Abstract

Oilcakes from the oilseed industry are rich in dietary fibre and protein by-products. We assessed the impact of wheat flour replacement with raspberry and strawberry oilcakes on the proximate composition of bread, colour, texture and water behaviour. The substitution influenced the ash, fat and protein content causing an increase in the content of each of the analysed macronutrients. The crumb colour components (CIE L*a*b*) were shifted toward red while the saturation of yellow decreased. Texture analysis showed that the hardness and chewiness of crumb with oilcakes increased as well as springiness decreased. It was found that flour substitution with oilcakes limited significantly water transport and also influenced the molecular dynamics of water in the bread crumb. 1H NMR measurement results of relaxation times demonstrated that the free water in relation to the bound water in the examined systems depended on the amount of the flour replaced by the oilcake, as well as on the botanical origin of the oilcakes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bread is one of the most popular cereal food products in the world. Due to its universal character and volume of consumption, it is possible to introduce new nutritional and bioactive compounds into the diet through the use of appropriate additives for bread production. Most studies focus on explaining the interaction of bread ingredients with the additives used, as well as on their activity after the digestion process [1,2,3]. It is worth remembering, however, that the use of unconventional additives may significantly change the physicochemical characteristics of the bread obtained, including the texture or water properties [4,5,6].

Fruits like raspberries and strawberries are small have fleshy consistency. These fruits are so popular in Europe and all over the world because of the taste. Raspberries and strawberries are perceived by consumers as healthy due to the rich composition of vitamins and minerals contained in them. They contain minerals such as: Cu, I, Fe, Mg, K and Mn and vitamins (K, C and B), folic acid, fatty acids, polyphenols [7].

Strawberries are a good source of antioxidants like polyphenolic, such as anthocyanins [8]. The total content of anthocyanins is 150–600 mg/kg of fresh weight [9]. Strawberries also contain proanthocyanidins, which may have antifungal properties [10]. Strawberry seeds constitute 1% of fruit, however, their content in the fruit depends on its species [11, 12]. In recent years, scientists have become interested in new, unconventional sources of plant oil. Strawberry seeds are one of the most interesting raw materials. After the pressing process, the oilcake, which is a production waste, is almost completely defatted [13]. Unlike strawberries, the content of seeds in raspberries is definitely higher. Also these fruits are great for human health because they contain antioxidant ingredients [8, 14, 15]. These are compounds that inhibit oxidation processes in small concentrations. To the main antioxidants compounds belong polyphenolic compounds that include phenolic acids, flavanols, anthocyanins, proanthocyanidins and ellagitannins. Total value of these ingredients is more than 200 mg per 100 g [16, 17]. The main value ingredients of raspberries are carbohydrates, they are 50–80% of total dry weight. Raspberries contain such sugars as: disaccharide sucrose fructose and monosaccharides glucose. The amount of sugars increases with increasing fruit maturity [18]. Raspberry seeds constitute 9–12% of the fruit weight and are a by-product formed mainly in the production of wine and juices. Due to the high recovery rate of oil, in the range of 10–23%, they are also increasingly used for the production of cold-pressed oil used more and more widely in cosmetics [19].

Processing of raspberries and strawberries into juices and purees usually removes seeds as a by-product [20]. The use of waste seeds as a food additive for bread production on the one hand will allow to develop the growing amount of waste, on the other hand it will allow to obtain new, previously unused food stuff with interesting nutritional values [21, 22]. According to Korus et al. [23], after the oil pressing process, almost completely fat-free oilcake was obtained, which can be used as a functional additive for the production of gluten-free bread. In addition, the use of by-products both after oil extraction as well as from fruit and vegetable processing can reduce the amount of waste generated [24]. Therefore, the aim of this work was to evaluate the effect of wheat flour replacement with raspberry or strawberry oilcake on nutritional value, crumb texture, water activity and dynamics of breads supplemented with them.

Materials and methods

Materials

Oilcakes from raspberries (Rubus idaeus L.) and strawberries (Fragaria grandiflora L.) were obtained, as by-products, by room-temperature pressing of berry seeds using a Farmet Uno cold-pressing machine (Farmet, Česká Skalice, Czech Republic) and were denoted in the text as ROC and SOC, respectively. The temperature of the heating sleeve in the press was 60 ± 10 °C, and the temperature of the oils, as well as oilcakes were 39 ± 1 °C [25]. After cooling, oilcakes were milled using a M 20 Universal mill (IKA®-Werke GmbH & CO. KG, Staufen, Germany) and then sieved through a 0.5 mm sieve using vibratory sieve shaker AS 200 basic (Retsch GmbH & Co. KG, Haan, Germany). Wheat flour (type 650) was purchased from GoodMills Polska sp. z o.o. (Grodzisk Wielkopolski, Poland), compressed baker’s yeast from Lesaffre (Poland) and salt from Kopalnia Soli ‘Kłodawa’ S.A. (Poland). All other reagents were of analytical grade.

Dough preparation and baking

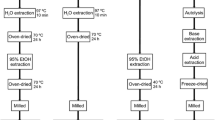

The recipe for reference bread (denoted as C in the text) was as follows: 500 g wheat flour, 15 g yeast, 7.5 g salt and 300 mL water. In the test samples wheat flour was replaced with powdered raspberries and strawberries oilcakes in three different quantities of 5%, 10% and 15%; the amounts of other components were unchanged. The samples were named B5R, B10R, B15R for raspberry oilcake and B5S, B10S and B15S for strawberry oilcake. Dough was prepared using a straight dough method. All the compounds were mixed together with the KitchenAid (model 5KPM5EWH, KitchenAid, USA) mixer for 10 min at a speed of 70 rpm. Next, the dough was fermented in the fermentation chamber for 60 min (temperature 35 °C, relative humidity 85%), punched, then the dough was divided into pieces of equal weight (350 g), hand-moulded, proofed for 20 min, and baked at 230 °C for 30 min (MIWE Michael Wenz GmbH, Amstein, Germany). Afterwards the obtained breads were left at room temperature for 2 h to cool down, weighed and packed in polypropylene pouches.

Proximate composition

The total nitrogen was determined, by Kjeldahl method, according to ISO 20483 [26] and was used to calculate the protein content (P) by multiplying the result by the conversion factor of 5.7. The ash content was determined according to ISO 2171 [27] and the total fat content (F) was determined according to AACC 30-25.01 [28]. The content of dietary fibre (DF) was determined by the enzymatic method in accordance to the AOAC official method 994.13 [29]. Measurement of moisture content measurement was performed according to AACCI 44-19.01 [30]. The proximate carbohydrate content (C) was estimated by subtracting the total ash, fat, fibre, protein and moisture content from 100%. Moreover, the energy value (EV) was calculated with the following formula [31]:

Colour measurements

The colour of the crumb was measured using a Chroma Meter CR-410 (Konica Minolta Sensing Inc., Tokyo, Japan) [32]. Differences in colour were recorded in CIE L*a*b* scale in terms of lightness (L*) and colour (a*—redness; b*—yellowness). Colour measurement was repeated 15 times for each sample. Additionally, the total colour difference (∆E) was calculated using the following formula [33]:

Texture analysis

Texture profile analysis of bread was performed with a TA.XTplus model texture analyser (Stable Micro System Co. Ltd., Surrey, England) equipped with a 5-kg load cell was used [34]. Each sample was compressed twice with a cylindrical plunger probe of a 35 mm diameter. The instrument test parameters were set as following: pre-test speed: 7.0 mm/s; test speed: 5.0 mm/s; post-test speed: 5.0 mm/s; strain 40%. Bread loaves were cut into slices (25 mm thick each and ends were discarded), and so used to evaluate hardness, springiness, cohesiveness, chewiness and resilience. Texture analysis was repeated 10 times for each sample.

Measurements of water activity

The changes of the water activity aw in the bread crumbs were conducted using a water diffusion and activity analyser ADA-7 (COBRABID, Poznań, Poland) with automatic recording of water evacuation from individual samples [35]. The amount of the sample was set at 5 mm and then placed in the measurement chamber. Before the analysis, the temperature was stabilized at 21.0 ± 0.1 °C using the Peltier modules, and then dried to the activity of 0.1000 ± 0.0005. Duration of one measurement was set to 1200 s. Water activity measurements were used to describe water transport in breads, employing following phenomenological model [36]:

where aw(t) is the temporary water activity value, a0 is the initial water activity, ap is the limit water activity (intermediate), ar is the water activity at equilibrium condition (final), VD is the transport rate, and Vp is the rate of the surface conduction.

NMR measurement

The NMR measurements were determined according to Baranowska’s method [37]. The crumb samples of 1.5 cm3 were placed in measuring tt tubes and sealed using Parafilm®. Measurements of the spin–lattice (T1) and spin–spin (T2) relaxation times were performed using a pulse NMR spectrometer MSL30 operating at 30 MHz (WL Electronics, Poland). The crumbs were measured at 21.0 ± 0.5 °C. The inversion–recovery (180–t–90) [38] pulse sequence was applied for measurements of the T1 relaxation times. Distances between RF pulses (t) were changed within the range from 20 to 80 ms and the repetition time was from 10 s. Each time, 32 FID signals and 119 points from each FID signal were collected. Calculations of the spin–lattice relaxation time values were performed with the assistance of the CracSpin program. The program for calculating relaxation parameters from experimental data uses ‘spin grouping’ approach. Marquardt`s method of minimization has been applied for fitting multiexponential decays. The accuracy of the relaxation parameters has been estimated with the standard deviation. Time changes of the current value of the FID signal amplitude in the employed frequency of impulses are described by the following formula:

where Mz(t) is the actual magnetization value, and M0 is the equilibrium magnetization value.

A monoexponentially magnetization recovery was found, which means that the system relaxes with one T1 spin–lattice relaxation time.

Measurements of the spin–spin (T2) relaxation times were taken using the pulse train of the Carr–Purcell–Meiboom–Gill spin echoes [90–t/2–(180)n] [38]. The distance (t) between 180 RF pulses amounted from 0.5 to 0.8 ms. The repetition time was 10 s. The number of spin echoes (n) amounted to 100. Five accumulation signals were employed. To calculate the spin–spin relaxation time values, the authors applied the adjustment of values of the echo amplitudes to the formula [39]:

where Mx,y (t) is the echo amplitude, M0 is the equilibrium amplitude, pi is the fraction of protons relaxing with the T2i spin–spin time.

The calculations were performed by using the dedicated software by application of non-linear least-square algorithm. The accuracy of the relaxation parameters was estimated with the standard deviation. The presence of two proton fractions was determined for all analysed systems.

Statistical analysis

For every test tree independent repeated measurements were done, unless stated otherwise. All measurements were studied using one-way analysis of variance independently for each dependent variable. A post hoc Tukey HSD (honest significant difference) multiple comparison tests were used to identify statistically homogeneous subsets at α = 0.05. Principal component analysis (PCA) was performed using selected data obtained in the analyses. The result is presented in a two-dimensional system (biplot) obtained by plotting the observations and variables on the plane formed by the calculated principal components. Additionally, a correlation matrix was constructed for the variables used in PCA. Statistical analysis of the data was performed with Statistica 13 (Dell Software Inc., USA) software.

Results and discussion

Proximate composition and colour

Fruit pomace is a rich source of nutrients such as sugars, organic acids, protein, dietary fibre, as well as polyphenols and tocopherols, so they can be a good addition to the bread to increase its nutritional value [40]. In the present study, oilcakes obtained after the oil pressing process were used. ROC and SOC were characterized for the content of the most important macronutrients. The moisture content was 7.47 ± 0.04% for ROC and 7.08 ± 0.03% for SOC; protein content 14.2 ± 1.21% and 18.4 ± 1.33%; ash content 2.14 ± 0.02% and 3.21 ± 0.04%, dietary fibre 69.11 ± 1.37% and 65.25 ± 1.71%, respectively. The results showed that the oilcakes are a good source of dietary fibre and are consistent with the literature data. According to Kosmala et al. [41], defatted strawberry seeds contain more protein than the raspberry seed oilcake. They also proved that the total dietary fibre content was 74% in the case of raspberry oilcake and 69% in the case of strawberry oilcake, including soluble dietary fibre, respectively: 6.1% and 1.4%. The effect of flour substation with ROC and SOC on nutritional value of obtained bread, understood as the content of protein, fat, ash and carbohydrates, was analysed. The results are presented in Table 1. It has been shown that the addition of SOC significantly increases the protein content in the bread by 12.23% for B15S compared to C. The addition of ROC also caused an increase in protein content, but at a much lower level (by 3.77%, respectively). The addition of ROC and SOC influenced the increase of fat content in the analysed bread, which ranged from 1.32 to 2.14% for B5R and B15R, and from 1.30 to 2.08% for B5S and B15S. An increase in ash and dietary fibre contents was also observed. According to the assumptions, the content of dietary fibre in enriched breads increased significantly, from 1.88% for C, to 7.36% for B15R and 7.90% for B15S. Food can be considered as ‘rich’ in fibre if it contains at least 6 g/100 g or 3 g/100 kcal. Most European countries recommend daily intake of fibre in the amount of 25–35 g for adults (25–32 g/day for adult women and 30–35 g/day for adult men) and less for children and elder people [42]. Consuming an adequate amount of dietary fibre has documented health benefits, e.g. 10 g of fibre daily reduces the overall mortality caused by various diseases by 11% [43], moreover for total dietary fibre intake indicate a reduction in cardiovascular disease events between 7 and 9% for each 7 g daily increment consumed [44, 45]. The consequence of changes in individual nutrients is the reduction of carbohydrates from 82.9 to 75.6% for B15R and 73.9% for B15S. Carbohydrates are particularly important in cereals, which usually contain about 50–80% carbohydrates on a dry basis, among which starch is the most common cereal polysaccharide and is the main reserve of food providing mass nutrients and energy in the human diet [46]. Differences in the content of macronutrients, however, did not affect the energy value of the obtained bread, which were similar to those described in the literature [47,48,49].

The consumers’ acceptance of food is based not only on the assessment of nutritional value, but also on sensory properties. An important parameter that directly affects consumer choice is its colour [50]. The CIE L*a*b* parameters corresponded, respectively, to the lightness of the samples, the saturation of the red and the saturation of the yellow [51]. The results of the colorimetric colour analysis showed that the value of the L* parameter was reduced, in relation to C, by approx. 30% for B15R and about 35% for B15S, which means obtaining a darker crumb compared to the sample without addition (Table 2). Also in the work published by Koca and Anil [52] a significant reduction in lightness was noted due to the addition of flaxseed. In addition, a significant increase in red saturation of the analysed samples was observed, which may be related to the content of anthocyanins in oilcake containing fruits containing them [40]. Similar results were obtained in the work of Korus et al. [23], where strawberry seeds were added to the bread. The yellow colour saturation in the analysed samples decreased compared to C (18.09) and ranged from 13.22 for B15S to 10.57 for B15R. The calculated total colour difference (ΔE), for individual test samples relative to the control, showed that the colour changes ranged from 16.87 to 23.99 for the ROC addition, and from 18.43 to 27.14 for the SOC addition. The colour difference greater than 3 (ΔE > 3) is so significant that it can be observed with the naked eye even by a non-trained assessor [53].

Textural properties

Differences in the proportions of macronutrients were reflected in the results of the TPA test, which were presented in Table 3. Analysis showed a clear influence of the used oilcakes on the textural properties of the obtained bread. Both the addition of ROC and SOC significantly increased the hardness by 62% for B15S and 94% for B15R compared to C. According to Kosmala et al. [41], ROC and SOC are raw materials containing significant amounts of dietary fibre and protein as well, which increased the content of these macronutrients in the obtained bread in our study, and consequently contributed to the increase of hardness of the crumb. ROC contains in its composition more fibre and protein, which directly affected the higher hardness of bread with ROC compared to SOC. However, no effect of 5% flour replacement on crumb hardness was observed. The increase in hardness of the crumb due to the replacement of wheat flour with raw materials containing fibre and protein is also confirmed by published data [6, 54]. In addition, published data indicates that changes in the recipe can cause the formation of not only harder but also less elastic crumbs [5, 55], which has also been demonstrated in these studies. The analysed breads showed, however, decreased elasticity indicated by the observed values of springiness and resilience. The springiness value of all analysed breads, except for B5S, decreased statistically significantly. Crumb chewiness reflects the energy required to masticate food to a ready-to-swallow state. This parameter derived from firmness, cohesiveness and springiness [56]. This parameter also significantly increases due to the use of oilcake from 1133 for C to even 2090 for B15R.

Water behaviour

Literature data suggest that changes at the molecular level that change the dynamics of water affect the texture of the product [57], thus the molecular properties of water were analysed in the tested samples. In the bread crumb the fraction of mobile water and the water fraction with inhibited dynamics could be observed [58]. The chemical exchange between the molecules of the bulk and bound water of the mobile fraction takes place quickly, hence the analysed systems are characterized by one relaxation time spin–lattice T1 (Table 4). The higher the value of T1 the more is mobile water molecules in the analysed system, compared to the water directly associated with the large molecules of biopolymers. It was found that the relaxation time values spin–lattice T1 decrease with the increase of wheat flour replacement with the oilcakes, therefore the oilcake is a water absorber. The crumb of bread with the addition of ROC is characterized by a larger amount of bound water fraction compared to the bulk water fraction, than the crumb of bread with the addition of SOC, which explains the differences in hardness. Water participates in the creation of the polymer network structure in bread. The fewer molecules of water trapped in the network—bound water fraction—the less hardness and greater springiness. However, the addition of SOC slightly more inhibits the mobility of bulk water molecules, which is manifested by the smaller values of T22 spin–spin relaxation times recorded for individual sample variants. This is related to the presence of a large amount of protein, the content of which determines mobility mainly the bulk fraction. The more protein, the less possible the rotational movements of water molecules. In comparison to the control crumb, those with the addition of 5% or 10% of the oilcakes are characterized by very small values of T21—the component of the relaxation time describing the molecular dynamics of bound water fraction. The mobility of free water is limited by the formation of ionic and hydrogen bonds between water molecules and macromolecules, for example protein [59], thus the higher content in tested breads of this ingredient could affect the changes observed. The decrease in the T22 value suggests a significant change in the dynamics of the free water fraction. It can therefore be concluded that this bread not only contains the lowest amount of free water, but this fraction has also the most limited molecular dynamics. The empirical model of activity and diffusion of water in the biopolymer structure was used [36] to analyse the diffusion rate of water in the tested samples. It was noticed that the oilcakes of both types (from raspberry and strawberry seeds) limit the rate of diffusion of water molecules in the interior of the crumb. It has been found that as the amount of the oilcake increases, the diffusion rate increases. The addition of 5% and 10% of oilcake reduces the evacuation of water from the sample surface compared to the control sample.

LF NMR measurements, diffusion and water activity are related to studies of molecular water properties, and the results complement macroscopic studies. A correlation was found between the water diffusion rate in bread (VD) and spin–lattice relaxation time T1 (Fig. 1a), as well as long components of spin–spin relaxation times T22 (Fig. 1b). The translational movement of water molecules is inhibited by the immobilization of unbound water, which manifests itself in inversely proportional dependence VD = f(T22). The rate of evacuation of water from the surface of the test (Vp) increases as the mobility of molecules of water bound increases (Fig. 1c). The presented work attempts to correlate parameters analysed by two independent methods describing various aspects of the dynamic properties of water in bread. LF NMR reflects the rotational dynamics of water, while the model of activity and diffusion allows the analysis of the translational properties of water molecules. It is well known that the values of relaxation times are correlated with the water content and the manner of its binding. However, the novel approach to the molecular properties of water in the studied system, which is not widely used, gives the possibility of a wider analysis than the relationships described so far between LF NMR results and water activity.

Principal component analysis of the two texture parameters (hardness, springiness), NMR relaxometry results (T1, T21, T22), equilibrium water activity (ar), limit water activity (ap) and proximate composition (ash, carbohydrates, fat and protein contents) of the tested samples was performed to analyse the main factors determining the properties of the analysed breads. The two principal components explained 75.99% of the total variance. The first main component contains 50.35% of the information about the tested products represented by variables, while the second main component contains 25.64% of the information. Each of the vectors, shown in Fig. 2a, represents one variable, and its size and direction describes the influence exerted on the main components. Details concerning correlations between the variables are included in Table S1. Projection of the cases on the factor plane (Fig. 2b) indicated the similarity between the breads with the same level of wheat flour replacement with ROC and SOC. At the same time the C sample differed from the others.

Conclusions

Wheat bread with ROC and SOC was designed and tested during the reported research. The amount of oilcakes introduced into the recipe influences the proximate composition, colour, texture and water properties of the final product. However, some effects on different responses depending on the botanical origin of oilcakes. Replacing wheat flour with oilseed cakes caused an increase in the content of ash (from 0.84 g/100 g for C, to 1.07 and 1.27 g/100 g for B15R and B15S, respectively), fat (1.10, 2.15 and 2.08 g/100 g, respectively) and protein (13.25, 13.75 and 14.87 g/100 g). The increase of total dietary fibre content was also noted [from 1.88 (C) to 7.36 (B15R) and 7.90 g/100 g (B15S)]. Generally, the observed changes were more extensive when higher amount of oilcake was introduced, especially in the case of colour and textural properties. The colour of the crumb was shifted towards red and blue, and the lightness decreased. Moreover, the more ROC and SOC entered the recipe, the higher the hardness of the crumb was (14.56 N for C, 28.28 N for B15R and 23.61 N for B15S). The addition of oilcakes influenced also on the molecular dynamics of water in the bread crumb. These changes depend both on the amount of the flour replacement by the oilcake and on the botanical origin of the oilcakes. The obtained results indicate that 15% substitution of wheat flour by the oilcake result in a significant reduction of the amount of unbound water in the crumb, in relation to bound water, and higher (than in the control sample) rate of water evacuation from the surface. Also the speed of translational diffusion in such samples is comparable to that which is characterized by the crumb of bread without the addition of cakes. Combination of molecular studies on the properties of water with the analysis of macroscopic changes allows for a more complete analysis of enriched food products.

References

Świeca M, Gawlik-Dziki U, Dziki D et al (2013) The influence of protein–flavonoid interactions on protein digestibility in vitro and the antioxidant quality of breads enriched with onion skin. Food Chem 141:451–458. https://doi.org/10.1016/j.foodchem.2013.03.048

Sivam AS, Sun-Waterhouse D, Perera CO, Waterhouse GIN (2012) Exploring the interactions between blackcurrant polyphenols, pectin and wheat biopolymers in model breads; a FTIR and HPLC investigation. Food Chem 131:802–810. https://doi.org/10.1016/j.foodchem.2011.09.047

Glei M, Kirmse A, Habermann N et al (2006) Bread enriched with green coffee extract has chemoprotective and antigenotoxic activities in human cells. Nutr Cancer 56:182–192. https://doi.org/10.1207/s15327914nc5602_9

Gill S, Vasanthan T, Ooraikul B, Rossnagel B (2002) Wheat bread quality as influenced by the substitution of waxy and regular barley flours in their native and extruded forms. J Cereal Sci 36:219–237. https://doi.org/10.1006/jcrs.2001.0458

Ziobro R, Witczak T, Juszczak L, Korus J (2013) Supplementation of gluten-free bread with non-gluten proteins. Effect on dough rheological properties and bread characteristic. Food Hydrocoll 32:213–220. https://doi.org/10.1016/j.foodhyd.2013.01.006

Kaack K, Pedersen L, Laerke HN, Meyer A (2006) New potato fibre for improvement of texture and colour of wheat bread. Eur Food Res Technol 224:199–207. https://doi.org/10.1007/s00217-006-0301-5

Pereira CC, do Nascimento da Silva E, de Souza AO et al (2018) Evaluation of the bioaccessibility of minerals from blackberries, raspberries, blueberries and strawberries. J Food Compos Anal 68:73–78. https://doi.org/10.1016/j.jfca.2016.12.001

Wang SY, Lin H-S (2000) Antioxidant activity in fruits and leaves of blackberry, raspberry, and strawberry varies with cultivar and developmental stage. J Agric Food Chem 48:140–146. https://doi.org/10.1021/jf9908345

Giampieri F, Tulipani S, Alvarez-Suarez JM et al (2012) The strawberry: composition, nutritional quality, and impact on human health. Nutrition 28:9–19. https://doi.org/10.1016/j.nut.2011.08.009

Ayala-Zavala JF, Wang SY, Wang CY, González-Aguilar GA (2004) Effect of storage temperatures on antioxidant capacity and aroma compounds in strawberry fruit. LWT Food Sci Technol 37:687–695. https://doi.org/10.1016/j.lwt.2004.03.002

Aaby K, Wrolstad RE, Ekeberg D, Skrede G (2007) Polyphenol composition and antioxidant activity in strawberry purees; impact of achene level and storage. J Agric Food Chem 55:5156–5166. https://doi.org/10.1021/jf070467u

Cheel J, Theoduloz C, Rodríguez JA et al (2007) Free radical scavenging activity and phenolic content in achenes and thalamus from Fragaria chiloensis ssp. chiloensis, F. vesca and F. x ananassa cv. Chandler. Food Chem 102:36–44. https://doi.org/10.1016/j.foodchem.2006.04.036

Rój E, Dobrzyńska-Inger A, Kostrzewa D et al (2009) Extraction of berry seed oils with supercritical CO2. Przem Chem 88:1325–1330

Beekwilder J, Jonker H, Meesters P et al (2005) Antioxidants in raspberry: on-line analysis links antioxidant activity to a diversity of individual metabolites. J Agric Food Chem 53:3313–3320. https://doi.org/10.1021/jf047880b

Mildner-Szkudlarz S, Bajerska J, Górnaś P et al (2016) Physical and bioactive properties of muffins enriched with raspberry and cranberry pomace powder: a promising application of fruit by-products rich in biocompounds. Plant Foods Hum Nutr 71:165–173. https://doi.org/10.1007/s11130-016-0539-4

Teng H, Lee WY, Choi YH (2013) Optimization of microwave-assisted extraction for anthocyanins, polyphenols, and antioxidants from raspberry (Rubus Coreanus Miq.) using response surface methodology. J Sep Sci 36:3107–3114. https://doi.org/10.1002/jssc.201300303

Hancock RD, Petridis A, McDougall GJ (2018) Raspberry fruit chemistry in relation to fruit quality and human nutrition. Raspberry. Springer International Publishing, Cham, pp 89–119

Surya M, Suhartati S, Ismaini L et al (2018) Fruit nutrients of five species of wild raspberries (Rubus spp.) from Indonesian Mountain’s forests. J Trop Life Sci 8:75–80. https://doi.org/10.11594/jtls.08.01.13

Teng H, Chen L, Huang Q et al (2016) Ultrasonic-assisted extraction of raspberry seed oil and evaluation of its physicochemical properties, fatty acid compositions and antioxidant activities. PLoS One 11:e0153457. https://doi.org/10.1371/journal.pone.0153457

Brownmiller C, Howard LR, Prior RL (2008) Processing and storage effects on monomeric anthocyanins, percent polymeric color, and antioxidant capacity of processed blueberry products. J Food Sci 73:H72–H79. https://doi.org/10.1111/j.1750-3841.2008.00761.x

Bushman BS, Phillips B, Isbell T et al (2004) Chemical composition of caneberry (Rubus spp.) seeds and oils and their antioxidant potential. J Agric Food Chem 52:7982–7987. https://doi.org/10.1021/jf049149a

Parry J, Yu L (2006) Fatty acid content and antioxidant properties of cold-pressed black raspberry seed oil and meal. J Food Sci 69:FCT189–FCT193. https://doi.org/10.1111/j.1365-2621.2004.tb13356.x

Korus J, Juszczak L, Ziobro R et al (2012) Defatted strawberry and blackcurrant seeds as functional ingredients of gluten-free bread. J Texture Stud 43:29–39. https://doi.org/10.1111/j.1745-4603.2011.00314.x

Nawirska A, Kwaśniewska M (2005) Dietary fibre fractions from fruit and vegetable processing waste. Food Chem 91:221–225. https://doi.org/10.1016/j.foodchem.2003.10.005

Mildner-Szkudlarz S, Różańska M, Siger A et al (2019) Changes in chemical composition and oxidative stability of cold-pressed oils obtained from by-product roasted berry seeds. LWT Food Sci Technol 111:541–547. https://doi.org/10.1016/j.lwt.2019.05.080

ISO (2013) ISO 20483:2013 Cereals and pulses—determination of the nitrogen content and calculation of the crude protein content—Kjeldahl method. International Organization for Standardization, Geneva

ISO (2007) ISO 2171:2007 Cereals, pulses and by-products—determination of ash yield by incineration. International Organization for Standardization, Geneva

AACC (2009) AACCI 30-25.01 crude fat in wheat, corn, and soy flour, feeds, and mixed feeds. In: AACC international approved methods. AACC International, Minnesota

AOAC (2007) AOAC official method 994.13. Total dietary fiber. AOAC international, Rockville

AACC (2009) AACCI 44-19.01 moisture–air-oven method, drying at 135 degrees. In: AACC international approved methods. AACC International, Minnesota

Montowska M, Kowalczewski PŁ, Rybicka I, Fornal E (2019) Nutritional value, protein and peptide composition of edible cricket powders. Food Chem 289:130–138. https://doi.org/10.1016/j.foodchem.2019.03.062

Pauter P, Różańska M, Wiza P et al (2018) Effects of the replacement of wheat flour with cricket powder on the characteristics of muffins. Acta Sci Pol Technol Aliment 17:227–233. https://doi.org/10.17306/J.AFS.2018.0570

Poliszko N, Kowalczewski PŁ, Rybicka I et al (2019) The effect of pumpkin flour on quality and acoustic properties of extruded corn snacks. J Consum Prot Food Saf. https://doi.org/10.1007/s00003-019-01216-6

Kowalczewski PŁ, Walkowiak K, Masewicz Ł et al (2019) Gluten-free bread with cricket powder—mechanical properties and molecular water dynamics in dough and ready product. Foods 8:240. https://doi.org/10.3390/foods8070240

Płowaś-Korus I, Masewicz Ł, Szwengiel A et al (2018) A novel method of recognizing liquefied honey. Food Chem 245:885–889. https://doi.org/10.1016/j.foodchem.2017.11.087

Masewicz L, Lewandowicz J, Le Thanh-Blicharz J et al (2016) Diffusion of water in potato starch pastes. In: Proceedings of the 12th international conference on polysaccharides—glycoscience, Prague, pp 193–195

Baranowska HM, Masewicz Ł, Kowalczewski PŁ et al (2018) Water properties in pâtés enriched with potato juice. Eur Food Res Technol 244:387–393. https://doi.org/10.1007/s00217-017-2965-4

Brosio E, Gianferri RR (2009) An analytical tool in foods characterization and traceability. Basic NMR in foods characterization. Research Signpost, Kerala, pp 9–37

Baranowska HM (2011) Water molecular properties in forcemeats and finely ground sausages containing plant fat. Food Biophys 6:133–137. https://doi.org/10.1007/s11483-010-9190-z

Górnaś P, Juhņeviča-Radenkova K, Radenkovs V et al (2016) The impact of different baking conditions on the stability of the extractable polyphenols in muffins enriched by strawberry, sour cherry, raspberry or black currant pomace. LWT Food Sci Technol 65:946–953. https://doi.org/10.1016/j.lwt.2015.09.029

Kosmala M, Zduńczyk Z, Juśkiewicz J et al (2015) Chemical composition of defatted strawberry and raspberry seeds and the effect of these dietary ingredients on polyphenol metabolites, intestinal function, and selected serum parameters in rats. J Agric Food Chem 63:2989–2996. https://doi.org/10.1021/acs.jafc.5b00648

Stephen AM, Champ MM-J, Cloran SJ et al (2017) Dietary fibre in Europe: current state of knowledge on definitions, sources, recommendations, intakes and relationships to health. Nutr Res Rev 30:149–190. https://doi.org/10.1017/S095442241700004X

Kim Y, Je Y (2014) Dietary fiber intake and total mortality: a meta-analysis of prospective cohort studies. Am J Epidemiol 180:565–573. https://doi.org/10.1093/aje/kwu174

Threapleton DE, Greenwood DC, Evans CEL et al (2013) Dietary fiber intake and risk of first stroke. Stroke 44:1360–1368. https://doi.org/10.1161/STROKEAHA.111.000151

Threapleton DE, Greenwood DC, Evans CEL et al (2013) Dietary fibre intake and risk of cardiovascular disease: systematic review and meta-analysis. BMJ 347:f6879. https://doi.org/10.1136/bmj.f6879

Shelton DR, Lee WJ (2000) Cereal carbohydrates. In: Kulp K, Ponte JGJ (eds) Handbook of cereal science and technology, 2nd edn. Marcel Dekker Inc., New York, pp 385–416

Isaksson H, Sundberg B, Åman P et al (2008) Whole grain rye porridge breakfast improves satiety compared to refined wheat bread breakfast. Food Nutr Res 52:1809. https://doi.org/10.3402/fnr/v52i0.1809

Bresciani L, Scazzina F, Leonardi R et al (2016) Bioavailability and metabolism of phenolic compounds from wholegrain wheat and aleurone-rich wheat bread. Mol Nutr Food Res 60:2343–2354. https://doi.org/10.1002/mnfr.201600238

Laatikainen R, Koskenpato J, Hongisto S-M et al (2017) Pilot study: comparison of sourdough wheat bread and yeast-fermented wheat bread in individuals with wheat sensitivity and irritable bowel syndrome. Nutrients 9:1215. https://doi.org/10.3390/nu9111215

Sandvik P, Marklinder I, Nydahl M et al (2016) Characterization of commercial rye bread based on sensory properties, fluidity index and chemical acidity. J Sens Stud 31:283–295. https://doi.org/10.1111/joss.12211

Robertson AR (1977) The CIE 1976 color-difference formulae. Color Res Appl 2:7–11. https://doi.org/10.1002/j.1520-6378.1977.tb00104.x

Koca AF, Anil M (2007) Effect of flaxseed and wheat flour blends on dough rheology and bread quality. J Sci Food Agric 87:1172–1175. https://doi.org/10.1002/jsfa.2739

Bellary AN, Indiramma AR, Prakash M et al (2016) Anthocyanin infused watermelon rind and its stability during storage. Innov Food Sci Emerg Technol 33:554–562. https://doi.org/10.1016/j.ifset.2015.10.010

O’Brien CM, Mueller A, Scannell AGM, Arendt EK (2003) Evaluation of the effects of fat replacers on the quality of wheat bread. J Food Eng 56:265–267. https://doi.org/10.1016/S0260-8774(02)00266-2

Crockett R, Ie P, Vodovotz Y (2011) Effects of soy protein isolate and egg white solids on the physicochemical properties of gluten-free bread. Food Chem 129:84–91. https://doi.org/10.1016/j.foodchem.2011.04.030

Bourne MC (2002) Texture, viscosity, and food. In: Food texture and viscosity. Elsevier, London, pp 1–32

Li C, Wang D, Xu W et al (2013) Effect of final cooked temperature on tenderness, protein solubility and microstructure of duck breast muscle. LWT Food Sci Technol 51:266–274. https://doi.org/10.1016/j.lwt.2012.10.003

van Nieuwenhuijzen NH, Tromp RH, Mitchell JR et al (2010) Relations between sensorial crispness and molecular mobility of model bread crust and its main components as measured by PTA, DSC and NMR. Food Res Int 43:342–349. https://doi.org/10.1016/j.foodres.2009.10.015

Laage D, Stirnemann G, Hynes JT (2010) Water reorientation in the hydration shells of hydrophilic and hydrophobic solutes. Sci China Phys Mech Astron 53:1068–1072. https://doi.org/10.1007/s11433-010-3215-y

Funding

The authors received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Compliance with ethics requirements

All procedures followed were in accordance with the ethical standards of the responsible committee on human experimentation (institutional and national).

Informed consent

Informed consent was obtained from all panelist for being included in the study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kowalczewski, P.Ł., Walkowiak, K., Masewicz, Ł. et al. Wheat bread enriched with raspberry and strawberry oilcakes: effects on proximate composition, texture and water properties. Eur Food Res Technol 245, 2591–2600 (2019). https://doi.org/10.1007/s00217-019-03370-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-019-03370-5