Abstract

Dried powder from Moringa oleifera L. leaves (MOLP) could be considered a promising naturally gluten-free (GF) ingredient to be added in the formulation of GF food products aiming to improve the overall nutritional characteristics. In this work, GF biscuits were formulated by replacing a commercial GF flour mix with 0, 5, 10, and 15 g/100 g of MOLP. Chemical composition, physical and textural characteristics, starch pasting properties, and the in vitro starch digestibility were considered. Adding MOLP increased the amount of protein and total dietary fibre. Even at the lowest MOLP-substitution level, the biscuits had a total dietary fibre content > 6 g/100 g dry matter. Differences in the chemical composition might account for differences in starch properties in terms of pasting behaviour and in vitro digestibility. Using MOLP decreased the in vitro starch hydrolysis index of biscuits, the lowest value (69.3) obtained at the greatest MOLP inclusion level. In addition, an increase in the resistant starch content was reported, passing from 1.1 to 2.7 g/100 g dry matter for GF biscuits containing 0 to 15 g/100 g of MOLP. Colour, spread ratio, and hardness were affected by MOLP inclusion. Biscuits containing 15 g/100 g of MOLP were characterized by the highest hardness value (41.9 N). Substitution level of 10 g/100 g should be considered the threshold level for obtaining a product with similar spread ratio than the control.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The market demand of gluten-free (GF) baked goods and pasta is expanding [1]. Despite the health halo associated with GF food category, commercially available GF cereal-based foods are often characterised by lower nutritional quality than their gluten-containing counterparts, having lower dietary fibre, protein and resistant starch (RS) contents, along with enhanced starch digestion rates and extents [2].

Plenty of research has been, therefore, conducted to ameliorate the nutritional profile of GF foods and one of the possible strategies is the partial replacement of common GF-flours with novel nutrient-dense raw materials [3]. Legume flours, dairy proteins, fruits and vegetable-based powders, along with fibre sources and other GF materials have been added at different inclusion levels in GF baked goods aiming to enhance their technological and nutritional profiles [4, 5].

In this context, dried powder from Moringa oleifera L. leaves (MOL) could be considered a promising naturally GF ingredient to be added in the formulation of GF food products. Specifically, leaves from Moringa oleifera L. are completely safe for human consumption and represent a good source of proteins, essential amino acids, dietary fibres, vitamins and minerals, while being low in fat, sugars, and total starch [6, 7]. In addition, the MOL contain several classes of polyphenols, including flavonoids, phenolic acids, and lignans [8]. Accordingly, MOL powder (MOLP) has been used in the formulation of amala (stiff dough), wheat-based foods (e.g. bread, cookies, pasta), dairy products and soups [9]. Previous experiments conducted on wheat-based cookies and pasta showed that the addition of MOLP in the range of 10–15% can contribute to improve the overall nutritional value [8, 10, 11]. In addition, Rocchetti et al. [8] reported that the inclusion of MOLP in semolina fresh pasta contributed to modulate the in vitro starch digestion of optimally cooked samples. Considering the sensory attributes, Dachana et al. [10] reported that an addition of beyond 10% level of MOLP produced unacceptable wheat-based biscuits. On the contrary, Simonato et al. [11] showed that the addition of MOLP in wheat-based fresh pasta up to 15% w/w did not affect the overall acceptability of the products, despite herbaceous aroma, cooked vegetable taste, grittiness, and astringency were significantly perceived in MOLP-containing pasta.

Within this perspective, biscuits, being one the largest categories of ready-to-eat foods, can be considered as a potentially nutritious GF snack through reformulation. However, the nutritional and physicochemical roles of MOLP in GF biscuits have not been fully addressed. In addition, there is no study which showed if the incorporation of MOLP in GF biscuits could also contribute modifying the in vitro starch digestibility.

The present study evaluated the chemical composition, the physical and textural characteristics of GF biscuits prepared by replacing commercially available all-purpose GF flour mix with increasing levels of dried MOLP. Biscuits with different substitution levels of MOLP (i.e. 0, 5, 10, and 15 g/100 g) were produced. The MOLP substitution level of 15 g/100 g was selected as the maximum level since greater levels can impair the overall sensory properties [9]. Newly developed GF products were also evaluated for their resistant starch content, along with the in vitro starch digestibility.

Materials and methods

Raw materials

All materials (food grade) were acquired at local markets. According to the nutritional label on the box, the nutritional composition of the all-purpose GF flour mix (GFM; Mix It! Universal; rice flour, potato starch, sugar, thickener: hydroxypropyl-methyl-cellulose, locust bean gum; salt, emulsifier: mono- and diglycerides of fatty acids; Dr. Schär, Burgstall, Bolzano, Italy) was total starch: 79.5 g; total sugars 3.5 g; total protein: 3.6 g; total fat: 1.1 g; total dietary fibre: 3.1 g (for 100 g product). For the dried MOLP (International Food Europe srl., Roma, Italy): total starch: 15.4 g; total sugars: 3.1 g; total protein: 38.7 g; total fat: 5.1 g; total dietary fibre: 29.7 g (for 100 g product). The GFM and MOLP had a particle size smaller than 0.2 mm.

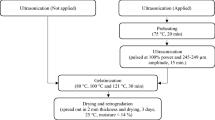

Biscuit-making procedure

Biscuits were formulated by replacing the GFM with 0, 5, 10 and 15% (w/w) of MOLP, obtaining CTR, M5, M10 and M15 biscuits, respectively. The recipe was based on 120 g of composite flours, 60 g of whole egg, 40 g of tap water, 25 g of unsalted butter, 0.5 g of salt and 0.5 g of sodium bicarbonate. Butter was creamed, mixed with whole eggs and water and then the dry blend basis was added. Materials were mixed with a domestic blender (Kitchen Aid, Model K5SSWH, St. Joseph, Mich., U.S.A.) for 7 min at intermediate speed. The dough was laminated by a pasta roller attachment at 0.5 cm height, allowed to rest for 45 min at 4 °C, cut into circular shapes of 4 cm diameter and baked (190 ± 3 °C for 18 ± 1 min) in a household oven (RKK 66130, Rex International, Italy). After baking, biscuits were cooled at room temperature and stored in airtight plastic bags. For each recipe, three batches were produced on the same day. For chemical composition and pasting properties, samples were ground using a knife mill (Retsch Grindomix GM 200; Brinkman Instruments, Rexdale, ON, Canada).

Chemical composition of biscuits

Analyses were performed according to AOAC [12] for dry matter (DM; method 930.15), ash (method 942.05), crude protein (method 976.05), crude lipid (method 954.02 without acid hydrolysis), total starch [method 996.11, using thermostable α-amylase (Megazyme cat. no. E-BSTAA) and amyloglucosidase (Megazyme cat. no. E-AMGDF)] total, soluble and insoluble dietary fibre (method 991.43), and resistant starch (RS; method 2002.02). Free sugars were assessed using the Megazyme assay kit K-SUFRG 06/14 (Megazyme, Wicklow, Ireland). For each treatment, each batch was analysed in triplicate.

Physical and textural characteristics of biscuits

Thickness and diameter were evaluated with a Vanier calliper at three different places in each sample. The spread ratio was calculated by dividing values of the diameter by the thickness. The surface colour was measured on the basis of CIE L* (lightness), a* and b* colour system using a Minolta CR410 Chroma Meter (Konica Minolta Co., Japan). A negative value of a* indicates greenness, whereas a positive value indicates redness. A negative value of b* indicates blueness and a positive value indicates yellowness. Five readings were taken for each batch of samples.

Hardness analysis was conducted 24 h after the baking and was performed with a TA-XT2i Texture Analyser (Stable Micro Systems, UK) fitted with a shape blade-cutting probe. The crosshead speed was 10 mm/s, data were acquired with a resolution of 500 Hz and a 5 kg load cell was used. For each batch, five biscuits were tested. Texture Export Exceed Release 2.54 (Stable Micro System) was used to acquire the maximum peak force to snap biscuits (hardness) expressed as fracture force (N) [13].

Pasting properties

Pasting properties were evaluated on both raw materials (i.e. pure GFM, pure MOLP and the different flour blends) and experimental biscuits using the Micro-Visco-Amylo-Graph device (MVAG; Brabender, Duisburg, Germany). Briefly, 12 g of sample was suspended in 100 mL of distilled water, sample moisture was corrected at 14%, bowl rotations set at 250 rpm and the measuring range at 300 cmg. Sample suspensions were equilibrated at 30 °C for 1 min, heated to 95 °C at 3 °C/min, held at 95 °C for 20 min, cooled to 30 °C at 3 °C/min, and held at 30 °C for 1 min. The analysis was carried out in duplicate, and one representative curve for each sample was reported.

In vitro starch digestion and calculations

Conventional (CTR) and MOLP-containing biscuit (i.e. M5, M10 and M15) were in vitro digested to assess the effect of formulation on starch digestion. A multi-enzymatic in vitro starch digestion protocol was employed [14]. Biscuits were cut through a meat mincer into homogeneous small pieces to mimic mastication, weighed (800 mg of total starch) and suspended in a 0.05 M HCl solution containing pepsin (5 mg/mL; P-7000, Sigma-Aldrich® Co., Milan, Italy) at 37 °C under agitation. Five glass balls were added. After 30 min of incubation, the solution pH was adjusted to 5.2 with 0.1 M sodium acetate buffer and an enzyme mixture with an amylase activity of about 7000 U/mL) was added [14]. Aliquots were taken at 0 (prior to the addition of the pancreatic enzyme mixture) and every 30 min up to 180 min after the enzyme addition and mixed with absolute ethanol to stop the enzyme action. The amount of released glucose was determined by colorimetric approach (glucose oxidase kit GODPOD 4058, Giesse Diagnostic s.n.c., Rome, Italy) and hydrolysed starch was quantified using a factor of 0.9. Values were then plotted on a graph vs. time, and the area under the hydrolysis curve (AUHC; 0–180 min) was measured using the trapezoid rule. The starch hydrolysis index (HI) value was calculated as the AUHC with the product as a percentage of the corresponding area using commercial fresh white wheat bread over the same period [15]. Analyses were run in triplicate on each biscuit batch.

Statistical analysis

Normal distribution of data was verified by the Shapiro–Wilk test before statistical analysis. Data were analysed as a completely randomised design using the GLM procedure of SAS 9.3 (SAS Inst. Inc., Cary, N.C., USA) according to the model: Yij = μ + αi + eij, where Yij is the dependent variable on the jth subject (GF biscuit batch) assigned to treatment i, μ is the overall mean, αi is the fixed effect of MOLP substitution level to GFM (i = 0, 5, 10 and 15 g/100 g), and eij is the residual error. Experimental unit was the batch and significance was declared at p < 0.05.

Results and discussion

Chemical composition of biscuits

The chemical composition of GF biscuits is reported in Table 1. Among samples, similar moisture, free sugars and lipid contents (being on average 3.2 g water/100 g food, 3.1 and 10.8 g/100 g DM, respectively) were recorded. Previous indications reported that a moisture content lower than 4 g/100 g product can guarantee a long shelf life [15]. The M15 samples were characterized by the lowest total starch content (i.e. 59.0 g/100 g DM; p < 0.05) and the highest crude protein content (i.e. 9.9 g/100 g DM; p < 0.05). These differences are related to the chemical composition of the selected ingredients as well as to their level in the recipe. Similar results have already been reported in wheat-based biscuits and oat-based expanded snacks formulated with increasing levels of MOLP [10, 16]. The gradual substitution of the GFM with MOLP raised the total dietary fibre content, the highest value obtained for M15 biscuits (i.e. 11.2 g/100 g DM; p < 0.05). From a nutritional standpoint, all MOLP-containing biscuits can be considered GF food products high in dietary fibre, having a total dietary fibre content higher than 6 g /100 g. Gluten-free bakery foods with greater amount of dietary fibre are considered beneficial for health, since a common low intake of this food component has been reported for people affected by the coeliac disease [1, 2]. Moreover, MOLP addition increased the level of soluble dietary fibre since the soluble/insoluble dietary fibre ratio ranged from 0.1 to 0.3 for CTR and M15 biscuits, respectively.

The RS represents the starch fraction that is not absorbed in the small intestine but it is fermented in the large intestine of normal human beings to produce short-chain fatty acids, thus providing a series of health benefits [17, 18]. The RS content of the CTR samples (i.e. 1.1 g/100 g DM) appeared in line with previous findings for similar food products [14, 15]. With the exception of M5, the RS content of the MOLP-substituted biscuits increased with the increasing inclusion level of MOLP in the recipe (i.e. M10 and M15), the highest value recorded for M15 (i.e. 2.7 g/100 g DM; p < 0.05) (Table 1). The increase in the RS following MOLP addition could be attributable to interactions between the starch and other food components that may occur during baking [17,18,19]. For instance, the increasing amount of dietary fibre and proteins characterising MOLP-enriched GF biscuits could have contributed to reduce the starch gelatinization and/or the accessibility of amylase to hydrolyse the starch by acting as a physical barrier and/or by increasing viscosity [15]. Accordingly, higher RS contents have been reported in GF biscuits formulated with increasing amounts of high-fibre/high-protein flour from alfalfa seed flour [15].

Physical and textural characteristics of biscuits

The physical characteristics of samples are presented in Table 2. Combining the GFM with MOLP influenced the spread ratio of biscuits at the highest substitution level, being the lowest value recorded for M15 samples (i.e. 4.1; p < 0.05). Generally, biscuits with higher spread ratio are considered the most desirable. However, flours with high protein content can impair the spread ratio of biscuits, by retaining higher amount of water in the dough system and thus increasing dough viscosity [10, 15]. Comparable results have been reported by Dachana et al. [10], where a significant reduction (about -10%) in the spread ratio of wheat-based biscuits at the highest MOLP inclusion level in the recipe (i.e. 15% w/w) was measured.

Colour is an important parameter for consumer preference, and it depends on physicochemical parameters of both ingredients and baking conditions. As presented in Table 2, significant differences (p < 0.05) in colour measurements were reported. According to the values obtained for L* and a* parameters, the MOLP-substituted biscuits appeared less luminous and more greenness with respect to the CTR, as the level of MOLP increased in the recipe. In addition, the b* value gradually decreased (p < 0.05) with the increase in MOLP level. These changes were expected since the MOLP is characterized by a dark green colour. Similar results have been reported in MOLP-enriched maize-based tortillas [7]. In addition, previous indications suggested that the protein content can be negatively related to the lightness of biscuits, indicating that the Maillard reactions also played a role during colour formation [15].

The M15 biscuits were characterized by the greatest hardness value, whereas the CTR by the lowest one (i.e. 41.9 versus 18.9 N, respectively; p < 0.05). The hardness of biscuits is affected by both flour composition and the interactions among the ingredients [20]. Greater protein level may form harder structure as a result of strong adherence between proteins and starch [21]. Dachana et al. [10] pointed out to a similar result in MOLP-substituted wheat-based biscuits. In particular, the authors reported an increase in the breaking strength, a measure of the texture, with increasing amount of MOLP in the recipe. In addition, in GF biscuits, the presence of fibre can also contribute to influence the texture values, since grater levels of fibre can compact the structure of the dough [15].

Pasting properties of flours and biscuits

The pasting profiles of the raw materials (i.e. GFM, MOLP), along with the different blends and the related food products are shown in Fig. 1. The GFM (blend 0% w/w MOLP: Fig. 1a) exhibited a two-stage swelling: an initial rapid increase in viscosity development at about 70 °C, which agrees with the maximum gelatinization temperature of potato starch (one of the main ingredients of the commercial mix), followed by a slower increase at higher temperatures (90 °C), that can be attributed to the rice flour gelatinization peak. Similar observations were reported when potato starch was blended with rice or maize flours [22]. As the MOLP-enrichment level increased in the flour blends, the intensity of the viscosity peak at 90 °C decreased. The low amount of starch in MOLP (i.e. 15.4 g/100 g of product) accounts for the low viscosity values during the heating and cooling phase. Adding MOLP to the GFM at different substitution levels led to an increase in the pasting temperature that increased from 54.8 to 58.0 °C in the 5% w/w MOLP–GFM blend, with no further increase from 5 to 15% w/w (i.e. 59.0 °C). Incorporating MOLP did not affect the peak temperature (that was 69.0 °C), except for the 5% w/w MOLP–GFM blend, whose peak viscosity shifted toward higher temperature (i.e. 73.0 °C). On the other side, blending the GFM with the MOLP led to a linear decrease in the peak viscosity. A similar behaviour has been observed when Moringa oleifera leaves or seeds have been added to plantain [23] or wheat flours [10, 24]. This might suggest difficulty in starch swelling and gelatinization in the presence of water, likely due to either the low starch and the high fibre and protein content of MOLP (Table 1). However, since the effect of MOLP addition on reducing starch gelatinization was dramatic already at low percentage (i.e. 5% w/w), it can be stated that the role of starch–fibre–water and/or starch–protein–water interactions prevails on the starch dilution effect. All the blends showed a high tendency to be more resistant to both high temperature and continuous shearing. This is also evident from the breakdown viscosity, whose value ranged between 470 and 163 BU for the GFM and 15% MOLP–GFM flour blend, respectively. Results suggest that the 15% MOLP–GFM blend will constitute the most stable starch gel during cooking. Starches with low breakdown values are recommended for products where stability at very high temperature is required to prevent their breakdown. Incorporation of MOLP led to a significant reduction in both the final viscosity of the blends. This trend might be due to interference in the aggregation of amylose molecules in the starch granules of the GFM, as suggested by Badejo et al. [23]. Consequently, the MOLP blends showed a low tendency toward retrogradation, as suggested by the lower setback values (545 BU, 185 BU, 79 BU, and 55 BU for CTR, 5%, 10%, and 15% w/w MOLP–GFM blends, respectively). The decrease in the above parameters could be due to decrease in the available starch for gelatinization [10, 25].

Pasting profile of raw flour blends (a) and biscuits (b) prepared with Moringa oleifera leaf powder (MOLP) at different levels. For biscuits: CTR control biscuits formulated with 0:100 MOLP: gluten free (GF) flour mix; M5 formulated with 5:95 MOLP:GF flour mix; M10 formulated with 10:90 MOLP:GF flour mix; M15 formulated with 15:85 MOLP:GF flour mix

Assessing the pasting properties of flours provides useful information on starch behaviour during processing involving heating and cooling steps. When applied to end-products, the test provides insights into the effect of processing on starch gelatinization and retrogradation properties [25,26,27]. Specifically, in this study, the MVAG test was used to assess the effect of baking on MOLP-enriched formulations, and the potential impact of MOLP on starch gelatinization properties during baking. Looking at the pasting profiles of the biscuits (Fig. 1b), these were completely different from the related composite flours. Specifically, an increase in the pasting temperature and a decrease in the viscosity, with the lack of the typical peak of viscosity and thus lack of breakdown, were observed. Such changes are related to the starch modification occurring during baking, whose effects are like those of heat-moisture treatments [25]. Baking also affected the starch properties on cooling, as the final viscosity was lower in biscuits than flours, in agreement with a previous study on wheat flour [25]. It was suggested that baking facilitated greater amylose leaching and its aggregation upon cooling, leading to gel formation which resulted in greater final viscosity [25]. Comparing the formulations, MOLP-containing biscuits showed low viscosity values (with no differences between 10 and 15% w/w of enrichment level) upon heating and cooling, suggesting lower starch swelling power and retrogradation tendency.

In vitro starch digestion of gluten-free biscuits

Average cumulative curves of time course in vitro starch digestion (given as a percentage of total dry starch after the different incubation times) are presented in Fig. 2. When compared to experimental biscuits, starch from white wheat bread was in vitro digested to a higher extent for the entire incubation period, in line with previous findings [22]. In addition, experimental biscuits exhibited a decrease in the extent of the in vitro starch digestion up to 120 min of incubation as the level of MOLP increase in the recipe. Consistently, different starch HI were measured (Table 1). The starch HI is commonly applied to predict the likely in vivo glycemic response and/or to calculate the glycemic index of certain starch-based foods using predictive equations [18]. The HI of the CTR biscuit was 81.3, in line with similar GF food products [15]. The substitution of a part of the GFM with increasing levels of MOLP contributed to decrease (p < 0.05) the HI of the samples, with the lowest values being recorded for M15 (i.e. 69.3; p < 0.05). Similarly, Rocchetti et al. [8] reported a gradual decrease in the in vitro starch HI of cooked to optimum semolina fresh pasta as the amount of MOLP in the recipe increase. The decrease in the HI values as a function of the substitution level of MOLP could be related to the chemical composition of the samples, as well as to the different behaviour of the starch system during the heating of processing, as outlined in the pasting properties of the starch within each specific biscuit formulation (Fig. 1b). In particular, MOLP contains greater amounts of dietary fibre and protein than the GFM. This may have contributed to change the physical and chemical properties of the starch system by entrapping starch granules into a non-starchy network with limited enzyme accessibilities [2, 8, 18]. Dachana et al. [10] reported that micrograph sections of MOLP-substituted wheat-based biscuits showed the starch granules coated with certain dietary fibre components. Furthermore, greater RS contents may also influence the digestibility of the available starch fraction, through the encapsulation of gelatinized starch between layers of RS [14, 15]. Lastly, certain classes of phenolic compounds naturally found in MOLP may have mutually influenced the in vitro starch digestibility, via inhibition of the starch digestive enzymes and/or through the formation of inclusion and non- inclusion starch complexes with a limited enzyme accessibility [8, 28, 29].

In vitro starch digestion of gluten-free biscuits prepared with Moringa oleifera leaf powder (MOLP) at different levels. CTR control biscuits formulated with 0:100 MOLP:gluten-free (GF) flour mix; M5 formulated with 5:95 MOLP:GF flour mix; M10 formulated with 10:90 MOLP:GF flour mix; M15 formulated with 15:85 MOLP:GF flour mix. White wheat bread used as reference

Conclusions

Gluten-free biscuits were produced by replacing a commercial GF–flour mix with increasing levels of MOLP. Results showed that the addition of MOLP contributed to increase the protein and dietary fibre content of the samples, while decreasing the total starch content, even at the lowest MOLP-substitution level (i.e. 5 g/100 g). Significant differences in colour, spread ratio and hardness values were reported, as a function of MOLP-substitution level in the recipe. The addition of MOLP modifies the starch pasting properties in biscuits. In particular, lower viscosity values upon heating and cooling were detected, indicating lower starch swelling power and retrogradation tendency in MOLP-substituted biscuits with respect to the control. Meanwhile, in vitro starch digestion data indicated that the inclusion of MOLP contributed to formulate GF biscuit with likely slowly digestible starch properties and higher resistant starch content. Taken together, the present findings support the fact that MOLP may represent a valuable ingredient to produce GF-biscuits with enhanced nutritional characteristics. It was also observed that the MOLP-substitution level of 10% w/w may represent a good compromise between physicochemical and nutritional characteristics for GF-biscuits. To confirm present findings, a sensory evaluation should be carried out to assess the effect of MOLP addition in GF-biscuit formulation.

References

Padalino L, Conte A, Del Nobile MA (2016) Overview on the general approaches to improve gluten-free pasta and bread. Foods 5:87

Giuberti G, Gallo A (2018) Reducing the glycaemic index and increasing the slowly digestible starch content in gluten-free cereal-based foods: a review. Int J Food Sci Technol 53:50–60

Jnawali P, Kumar V, Tanwar B (2016) Celiac disease: overview and considerations for developments of gluten-free foods. Food Sci Hum Wellness 5(4):160–176

El Khoury D, Balfour-Ducharme S, Joye IJ (2018) A review on the gluten-free diet: technological and nutritional challenges. Nutrients 10:1410. https://doi.org/10.3390/nu10101410

Ciudad-Mulero M, Fernández-Ruiza V, Cuadrado C, Arribas C, Pedrosa MM, Berrios JDJ, Pan J, Morales P (2020) Novel gluten-free formulations from lentil flours and nutritional yeast: evaluation of extrusion effect on phytochemicals and non-nutritional factors. Food Chem 315:126175

Gopalakrishnan L, Doriya K, Kumar DS (2016) Moringa oleifera: a review on nutritive importance and its medicinal application. Food Sci Hum Wellness 5:49–56

Páramo-Calderón DE, Aparicio-Saguilán A, Aguirre-Cruz A, Carrillo-Ahumada J, Hernández-Uribe JP, Acevedo-Tello S, Torruco-Uco JG (2019) Tortilla added with Moringa oleífera flour: physicochemical, texture properties and antioxidant capacity. LWT Food Sci Technol 100:409–415

Rocchetti G, Rizzi C, Pasini G, Lucini L, Giuberti G, Simonato B (2020) Effect of Moringa oleifera L. leaf powder addition on the phenolic bioaccessibility and on in vitro starch digestibility of durum wheat fresh pasta. Foods 9:628. https://doi.org/10.3390/foods9050628

Oyeyinka AT, Oyeyinka SA (2018) Moringa oleifera as a food fortificant: recent trends and prospects. J Saudi Soc Agric Sci 17:127–136

Dachana KB, Rajiv J, Indrani D, Prakash J (2010) Effect of dried moringa (Moringa oleifera Lam.) leaves on rheological, microstructural, nutritional, textural and organoleptic characteristics of cookies. J Food Qual 33:660–677

Simonato B, Tolve R, Rainero G, Rizzi C, Sega D, Rocchetti G, Lucini L, Giuberti G (2020) Technological, nutritional, and sensory properties of durum wheat fresh pasta fortified with Moringa oleifera L. leaf powder. J Sci Food Agric. https://doi.org/10.1002/jsfa.10807

Association of Official Analytical Chemists (AOAC) (2000) Official methods of analysis, 17th ed.; AOAC, Inc.: Arlington, VA, USA

Sharma S, Saxena DC, Riar CS (2016) Nutritional, sensory and in-vitro antioxidant characteristics of gluten free cookies prepared from flour blends of minor millet. J Cereal Sci 72:153–161

Giuberti G, Marti A, Fortunati P, Gallo A (2017) Gluten free rice cookies with resistant starch ingredients from modified waxy rice starches: nutritional aspects and textural characteristics. J Cereal Sci 76:157–164

Giuberti G, Rocchetti G, Sigolo S, Fortunati P, Lucini L, Gallo A (2018) Exploitation of alfalfa seed (Medicago sativa L.) flour into gluten-free rice cookies: nutritional, antioxidant and quality characteristics. Food Chem 239:679–687

Liu S, Alavi S, Abu Ghoush M (2011) Extruded Moringa leaf-oat flour snacks: physical, nutritional, and sensory properties. Int J Food Prop 14:854–869

Tian S, Sun Y (2020) Influencing factor of resistant starch formation and application in cereal products: a review. Int J Biol Macromol 149:424–431

Sajilata MG, Singhal RS, Kulkarni PR (2006) Resistant starch—a review. Comp Rev Food Sci Food Saf 5:1–17

Jia M, Yu Q, Chen J, He Z, Chen Y, Xie J, Nie S, Xie M (2020) Physical quality and in vitro starch digestibility of biscuits as affected by addition of soluble dietary fiber from defatted rice bran. Food Hydrocoll 99:105349

Gurjal HS, Mehta S, Samra IS, Goyal P (2003) Effect of wheat bran, coarse wheat flour, and rice flour on the instrumental texture of cookies. Int J Food Prop 6:329–340

Wani AA, Sogi DS, Singh P, Sharma P, Pangal A (2012) Dough-handling and cookie-making properties of wheat flour-watermelon protein isolate blends. Food Bioprocess Technol 5:1612–1621

Waterschoot J, Gomand SV, Willebrords JK, Fierens E, Delcour JA (2014) Pasting properties of blends of potato, rice and maize starches. Food Hydrocoll 41:298–308

Badejo AA, Osunlakin AP, Famakinwa A, Idowu AO, Fagbemi TN (2017) Analyses of dietary fibre contents, antioxidant composition, functional properties of plantain and Moringa oleifera composite flour blends. Cogent Food Agric 3:1278871

Ogunsina BS, Radha C, Indrani D (2011) Quality characteristics of bread and cookies enriched with debittered Moringa oleifera seed flour. Int J Food Sci Nutr 62:185–194

Walker S, Seetharaman K, Goldstein A (2012) Characterizing physicochemical changes of cookies baked in a commercial oven. Food Res Int 48:249–256

Besbes E, Le Bail A, Seetharaman K (2014) Effect of baking conditions on properties of starch isolated from bread crumbs: pasting properties, iodine complexing ability, and X-ray patterns. Food Bioprocess Technol 7(12):3407–3415

Marti A, Fongaro L, Rossi M, Lucisano M, Ambrogina Pagani M (2011) Quality characteristics of dried pasta enriched with buckwheat flour. Int J Food Sci Technol 46(11):2393–2400

Giuberti G, Rocchetti G, Lucini L (2020) Interactions between phenolic compounds, amylolytic enzymes and starch: an updated overview. Curr Opin Food Sci 31:102–113

Rocchetti G, Giuberti G, Lucini L (2018) Gluten-free cereal-based food products: the potential of metabolomics to investigate changes in phenolics profile and their in vitro bioaccessibility. Curr Opin Food Sci 22:1–8

Acknowledgements

This work was supported by the Cremona FoodLAB (Fondazione Cariplo e Regione Lombardia, Italy).

Funding

Open access funding provided by Università Cattolica del Sacro Cuore within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare no conflict of interest.

Ethical approval

Ethics approval was not required for this research.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Giuberti, G., Bresciani, A., Cervini, M. et al. Moringa oleifera L. leaf powder as ingredient in gluten-free biscuits: nutritional and physicochemical characteristics. Eur Food Res Technol 247, 687–694 (2021). https://doi.org/10.1007/s00217-020-03656-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-020-03656-z