Abstract

The most common preservation process for chili peppers is drying, which inevitably causes oxidative degradation of thermolabile molecules. The aim of this research was to evaluate the potential protective effect exerted by an active ingredient based on grape seed oil, on pepper fruits. Grapeseed oil is rich in antioxidant compounds and was applied to pepper’s surface in form of a sol–gel product, before fruit thermal treatment. In this work, chili peppers samples were preventively treated with an active solution, and controls (untreated peppers), were submitted to a drying process performed at two different temperatures: 45 and 65 °C. Analysis of capsaicinoids, carotenoids, apocarotenoids, and phenolic content was performed to evaluate possible differences between the sets of samples. Oxidative stability of oil enriched with chili pepper powder aliquots was also measured to evaluate the antioxidant power of the samples. Obtained data showed that treated samples retained a higher amount of capsaicinoids and carotenoids. Oxidative stability of pepper powder was also higher for treated samples than for controls. Furthermore, the thermal treatment performed at 45 °C caused milder modifications than the 65 °C treatment. The applied pre-drying treatment can be proposed to prevent bioactive compounds loss and to enhance product stability and shelf-life.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Chili pepper is one of the most consumed spice in the world. It has a great economic value, and it is required by a multitude of food industries for the preparation of sauces, meat derivatives, paprika, and many other products[1]. Fresh fruits are obviously not stable during the post-harvest time and need to be technologically treated to prolong their shelf-life. The most common preservation process at the industrial level is drying in an oven with circulating air, commonly at temperatures between 45 and 75 °C. The time of the thermal treatment can be optimized depending on the fruit dimension, and the relative moisture, and can reach 80 h. This treatment inevitably causes oxidative degradation of thermolabile molecules, and changes in colour, consistence, and nutritional properties of food products[2, 3]. It has a great impact on molecules such as carotenoids and apocarotenoids[4]. Previous studies also showed a progressive decrease of capsaicinoids content after drying processes, as well as during subsequent storage[5].

The proper regulation of drying conditions, in terms of temperature and time, has great importance for the result achieved, since those variables can strongly affect the main features of the product, and consequently exert a great impact on the quality and commercial value of chili peppers[6]. Literature studies reported that the increase in temperature used can cause a strong decrease in the pepper quality parameters, due to oxidative phenomena[6, 7] involving more than thirty different types of carotenoids. Browning reactions linked to Maillard reaction and Amadori compounds formation have also been observed [8, 9].

The oxidation process can be slowed by using antioxidants. Synthetic molecules, largely used in the past, are actually generally avoided due to their possible toxic effects [10]. Therefore, in the latest years, great attention has been paid to the use of natural substances mainly extracted from vegetables [11]. In a sustainability context, the use of agricultural by-products is also promoted to obtain antioxidant compounds. Grapeseed oil is an example of active extract deriving from grape pomace generated during winemaking. It is rich in bioactive molecules, exhibiting antioxidant and antimicrobial properties [12], and it has been successfully employed to preserve cheese and fish products from oxidative deterioration during storage [13].

In this work, grape seed oil has been selected to perform a protective film based on a sol–gel system on pepper’s surface by dipping, before the drying process. To evaluate the effects of this pretreatment, a punctual analysis of the main compounds responsible for chili pepper’s quality was performed. The most important categories of compounds affected by thermal treatments are carotenoids and capsaicinoids [6]. Besides, the amount of total phenolics and the antioxidant power are also useful parameters to monitor to evaluate pepper quality [14].

Carotenoids in plants accelerate photomorphogenesis upon illumination and are precursors of the phytohormones ABA (abscisic acid) and SL (strigolactones) [15]. Furthermore, carotenoids, associated with chloroplasts, facilitate photosynthetic processes and protect the photosynthetic apparatus from photooxidative damage by decreasing the number of free radicals [16].

In humans, carotenoids have an antioxidant effect and are the precursors of vitamin A (retinol), moreover, recent studies have shown their importance as co-activators and co-inhibitors of numerous metabolic processes such as the reduction of age-related macular degeneration and the risk of certain types of cancer [17].

Iron-dependent enzymes (CCDs) catalyse the specific oxidative cleavages of carotenoids to produce apocarotenoids [18]. In mammals, apocarotenoids are fundamental in important biological processes. For example, vitamin A (essential for vision and cell differentiation) is produced by the symmetrical oxidative cleavage of β-carotene and other provitamin A carotenoids, such as α-carotene and γ-carotene [19].

Often, in nature hydroxy-carotenoids and hydroxy-apocarotenoids are esterified with fatty acids, the most common esters are formed with lauric (C12:0), myristic (C14:0) and palmitic (C16:0) acids. These molecules have not proven biological effects, but esterification provides greater stability to the molecule, their formation is thought to be due to a form of conservation and storage within the organism of the precursor molecules [20, 21].

Chilies are an exceptional source of carotenoids, apocarotenoids and their esters. However, the inconvenient storage conditions tend to enhance the rapid degradation of these compounds.

Previous studies evaluated the total capsaicinoids and carotenoids, without considering the complete compound patterns. In this work, for the first time, even the single apocarotenoids have been analysed.

Capsaicinoids are a compound family known for their pungent effect and the peculiar taste and spiciness associated with chili pepper consumption. These compounds are able to activate the Transient Receptor Potential Vanilloid 1 (TRPV1) in humans [22, 23]. The amount of capsaicinoids has been reported to decrease during the storage of powdered peppers, and thus it can be considered a marker of quality affecting the market value [24].

The total amount of phenolic compounds measured by spectrophotometric assay can be considered a parameter to evaluate peppers quality, and is useful to monitor the stability of this class of thermolabile substances, linked to the antioxidant power of the product. Furthermore, the evaluation of the oxidative stability of oil enriched with chili powder by Oxitest provides data to estimate the behavior of the product during aging [25].

This study is focused on the evaluation of the effect of a treatment based on dipping the peppers in a sol–gel system of grapeseed oil before the drying process. To this aim, untreated and treated peppers were dried at two different temperatures. The content of capsaicinoids, carotenoids, apocarotenoids and esters, phenolics, and oxidative stability have been monitored on fresh and dried peppers (both untreated and treated), to evaluate the effects of the pretreatment on the main quality parameters.

Materials and methods

Chemicals

Water (MilliQ), ethanol 96%, acetonitrile, acetone, sodium carbonate, Folin-Ciocalteu reagent, capsaicin, dihydrocapsaicin were purchased from Sigma-Aldrich. Methanol (MeOH) was HPLC–MS grade and was purchased from Merck KGaA (Darmstadt, Germany). Carotenoids standards (zeaxanthin, lutein, capsanthin, and β-carotene) were purchased from Extrasynthese (Genay, France). Apocarotenoid standard (apo-8′-β-carotenal) was acquired from Carote Nature GmbH (Münsingen, Switzerland). In addition, a series of β-apocarotenals, apozeaxanthinals, and ε-apoluteinals were generated by oxidative cleavage of β-carotene, zeaxanthin, and lutein, respectively, following the procedure described by Rodriguez and Rodriguez-Amaya for β-carotene [26], and also reported by Giuffrida et al. for zeaxanthin [27], and Zoccali et al. for lutein [28].

Samples

The chili pepper samples used for this study were cultivated in Calabria region, in the South of Italy, and belong to the Capsicum Annuum cv. Pizzitano. Fruits were harvested in September from one year-aged plants and immediately transferred to the laboratory without further manipulation. They were characterized by a high spiciness, red color and an average weight of 10–15 g (fresh fruits). Twenty pepper samples were analysed as control, and twenty more samples were subjected to a treatment of dipping in a plant extract based on grape seeds provided by a local wine producer. The oil was obtained from grape seeds milled by a grinder, using liquid nitrogen, and then submitted to ultrasound-assisted extraction (UAE) for 45 min at room temperature. Sol–gel solution was prepared on the basis of previous research [29] according to the following procedure. A 1% w/v solution of sodium alginate was prepared by adding the salt to distilled water at 70 °C under vigorous stirring until complete solubilization. Glycerol was added in an amount of 0.300 g/g of sodium alginate. In a different beaker, a suspension of CaCO3 (0.04 g/g of alginate) and glucono-delta-lactone (GDL) (5.4 g/g of CaCO3) was prepared in 100 mL of distilled water. The suspension was then added to the alginate solution under vigorous stirring (100 g), kept at 55 °C for 30 min to allow the removal of CO2 from the reaction environment, and placed in an ultrasonic bath for 40 min to eliminate bubbles. Bubbles were formed as a result of both the homogenization and the release of Ca++ ions promoted by GDL with the related development CO2; this last point is very important since CO2 may be responsible for cavities formation in the gel during the cross-linking phase, thus compromising the final result [29].

To obtain sol–gel solution 10% p/v of grape seeds extract was added under moderate stirring for 70 min at room temperature. Each pepper sample was dipped in the sol–gel solution 10 times for 10 s.

All peppers were grouped into two sets of samples: one group of controls, and a group of treated fruits were dried at 45 °C for 72 h; another group of samples was dried at 65 °C for 22 h. The chosen conditions for thermal treatment were based on common industrial procedures. Times were calculated through cook value measurement to submit the samples to the same thermal effect, considering the energy directed on the product, expressed as minute equivalents at 100 °C[30]. For both conditions, the calculated cook value was about 100, and was sufficient to drying products to constant weight.

Dried samples were powdered and submitted for analysis. Aliquots of each type were stored on an aluminum foil at room temperature for 30 days.

Analysis of capsaicinoids

Capsaicinoids were analysed by Gas Chromatography-Mass spectrometry (GC–MS) after a preliminary extraction using acetone, as reported in a previous article[5]. For the chromatographic separation, a Thermo Trace 1300 gas chromatograph equipped with an autosampler, splitless injector, thermostatic oven and Thermo TSQ 8000 mass spectrometer was used. An Agilent HP-5MS UI 30 m (0.250 mm × 0.25 μm) capillary column allowed separation and qualitative and quantitative analysis. Samples (1 μL) were injected using helium as inert gas at a flow of 1.2 mL min−1. The separation method involved a programmed temperature that increased from 35 to 250 °C at the rate of 5 °C min−1. Detection was achieved by mass spectrometry, through acquisition in FullScan mode (from 40 to 1000 m/z). Available standards and NIST library permitted the identity attribution of the compounds. Calibration curves were built using capsaicin as standard, in the range of concentration between 5 and 500 µg mL−1.

Analysis of carotenoids and apocarotenoids: SFE-SFC-QqQ MS instrumentation

The supercritical fluid extraction–supercritical fluid chromatography–tandem mass spectrometry (SFE-SFC-QqQ MS) analyses were performed on 10 mg of a milled sample using a Shimadzu Nexera UC system (Shimadzu, Japan), coupled with a triple quadrupole mass spectrometer LCMS-8050 (Shimadzu) equipped with an atmospheric pressure chemical ionization (APCI) source (the entire flow was directed into the MS). The entire system was controlled by the software LabSolution ver. 5.8. The characteristics of the instrument were described in Zoccali et al. [28].

SFE-SFC-QqQ MS conditions: supercritical fluid extraction conditions were as follows: mobile phase A CO2, mobile phase B MeOH. The static extraction was performed for 3 min using 10% of mobile phase B, the dynamic extraction was performed for 1 min with 100% of mobile phase A. Both static and dynamic extractions were performed at a flow of 2 mL min−1. The extraction vessel temperature was 80 °C, the backpressure regulator (BPR) was 150 bar at a temperature of 50 °C.

Supercritical fluid chromatography conditions were as follows: mobile phase A CO2, mobile phase B MeOH, from 4 to 6 min 100% of A, from 6 to 17 min increasing from 0 to 60% of B, then from 17 to 21 min increasing up to 100% B, and then 100% B for 2 min. Flow rate: 2 mL min−1. Make-up solvent B at flow 1.0 mL min−1. Separation was carried out on an Ascentis Express C30, 150 mm × 4.6 mm × 2.7 μm d.p. (Merck KGaA). The column oven temperature was 35 °C and the BPR was 150 bar at 50 °C.

The mass spectrometer conditions were as follows: MS source APCI, acquisition mode: SCAN ( ±) in the 200–1200 m/z range, selective ion monitoring (SIM), and multiple reaction monitoring (MRM). The event time was 0.05 s for each event. Interface temperature: 350 °C; DL temperature: 200 °C; block heater temperature: 200 °C; nebulizing gas flow (N2) 3 L min−1; drying gas flow (N2) 5 L min−1;

Carotenoids and apocarotenoids were identified using the available standards analysed in SCAN, SIM, and MRM modes. For further information on the selected ions and the MRM transitions please refer to previously published papers[27, 28].

Analysis of total phenolic content

Total Phenolic Content (TPC) was determined by a spectrophotometric assay based on the Folin Ciocalteu method. At 50 μL of extract, 1160 μL of milliQ water, 100 μL of Folin Ciocalteu reagent and 300 μL of Na2CO3 20% w/w were added. The sample was incubated at 40 °C for 30 min. The UV–vis spectrophotometer was set at 750 nm. Calibration curve was prepared in the range 0.93- 60 μg in the same condition of a sample using gallic acid as standard. All measurements were performed in triplicate.

Analysis of oxidative stability

Oxidative stability of a model sample (virgin sunflower oil) enriched with the different types of chili pepper powders (30%) was evaluated by Oxitest Instrument (Velp Scientifica, Italy). This device is composed of two reactors, and permits to accelerate the samples oxidation process through temperature and oxygen pressure increase. 10 g of each chili powder sample, without any preliminary extraction step, were placed in each of the two chambers. Oxygen pressure was set at 6 bars, and temperature at 90 °C. The system measures the absolute pressure change inside the chambers, and monitors the oxygen uptake by the reactive components occurring in the sample. An Induction Period (IP), expressed in minutes, corresponds to the time at which a sudden change in the rate of oxidation is detected. Higher IP values indicate higher stability against oxidation. The measure takes into account all the antioxidants compounds occurring in the whole sample, with no need for previous extraction involving specific classes of compounds.

Statistical analysis

Data were processed to calculate mean values, standard deviations, and one-way ANOVA (p ≤ 0.05) by SPSS statistical software (Version 24.0, SPSS Inc, Chicago, USA).

Results

Analysis of capsaicinoids

GC–MS provided data about capsaicinoids occurring in the samples. Figure 1 shows a chromatogram related to a chili pepper extract derived from a sample dried at 45 °C (not treated with grape seed oil). Three main peaks can be seen, corresponding to nordihydrocapsaicin, capsaicin, and dihydrocapsaicin, contributing to the total pungency.

In all samples, capsaicin was the most abundant peak, followed by dihydrocapsaicin and then nordihydrocapsaicin. Quantitative analyses have been performed by means of calibration curves, and data were expressed as Scoville Units (SHU), calculated by multiplying the amount expressed as microgram/g by a conversion factor linked to the hotness value of each capsaicinoid. The calculation made and obtained data for the fresh and dried samples are reported in Table 1. It can be seen that the latter compound has only a limited impact on the total pungency, as its conversion factor to Scoville Units is about half respect to the other molecules.

The higher SHU value was observed for the fresh sample, and corresponded to 82,000, followed by the one dried at 45 °C (about 55,000), and then the sample dried at 65 °C (about 47,000). The differences in the pattern of the monitored compounds showed that capsaicin was the substance most affected by the thermal treatment, as its decrease after drying at 65 °C was about 43%, while at 45 °C a value of decrement of about 33% was recorded.

A subsequent step of this work was the investigation of the behavior of chili pepper powders during storage. To this aim, measures of SHU were performed again after 30 days of storage of pepper powders, covered by an aluminum foil, to avoid a too intense oxidation activity that could be due to a direct oxygen and light exposure. Besides, the use of aluminum allowed to preserve the powder from humidity that could cause deterioration and even favor possible mold development.

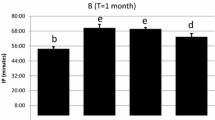

A strong loss of SHU value after thirty days of storage was observed for all samples, processed at both evaluated temperatures. Data about the decrement recorded for each sample from day 0 (just after essiccation) to day n. 30, are reported in Fig. 2 (“tr” indicates samples treated with grape extract).

Percentage of capsaicinoids loss calculated by comparing the SHU values measured just after essiccation, and again after 30 days of shelf-life (samples named accordingly to the temperature treatment. Samples treated with grape seed extract were labelled using “tr”). Values are means of three replicates. Different superscript letters indicate statistical significance

The highest loss is observed in samples dried at 65 °C, demonstrating that the strongest exposure to high temperature lead to a more pronounced effect. Besides, by comparing data of untreated fruits with those dipped in the grapeseed oil, it can be seen that the protective action of the antioxidant pretreatment allowed to retain capsaicinoids in treated fruits with respect to untreated ones.

The reported data suggest that the use of the proposed active solution can be useful to preserve capsaicinoids, and subsequently pepper’s piquancy, during storage after the drying process.

Carotenoid and apocarotenoid analysis

The analysis of carotenoids and their enzymatic or non-enzymatic oxidative cleavage derivatives, namely apocarotenoids was performed using an online SFE-SFC-QqQ MS system. The online nature of the system allows both extraction and analysis in a fully automatic way, according to a previously developed and slightly modified method [31].

To evaluate the potential protective effect with regard to carotenoids and apocarotenoids, exerted by the active ingredient when samples were submitted to thermal treatment, fresh and dried samples were analyzed. Initially, fresh samples (n = 3) were analyzed to establish the carotenoids and apocarotenoids content. Totally, 20 compounds were identified: 2 carotenoid precursors, 5 free carotenoids, 7 free apocarotenoids and 6 apocarotenoid fatty acid esters in all the analyzed samples, both fresh and dry peppers, and were reported in Table 2.

Compounds identification was performed using both the SIM and MRM modes. The areas of the identified compounds in the fresh Capsicum Annuum Pizzitano samples were compared with the areas, normalized according to drying yields, of both treated (with grape seeds extract) and not treated samples dried at 45 °C for 72 h and at 65 °C for 22 h.

By comparing the obtained values is clear that the treatment at 45 °C for 72 h lead to a higher quantity of molecules of interest compared to the treatment carried out at 65 °C for 22 h, as shown in Fig. 3.

We can affirm that, in the analyzed samples, the molecules of interest undergo a less oxidative degradation process with drying processes at low temperatures and prolonged times compared to processes that use reduced times but high temperatures, especially considering the sample treated with the grape extract.

Very interestingly, the treatment with grape seed extract along with the lower temperature, on the whole, has a protective effect on the molecules analyzed, decreasing the oxidative degradation process. The use of grape seed as an antioxidant to prolong shelf-life was already reported by Ameur et al. [32]. In that case, the authors used grape seed nanoemulsion to protect flathead mullet fillets from oxidation of lipids and, consequently, decay. Figure 4 shows that the sum of the yields, considering all the molecules of interest is greater for the samples treated with the grape seed extract at 45 °C compared to the other samples. We can affirm that grape seed can be used as new technology to prevent the oxidation process of carotenoids and their derivatives.

Total phenolics content (TPC)

The total amount of phenolics contained in the treated and untreated peppers, after the drying process, was evaluated by the Folin-Ciocalteu assay, and data were compared in Fig. 5.

It can be seen that samples subjected to 45 °C, corresponding to the lighter thermal treatment, shows a higher TPC content, followed by the samples treated at a higher temperature. This behavior seems clearly related to a loss of phenolics due to exposure at high temperature.

As for the fruits protected by antioxidant coating, they showed lower results, that can be explained by taking into account the combination of the above-described effect with different phenomena contributing to the final value. One of them is linked to the possible increase in TPC described in literature studies about vegetable heating [6]. In particular, thermal stress has been reported to be responsible for an increase in the polyphenolic values due to the formation of intermediate compounds from the Maillard reaction. Besides, more contrasting phenomena were observed during heating, and can be related to (I) oxidation of phenolics due to enzymatic action, contributing to TPC decrease [33]; and (II) favored collapse of cellular structures leading to the dissociation of active compounds from cell walls, thus being available to react with assay reagent, and contributing to TPC increase [34]. Therefore, the recorded value should be the result of the combination of complex different mechanisms, even interacting with each other. Thus, they cannot be evaluated separately.

Since this spectrophotometric assay was limited to the measurement of phenolic amounts, an assessment of the antioxidant activity of the whole sample, based on a different test, was performed.

Oxidative stability

Figure 6 shows the results related to the induction periods measured by Oxitest for the different samples of virgin sunflower oil after chili pepper powder addition. It is important to underline that these results derive from a measure involving the activity of all the antioxidant compounds occurring in the entire sample, and are not related to the extraction or a reaction of a class of compounds, such as phenolics.

All samples, except the untreated one subjected to 65 °C, showed an increase in the induction period with respect to sunflower oil control. This confirms a positive antioxidant effect exerted by the pepper powder addition in increasing oil oxidative stability.

About comparison between fruits treated with the grape seed coating, and untreated, the antioxidant power recorded for untreated samples dried at 65 °C was not statistically different from the sunflower oil itself, whereas a slight increase was seen for the coated samples dried at the same temperature. The coated samples submitted to lower temperature did not show significant variation compared to uncoated peppers, whereas the higher temperature determined a strong loss of stability for the uncoated samples.

These data, if compared to those from the TPC assay, show a similar trend, but also some differences. Both techniques showed higher values for uncoated samples submitted to 45 °C thermal treatment compared to those at 65 °C. In fact, a high correlation between data recorded by Oxitest and TPC values was observed (correlation of 0,72), confirming that polyphenols can be considered in part responsible for the antioxidant power, as previously reported [35]. On the other hand, some differences can be noticed, mainly related to the activity of samples treated with grape seed oil, that showed less phenolic content, but a stable or even an increase in the antioxidant activity (at least for samples dried at 65 °C). The reason for this difference can be explained by taking into account that the measures of Oxitest evaluate the total effect exerted by many different active compounds, not only by phenolics. Therefore, possible synergic or combined action of different compounds (not belonging to the class of phenolics), such as vitamins, was evaluated.

In conclusion, the two techniques are based on different principles: TPC assay measures phenolic compounds of an extract, whereas Oxitest evaluates the activity of the entire pattern of active compounds occurring in the whole samples, not submitted to any preliminary step of extraction, and can thus be considered more reliable.

Conclusions

The data reported in this work showed that a preliminary coating of chili peppers with grape seed oil extract is able to preserve their main property, linked to spiciness. This action is exerted through a protective effect against capsaicinoids degradation, not only during thermal treatments but also during storage. These findings, limited to laboratory scale experiments, could be useful to set up the development of the best conditions for vegetables drying process at the industrial level.

The automated online SFE-SFC-QqQ MS system allowed to identify and/or quantify specific micronutrients contributing to the conservation status of food matrices.

The results obtained by Oxitest analyses, that measures the activity of the entire pattern of antioxidant compounds occurring, showed that the chili pepper treatment with grape seed extract, along with the lower temperature, on the whole, has a protective effect on the active molecules.

References

Baenas N, Belović M, Ilic N, Moreno DA, García-Viguera C (2019) Industrial use of pepper (Capsicum annum L.) derived products: technological benefits and biological advantages. Food Chem 274:872–885. https://doi.org/10.1016/J.FOODCHEM.2018.09.047

Vega-Gálvez A, Ah-Hen K, Chacana M et al (2012) Effect of temperature and air velocity on drying kinetics, antioxidant capacity, total phenolic content, colour, texture and microstructure of apple (var. Granny Smith) slices. Food Chem 132:51–59. https://doi.org/10.1016/J.FOODCHEM.2011.10.029

Verma DK, Thakur M, Srivastav PP et al (2020) Effects of drying technology on physiochemical and nutritional quality of fruits and vegetables. Emerging thermal and nonthermal technologies in food processing. Apple Accademic Press, Canada, USA, pp 69–116

Dias MG, Borge GIA, Kljak K et al (2021) European database of carotenoid levels in foods. Factors Affect Carotenoid Content Foods 10:1–31. https://doi.org/10.3390/foods10050912

Giuffrida D, Dugo P, Torre G et al (2013) Characterization of 12 Capsicum varieties by evaluation of their carotenoid profile and pungency determination. Food Chem 140:794–802. https://doi.org/10.1016/J.FOODCHEM.2012.09.060

Vega-Gálvez A, Di Scala K, Rodríguez K et al (2009) Effect of air-drying temperature on physico-chemical properties, antioxidant capacity, colour and total phenolic content of red pepper (Capsicum annuum, L. var. Hungarian). Food Chem 117:647–653. https://doi.org/10.1016/J.FOODCHEM.2009.04.066

Di Scala K, Crapiste G (2008) Drying kinetics and quality changes during drying of red pepper. LWT - Food Sci Technol 41:789–795. https://doi.org/10.1016/J.LWT.2007.06.007

Fratianni A, Niro S, Messia MC et al (2017) Kinetics of carotenoids degradation and furosine formation in dried apricots (Prunus armeniaca L.). Food Res Int 99:862–867. https://doi.org/10.1016/j.foodres.2016.12.009

Suri K, Singh B, Kaur A et al (2019) Impact of infrared and dry air roasting on the oxidative stability, fatty acid composition, Maillard reaction products and other chemical properties of black cumin (Nigella sativa L.) seed oil. Food Chem 295:537–547. https://doi.org/10.1016/j.foodchem.2019.05.140

Garau MC, Simal S, Rosselló C, Femenia A (2007) Effect of air-drying temperature on physico-chemical properties of dietary fibre and antioxidant capacity of orange (Citrus aurantium v. Canoneta) by-products. Food Chem 104:1014–1024. https://doi.org/10.1016/J.FOODCHEM.2007.01.009

Montenegro-Landívar MF, Tapia-Quirós P, Vecino X et al (2021) Fruit and vegetable processing wastes as natural sources of antioxidant-rich extracts: evaluation of advanced extraction technologies by surface response methodology. J Environ Chem Eng 9:105330. https://doi.org/10.1016/J.JECE.2021.105330

Yang C, Shang K, Lin C et al (2021) Processing technologies, phytochemical constituents, and biological activities of grape seed oil (GSO): a review. Trends Food Sci Technol 116:1074–1083. https://doi.org/10.1016/J.TIFS.2021.09.011

Ceylan Z, Kutlu N, Meral R et al (2021) Protective effect of grape seed oil-loaded nanofibers: limitation of microbial growth and lipid oxidation in kashar cheese and fish meat samples. Food Biosci 42:101076. https://doi.org/10.1016/J.FBIO.2021.101076

Ramandeep K, Kamaljit K (2020) Effect of processing on color, rheology and bioactive compounds of different sweet pepper purees. Plant foods Hum Nutr 75:369–375. https://doi.org/10.1007/S11130-020-00824-0

Sun T, Yuan H, Cao H et al (2018) Carotenoid metabolism in plants: the role of plastids. Mol Plant 11:58–74. https://doi.org/10.1016/j.molp.2017.09.010

Nisar N, Li L, Lu S et al (2015) Carotenoid metabolism in plants. Mol Plant 8:68–82. https://doi.org/10.1016/j.molp.2014.12.007

Rao AV, Rao LG (2007) Carotenoids and human health. Pharmacol Res 55:207–216. https://doi.org/10.1016/J.PHRS.2007.01.012

Harrison PJ, Bugg TDH (2014) Enzymology of the carotenoid cleavage dioxygenases: Reaction mechanisms, inhibition and biochemical roles. Academic Press

Fernandes AS, de Nascimento TC, Jacob-Lopes E et al (2018) Introductory chapter: carotenoids - a brief overview on its structure biosynthesis synthesis and applications. In: Jacob-Lopes E, Zepka LQ, Rosso VVD (eds) Progress in carotenoid research. IntechOpen, UK, pp 1–11

Giuffrida D, Zoccali M, Mondello L (2020) Recent developments in the carotenoid and carotenoid derivatives chromatography-mass spectrometry analysis in food matrices. TrAC - Trends Anal Chem 132:116047. https://doi.org/10.1016/j.trac.2020.116047

Zoccali M, Giuffrida D, Salafia F et al (2021) Apocarotenoids profiling in different capsicum species. Food Chem. https://doi.org/10.1016/j.foodchem.2020.127595

Koichiro O, Shoji N, Satoshi M et al (2001) CH-19 sweet, a non-pungent cultivar of red pepper, increased body temperature and oxygen consumption in humans. Biosci Biotechnol Biochem 65:2033–2036. https://doi.org/10.1271/BBB.65.2033

Iida T, Moriyama T, Kobata K et al (2003) TRPV1 activation and induction of nociceptive response by a non-pungent capsaicin-like compound, capsiate. Neuropharmacology 44:958–967. https://doi.org/10.1016/S0028-3908(03)00100-X

Bignardi C, Cavazza A, Rinaldi M, Corradini C (2016) Correlation between different markers for the assessment of red chilli pepper powders stability during shelf-life. Int J Food Sci Nutr 67:391–399. https://doi.org/10.3109/09637486.2016.1164671

Cavazza A, Corti S, Mancinelli C et al (2015) Effect of the addition of chili pepper powder on vegetable oils oxidative stability. J Am Oil Chem Soc 92:1593–1599. https://doi.org/10.1007/S11746-015-2738-9

Rodriguez EB, Rodriguez-Amaya DB (2007) Formation of apocarotenals and epoxycarotenoids from β-carotene by chemical reactions and by autoxidation in model systems and processed foods. Food Chem 101:563–572. https://doi.org/10.1016/j.foodchem.2006.02.015

Giuffrida D, Zoccali M, Giofrè SV et al (2017) Apocarotenoids determination in capsicum chinense Jacq. cv. Habanero, by supercritical fluid chromatography-triple-quadrupole/mass spectrometry. Food Chem 231:316–323. https://doi.org/10.1016/j.foodchem.2017.03.145

Zoccali M, Giuffrida D, Salafia F et al (2018) Carotenoids and apocarotenoids determination in intact human blood samples by online supercritical fluid extraction-supercritical fluid chromatography-tandem mass spectrometry. Anal Chim Acta 1032:40–47. https://doi.org/10.1016/j.aca.2018.06.022

Benavides S, Villalobos-Carvajal R, Reyes JE (2012) Physical, mechanical and antibacterial properties of alginate film: effect of the crosslinking degree and oregano essential oil concentration. J Food Eng 110:232–239. https://doi.org/10.1016/J.JFOODENG.2011.05.023

Tucker G, Featherstone S (2021) Cook values and optimisation of thermal processes. Essentials of thermal processing. John Wiley & Sons, Ltd, pp 173–193

Zoccali M, Giuffrida D, Dugo P, Mondello L (2017) Direct online extraction and determination by supercritical fluid extraction with chromatography and mass spectrometry of targeted carotenoids from red Habanero peppers (Capsicum chinense Jacq.). J Sep Sci 40:3905–3913. https://doi.org/10.1002/jssc.201700669

Ameur A, Bensid A, Ozogul F et al (2022) Application of oil-in-water nanoemulsions based on grape and cinnamon essential oils for shelf-life extension of chilled flathead mullet fillets. J Sci Food Agric 102:105–112. https://doi.org/10.1002/jsfa.11336

Torki-Harchegani M, Ghanbarian D, Ghasemi Pirbalouti A, Sadeghi M (2016) Dehydration behaviour, mathematical modelling, energy efficiency and essential oil yield of peppermint leaves undergoing microwave and hot air treatments. Renew Sustain Energy Rev 58:407–418. https://doi.org/10.1016/j.rser.2015.12.078

Multari S, Marsol-Vall A, Keskitalo M et al (2018) Effects of different drying temperatures on the content of phenolic compounds and carotenoids in quinoa seeds (Chenopodium quinoa) from Finland. J Food Compos Anal 72:75–82. https://doi.org/10.1016/j.jfca.2018.06.008

Cavazza A, Corti S, Mancinelli C et al (2015) Effect of the addition of chili pepper powder on vegetable oils oxidative stability. J Am Oil Chem Soc 9211(92):1593–1599. https://doi.org/10.1007/S11746-015-2738-9

Acknowledgements

The authors acknowledge Shimadzu Corporation and Merck Life Science for their continuous support.

Funding

Open access funding provided by Università degli Studi di Parma within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Grimaldi, M., Cavazza, A., Pitirollo, O. et al. Analytical evaluation of carotenoids, apocarotenoids, capsaicinoids, and phenolics to assess the effect of a protective treatment on chili peppers dried at different temperatures. Eur Food Res Technol 248, 2339–2349 (2022). https://doi.org/10.1007/s00217-022-04049-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-022-04049-0