Abstract

Blackcurrant juices prepared with or without enzyme treatment at industrial scale were stored at room temperature or + 4 °C for 1 year, and their sensory profiles, chemical composition and rheological properties were investigated. The juice without enzyme treatment had less intense colour and it was perceived and measured as more viscose than the juice produced with enzyme assistance. Content of monomeric anthocyanins decreased significantly during storage in both juice types under both storing conditions. However, changes in colour intensity were observed only in the non-enzymatic juices. In the discrimination tests based on the appearance, the stored samples were detected as significantly different. Storage resulted in significant changes in contents of hydroxycinnamic acids and flavonols, but this did not have an impact on the bitterness or astringency of the juices. Moreover, sugar and acid contents were mainly unchanged during storage. Storage resulted in a decrease in dynamic viscosity and greater differences in viscoelastic properties for the juice with enzymatic assistance. This study provides important information about the stability of juices typically stored at room temperature for a long time.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Berries and fruits are typically processed to juices, jams, jellies, purées, concentrates, alcoholic drinks or eaten whole. Juice processing includes various steps, such as thawing, crushing, heating, enzymatic maceration, pressing and clarification. Enzyme treatment is typically used to break down polymeric structures, such as pectins, cellulose and hemicellulose in the berry pulp and skins to reduce increase the juice yield and reduce its viscosity. Various health-related bioactive phenolic compounds, such as anthocyanins and flavonols, are concentrated in the skin fractions of the berries [1]. Use of enzymes in juice processing results in higher yields of these compounds [2,3,4,5,6]. At the same time, the enzyme-aided juice processing significantly alters the sensory quality of the juice by, for example, increasing astringency and bitterness [7, 8] or the aroma of the juices [9].

Blackcurrants (Ribes nigrum) are commonly cultivated in Europe and are the second most cultivated berry in Finland. Various factors affect the composition and contents of phenolic compounds in the berry, such as cultivar, growth location and conditions, and ripeness of the berries [10,11,12,13,14]. Different current cultivars may also have significantly different sensory profiles [7, 15, 16]. Additionally, the content of the compounds in the end-products depends on various postharvest processing factors, such as parameters used in the aforementioned enzyme-aided processing. Processing typically involves the application of high temperatures, e.g., pasteurisation, to deactivate spoiling micro-organisms and endogenous enzymes, which in turn result in losses of various phenolic compounds, particularly of anthocyanins [17,18,19,20,21]. High temperatures may also significantly affect the sensory quality of the juices [8, 22]. Anthocyanin content typically decreases significantly during storage of the juices whereas other phenolic compound classes are not equally susceptible to changes [20, 23,24,25,26,27]. Degradation of anthocyanins during storage may be accompanied by an increase in polymeric colours and co-pigmentation [17, 18, 27]. Despite multiple studies focusing on the changes in the chemical quality, few studies have focused on the stability or changes in sensory qualities of blackcurrant juices during storage [8, 20, 28].

The juices in this study were produced in industrial facilities with and without the use of pectinolytic enzymes [29]. The former juice type resembled typical commercial blackcurrant product whereas the latter consisted mainly of the berry pulp without seeds and skins. In our previous study, the perceived aroma attributes of the blackcurrant juices and the contents of volatile compounds changed significantly during 1 year [28]. The aim of this study was to investigate the stability of blackcurrant juices during storage for 1 year in refrigerator and at room temperature by studying the changes in sensory quality (taste, astringency and appearance). Generic descriptive analysis was used in the sensory test and main focus were in the start and end-points (i.e., 0 and 12 months) of the storage and in the storing temperatures. We have previously reported with similar juices made in a laboratory scale that storage has significant effects on the colour of juices, but it had little impact on the taste attributes [20]. However, in this study the used manufacturing processes were more relevant to juice industry and therefore more subtle in comparison to the small scale laboratory processes. Special focus was on the visual changes in the juices due to the well-acknowledged decrease of anthocyanins during storage using discrimination tests in addition to the descriptive analysis. In addition to the colour compounds, various instrumental quality factors were investigated based on the results of the sensory tests. The contents of various known sensory-active non-volatile compounds, such as sugars, fruit acids and phenolic compounds, which were also investigated in our earlier studies in stored juices [20, 25], were investigated using GC-FID, HPLC-DAD and HPLC-ESI-MS methods. Finally, the potential changes in the rheological properties of the stored blackcurrant juices were also studied.

Materials and methods

Juice samples

Two blackcurrant juices were produced at an industrial scale as previously described [29]. Berries (3000 kg) of blackcurrant cultivar ‘Mortti’ were harvested in 2011 from the plantation of Saarioinen Oy (Huittinen, Finland). The berries were cleaned at Toripiha Oy (Vesanto, Finland) by removing leaves, stems and other impurities and frozen immediately. The frozen berries were processed in 500–1250 kg batches with the industrial-scale facilities at Saarioinen Oy. The process scheme consisted of thawing with steam, crushing, heating (approximately 38–49 °C), enzyme addition (using an in-house pectinase product), incubation (approximately 2 h at 40–50 °C), hydraulic pressing, clarification and filtration. The first juice was produced by following the process protocol without enzymatic treatment, clarification or filtration (NEnz samples). The second juice was extracted by following the conventional juice processing procedure including all the aforementioned steps (Enz). The products were pasteurised and bottled in 375-mL glass bottles in Marjajaloste Meritalo Oy (Salo, Finland). Pasteurisation was carried out with Gebhardt model EHA27E machinery (Gebhardt Anlagentechnik GmbH & Co. KG, Kenzingen—Bombach, Germany) resulting in juices of 87–89 °C. After pasteurisation, the bottled juices were stored in the dark at + 4 °C (12F samples) or at ambient room temperature (approx. 21 °C) for 12 months (12RT). Samples for sensory evaluation and chemical analyses were stored in a freezer (− 20 °C) until analysed.

Sensory evaluation

Descriptive analysis

The sensory evaluation using generic descriptive analysis and the sensory characteristics of the juice samples were based on our previous studies [7, 20, 29]. The panel (n = 11) was trained to evaluate appearance, flavour, taste and mouthfeel attributes (Table 1) of the juice samples using a scale 0–10 (0 = no attribute, 10 = very intense). Six thawed juice samples were presented all at the same time in a fixed order in two separate sets to emphasise the potential differences within the juice type derived from storing. The three Enz-juices (pasteurised, 12F and 12RT) were presented first in a randomised order followed by the three corresponding NEnz-juices in a randomised order. The samples were presented as 10 mL portions in transparent 50 mL beakers with glass lids, and they were evaluated in triplicate sessions. The data were collected using Compusense-five software (Compusense Inc., Guelph, Canada).

Discrimination test

Tetrad test [30] was used to detect differences in the appearance of the stored blackcurrant juices. Juice samples from both processes (Enz- and NEnz-juices), both storage conditions (+ 4 °C, RT) and all the time-points i.e., 0, 3 and 12 months were included in the test. Voluntary untrained panelists (n = 23) evaluated the samples during three sessions, and they were given 12 (two storage conditions × three time-points × two replicates) or eight (two juice processes × two storage conditions × two replicates) sets of four samples during each session. The samples and sample sets were presented in a randomised order. The samples were given in 10 mL transparent glass tubes with plastic corks on a white tube rack. The samples were coded with three-digit random numbers. During each session, the panelists were asked to divide the four samples into two pairs based on their similarities and differences in appearance [31] and mark the pairs on a paper showing the sample codes. The panelists were encouraged to lift the samples in the set of four samples from the rack and evaluate their appearance by gently turning them around and placing them against white A4 sized paper.

Instrumental analyses

Sugars, acids and phenolic compounds

Sugars and non-phenolic fruit acids in juices were analysed with gas chromatography as trimethylsilyl (TMS) derivatives using a method previously applied in our laboratory [32]. The analytes were identified by co-injection of reference compounds and quantified (g/100 mL) using internal standards [32].

The phenolic compounds (monomeric anthocyanins, hydoxycinnamic acid derivatives and flavonols) were analysed with HPLC-DAD and HPLC-ESI-MS [25]. Phenolic compounds in the juices were identified based on chromatographic retention times, reference compounds, UV spectra, mass spectral characteristics, and the literature references. Quantification of phenolic compounds (µg/100 mL) was carried out using external standards and calibration curves of authentic reference compounds [25].

Rheology

The rheological properties of the juices were studied by Anton-Paar MCR 102 rheometer (Anton Paar GmbH, Graz, Austria) both in the rotational and oscillatory mode to determine the flow properties and thixotropic behaviour of the Enz- and NEnz-juices. The structural homogeneity and recovery after shear were measured in the oscillatory mode with a three interval test method (from low shear to high shear and back) at room temperature by keeping angular frequency (ω) constant at 10 rad/s, but by stepping the amplitude from low (strain 5%) to high (strain 100%) and back (strain 5%). The stepping up from 5 to 100% was conducted in 60 s, the strain was kept at 100% for 150 s and stepping down from 100 to 5% was conducted in 60 s. The juices were also studied for flow properties and thixotropy in the rotational mode by measuring the dynamic viscosity at different shear rates, stepping first from 2.1/s to 50.1/s, keeping it constant at 50.1/s for 50 s and back to 2.1/s. Analyses were carried out in triplicate.

Statistical analyses

Differences between the samples were defined by analyses of variance (ANOVA) together with a suitable post-hoc test (LSD, Tukey’s or Tamhane’s). One-way ANOVA was used for comparing chemical variables within both juice pressing methods. Three-way ANOVA (sample, panelist, session, and their interactions) was used for the results from the descriptive analysis juice samples as fixed factors and sessions and panelists as random factors. Student’s t test was used to analyse differences in chemical or sensory variables between the two juice types. The criterion for statistical significance in all tests was p < 0.05. ANOVA models and t-tests were performed using SPSS version 22 (SPSS Inc. H, Chicago, IL). Results of the discrimination test (tetrad test) were based on binomial distributions [33]. In the generic descriptive analysis, the panel sensitivity, reproducibility and agreement was first analysed with PanelCheck 1.4.2 (Nofima, Tromsø, Norway) following the suggested workflow described by Næs, Brockhoff, and Tomić [34].

Results and discussion

Changes in sensory quality during storage

The samples for the descriptive analysis were selected based on the results of our previous study with laboratory made juices [20] in which we found relatively small changes in the sensory quality of juices stored for 1 year. Therefore, only the starting and end-point samples were taken for the sensory evaluations in this study. Additionally, the samples were presented in two separate sets (Enz- or NEnz-juices) to emphasise differences within the sets due to storage.

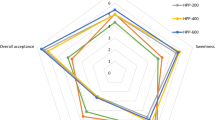

The three-way ANOVA showed significant sample main effects in colour intensity, viscosity, total intensity of flavour and in the berry flavour (Table 2). The three taste attributes were the most well-understood attributes by the panel due to very low and no significant sample × panelist interactions. This together with no significant sample main effects demonstrated that there were no differences among samples in the taste attributes. In the panel performance assessed with Panelcheck (data not shown), none of the panelists showed consistently poor performance. The exclusion of one or two of the most extreme assessors (with worst repeatability, sensitivity or agreement) had little effect on the differences between the samples. The most notable disagreements were with the berry flavour and total intensity of flavour whereas the panel was in high agreement with visual assessment of viscosity and colour intensity.

The two juice types had significantly different sensory profiles (Table 2). NEnz-juices had more intense blackcurrant flavour and higher viscosity, whereas the Enz-juices had the higher total intensity of flavour. These differences are in accordance with our previous studies [7, 8, 29]. Bitterness and especially astringency have been previously shown to be higher in enzyme-aided juices compared with the juice pressed without enzymatic treatment [7, 8, 29]. However, in this study, the panel was instructed to focus on the juice types (with/without enzymes) in the separate sets of three samples (0 months, 12 months in RT and 12 months + 4 °C). Differences between juice types were not statistically significant.

The storage influenced only some of the sensory attributes in addition to the previously reported changes in odour quality [28]. The changes observed during the storage of different time periods or under different conditions were notably smaller in comparison to the differences between the juice types. The taste properties and astringency remained the same during the 1-year storage under both storage conditions. Significant changes were observed in appearance and flavour characteristics. The typical blackcurrant berry flavour of the pasteurised NEnz-juice was significantly lowered by storage at RT, but well reserved during storage at + 4 °C (Table 2). Similarly, the orthonasally perceived berry odour of these juices also decreased in our earlier study [28]. At the same time, the total intensity of flavour in the Enz-juices decreased in 12RT-juices and remained the same for 12F-juices. Thus cooled storage is needed in both juice types to maintain the initial flavour (and odour) characteristics.

The colour intensity of the NEnz-juice rich in berry pulp changed during storage (Tables 2, 3). This juice contained initially less anthocyanins (Table 4) and had significantly lower colour intensity after storage at RT. Interestingly, the storage had also an effect on the visually observed sample viscosity at 12RT-juice but not in 12F-juice. To further examine the potential differences during storage, sets of discrimination tests based on appearance were conducted using the tetrad test (Table 3). More correct judgements by the panel in comparison the minimum level (at probability level 5% in the discrimination tests [33]) was required to establish statistical significance. Significant differences were observed by the panel (n = 23 × 2) in most of the test sets. The stored Enz-juices were also perceived to be significantly different. This was despite the no significant differences in the descriptive profile (Table 2). Even in the comparisons of the 12F-juices, enough correct judgements were made by the panel. However, more significant differences (i.e., differences observed more often by the panel) were detected in the 12RT-juices. The differences detected by the panel, and thus forming the correct of two pairs in the tetrad tests, were most likely due to both colour and viscosity changes as the panelists were allowed to lift and turn around the sample tubes.

Changes in phenolic compounds, sugars and acids during storage

Table 4 shows the sums of the different phenolic compound classes, and more detailed compound groups according to Mäkilä et al. [20] are shown in the Supplementary table. Identifications of the compounds were made based on the procedure of Mäkilä et al. [25]. The Enz-juices had higher initial contents of all the three compound classes compared to the NEnz juices, as expected. The contents of anthocyanins decreased in both juice types and both storage temperatures (Table 4). The losses were higher in the 12RT-juices (84 or 81% losses for Enz- and NEnz-juices, respectively) than in 12F-juices (13 or 26%). At the same time, there were notable increases in some of the degradation products of the monomeric anthocyanins, such as protocatechuic acid, 4-hydroxybenzoic acid and phloroglucinaldehyde, in agreement with the previous findings [20, 25]. However, a significant increase was mainly detected in the RT samples. Despite the notable loss of the monomeric anthocyanins in the Enz-juices stored in RT for 12 months, the sensory panel did not detect differences in colour between the samples (Table 2). These samples remained intensely dark after the storage, which may partly explain the lack of observed differences. The processes used in the juice industry (including the used enzyme product) typically are highly temperature-controlled aiming to maintain the original colour of the fruit or berry. The unchanged colour indicates also to potential co-pigmentation reactions in the juice, where the anthocyanins may remain in polymeric forms [27]. Pectins and the oligosaccharides derived from polysaccharides during the juice processing may interact with juice anthocyanins depending on the anthocyanin and pectin structures [35], which may affect the stability of the colour and further highlights the importance of enzyme selection and process control in the juice manufacturing.

The total content of hydroxycinnamic acids remained relatively stable during storage in both juice types (Table 4). However, there were significant increases in free hydroxycinnamic acids (caffeic, p-coumaric, and ferulic acids) derived from the corresponding derivatives. Similar to anthocyanins, the increases of the degradation products were higher in the RT-juices than in F-juices. Flavonols were the most stable during storage of the three compound classes investigated (Table 4). Higher initial levels of free flavonol aglycons were detected in the NEnz-juices resulting from the juice processing. On the other hand, the notable increases during storage in the contents of free flavonol aglycons were detected only in the Enz-juices (RT samples, Table 4). Thus, the juice matrix may have provided more protection for the flavonols in the NEnz-juices during storage.

The initial compositions of non-phenolic organic acids and sugars in the two juice types were significantly different (Table 5). The total content of acids and sugars remained the same during the 12-month storages in both juice types. Significant increase in the fructose content was detected with the Enz-juices indicating enzymatic activities not deactivated during the pasteurisation.

Changes in rheological properties during storage

Due to the significant changes in the viscosity of juices observed during storage and the differences detected in the discrimination tests (Tables 2, 3), the rheological properties of the six juices included in the descriptive sensory profile were studied. Rheological properties of juices are affected by various quality factors, such as the composition and contents of monomeric and polymeric carbohydrates in the fruit [36, 37]. Depectination and clarification of blackcurrant juice (or juice from other similar berries) using enzymes result in more Newtonian fluid behaviour in comparison to the non-Newtonian behaviour of the initial berry puree [37, 38]. Previous study with blueberry and raspberry purees showed that berry processing affects the rheological properties of the products resulting in lowered apparent viscosity in comparison to raw untreated puree [39]. At the same time, blackcurrant juice produced without enzymatic assistance is significantly more viscous in comparison to the other berries, such as blueberries or raspberries [40], which highlights the need of enzymatic treatments to reduce the viscosity to transport juices through pipelines in industrial-scale facilities.

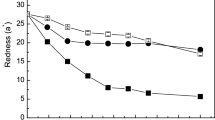

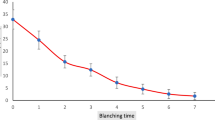

The rotational mode measurements for dynamic viscosity showed expected shear-thinning behaviour for both juice types during storage (Fig. 1). The level of dynamic viscosity was clearly higher in the NEnz-juices compared with the Enz-juices. Values of the former juice started at a low shear rate (2.1/s) from 2000 to 3000 mPas and ended up with 224–234 mPas at the shear rate of 50.1/s (Fig. 1a). The corresponding values for the Enz-juices were about 100–200 times lower ranging from 19 to 38 mPas at 2.1/s to approx. 1 mPas at 50.1/s (Fig. 1b). The obvious, expected reason for this is the lower solid content of the latter juices and especially, the presence of non-degraded pectins in the non-enzymatic juices [38, 40]. The dynamic viscosity curves also showed hysteresis, and thus thixotropic behaviour, especially for the Enz-juices, in spite of their low dynamic viscosity levels. The relative difference in dynamic viscosity at a low shear rate (2.1/s) was greater (from approx. 3- to eightfold greater in the beginning of the measurement than in the end) when compared with the relative differences for the NEnz-juices (twofold greater for the 12F-juice, 1.5-fold greater for the others). Hence, the recovery from the shear was better for the juices produced without the enzymatic assistance. The rheological results verify the clear difference in viscosity observed in the descriptive sensory evaluation and in the tetrad tests (Tables 2, 3). Both dynamic and complex viscosity and elastic modulus are clearly lower for the juices manufactured with the enzyme assistance, which depend on the clear differences in the solid content and pectin degradation.

Dynamic viscosity of the juices without enzymatic assistance (a) and with the enzymatic assistance (b) shown against shear rate (showing only rates up to 20/s) and thixotropic behaviour of the juices without enzymatic assistance (c) and with the enzymatic assistance (d) expressed as loss factor [tan δ = (loss modulus (G″)/storage modulus (G′)] before the storage (circle markers), as stored for 12 months at + 4 °C (rectangles), and as stored at room temperature for 12 months (triangles). The dashed line shows the Tan δ value that indicates the gel point (or the value at which a flowing system turns into a non-flowing system or vice versa

Storage had some effects on the dynamic viscosity of the juices. The largest hysteresis for the NEnz-juices was observed for the 12F-juice. A decrease in the dynamic viscosity was observed for the Enz-juice. The dynamic viscosity for the juice before the storage was about twofold (above 15.1/s) compared with that of the 12RT-juices, and 20–40% higher than that of the 12F-juice. This is in accordance with the observations of decreasing viscosity for cloudy juices as a function of storage time at + 4 °C, which may depend on the precipitation of pulp and degradation of pectin [19]. The results also suggest that the effect is accelerated if the juice is stored at room temperature.

The thixotropic behaviour was also observed with a three-interval test method conducted in the oscillatory mode and the difference was clear between the two juice types. The results are summarised in the Fig. 1c, d, where the loss factor [tan δ = ratio between the loss (G″) and storage (G′) modulus] is shown as a function of time. The NEnz-juices recovered rather well from the shear, however, the 12F-juice differed again by showing flow properties (and shear) at all time points. Thus, the loss factor stayed above one all the time, which is a typical indication of a flowing material. The other NEnz-juices (0 and 12F) recovered also from the shear, but the loss tangent values were somewhat below one at low shear (both in the beginning and in the end of the measurements) indicating a non-flowing, loose gel-like structure. However, the Enz-juices behaved differently and they did not recover well from the shear. For Enz_0- and Enz_12F-juices, the loss factors were in the beginning (at low shear) below one showing a non-flowing structure. However, in the end (again at low shear), they stayed above one, i.e., in a flowing condition. The loss factor for the 12F-juice stayed below one all the time, but the recovery was not particularly good. The loss factor was very near one, i.e., still a gel-like structure, but near a flowing structure, after the period of constant high amplitude (strain = 100%) under high shear, but the juice turned again into a more non-flowing structure when the shear is lowered. The results suggested structural heterogeneity due to the shear, i.e., components of the juices that made them non-flowing and gel-like have been re-ordered or interactions between the components have been disrupted. The juices made with enzymatic assistance typically contain some oligomeric species [35]. These oligomers in the Enz-juices may have formed gel-like structures with weak and irreversible (at least not right after the shear) interactions. The oscillatory measurements also supported the observation made in the rotational measurements for dynamic viscosity that the RT-juice has changed more during the storage than the 12F-juice. Despite of the aforementioned differences detected in the rheological analyses for Enz-juices, no significant differences were observed in the descriptive sensory analysis (Table 2).

The rheological results verify the clear difference in viscosity observed in the sensory tests (Tables 2, 3). Both dynamic and complex viscosity and elastic modulus were clearly lower for the Enz-juices due to the clear differences in the solid contents and pectin degradation. However, when comparing the Enz-juices to each other, the results showed decreasing dynamic viscosity as a function of storage time. Additionally, the thixotropic analysis by the oscillatory measurements showed worse recovery due to changes in the juice structure under the shear. However, no significant differences were observed in the viscosity of the sensory evaluation (Table 2) most likely due to low viscosity levels in all Enz-juices. The difference in the dynamic viscosity or changing flow properties due to shear by mixing or shaking was too low to be observed by visual observation. The decrease in the viscosity in the sensory test (Table 2) for the NEnz-juices stored at RT was not correlated with the rheological measurements. The dynamic viscosity was lower for the 12RT-juice than for the 12F-juice, but no changes were observed when comparing it to the dynamic viscosity of NEnz_0-juice. Both juice types (Enz and NEnz) showed some gel-like properties at low shear, and the properties were clearest for the Enz_12RT-juice. However, this was not observed in the descriptive sensory evaluation (Table 2) as the higher viscosity due to the higher solid content and non-degraded pectin dominated the observation of the viscosity.

In conclusion, significant changes were observed during storage in both juice types. As expected, the contents of anthocyanins decreased significantly in both juices during the 12-month storage at both temperatures, but changes in colour intensity were only observed in sensory analyses of juices without enzymatic assistance. Viscosities of the juices were evaluated as different in the descriptive sensory analysis and the juices were observed as significantly different in the discrimination tests showing notable changes in the juice textural properties during storage. This was confirmed in the rheological analyses. On the other hand, no changes due to the storage were observed in the taste and astringency of the juices. At the same time, significant changes were observed in the contents of hydroxycinnamic acids and flavonols, which are often linked to astringent properties and to bitter taste. But these changes did not have perceivable influence on the sensory qualities of the juices. This study provides important information for the juice industry concerning the stability of quality factors of blackcurrant juices during storage as well as the impact of processing technologies and storage conditions. The berry juices are typically stored at room temperature for a long time thus storing in cooled conditions may be required to maintain the original sensory properties.

References

Sandell M, Laaksonen O, Järvinen R, Rostiala N, Pohjanheimo T, Tiitinen K, Kallio H (2009) Orosensory profiles and chemical composition of black currant (Ribes nigrum) juice and fractions of press residue. J Agric Food Chem 57:3718–3728. https://doi.org/10.1021/jf803884y

Buchert J, Koponen JM, Suutarinen M, Mustranta A, Lille M, Törrönen R, Poutanen K (2005) Effect of enzyme-aided pressing on anthocyanin yield and profiles in bilberry and blackcurrant juices. J Sci Food Agric 85:2548–2556. https://doi.org/10.1002/jsfa.2284

Koponen JM, Buchert J, Poutanen KS, Törrönen AR (2008) Effect of pectinolytic juice production on the extractability and fate of bilberry and black currant anthocyanins. Eur Food Res Technol 227:485–494. https://doi.org/10.1007/s00217-007-0745-2

Landbo A-K, Meyer AS (2001) Enzyme-assisted extraction of antioxidative phenols from black currant juice press residues (Ribes nigrum). J Agric Food Chem 49:3169–3177. https://doi.org/10.1021/jf001443p

Landbo A-K, Meyer AS (2004) Effects of different enzymatic maceration treatments on enhancement of anthocyanins and other phenolics in black currant juice. Innov Food Sci Emerg Technol 5:503–513. https://doi.org/10.1016/j.ifset.2004.08.003

Lachowicz S, Oszmiański J, Kolniak-Ostek J (2018) Influence of different pectinolytic enzymes on bioactive compound content, antioxidant potency, colour and turbidity of chokeberry juice. Eur Food Res Technol 244:1907–1920. https://doi.org/10.1007/s00217-018-3103-7

Laaksonen O, Mäkilä L, Tahvonen R, Kallio H, Yang B (2013) Sensory quality and compositional characteristics of blackcurrant juices produced by different processes. Food Chem 138:2421–2429. https://doi.org/10.1016/j.foodchem.2012.12.035

Laaksonen O, Sandell M, Nordlund E, Heiniö R-L, Malinen H-L, Jaakkola M, Kallio H (2012) The effect of enzymatic treatment on blackcurrant (Ribes nigrum) juice flavour and its stability. Food Chem 130:31–41. https://doi.org/10.1016/j.foodchem.2011.06.048

Mikkelsen BB, Poll L (2002) Decomposition and transformation of aroma compounds and anthocyanins during black currant (Ribes nigrum L.) juice processing. J Food Sci 67:3447–3455. https://doi.org/10.1111/j.1365-2621.2002.tb09604.x

Mattila PH, Hellström J, Karhu S, Pihlava J-M, Veteläinen M (2016) High variability in flavonoid contents and composition between different North-European currant (Ribes spp.) varieties. Food Chem 204:14–20. https://doi.org/10.1016/j.foodchem.2016.02.056

Milivojevic J, Slatnar A, Mikulic-Petkovsek M, Stampar F, Nikolic M, Veberic R (2012) The influence of early yield on the accumulation of major taste and health-related compounds in black and red currant cultivars (Ribes spp.). J Agric Food Chem 60:2682–2691. https://doi.org/10.1021/jf204627m

Mikulic-Petkovsek M, Rescic J, Schmitzer V, Stampar F, Slatnar A, Koron D, Veberic R (2015) Changes in fruit quality parameters of four Ribes species during ripening. Food Chem 173:363–374. https://doi.org/10.1016/j.foodchem.2014.10.011

Vagiri M, Ekholm A, Öberg E, Johansson E, Andersson SC, Rumpunen K (2013) Phenols and ascorbic acid in black currants (Ribes nigrum L.): Variation due to genotype, location, and year. J Agric Food Chem 61:9298–9306. https://doi.org/10.1021/jf402891s

Zheng J, Yang B, Ruusunen V, Laaksonen O, Tahvonen R, Hellsten R, Kallio H (2012) Compositional differences of phenolic compounds between black currant (Ribes nigrum L.) cultivars and their response to latitude and weather conditions. J Agric Food Chem 60:6581–6593. https://doi.org/10.1021/jf3012739

Brennan RM, Hunter EA, Donald Muir D (1997) Genotypic effects on sensory quality of blackcurrant juice using descriptive sensory profiling. Food Res Int 30:381–390. https://doi.org/10.1016/S0963-9969(97)00063-X

Brennan RM, Hunter EA, Muir DD (2003) Relative effects of cultivar, heat-treatment and sucrose content on the sensory properties of blackcurrant juice. Food Res Int 36:1015–1020. https://doi.org/10.1016/j.foodres.2003.07.004

Brownmiller C, Howard LR, Prior RL (2008) Processing and storage effects on monomeric anthocyanins, percent polymeric color, and antioxidant capacity of processed blueberry products. J Food Sci 73:H72–H79. https://doi.org/10.1111/j.1750-3841.2008.00761.x

Howard LR, Prior RL, Liyanage R, Lay JO (2012) Processing and storage effect on berry polyphenols: Challenges and implications for bioactive properties. J Agric Food Chem 60:6678–6693. https://doi.org/10.1021/jf2046575

Jimenez-Garcia SN, Guevara-Gonzalez RG, Miranda-Lopez R, Feregrino-Perez AA, Torres-Pacheco I, Vasquez-Cruz MA (2013) Functional properties and quality characteristics of bioactive compounds in berries: biochemistry, biotechnology, and genomics. Food Res Int 54:1195–1207. https://doi.org/10.1016/j.foodres.2012.11.004

Mäkilä L, Laaksonen O, Kallio H, Yang B (2017) Effect of processing technologies and storage conditions on stability of black currant juices with special focus on phenolic compounds and sensory properties. Food Chem 221:422–430. https://doi.org/10.1016/j.foodchem.2016.10.079

Weber F, Larsen LR (2017) Influence of fruit juice processing on anthocyanin stability. Food Res Int 100:354–365. https://doi.org/10.1016/j.foodres.2017.06.033

Varming C, Andersen ML, Poll L (2004) Influence of thermal treatment on black currant (Ribes nigrum L.) juice aroma. J Agric Food Chem 52:7628–7636. https://doi.org/10.1021/jf049435m

Dobson G, McDougall GJ, Stewart D, Cubero MA, Karjalainen RO (2017) Effects of juice matrix and pasteurization on stability of black currant anthocyanins during storage. J Food Sci 82:44–52. https://doi.org/10.1111/1750-3841.13575

Hellström J, Mattila P, Karjalainen R (2013) Stability of anthocyanins in berry juices stored at different temperatures. J Food Compos Anal 31:12–19. https://doi.org/10.1016/j.jfca.2013.02.010

Mäkilä L, Laaksonen O, Alanne A-L, Kortesniemi M, Kallio H, Yang B (2016) Stability of hydroxycinnamic acid derivatives, flavonol glycosides, and anthocyanins in black currant juice. J Agric Food Chem 64:4584–4598. https://doi.org/10.1021/acs.jafc.6b01005

Teleszko M, Nowicka P, Wojdyło A (2016) Effect of cultivar and storage temperature on identification and stability of polyphenols in strawberry cloudy juices. J Food Compos Anal 54:10–19. https://doi.org/10.1016/j.jfca.2016.09.009

Wilkes K, Howard LR, Brownmiller C, Prior RL (2014) Changes in chokeberry (Aronia melanocarpa L.) polyphenols during juice processing and storage. J Agric Food Chem 62:4018–4025. https://doi.org/10.1021/jf404281n

Marsol-Vall A, Laaksonen O, Yang B (2019) Effects of processing and storage conditions on volatile composition and odor characteristics of blackcurrant (Ribes nigrum) juices. Food Chem 293:151–160. https://doi.org/10.1016/j.foodchem.2019.04.076

Laaksonen OA, Mäkilä L, Sandell MA, Salminen J-P, Liu P, Kallio H, Yang B (2014) Chemical-sensory characteristics and consumer responses of blackcurrant juices produced by different industrial processes. Food Bioprocess Technol 7:2877–2888. https://doi.org/10.1007/s11947-014-1316-8

Ennis JM (2012) Guiding the switch from triangle testing to tetrad testing. J Sens Stud 27:223–231. https://doi.org/10.1111/j.1745-459X.2012.00386.x

Rousseau B, Ennis JM (2013) Importance of correct instructions in the tetrad test. J Sens Stud 28:264–269. https://doi.org/10.1111/joss.12049

Zheng J, Yang B, Tuomasjukka S, Ou S, Kallio H (2009) Effects of latitude and weather conditions on contents of sugars, fruit acids, and ascorbic acid in black currant (Ribes nigrum L.) juice. J Agric Food Chem 57:2977–2987. https://doi.org/10.1021/jf8034513

Lawless HT, Heymann H (2010) Sensory evaluation of food: principles and practices. Springer-Verlag, New York

Næs T, Brockhoff PB, Tomic O (2010) Statistics for sensory and consumer science. Wiley (ISBN: 978-1-119-95724-9). https://www.wiley.com/en-fi/Statistics+for+Sensory+and+Consumer+Science-p-9781119957249

Larsen LR, Buerschaper J, Schieber A, Weber F (2019) Interactions of anthocyanins with pectin and pectin fragments in model solutions. J Agric Food Chem 67:9344–9353. https://doi.org/10.1021/acs.jafc.9b03108

Salehi F (2020) Physico-chemical and rheological properties of fruit and vegetable juices as affected by high pressure homogenization: a review. Int J Food Prop 23:1136–1149. https://doi.org/10.1080/10942912.2020.1781167

Diamante L, Umemoto M (2015) Rheological properties of fruits and vegetables: a review. Int J Food Prop 18:1191–1210. https://doi.org/10.1080/10942912.2014.898653

Ibarz A, Pagán J, Miguelsanz R (1992) Rheology of clarified fruit juices. II: blackcurrant juices. J Food Eng 15:63–73. https://doi.org/10.1016/0260-8774(92)90040-D

Medina-Meza IG, Boioli P, Barbosa-Cánovas GV (2016) Assessment of the effects of ultrasonics and pulsed electric fields on nutritional and rheological properties of raspberry and blueberry purees. Food Bioprocess Technol 9:520–531. https://doi.org/10.1007/s11947-015-1642-5

Bender C, Killermann KV, Rehmann D, Weidlich HH (2017) Effect of mash enzyme and heat treatments on the cellular antioxidant activity of black currant (Ribes nigrum), raspberry (Rubus idaeus), and blueberry (Vaccinium myrtillus) juices. CyTA J Food 15:277–283. https://doi.org/10.1080/19476337.2016.1247914

Acknowledgements

The research was part of the project ‘‘Black Currant as Unique Source of Functional Ingredients of Food: Novel Processes and Innovations” (26001642) funded by the Tekes—Finnish Funding Agency for Technology and Innovation together with Finnish food companies. The authors thank Tiina Pasma, Karoliina Hirvonen, Ville Ruusunen, and Anita Vanag for their contributions in the sensory and instrumental analyses.

Funding

Open access funding provided by University of Turku (UTU) including Turku University Central Hospital.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors declare no conflicts of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Laaksonen, O., Mäkilä, L., Jokinen, M. et al. Impact of storage on sensory quality of blackcurrant juices prepared with or without enzymatic treatment at industrial scale. Eur Food Res Technol 246, 2611–2620 (2020). https://doi.org/10.1007/s00217-020-03601-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-020-03601-0