/m2 of light energy input equals one day of the daily light condition in the supermarket.

Thermal storage test (TST)

The effect of temperature on curcuminoid stability was monitored by the thermal storage test. The emulsions were kept at 4 °C, 25 °C, and 40 °C to mimic the temperature in the cooling refrigerator, room temperature, and phase separation temperature for 7 weeks. The samples were measured weekly.

Emulsion viscosity measurement

Rheology (Model MCR 302, Anton Paar GmbH, Graz, Austria) was used to measure the apparent viscosity of the emulsion. The rheology is equipped with a concentric cylinder (20-mm diameter) measuring system and 1-mm gap. The measurement was performed at 25 °C in the shear rate range between 10–1 and 102 (s−1). To evaluate the viscosity behavior of the emulsion, a small amplitude oscillatory shear was used. First, a strain sweep was carried out to determine the linear viscosity region of the emulsion at a shear rate of 0.001–500 s−1, 1 Hz and 25 °C. A new sample was used for rheological measurements each time, and all the measurements were conducted at least in triplicate. The sample was subject to the increase from low shear rate to high shear rate with the 30 s step.

Emulsion color measurement

The color of the emulsion was measured by Digi- Eye equipment (Carl von Gehlen Spezialmaschinen und Zubehör GmbH & Co. KG, Mönchengladbach, Germany) with an integrated digital camera (D-90, Nikon, Tokyo, Japan). The emulsion bottles were kept 45° angle to the lens to avoid light reflection on the camera. The b* values (yellowness) according to the CIELab system of the emulsion were recorded.

Morphology

The morphology of the droplet was observed by a light microscope (Olympus BX51, Tokyo, Japan) connected to a camera (Olympus XC50, Tokyo, Japan). Approximately 100 μL of sample was placed into a microscope glass slide and a coverslip was placed on top, ensuring no air gap (or bubbles) trapped between the sample and coverslip. The samples were observed at room temperature (25 ± 1 °C). The microscopy image was visualized and processed using cellSens Dimension software (version 1.12).

Statistical analysis

All pretreatments and analyses were measured in triplicates. Statistical analyses were obtained using Statgraphics Centurion XVII, version 17.1.04 (Statpoint Technologies, Inc., Warrenton, VA, USA). Results are expressed as mean ± standard deviations of three single determinations. One-way ANOVA (analysis of variance with α = 0.05) and Fisher's least significance test was used to describe the significance of differences among the mean values.

Result and discussion

Effect of curcuminoid source on emulsion composition and the physical stability of the emulsion

It is important to understand the effect of emulsion composition on the stability of loaded curcuminoids. The curcuminoid sources could improve the emulsion stability due to their contribution of protein and α-glucans to the emulsion. The composition of different emulsion formulas is shown in Table 1. The curcuminoid source of the CUE formula was pure curcuminoid powder, which led to the final composition containing 0% of protein and 0.76% of α-glucans. The POE has 0.74% protein and 2.83% α-glucans, while the COE contains 0.83% protein and 16.11% α-glucans (Table 1). Due to the different composition of turmeric sources, the contribution of these fractions to the emulsion was very different. In detail, the natural protein (turmerin—an antioxidant protein from turmeric) and α-glucans in turmeric provided protein and α-glucans to the emulsion; these contributions affect the emulsion properties and curcuminoid stability during storage.

In CUE, the protein content is 0%, whereas the COE had a protein content of 0.83% from the turmeric concentrate, and the POE had a protein content of 0.74% from turmeric powder (Table 1). Regarding α-glucans content, 15.35% of α-glucans from turmeric concentrate contributed to the COE, and 2.07% of α-glucans from turmeric powder were added to the POE (Table 1). The findings of turmeric in the previous reports could explain these contributions. The major fraction in fresh turmeric is high-amylose starch (44.15% w/w) and free sugars (10.05% w/w) [22]. In the turmeric starch fraction, amylose content is 48.4% w/w [20]. In the report of Kuttigounder et al. [19], the total α-glucans content in turmeric could be up to 67% w/w.

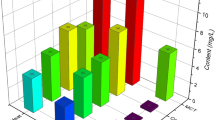

According to Lu et al. [27], the high amylose content material could create a highly stable network compared to the low amylose materials. In the study of Zhou et al. [50] on coconut milk stability with different starch materials, the authors suggested that high-amylose materials contributed significantly to the emulsion stability, expressed by a high cross-linking network and stronger hydrogen bonds. In the present work, the amount of α-d-glucose polymers was investigated and described as α-glucans content. These components were derived from curcuminoid sources (turmeric concentrate and turmeric powder), and these fractions contributed a high amount of hydrogen bonds to the emulsions. Besides, the emulsion's viscosity increased while these components increased (Fig. 2). According to Lu et al. [27], the increase in α-glucans in the system could change rheological properties,furthermore, the droplet movement in the emulsion could be reduced; finally, the droplet agglomeration was limited. This observation agrees with studies of Lu et al. [27],the high amount of α-glucans could inhibit droplet flocculation and particle aggregation. At different emulsion formulas, the phase separation was not observed at 4 °C and 25 °C after 49 days (see Fig. 3); the droplet size provides confirmatory evidence that there was no change during the storage period.

The viscosity of emulsion was measured in the shear rate range from 0.1 to 100 s−1 (Fig. 2). The viscosity of the curcuminoid emulsions was dependent on the shear rate and expressed as non-Newtonian fluid. Notably, the viscosity of curcuminoid emulsions reduces after 49-day storage for all three emulsion types.

On the contrary with COE and POE, the higher water content in the CUE and lower viscosity could involve higher droplet movement and lead to droplet accumulation. The InI values of CUE increased significantly at 25 °C and 40 °C after 49 storage days (Fig. 3), and the InI values of CUE were 25% higher than InI of COE and 22% higher than InI of POE after 49-day TST at 40 °C. Besides, the DS in CUE was increased dramatically after 28 days of storage at 40 °C, while the DS of COE showed a slower increasing rate at the same condition (Fig. 4). In the previous study of Lu et al. [27] on coconut milk emulsions stabilized with starch, when the DS increase, the surfactants reduce the stabilized ability.

Furthermore, the DS increase in CUE could be explained by the Ostwald ripening phenomenon, which describes the redistribution of inhomogeneous matrix compounds over time or redeposits of small droplets onto larger droplets [14, 15]. When this phenomenon happens, the surfactants reduce their encapsulation ability [27]. On the contrary, the reduction in Brownian movement in the high-density compound system (POE and COE) leads to a lower collision frequency and improves the system's stability [6]. For instance, the results of InI (Fig. 3) showed a higher value of CUE than COE and POE before and after the storage period at 4 °C, 25 °C, and 40 °C. Notably, at 40 °C, the droplet agglomeration was noticeably increased from day 21 to day 49 (see DS in Fig. 4d, e, f), while in the first 20 days, the DS change was minimal (Fig. 4). This observation suggests that when the Ostwald ripening phenomenon occurs, the aggregation rate of the droplet could be increased over time. These available evidences suggest that the protein and α-glucans in the matrix compounds system could promote curcuminoid dispersion stability.

Total curcuminoid retention in the thermal storage test

In the previous studies, the obtained results showed that curcuminoids were relatively stable at high temperatures. For example, at 70 °C, curcuminoids were very stable [23]; above this temperature, curcuminoids started to degrade at 100 °C [44]. In the report of Lestari and Indrayanto [23], 27% and 32% of curcuminoids were lost when boiling the sample for 10 and 20 min, respectively.

In the current studies, the TC retention in the thermal storage test (TST) was investigated at 4 °C, 25 °C, and 40 °C for 49 days; the results are shown in Fig. 5. After 49 storage days at 40 °C in the dark condition, the curcuminoid content of CUE, COE, and POE reduced by 11.94%, 6.35%, and 4.21%, respectively (Fig. 5). This observation could relate to the difference in protein, α-glucans, and the water content of the formulas. Existed studies suggested that increased protein content in the emulsion could affect curcuminoid stability [7, 31]. In the study about curcuminoid degradation by autoxidative transformation, Schneider et al. [41] suggested that adding protein could also inhibit curcuminoid degradation. Besides, the protein could effectively deliver curcuminoids into functional food or beverages [49].

Although the physical stability of the matrix compound system was not stable during the thermal storage test; nevertheless the curcuminoid content in the system did not show a significant reduction over time (Fig. 5b, c, d). After 49 days in the thermal test at 40 °C, the TC in CUE, COE, and POE were 88.06%, 93.65%, and 95.79%, respectively. This observation shows that curcuminoids are stable when light is excluded despite the emulsion's phase separation. This result agrees with the previous report of Kharat et al. [17],the TC was retained at more than 85% after 30 days of incubation at 37 °C. Furthermore, in the storage test at 55 °C, after 60 days, up to 59% of TC could be degraded [30].

According to Suresh et al. [42], the high temperature could trigger the degradation of free curcuminoids,these changes could be originated from the keto-enol group in the molecule [34]. The emulsion composition confirmed the evidence of curcuminoid protection with the temperature.

The COE, POE, and CUE remained more than 88% of curcuminoid content compared to the initial content, while free curcuminoids in MCT remained 78.41% after 49 days at 40 °C. Based on these observations, it could be stated that TC retention was only reduced slightly after 49 days of the temperature of 4 °C, 25 °C, and 40 °C in the dark condition.

Total curcuminoid retention in the light exposure test

Curcuminoids are highly sensitive to light [41]. Under light effect, CUR could be degraded into trans-6-(4'- hydroxy-3’-methoxyphenyl)-2,4-dioxo-5-hexenal, vanillin, ferulic acid, and feruloylmethane [10, 21], and vanillin was the primary degradation product [23]. The wavelength of the light source in the current study was set to 300–800 nm due to CUR strongly absorbing the visible wavelength range [23]. In addition, this absorbance took place in both crystal state or dissolve state of CUR [12].

The light-induced degradation of free curcuminoids followed the first-order kinetics (Fig. 5a), in which the half-lives were 80 min, equivalent to the input energy of 2.38 kW. The results are consistent with the report of Price and Buescher [37],the degradation rates of each pigment in curcuminoids followed the first-order kinetics.

The emulsions showed different retention of curcuminoids under the light exposure condition. In the light exposure test (LET), the half-life of free curcuminoids was 80 min, while the emulsion showed the higher protection abilities; for instance, the half-lives of curcuminoids in CUE, COE, and POE were 6 h, 13 h, and 21 h, respectively (Fig. 5a).

After 168-h exposures (equivalent to light input energy of 284.3 kW—see Table 2), the free curcuminoids in MCT oil and curcuminoids in CUE were degraded entirely, while curcuminoids in POE and COE remained 2.38% and 22.65%, respectively (Fig. 5a). Although the intense degradation of curcuminoid in the LET, the mean droplet size was not significantly changed (Fig. 4a, b, c).

Although the TC reduced dramatically, the InI showed that the emulsion was stable after 7 days of light exposure. This result indicated that the Ostwald ripening phenomenon did not occur during the LET. Notably, in the TST at 25 °C, the InI of different emulsions (see CUE/COE/POE_25 °C_49d in Fig. 3) did not considerably increase after 7 weeks. Based on this observation, it could be concluded that the temperature of 25 °C has less effect on emulsion stability, independent of light/ dark conditions. Similar findings were reported by Piorkowski and McClements [36],the authors concluded that gravity is the primary impact that causes precipitation and coagulation of the system.

It could be concluded that the curcuminoid retention of different matrix compound systems followed the order: COE > POE > CUE. The reason could be because the amount of protein and α-glucans in the emulsion followed the order: COE > POE > CUE; these co-compounds play a role as a hydrocolloid thickening agent in the matrix compound system; and the high density of these molecules in the matrix compound could inhibit the effect of light on the curcuminoids molecules [47].

Yellowness reduction

Color plays an essential role in consumers' sensory acceptance and purchase intention [26]; therefore, the color reduction in food coloring products is one of the most important food sensory characteristics. In this study, yellowness is considered the vital criterion for comparing different emulsions' protection ability.

Curcuminoids could be degraded during the accelerated tests into p-hydroxybenzoic acid, ferulic aldehyde, p-hydroxybenzaldehyde, vanillic acid vanillin, and ferulic acid [40]. These changes start from the reaction of a keto-enol group in curcumin molecules [2]. According to Wikene et al. [45], these complex reactions resulted in color deterioration. In general, all of the emulsions showed a considerable reduction in yellowness in the LET (Fig. 6a), while in the TST, the yellowness reduction was witnessed only for the 40 °C conditions (Fig. 6b, c, d).

The COE showed the lowest yellowness initially and during the storage test (Fig. 6), although the TC in COE samples was highest (Fig. 5). The available evidence seems to be that the emulsion's yellowness depends not only on TC but also on the composition of the matrix compound system (α-glucans, protein, and water content—see Table 1).

A closer look at the DS data, the increase in DS under the conditions of 40 °C in 7 weeks had a significant impact on the color change of the sample (Fig. 4). According to McClements [32], the emulsion's mean droplet size and the thickness could affect its color. The conditions of 4 °C and 25 °C maintained yellowness effectively,it did not show yellowness reduction after 7 weeks of storage (Fig. 6b, c). The InI and TC value could be used to explain this observation. Both InI and TC were insignificantly changed after 7 weeks at the temperature of 4 °C and 25 °C (see Fig. 3 and Fig. 5).

Based on these observations, it could be stated that the yellowness of the curcuminoid emulsion is not only dependent on the curcuminoid content inside but also on the co-compounds and colloidal characteristics of the matrix compounds system.

The visual images of emulsions before and after the LET and TST are shown in Figs. 7 and 8. The substantial yellowness reduction was witnessed in LET but not in TST.

Conclusion

Natural curcuminoid sources showed good retention and stabilizing ability under different storage conditions. These sources are familiar and applicable materials in the food industry. Besides MCT oil, lecithin, and pectin, the co-compounds from the materials contributed to the stability of the emulsion. The matrix compound system remained considerably curcuminoid content during the light exposure and thermal storage tests. The amount of protein and α-glucans in the emulsion followed the order: COE > POE > CUE. Under the light exposure conditions, the present co-components showed the role of hydrocolloid thickening agents, which increased the curcuminoid half-life up to 21 h compared to 1.3 h of free curcuminoids. The high amount of co-components in COE maintained 93.65% of curcuminoids after 49-day storage at 40 °C, while free curcuminoids in MCT remained at a level of 78.41%. Curcuminoids were very sensitive to light exposure conditions but stable in the thermal exposure test. The yellowness reduction depended on TC, co-components content, and colloidal characteristics of the emulsion. In conclusion, the turmeric concentrate expressed the best performance to enhance the curcuminoid stability by supplying co-component to the system, improving the emulsion's rheology property and physical stability. The findings support the concept of the application of functional fractions and illustrate the stabilizing power of complex matrices compared to single compounds.

References

Anand P, Kunnumakkara AB, Newman RA, Aggarwal BB (2007) Bioavailability of curcumin: problems and promises. Mol Pharm 4(6):807–818

Anand P, Thomas SG, Kunnumakkara AB, Sundaram C, Harikumar KB, Sung B, Tharakan ST, Misra K, Priyadarsini IK, Rajasekharan KN, Aggarwal BB (2008) Biological activities of curcumin and its analogues (Congeners) made by man and Mother Nature. Biochem Pharmacol 76(11):1590–1611

Bansal SS, Goel M, Aqil F, Vadhanam MV, Gupta RC (2011) Advanced drug delivery systems of curcumin for cancer chemoprevention. Cancer Prev Res 4(8):1158–1171

Borrin TR, Georges EL, Brito-Oliveira TC, Moraes IC, Pinho SC (2018) Technological and sensory evaluation of pineapple ice creams incorporating curcumin-loaded nanoemulsions obtained by the emulsion inversion point method. Int J Dairy Technol 71(2):491–500

Cano-Higuita D, Malacrida C, Telis V (2015) Stability of curcumin microencapsulated by spray and freeze drying in binary and ternary matrices of maltodextrin, gum arabic and modified starch. J Food Process Preserv 39(6):2049–2060

Capek I (2004) Degradation of kinetically-stable o/w emulsions. Adv Coll Interface Sci 107(2–3):125–155

Chen S, Zhang N, Tang C-H (2016) Influence of nanocomplexation with curcumin on emulsifying properties and emulsion oxidative stability of soy protein isolate at pH 3.0 and 7.0. Food Hydrocolloids 61:102–112

Chuah AM, Kuroiwa T, Kobayashi I, Nakajima M (2009) Effect of chitosan on the stability and properties of modified lecithin stabilized oil-in-water monodisperse emulsion prepared by microchannel emulsification. Food Hydrocolloids 23(3):600–610

Commission EP, Medicines EDFTQO, & Healthcare (2010) European pharmacopoeia (Vol. 1). Council of Europe

Goel A, Kunnumakkara AB, Aggarwal BB (2008) Curcumin as “Curecumin”: from kitchen to clinic. Biochem Pharmacol 75(4):787–809

Gordon ON, Luis PB, Ashley RE, Osheroff N, Schneider C (2015) Oxidative transformation of demethoxy-and bisdemethoxycurcumin: products, mechanism of formation, and poisoning of human topoisomerase IIα. Chem Res Toxicol 28(5):989–996

Jankun J, Wyganowska-Świątkowska M, Dettlaff K, Jelińska A, Surdacka A, Wątróbska-Świetlikowska D, Skrzypczak-Jankun E (2016) Determining whether curcumin degradation/condensation is actually bioactivation. Int J Mol Med 37(5):1151–1158

Jin B, Zhou X, Zhou S, Liu Y, Guan R, Zheng Z, Liang Y (2019) Influence of phenolic acids on the storage and digestion stability of curcumin emulsions based on soy protein-pectin-phenolic acids ternary nano-complexes. J Microencapsul 36(7):622–634

Kabalnov A (2001) Ostwald ripening and related phenomena. J Dispersion Sci Technol 22(1):1–12

Kabalnov AS, Shchukin ED (1992) Ostwald ripening theory: applications to fluorocarbon emulsion stability. Adv Coll Interface Sci 38:69–97

Kharat M, Aberg J, Dai T, McClements DJ (2020) Comparison of emulsion and nanoemulsion delivery systems: the chemical stability of curcumin decreases as oil droplet size decreases. J Agric Food Chem 68(34):9205–9212

Kharat M, Du Z, Zhang G, McClements DJ (2017) Physical and chemical stability of curcumin in aqueous solutions and emulsions: impact of pH, temperature, and molecular environment. J Agric Food Chem 65(8):1525–1532

Kharat M, Zhang G, McClements DJ (2018) Stability of curcumin in oil-in-water emulsions: impact of emulsifier type and concentration on chemical degradation. Food Res Int 111:178–186

Kuttigounder D, Lingamallu JR, Bhattacharya S (2011) Turmeric powder and starch: selected physical, physicochemical, and microstructural properties. J Food Sci 76(9):C1284–C1291

Le-Tan H, Fauster T, Vladic J, Gerhardt T, Haas K, Jaeger H (2021) Application of emerging cell disintegration techniques for the accelerated recovery of curcuminoids from curcuma longa. Appl Sci 11(17):8238

Lee W-H, Loo C-Y, Bebawy M, Luk F, Mason RS, Rohanizadeh R (2013) Curcumin and its derivatives: their application in neuropharmacology and neuroscience in the 21st century. Curr Neuropharmacol 11(4):338–378

Leonel M, Sarmento SB, Cereda MP (2003) New starches for the food industry: curcuma longa and Curcuma zedoaria. Carbohyd Polym 54(3):385–388

Lestari ML, Indrayanto G (2014) Curcumin. Profiles Drug Subst Excip Relat Methodol 39:113–204. https://doi.org/10.1016/B978-0-12-800173-8.00003-9

Lestari ML, Indrayanto G (2014) Curcumin. Profiles Drug Substances Excip Relat Methodol 39:113–204

Lev-Ari S, Starr A, Vexler A, Karaush V, Loew V, Greif J, Fenig J, Aderka D, Ben-Yosef R (2006) Inhibition of pancreatic and lung adenocarcinoma cell survival by curcumin is associated with increased apoptosis, down-regulation of COX-2 and EGFR and inhibition of Erk1/2 activity. Anticancer Res 26(6B):4423–4430

Lima EMF, Madalão MCM, dos Santos WC, Bernardes PC, Saraiva SH, Silva PI (2019) Spray-dried microcapsules of anthocyanin-rich extracts from Euterpe edulis M as an alternative for maintaining color and bioactive compounds in dairy beverages. J Food Sci Technol 56(9):4147–4157

Lu X, Su H, Guo J, Tu J, Lei Y, Zeng S, Chen Y, Miao S, Zheng B (2019) Rheological properties and structural features of coconut milk emulsions stabilized with maize kernels and starch. Food Hydrocolloids 96:385–395

Lv P, Wang D, Dai L, Wu X, Gao Y, Yuan F (2020) Pickering emulsion gels stabilized by high hydrostatic pressure-induced whey protein isolate gel particles: Characterization and encapsulation of curcumin. Food Res Int 132:109032

Ma L, Zou L, McClements DJ, Liu W (2020) One-step preparation of high internal phase emulsions using natural edible Pickering stabilizers: Gliadin nanoparticles/gum Arabic. Food Hydrocolloids 100:105381

Ma P, Zeng Q, Tai K, He X, Yao Y, Hong X, Yuan F (2017) Preparation of curcumin-loaded emulsion using high pressure homogenization: Impact of oil phase and concentration on physicochemical stability. LWT 84:34–46

Marhamati M, Ranjbar G, Rezaie M (2021) Effects of emulsifiers on the physicochemical stability of Oil-in-water Nanoemulsions: a critical review. J Mol Liq 340:117218

McClements DJ (2002) Colloidal basis of emulsion color. Curr Opin Colloid Interface Sci 7(5–6):451–455

Naksuriya O, Okonogi S, Schiffelers RM, Hennink WE (2014) Curcumin nanoformulations: a review of pharmaceutical properties and preclinical studies and clinical data related to cancer treatment. Biomaterials 35(10):3365–3383

Niu Y, Ke D, Yang Q, Wang X, Chen Z, An X, Shen W (2012) Temperature-dependent stability and DPPH scavenging activity of liposomal curcumin at pH 70. Food Chem 135(3):1377–1382

Peng S, Zou L, Liu W, Liu C, McClements DJ (2018) Fabrication and characterization of curcumin-loaded liposomes formed from sunflower lecithin: impact of composition and environmental stress. J Agric Food Chem 66(46):12421–12430

Piorkowski DT, McClements DJ (2014) Beverage emulsions: Recent developments in formulation, production, and applications. Food Hydrocolloids 42:5–41

Price LC, Buescher R (1996) Decomposition of turmeric curcuminoids as affected by light, solvent and oxygen 1. J Food Biochem 20(5):125–133

Ramalingam P, Ko YT (2014) A validated LC-MS/MS method for quantitative analysis of curcumin in mouse plasma and brain tissue and its application in pharmacokinetic and brain distribution studies. J Chromatogr B 969:101–108

Ren W, Zhao S, Lian Y, Yang Y, Tian G, Zhao C, Gao W, Zheng J (2020) Effects of hydrosoluble calcium ions and organic acids on citrus oil emulsions stabilized with citrus pectin. Food Hydrocolloids 100:105413

Schieffer GW (2002) Pressurized liquid extraction of curcuminoids and curcuminoid degradation products from turmeric (Curcuma longa) with subsequent HPLC assays. J Liq Chromatogr Relat Technol 25(19):3033–3044

Schneider C, Gordon ON, Edwards RL, Luis PB (2015) Degradation of curcumin: from mechanism to biological implications. J Agric Food Chem 63(35):7606–7614

Suresh D, Manjunatha H, Srinivasan K (2007) Effect of heat processing of spices on the concentrations of their bioactive principles: Turmeric (Curcuma longa), red pepper (Capsicum annuum) and black pepper (Piper nigrum). J Food Compos Anal 20(3–4):346–351

van der Goot AJ, Pelgrom PJ, Berghout JA, Geerts ME, Jankowiak L, Hardt NA, Keijer J, Schutyser MA, Nikiforidis CV, Boom RM (2016) Concepts for further sustainable production of foods. J Food En 168:42–51

Wang Y, Lu Z, Lv F, Bie X (2009) Study on microencapsulation of curcumin pigments by spray drying. Eur Food Res Technol 229(3):391–396

Wikene KO, Bruzell E, Tønnesen HH (2015) Characterization and antimicrobial phototoxicity of curcumin dissolved in natural deep eutectic solvents. Eur J Pharm Sci 80:26–32

Wu Y, Eskin N, Cui W, Pokharel B (2015) Emulsifying properties of water soluble yellow mustard mucilage: A comparative study with gum Arabic and citrus pectin. Food Hydrocolloids 47:191–196

Zhang R, Belwal T, Li L, Lin X, Xu Y, Luo Z (2020) Recent advances in polysaccharides stabilized emulsions for encapsulation and delivery of bioactive food ingredients: a review. Carbohyd Polym 242:116388

Zheng B, Zhang X, Peng S, McClements DJ (2019) Impact of curcumin delivery system format on bioaccessibility: nanocrystals, nanoemulsion droplets, and natural oil bodies. Food Funct 10(7):4339–4349

Zhou H, Zheng B, McClements DJ (2021) Encapsulation of lipophilic polyphenols in plant-based nanoemulsions: impact of carrier oil on lipid digestion and curcumin, resveratrol and quercetin bioaccessibility. Food Funct 12(8):3420–3432

Zhou W, Yang J, Hong Y, Liu G, Zheng J, Gu Z, Zhang P (2015) Impact of amylose content on starch physicochemical properties in transgenic sweet potato. Carbohyd Polym 122:417–427

Zhu X, Chen J, Hu Y, Zhang N, Fu Y, Chen X (2021) Tuning complexation of carboxymethyl cellulose/cationic chitosan to stabilize Pickering emulsion for curcumin encapsulation. Food Hydrocolloids 110:106135

Acknowledgements

The authors gratefully acknowledge the Food Rheology Laboratory of the Institute of Food Science, Department of Food Sciences and Technology, Boku University (Vienna, Austria), for providing the experimental facilities used in this work. Furthermore, part of this work was performed with equipment kindly provided by the EQ-BOKU VIBT GmbH and the Food Stability Center as well as the BOKU Core Facility Food & Bio Processing.

Funding

Open access funding provided by University of Natural Resources and Life Sciences Vienna (BOKU). This study was supported by the University of Natural Resources and Life Sciences Vienna (BOKU) in the frame of the OeAD Grant No. Ref. MPC-2021-00731.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Le-Tan, H., Fauster, T., Haas, K. et al. Evaluation of the synergistic effect of plant-based components on the stability of curcuminoid emulsion. Eur Food Res Technol 248, 2615–2628 (2022). https://doi.org/10.1007/s00217-022-04074-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-022-04074-z