Abstract

Gluten-free breads often show a reduced specific bread volume, in comparison to gluten-containing products, caused by non-adapted processing technologies of gluten-free dough. In this investigation, different mixing speeds and durations (600–3000 rpm for 3 min, 5 min or 8 min, respectively) as well as variations in the pressure (prel – 50 to prel + 130 kPa) in the headspace atmosphere during mixing (Stephan mixer) and pressure ratios of overpressure/negative pressure of 8 min mixing (20/80, 50/50, 80/20) were studied to determine their impact on the gas volume fraction of dough and specific volume of breads. A pressure rise of prel 50 kPa, prel 100 kPa or prel 130 kPa increased the gas volume fraction in dough of 60%, 100% or 120%, respectively, and led to a significant higher specific bread volume (7%) and the reduction of crumb hardness (35%) at prel 130 kPa. A linear correlation (R2 = 0.843) between the pressure and specific volume of breads was found. An extended first mixing phase at overpressure resulted in the formation of a very fine pore structure, whereby a short overpressure phase caused the formation of big pores. Thus, the control of the headspace atmosphere during mixing is a suitable parameter to adjust the density of dough and consequently, the pore size distribution for a specific texture design.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The finale volume of baked goods depends on the gas production or gas entrapment of dough, as well as the gas stabilization during dough preparation and baking process [1, 2]. Long time, scientific focus was on the optimization of gas stabilization in gluten-free (gf) dough, for instance by the addition of hydrocolloids or other functional polymers to the bulk phase, as well as the improvement of the hydration properties of dough [3,4,5,6,7]. In recent approaches, the finale gas volume ratio of gf breads is optimized by focusing on the gas introduction in gf dough by the adaption of the mixing process [8] or extrusion processes [9]. Since gf dough resembles cake batters in its functional properties [10], the finale gas volume of baked goods (37–73%) strongly depends on the mixing process [8, 11]. Even if the stabilization of gas bubbles differs tremendously between cake and dough systems, an early incorporation of a high proportion of gas into the liquid dough could be advantageous. This applies especially for the mentioned liquid dough types, since these have no intermediate forming and shaping step, in which the incorporated gas from the mixing process would be re-distributed. Studies on these gf dough types showed an increased finale volume of gf bread by 12–21% [12] by varying process parameters, as mixing speed and time, or the geometry of mixers, or introduction of novel heating methods, as Ohmic heating [13]. However, a further crucial factor—the headspace atmosphere (HSA)—was, to the best of our knowledge, not studied so far.

In wheat-based dough and baked goods, the application of a modified HSA (for instance in Chorleywood-kneaders) already showed positive changes in the number and distribution of gas nuclei and later bubbles in dough [14, 15], resulting in significant alterations of the pore structure [16] and consequently the bread volume:

-

− Kneading above atmospheric pressure generated gas bubbles, which did expand at atmospheric pressure.

-

− Kneading below atmospheric pressure caused the expansion of gas bubbles, which could easily be dispersed during kneading and which contracted at subsequent atmospheric pressure [17].

Beside the amount of gas bubbles in dough or pores in bread, the gas bubble distribution/size and pore structure (open cell/closed cell) in crumbs significantly affect the sensory of the product [18] and a homogenous distribution of bubbles is a requirement for most high-quality baked goods.

In wheat-based dough, a modified HSA can cause further changes of gluten proteins and its network formation by altering its chemical structure. This complicates the precise elucidation of the impact of the mechanical gas entrapment in dough and its influence on the finale bread sensory, especially since the effects of the modified HSA strongly depend on the used flour quality [19].

The usage of starch-based dough, among these gluten-free (gf) dough, overcomes the challenges of a possible chemical gluten modification caused by a modified HSA and enables new findings on the impact of modified HSA on the crumb texture. The knowledge of underlying mechanisms allows a better control of the bread crumb structure and finally quality of gf breads.

In the present study, the impact of extrinsic mixing parameters on the amount, size and distribution of gas bubbles in rice-based gluten-free (gf) dough and bread were determined. First, the impact of mixing time and speed was studied on the gas distribution, the final gas volume fraction in breads and its crumb hardness. Second, changes of dough density and bread volume at a modified headspace atmosphere (HSA) during mixing were investigated by means of an µ-CT-analysis of the crumb and a crumb density measurement. The purpose of the study was to investigate the effects of a controlled headspace atmosphere on the mechanical entrapping of gas in gluten-free dough and their mechanical distribution for a property-driven texture design of gluten-free food.

Materials and methods

Preparation of dough and bread

Dough were made in the UMSK 24 mixer of Stephan Machinery GmbH (Hameln, Germany). The mixing speed was set in a range of 300–3000 rpm and the relative pressure prel was adapted between 130 (overpressure) and − 80 kPa (negative pressure) (absolute pressure range 20–230 kPa).

The following experimental setups were performed and analyzed to enhance the gas volume fraction in gluten-free dough and bread:

-

Mixing speed and time during dough preparation: mixing speed was varied between 600 and 3000 rpm for 3 min, 5 min or 8 min, respectively.

-

Pressure of headspace atmosphere (HSA): relative pressure (difference between actual pressure during mixing and atmospheric pressure) of HSA ranged between − 50 and + 130 kPa (maximum pressure range for the used mixer) at mixing speeds of 1800 rpm, 2400 rpm and 3000 rpm for 5 min or 8 min, respectively.

-

Combinations of the pressure of the headspace atmosphere (HSA): combination of first and second mixing phase: 20/80 (96 s/384 s), 50/50 (240 s/240 s), 80/20 (384 s/96 s). First mixing phase was always performed with an overpressure (prel 130 kPa) at 3000 rpm. Negative pressure of the second mixing phase was − 80 kPa, − 50 kPa or − 20 kPa, respectively.

Dough were prepared in triplicates using rice flour (moisture determined by a moisture analyzer DAB or MLB 50-3, Kern & Sohn GmbH, Balingen, Germany) from Müller’s Mühle GmbH (Gelsenkirchen, Germany), with the addition of demineralized water (120 g 100 g−1 flour), margarine (3 g 100 g−1 flour, CSM Deutschland GmbH, Bingen am Rhein, Germany), sodium chloride (2 g 100 g−1 flour, purity 99.9%, Südsalz GmbH, Heilbronn, Germany), D(+)-glucose (2 g 100 g−1 flour, ApliChem GmbH, Darmstadt, Germany), Methocel™ (Hydroxypropylmethylcellulose (HPMC) (2 g 100 g−1 flour, Dow Wolff Cellulosics GmbH, Bomlitz, Germany) and dry yeast Fermipan red (2 g 100 g−1 flour, Casteggio Lieviti srl, Casteggio, Italy). The final water content was adjusted to the flour moisture content (14 g 100 g−1 flour) according to ICC 110/1. The temperature of added water is calculated using the following formula (modified to Cauvain et al. [20]), so that a final temperature of the dough of 26 ± 1 °C was achieved:

The ingredients were mixed for 60 s at 300 rpm, prior starting the testing experiments. The mixing speed, mixing time, headspace pressure and pressure combinations were varied. The mixing vessel was cooled through a double shell during the whole mixing process and the initial temperature of dough was varied to ensure a constant final temperature of dough under 26 ± 1 °C (compare Table 1). The temperature rise for each experiment is shown in the supplementary data (Fig. 1), which was the prerequisite to calculate the initial temperature.

After mixing, the density of the dough was measured (compare 2.3). Simultaneously, the dough was separated into eight pieces of 220 g. 4 pieces were placed in greased baking pans before resting in a proofing chamber CDS Sun Riser (KOMA GmbH (Roermond, Netherlands) at 30 °C with 80% relative humidity for 45 min (standard proofing). Afterward, the pieces were baked in a Matador 12.8 oven (Werner & Pfleiderer Lebensmitteltechnik GmbH, Dinkelsbühl, Germany) for 35 min at 220 °C upper heat, 230 °C bottom heat with 0.69 L initial steam and a 100% setting of the humidity draught. After cooling at 20 ± 2 °C for 150 min, the specific bread volume (cm3 g−1) was analyzed (compare settings in chapter 2.2).

Analysis of dough and breads

Gas volume fraction

The determination of the gas volume fraction requires the knowledge of the gas free dough density. Thus, the yeast-leavened dough was centrifuged at 4000 rpm for 20 min at room temperature, to degas the dough, and to determine the volume of the gas free dough (Vdough gas free). The density of the gas free dough is calculated using the following formula:

where mdough gas free. is the weight of the dough, Vdough gas free is the volume of the gas free dough and pgas free is the density of gas free dough.

The volume of the gas containing dough was determined by filling a defined dough volume into a beaker (100 ml CSM Deutschland GmbH, Bingen am Rhein, Germany) and determining the weight (the following formula):

where mdough with gas is the weight of the gas containing dough, Vdough with gas is the volume of the containing dough and pwith gas is the density of gas containing dough.

The percentage of the gas volume fraction φ is calculated with the following formula:

Specific bread volume

The specific bread volume was determined after 2.5 h of standardized cooling, using TexVol BVM-L370 (Perten Instruments, Sweden). Weighed breads (precision weight PCB, Kern & Sohn GmbH, Balingen, Germany) were clamped on a rotating bracket. The bread surface was scanned by a laser to evaluate the bread volume. Based on these results, the specific bread volume (volume/weight) was determined.

Crumb hardness

The crumb hardness was analyzed after 2.5 h of cooling using the texture analyzer TexVol Instrument f 300× (Perten Instruments, Sweden)). At first, two round discs of 15 mm were cut out the crumb with a sharp, jagged drilling head (Ritterwerk, Gröbenzell, Germany) without squeezing the crumb and rejected. The following bread slices were used for the analysis. Therefore, two discs (25 mm height, each 12.5 mm) were placed for compression (diameter: of stamp 20 mm). The crumb discs were compressed by 40% with a test speed of 1.7 mm s−1, a post-test speed of 1.0 mm s−1, and a trigger force of 0.049 N. The crumb hardness corresponds to the peak force of the first compression cycle.

Distribution of pores in crumb

A 12.5 mm crumb slice was photographed at standardized light conditions using a self-constructed photo box and the program Pylon Viewer (× 64).

µCT measurement

The non-destructive µCT measurement enables the analysis of the gas bubble distribution in dough and breads, as well as the determination of the dough density without gas. The 3D µCT measurement was performed of dough (without yeast) and breads, prepared with yeast using a portable CT system (CTportable 160.90) with the dimension (0.770 m × 0.375 m × 0.550 m (L × W × H). The resolution area was between 2 and 40 μm. Small portions of dough were taken carefully with a specifically manufactured centrifuge tube, whereby shearing of the dough was tried to keep minimal. To analyze the breads, the end of the bread (15 mm) was removed. Afterwards, a 20 mm thick bread slice was cut. A piece of crumb was punched with a cylinder (Ø 30 mm), which was analyzed, after performing a white balance. Samples were analyzed at the Fraunhofer Institute for Integrated Circuits IIS using the method of Eggert [21].

Statistical analysis

Statistical analysis was performed using JMP Pro (Version JMP Pro 12.2., JMP Software, SAS Institute Inc., Cary, NC, USA). Significant differences were determined using Tukey’s pairwise comparison (confidence level of 95%) with ANOVA.

Results and discussion

Impact of mixing speed and time

Gas entrapment in dough

The impact of mixing speed and time on the gas entrapment in dough was analyzed to determine suitable mixing parameters prior varying the headspace atmosphere (HSA). The results of three different mixing durations (3 min, 5 min and 8 min), as well as five mixing speeds (600 rpm, 1200 rpm, 1800 rpm, 2400 rpm and 3000 rpm) are shown in Fig. 2.

Impact of mixing speed on gas volume fraction of gluten-free dough at a mixing time of 3 (left), 5 (middle) or 8 (right) min, respectively. Final dough temperature was set to 26 ± 1 °C. Mean ± std., n = 3. Different letters demonstrate significant differences in gas volume fraction of dough (p values < 0.05), identified by one-way ANOVA Tukey Test

A prolonged mixing duration from 3 to 8 min led to a significant decrease in gas volume fraction. Furthermore, the increase in mixing speed from 600 to 1200 rpm caused a significant reduction in gas volume fraction of the dough for all three mixing durations (3 min, 5 min and 8 min). This result was unexpected, since the authors anticipated a rise in gas volume fraction of the dough with increase in mixing speed, as noticed by the authors Gómez et al. [22]. The incomplete homogenization of the dough at such low mixing speeds could explain the unexpected gas volume development, since massive sediments were visible on mixing elements. These sediments could affect the density of the dough, provoking variations in the gas volume fraction. A further increase in mixing speed up to 2400 rpm resulted in a significant rise in a gas volume fraction of the dough of 8.8%, 8.2% and 8.8% for a 3 min, 5 min and 8 min mixing process, respectively, in comparison to a mixing at 600 rpm. A final gas volume fraction (at 2400 rpm) of 12.0 ± 0.1%, 11.3 ± 0.1% and 10.9 ± 0.2% was achieved for 3 min, 5 min and 8 min mixing, respectively. For all mixing durations, the measured gas volume was above the known rise in gas volume fraction for gluten-free (gf) yeast-free dough (4–8%), as summarized by Campbell and Mougeot [11]. Consequently, the used mixer and the recipe was suitable to produce low density gf dough and could used for further experiments with altered headspace atmosphere (HAS).

A further rise in mixing speed up to 3000 rpm resulted in a reduction in gas volume fraction of the dough (statistically significant for 3 min mixing). On the one hand, the high mixing speed—thus mixing forces—at 3000 rpm, could evoke the destruction of gas-stabilizing dough structures, which were built by a HPMC network and/ or swollen starch granules. This is already known from cake batters or gluten-containing dough, where covalent bonds of gluten were fragmented at a high mixing speed [23]. On the other hand, high rotation speeds during mixing could cause an increase in dough temperature altering the gas cell stability. The negative effects on the gas volume fraction caused by a higher shear stress was also shown, when dough mixing durations are compared: the gas volume fraction of the dough decreased significantly by 9.5% with increase in mixing time from 3 to 8 min (at 600 rpm). This effect arises especially for higher mixing speeds (2400 rpm and 3000 rpm), which is in accordance to findings in cake batters [24]. Consequently, destroyed gas-stabilizing dough structure and altered temperatures during mixing can affect the gas entrapment in gluten-free dough at higher mixing speeds. Profound studies using time domain (TD) NMR and scanning electron microscopy (SEM) would contributed to a detailed elucidation of the cell structure and water distribution of gf cake batters and bread [25].

Baking performance based on varied mixing parameters

The final density of breads is determined by the mechanical gas entrapment during dough preparation, the gas production by the chemical or biological leavening of dough and the bulk-dependent gas stabilization during dough preparation and thermal transition of the biopolymers during baking [26]. For a mixing time of 3 min, the mean specific bread volume varied between 2.01 ml/g (600 rpm) and 2.15 ml/g (2400 rpm) for mixing speed between 600 and 3000 rpm (not significant, p values < 0.05) (compare Fig. 3, top). In general, alterations of the crumb hardness are accompanied inversely proportional to the rise in specific volume and decrease with increase in specific volume [27]. Although no statistically significant rise in specific bread volume was noticed, a significant reduction in crumb hardness occurred from 636.4 ± 45.6 N (600 rpm, 3 min mixing duration) to 397.2 ± 13.1 N (3000 rpm, 3 min mixing duration) (Fig. 3, bottom). Thus, a low mixing duration in combination with a high rotation speed caused the development of softer and more elastic crumbs. Since no significant alterations of the specific loaf volume occurred, the reduced crumb hardness can be lead back to a modified dough structure formation during mixing, and consequently, crumb structure formation during baking, evoking desired quality characteristics for gluten-free and gluten-containing breads.

Impact of mixing speed on the specific gluten-free bread volume and crumb hardness at a mixing time of 3 (left) or 8 (right) min, respectively. Mean ± std., n = 3. Different letters demonstrate significant differences in specific bread volume or crumb hardness (p values < 0.05), identified by one-way ANOVA Tukey Test

For a mixing duration of 8 min, however, no statistically significant (p values < 0.05) alterations of the specific bread volume (Fig. 3, top) and crumb hardness (Fig. 3, bottom) were noticed within the mixing speed of 600–3000 rpm. The specific bread volume ranged between 2.07 ± 0.05 ml/g (600 rpm) and 1.94 ± 0.05 ml/g (3000 rpm). A tendency to decrease with increase in mixing speed was also noticed by Gómez et al. [22] for the specific loaf volume of gf bread (hydration level 110%). Tan et al. [28] noted a steadily increase in crumb hardness with increase in mixing speed for cake batters, which is in accordance to our results, and an optimum for a mediate mixing time of 9 min. However, due to differences in the batter formulation and mixing geometry, results of Gómez et al. [22] and Tan et al. [28] are not directly transferable to our study.

Despite the possibility to improve the specific volume of gf breads by altering the mixing time and speed, the specific volume of gf breads was still lower in comparison to gluten-containing wheat bread (3.3–3.7 ml/g) [29]. Thus, further changes in process parameters were necessary to improve the quality (especially the specific volume) of gluten-free bread.

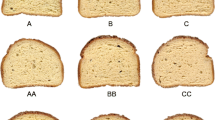

Beside the specific bread volume and the crumb hardness, the pore size and pore distribution are important quality parameters for gluten-free dough, whereby a uniform distribution of pores is preferred. Crumb pores got finer (with sporadic bigger pores) for a 3 min mixing, when the mixing speed was increased from 600 to 1200 rpm (Fig. 4). This was in accordance with the results of the gas volume fraction in dough, where a decrease in gas volume was noticed with the rise in mixing speed from 600 to 1200 rpm. The further rise in mixing speed up to 2400 rpm caused the formation of uniform, bigger pores. Thus, the higher mixing speed enabled a homogeneous pore size distribution. Furthermore, the bigger pores led to a lowered crumb hardness at high mixing speeds of 2400 and 3000 rpm. The combination of a high mixing speed and mixing time (8 min) resulted in the formation of very small pores, most likely since the increase in mixing time caused the dispersion of gas bubbles in the dough. Consequently, the partial pressure of each gas bubble increased, impeding the presence of CO2 (produced in yeast-leavened dough) in the gas state. In addition, the higher shear stress could destroy a gas-stabilizing network in dough causing an impaired gas stabilization in dough, as mentioned before.

Despite good results for the specific bread volume at a mixing time of 3 min, the authors decided not to use this low mixing duration for further experiments. A homogeneous distribution of components could not be ensured during mixing and massive sediments were visible on mixing elements. The same applied for low mixing speeds of 600 rpm and 1200 rpm, which were also excluded for further experiments. Experiments at varying headspace atmospheres (two-phase mixing) were, therefore, performed at 3000 rpm.

Although the adaption of mixing parameters, as speed and duration, could improve the gas volume fraction in dough, these parameters were not adequate to achieve a satisfying specific bread volume, comparable with gluten-containing wheat bread. Thus, further focus was on the impact of the headspace atmosphere and their effects on the gas volume fraction in dough and the specific bread volume.

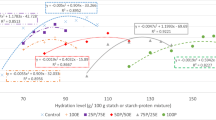

Impact of headspace atmosphere pressure during mixing—1 phase mixing

The effects of a pressure increase or pressure decline in the headspace atmosphere (HSA) during mixing was analyzed in the following chapter (results are displayed in Fig. 5). All pressure values are described as relative pressure in comparison to the atmospheric pressure, which is the normal pressure during mixing. Thus, the relative pressure is the difference between the pressure, which was present during mixing, and the atmospheric pressure (prel 0 kPa), with an overpressure of prel > 0 kPa and a negative pressure of prel < 0 kPa.

Impact of mixing speed and headspace atmosphere pressure (relative pressure compared to atmospheric pressure) for a 8 min mixing process on gas volume fraction (left), specific bread volume (middle) and crumb hardness (right) ( prel − 80 kPa,

prel − 80 kPa,  prel − 50 kPa,

prel − 50 kPa,  prel -20 kPa,

prel -20 kPa,  prel 0 kPa,

prel 0 kPa,  prel 50 kPa,

prel 50 kPa,  prel 100 kPa, and

prel 100 kPa, and  prel 130 kPa). Mean ± std., n = 3. Different letters demonstrate significant differences in gas volume fraction (p values < 0.05), identified by one-way ANOVA Tukey Test

prel 130 kPa). Mean ± std., n = 3. Different letters demonstrate significant differences in gas volume fraction (p values < 0.05), identified by one-way ANOVA Tukey Test

The mixing speed showed only little effects (no significant effects between mixing speed 2400 rpm and 3000 rpm) on the gas volume fraction of gluten-free dough, in comparison to pressure changes in the HAS: the pressure rise of 50 kPa (prel 50 kPa), 100 kPa (prel 100 kPa) or 130 kPa (prel 130 kPa) enabled a significant, relative increase in gas volume fraction of 52%, 100% or 120% (at 2400 rpm), respectively. As a result, the specific volume increased by 9%, leading to a reduction of crumb hardness by 45% (at prel 130 kPa, 2400 rpm). This behavior was also demonstrated for a mixing speed of 600 rpm and 3000 rpm. Otherwise, the reduction of pressure (prel < 0 kPa) in comparison to a mixing process at atmospheric pressure caused a degassing of the dough (significant reduction in gas volume fraction) and consequently a lowering of the specific bread volume and the rise in crumb hardness. Thus, overpressure or negative pressure modifies the gas entrapment in dough and additionally the dough rheology resulting in a modified crumb characteristic [14].

The µ-CT-analysis confirmed these findings of the gas volume fraction measurement and the analysis of the bread crumb (Fig. 6): with the increase in overpressure the volume of gas bubbles in dough increased, whereby the increase in gas fraction in dough could be transferred over the whole process into the crumb structure. The expansion of gas bubbles caused the formation of a finer lamellar structure, which, in turn, possibly stabilized the gas bubbles.

Figure 7 clarifies the relation of the pressure of the HSA (prel − 80 to prel 130 kPa), the dough density and its impact on the specific volume of gluten-free breads:

-

The dough density increased with decrease in pressure from prel + 130 kPa → prel − 80 kPa.

-

The bread volume decreased with increase in dough density.

To achieve highly inflated gluten-free breads, the mixing pressure should be kept high (to prevent a degassing of the dough) and to increase the volume of the product.

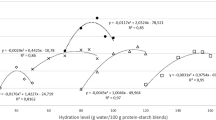

Impact of headspace atmosphere pressure variations during mixing—2 phase mixing

Based on the significant impact of the pressure of the headspace atmosphere (HSA) on the dough density and bread quality from the previous chapter, the effects of a two-phase mixing process, including a overpressure and negative pressure mixing step, were analyzed. The aim of the two-phase mixing process was to increase the gas entrapment in the dough during the first phase of mixing (overpressure) and to stretch the gas bubbles by applying negative pressure in the second mixing phase, so that they can easily be dispersed by the shear forces during mixing [30]. Consequently, finer gas bubbles should be present in the dough, which can expand during thermal processing and grow through biological gas entrapment by yeast cells. The 8 min mixing process was divided into a 1st phase (overpressure)/2nd phase (negative pressure) mixing at different durations: 20/80 (384 s/96 s), 50/50 (240 s/240 s) and 80/20 (96 s/384 s) at a mixing speed of 3000 rpm for both phases and a overpressure of prel 130 kPa at the 1st phase.

The results of this experiment showed a gas entrapment after the first mixing phase (prel 130 kPa) of 20%, however, the application of a negative pressure afterwards led to a degassing of the dough. This effect was heightened, when a negative pressure of − 80 kPa was used or the duration of the second phase was extended from 80/20 to 20/80 (Fig. 8). This is in accordance with findings of Sadot et al. [30], who noticed a dependency of the gas volume fraction exclusively with the final pressure of the mixing process.

Impact of mixing time in 2 phase mixing (1st phase/2nd phase: 20/80, 50/50, 80/20 time, based on a 8 min mixing process) and relative negative mixing pressure in second mixing phase of − 20 kPa, − 50 kPa and − 80 kPa on gas volume fraction, spec. bread volume and crumb hardness at a mixing speed of 3000 rpm for both phases and a overpressure during 1st mixing of prel 130 kPa and varied negative pressure levels in the 2nd mixing phase:  prel− 80 kPa,

prel− 80 kPa,  prel − 50 kPa and

prel − 50 kPa and  prel − 20 kPa. Mean ± std., n = 3. Different letters demonstrate significant differences in gas volume fraction, spec. bread volume or crumb hardness (p values < 0.05), identified by one-way ANOVA Tukey Test

prel − 20 kPa. Mean ± std., n = 3. Different letters demonstrate significant differences in gas volume fraction, spec. bread volume or crumb hardness (p values < 0.05), identified by one-way ANOVA Tukey Test

Despite the partial degassing of the dough (left part of Fig. 8), an extended second mixing phase (20/80) at different negative pressure levels (prel − 20 kPa to prel − 80 kPa) showed no negative effects on the specific volume of breads (middle) or a negative effect on the crumb hardness (right) in comparison to an equal first or second mixing phase (50/50) or elongated second mixing phase (80/20) (no significant differences between an elongated long first or second mixing phase, respectively). The poor correlation between dough stability and bread volume was already noticed by Correa, Pérez, and Ferrero on pectin supplemented dough and breads [31]. The longer first overpressure phase (80/20) does possibly slightly increase the dough temperature and consequently reduce the dough viscosity, so that the higher gas entrapment in the dough fraction during mixing cannot be transferred into the sponge matrix of the gluten-free bread [32]. In addition, the authors presume that just a partial degassing of gas bubbles occur during the second phase at elongated negative pressure, so that gas alveoli remained in the dough, which can expand by biological leavening processes and thermal steps, contributing to the final crumb structure [33]. Both mechanisms would minimize the effects between an elongated first (overpressure) mixing phase (80/20) and an elongated second (negative pressure) mixing phase (20/80). Thus, ratio of the duration of first to second mixing phase showed only limited effects.

However, the pressure of the second mixing phase was highly relevant: negative pressure during mixing should be avoided since higher bread volumes were gained without the application of negative pressure. Already the decrease in pressure from prel − 20 kPa to prel − 80 kPa caused a reduction in gas volume fraction in dough (for instance from 9.2 ± 0.3% to 3.8 ± 0.4% (20/80 first to second mixing phase)). The comparison with the one phase mixing continuously at prel 130 kPa demonstrated the enormous (negative) effects of the application of a negative pressure in the second mixing phase: the gas volume fraction in dough decreased from 23 to 1%, the specific bread volume decreased from 2.2 to 1.6 ml/g and the crumb hardness increased from 4.2 to 7.8 N, when mixing at overpressure (prel 130 kPa) was partially substituted by negative pressure of prel − 80 kPa (80/20 ratio) (compare Fig. 8 and Fig. 5).

The image analysis demonstrated the effects of the ratio of first to second mixing phase on the pore structure of the crumbs. Especially an extended first mixing phase (80/20) resulted in the formation of a very fine crumb structure containing small, homogenous distributed pores, whereby a short first mixing phase (20/80) caused the formation of bigger pores, which, however, were still homogenous distributed (Fig. 9). These results were unexpected, since it is known from the one phase ‘Chorleywood bread process’ that mixing below atmospheric pressure gives a fine pore structure and mixing above atmospheric pressure leads to an open cell structure [34]. Thus, the authors expected a finer pore structure with extended second (negative pressure) mixing phase. Since the data were achieved for only applying overpressure OR negative pressure from the ‘Chorleywood bread process’, they are not directly transferable to a two-phase mixing process. In addition, ‘Chorleywood bread process’ was developed and adapted for gluten-containing dough matrices, containing a gluten network to stabilize gas at negative pressure mixing of dough. This network is missing for gf dough, leading to an easier degassing of dough at negative pressure during mixing, why negative pressure come along with a lower specific bread volume. Furthermore, variations in the headspace atmosphere pressure reveal in gluten-containing matrices a physical (inflation/deflation) AND a chemical (supported/impeded oxidation of thiol groups) effect, whereas only physical effects are mainly present in gluten-free dough. Nonetheless, if the crumb structure is the principle focus, negative pressure of the headspace atmosphere can be used to create desired finer crumb structures of gluten-free breads at lower specific bread volumes.

Impact of mixing time in 2 phase mixing (1st phase/2nd phase: 20/80, 50/50, 80/20 time, based on a 8 min mixing process) and relative negative mixing pressure in second mixing phase of prel − 20 kPa, prel − 50 kPa and prel − 80 kPa on the pore size distribution in crumbs at a mixing speed of 3000 rpm for both phases and a overpressure during 1st mixing of prel 130 kPa

Further research is indispensable to elucidate gas bubble stabilization and crumb structure formation in a two-phase mixing process and a subsequent thermal processing step, to highlight differences between exclusively overpressure/negative pressure and a combination of pressure steps during mixing.

Conclusions

The understanding of processing technologies and mechanical methods to entrap gas into gluten-free matrices is elementary to improve the bread volume and pore size distribution of gluten-free (baked) products. This study demonstrated that capturing gas into a gluten-free dough matrix can be enhanced by an excess pressure (compressed air) in the headspace atmosphere during mixing in a Stephans mixer, then the adaption of mixing parameters, as mixing speed or duration. Thereby, the gas volume fraction of the dough showed a significant relation to the specific volume of the gluten-free breads (R2 = 0.876), resulting in the reduction of the crumb hardness. The application of negative pressure in the headspace atmosphere during mixing was an adequate tool to create a finer pore size distribution (finer/bigger pores) in gluten-free (gf) crumbs, but simultaneously lower specific bread volume caused the degassing of gf dough. Further studies are necessary to assign alterations in the crumb structure to rheological changes of the dough and to evaluate the impact of the gas composition of the headspace atmosphere on the gas entrapping in dough and breads. The current results show the extensive potential of the quality control and improvement of gluten-free products without the addition of food additives using a modified headspace atmosphere during mixing.

References

Elgeti DD (2017) Aeration strategies and identification of foam stabilization mechanisms for gluten-free dough systems. Technical University of Munich

Mancebo CM, San Miguel MÁ, Martínez MM, Gómez M (2015) Optimisation of rheological properties of gluten-free doughs with HPMC, psyllium and different levels of water. J Cereal Sci 61:8–15. https://doi.org/10.1016/j.jcs.2014.10.005

Föste M, Jekle M, Becker T (2017) Structure stabilization in starch-quinoa bran doughs: the role of water availability and gelatinization. Carbohydr Polym 174:1018–1025. https://doi.org/10.1016/j.carbpol.2017.06.068

Paulik S, Docx R, Becker T, Jekle M (2020) Texturmodifikation glutenfreier Backwaren. Cereal Technol 2:138–143

Bender D, Regner M, D’Amico S, Jäger H, Tömösközi S, Schoenlechner R (2018) Effect of differently extracted arabinoxylan on gluten-free sourdough-bread properties. J Food Qual 2018:1–10. https://doi.org/10.1155/2018/5719681

Wronkowska M, Haros M, Soral-Śmietana M (2013) Effect of starch substitution by buckwheat flour on gluten-free bread quality. Food Bioprocess Technol 6:1820–1827. https://doi.org/10.1007/s11947-012-0839-0

Bravo-Núñez Á, Sahagún M, Gómez M (2019) Assessing the importance of protein interactions and hydration level on protein-enriched gluten-free breads: a novel approach. Food Bioprocess Technol 12:820–828. https://doi.org/10.1007/s11947-019-02258-2

Elgeti D, Yu L, Stüttgen A, Jekle M, Becker T (2017) Interrelation between mechanical and biological aeration in starch-based gluten-free dough systems. J Cereal Sci 76:28–34. https://doi.org/10.1016/j.jcs.2017.05.008

Lammers V (2016) A novel technology to tailor foam structure in gluten-free bakery product systems. ETH Zürich

Sciarini LS, Ribotta PD, León AE, Pérez GT (2010) Influence of gluten-free flours and their mixtures on batter properties and bread quality. Food Bioprocess Technol 3:577–585. https://doi.org/10.1007/s11947-008-0098-2

Campbell GM, Mougeot E (1999) Creation and characterisation of aerated food products. Trends Food Sci Technol 10:283–296. https://doi.org/10.1016/S0924-2244(00)00008-X

Elgeti D, Peng L, Jekle M, Becker T (2017) Foam stabilization during processing of starch-based dough systems. Innov Food Sci Emerg Technol 39:267–274. https://doi.org/10.1016/j.ifset.2016.12.012

Bender D, Gratz M, Vogt S, Fauster T, Wicki B, Pichler S, Kinner M, Jäger H, Schoenlechner R (2019) Ohmic heating—a novel approach for gluten-free bread baking. Food Bioprocess Technol 12:1603–1613. https://doi.org/10.1007/s11947-019-02324-9

Chin NL, Campbell GM (2005) Dough aeration and rheology: Part 1. Effects of mixing speed and headspace pressure on mechanical development of bread dough. J Sci Food Agric 85:2184–2193. https://doi.org/10.1002/jsfa.2236

Trinh L (2013) Gas cells in bread dough. Thesis, at the University of Manchester, School of Chemical Engineering and Analytical Science

Cauvain SP, Young LS (2006) Chorleywood bread process fundamentals. In: The chorleywood bread process. Elsevier, pp 17–23

Schünemann C (2006) Lernfelder der Bäckerei - Produktion Praxis-Theorie-Lehrwerk für die Berufsausbildung zum Bäcker, zur Bäckerin. Gildebuchverl (ISBN 9783773401656)

Wang S, Austin P, Bell S (2011) It’s a maze: the pore structure of bread crumbs. J Cereal Sci 54:203–210. https://doi.org/10.1016/j.jcs.2011.05.004

Gao J, Koh AHS, Tay SL, Zhou W (2017) Dough and bread made from high- and low-protein flours by vacuum mixing: Part 1: Gluten network formation. J Cereal Sci 74:288–295. https://doi.org/10.1016/j.jcs.2017.03.008

Cauvain, Stanley P, Young LS (2007) Technology of breadmaking. Springer, Boston

Eggert A (2018) Fast laboratory micro-CT of food foams: principle, experimental setup for foam characterization and stability. Dr. Hut, München (ISBN 978-3843936637)

Gómez M, Talegón M, de la Hera E (2013) Influence of mixing on quality of gluten-free bread. J Food Qual 36:139–145. https://doi.org/10.1111/jfq.12014

Macritchie F (2007) Mechanical degradation of gluten proteins during high-speed mixing of doughs. J Polym Sci Polym Symp 49:85–90. https://doi.org/10.1002/polc.5070490108

Massey AH, Khare AS, Niranjan K (2008) Air inclusion into a model cake batter using a pressure whisk: development of gas hold-up and bubble size distribution. J Food Sci 66:1152–1157. https://doi.org/10.1111/j.1365-2621.2001.tb16097.x

Yildiz E, Guner S, Sumnu G, Sahin S, Oztop MH (2018) Monitoring the effects of ingredients and baking methods on quality of gluten-free cakes by time-domain (TD) NMR relaxometry. Food Bioprocess Technol 11:1923–1933. https://doi.org/10.1007/s11947-018-2152-z

Paulik S, Jekle M, Becker T (2019) A review: reverse approach to analyze the impact of starch modification on the inflation and gas holding properties of wheat-based matrices. Trends Food Sci Technol 91:231–239. https://doi.org/10.1016/J.TIFS.2019.07.031

Jekle M, Becker T (2012) Frischhaltung bei Weizenbroten. Backtechnik Eur 3:62–65

Tan MC, Chin NL, Yusof YA (2012) A Box-Behnken design for determining the optimum experimental condition of cake batter mixing. Food Bioprocess Technol 5:972–982. https://doi.org/10.1007/s11947-010-0394-5

Belitz H-D, Grosch W, Schieberle P (2008) Lehrbuch der Lebensmittelchemie : mit 634 Tabellen. Springer (ISBN 9783540732020)

Sadot M, Cheio J, Le-Bail A (2017) Impact on dough aeration of pressure change during mixing. J Food Eng 195:150–157. https://doi.org/10.1016/j.jfoodeng.2016.09.008

Correa MJ, Pérez GT, Ferrero C (2012) Pectins as breadmaking additives: effect on dough rheology and bread quality. Food Bioprocess Technol 5:2889–2898. https://doi.org/10.1007/s11947-011-0631-6

Mir SA, Shah MA, Naik HR, Zargar IA (2016) Influence of hydrocolloids on dough handling and technological properties of gluten-free breads. Trends Food Sci Technol 51:49–57. https://doi.org/10.1016/j.tifs.2016.03.005

Mills ENC, Wilde PJ, Salt LJ, Skeggs P (2003) Bubble formation and stabilization in bread dough. Food Bioprod Process 81:189–193. https://doi.org/10.1205/096030803322437956

Cauvain SP, Clark RH (2019) Baking technology and nutrition: towards a healthier world. Wiley

Acknowledgements

The authors would like to thank the ‘Weihenstephaner Institut für Getreideforschung’ (WIG) for enabling this research, as well as Müller’s Mühle GmbH (Gelsenkirchen, Germany) for the supply of rice flour.

Funding

Open Access funding enabled and organized by Projekt DEAL. This IGF Project of the FEI (18619N) was supported via AiF within the programme for promoting the Industrial Collective Research (IGF) of the German Ministry of Economic Affairs and Energy (BMWi), based on a resolution of the German Parliament.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Paulik, S., Paczkowski, C., Laukemper, R. et al. Texture design of gluten-free bread by mixing under controlled headspace atmosphere. Eur Food Res Technol 247, 2333–2343 (2021). https://doi.org/10.1007/s00217-021-03793-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-021-03793-z