Abstract

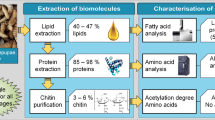

This study focusses on the fractionation of proteins and lipids from insect biomass, more specifically from black soldier fly larvae. Insects are rich in proteins and lipids and offer potential as a protein source for food and feed. Fractionation processes often focus on extracting only one compound (lipid or protein), neglecting the impact of the extraction method on other compounds. The current study aimed at the development of a robust fractionation process for wet insect biomass, targeting enriched protein fractions with higher valuable techno-functional properties as well as enriched lipid fractions. The use of different organic acids was evaluated and compared with an inorganic acid (HCl). A beneficial effect of organic acids on the lipid extraction yield (shift from 35 to 45%) was observed, that did not negatively influence the protein extraction efficiency. One organic acid, in particular, lactic acid, increased the lipid purity from 75 to 85%. Protein fractions with a purity of 60% proteins were achieved and were shown to preserve partial solubility. Use of some organic acids at low pH (pH 2) resulted in (1) a higher lipid purity in the lipid-enriched fraction and (2) had similar results in protein fractionation as the inorganic acid. Reproducibility of the fractionation process was proven.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Insect farming is attracting increasing attention due to the potential of insect biomass as an alternative source for nutritional proteins. It is well documented that the future generation is facing a shortage in protein sources worldwide [1,2,3] and in a search for new and alternative protein sources, insects have been identified as an innovative possibility [4]. Compared to other animals, insect breeding requires less land and water, produces fewer greenhouse gasses and insects have a low feed conversion ratio [FCR, the amount of feed needed (kg) to obtain one kg of weight increase in the animal] which is of interest for large-scale breeding [4]. For example, commercially bred yellow mealworms have an FCR of 2.2 on the standard diet and for black soldier fly larvae (BSFL) bred on chicken feed an FCR of 1.8 has been reported, whereas commercially bred poultry and cereal beef have an FCR of 2.3 and 8.8, respectively [5]. In addition, most insects are rich in proteins (13–77% depending on species and life stage) [4]. Larvae of the black soldier fly (protein content of 38–41% [6] in particular have been appointed to be one of the most likely successful insects for feed applications, together with the common housefly, silkworms and the yellow mealworm [4, 7]. However, insects contain besides proteins also significant amounts of lipids and chitin. Chitin is beneficial for feed applications in small amounts [8], but negatively affects the digestibility and utilization of other macro- and micro-nutrients at higher concentration [9,10,11]. Ozimek et al. [9], for example, found an increasing digestibility of honey bee–protein isolate compared to the digestibility of the whole bee (94% instead of 71%) and hypothesized that the removal of chitin is responsible for the improvement [9]. Hence, there is a possible benefit in separation of insect biomass to generate protein fractions with reduced chitin content. In addition, separate protein and lipid extracts will make it possible to reach a target protein/lipid content or ratio in feed diets. Studies have also indicated that human consumers are more likely to accept insects-based food when extracts are used as an ingredient [2, 12]. Based on a literature search, Nongonierma and FitzGerald [13] concluded that the current extraction procedures for insect proteins generally includes the following steps: (1) drying of the insect biomass, (2) homogenization, (3) defatting, (4) protein solubilization, (5) isoelectric precipitation of the proteins and (6) protein solubilization followed by a possible drying step [13]. In general, insects are freeze-dried [12, 14,15,16] and grinded into smaller particles for better solvent contact. Defatting (step 3) is commonly performed with organic solvents such as hexane or ethanol [13], but successful supercritical CO2 defatting has also been reported [17, 18]. In the fourth step, proteins are solubilized to separate soluble proteins from non-soluble matter (such as chitin). Generally, the pH of insects biomass is increased to perform an alkaline extraction in aqueous conditions [13]. During the fifth step, soluble proteins are precipitated by lowering the pH to the isoelectric point, which is generally around pH 5. In this way, the purity of the resulting protein fraction can be increased. The last step includes resolubilization by bringing the pH to neutral and drying [13]. However, literature indicates that not all steps are always included in extraction procedures and details of individual steps can vary considerably. For example, Yi et al. [19] did not perform the pre-drying step but used frozen insect and water to homogenize, added a filtration step to remove the chitin, while defatting was performed by centrifugation at 4 °C. Some studies only perform step 1–4 [16] or add an additional step such as filtration or acidifying the non-soluble fraction after alkaline pH [20]. More traditional methods to extract lipids, for example hydraulic pressing, solvent extraction and heat extraction, focus only on step 1–3 without a regard for the preservation of techno-functional proteins [21]. Heat extraction, also called rendering, can be performed on wet material; whereas solvent extraction and hydraulic pressing are best performed on dry material. Rendering, although very successful in extracting lipids, can cause protein denaturation, since high temperature and pressurized conditions are involved [22].

The first three steps of the procedure compiled by Nongonierma and FitzGerald [13] can be disadvantageous when applications in food and feed industries and upscaling are intended. Drying is often an energy-consuming step and difficult to scale up when no high temperatures are allowed [21]. In addition, solvent fat extraction requires pre-dried insect biomass and is often not eco-friendly or food-friendly [13, 23]. Despite the high yield of soluble proteins, alkaline conditions can impact the protein quality. For instance, anti-nutritional compounds can be formed such as lysinoalanine that negatively impacts protein digestibility and amino acid availability in food [24]. To make the fractionation procedure more applicable for feed/food industries on large scale, this study focusses on avoiding a drying step and possible losses in nutritional value. Since organic acids are allowed in the feed and food industry, the paper investigates the performance of fractionation at low pH with the use of organic acids where lipids are removed without the use of solvents. Earlier, Liang and Hultin [25] studied the impact of citric, lactic and malic acid on the separation of phospholipids lipids from solubilized proteins in fish muscle [25]. A positive impact of the organic acids was reported. Malic acid gave the best results for lipid removal, followed by citric acid and lactic acid. For protein extraction, citric- and malic acid resulted in the same yield, but a lower yield was noted with lactic acid [25]. The focus of that paper was on separating phospholipids from membrane proteins; while in the current study, all lipid classes are present and expected to separate. In addition, HCl is traditionally used for solubilization of proteins in the acid region; while this paper investigates the potential of organic acids. The current study aimed to develop a method to separate proteins from lipids in an aqueous environment while preserving the techno-functionalities of the proteins. For all obtained fractions, the distribution of lipids and proteins was evaluated to investigate not only the purity but also the maximum yield. The preservation of the techno-functionalities was evaluated based on the solubility of the proteins. To the best of our knowledge, such study has not been published before.

Materials and methods

Materials

Living black soldier fly larvae (BSFL), bred on broiler feed, were kindly provided by Millibeter (Belgium). BSFL juice was obtained after a mechanical separation (based on WO 2019081067), where the exoskeletons were removed. The insect juice was frozen immediately and stored at − 20 °C in vacuum bags till use. The bags were defrosted in room temperature water for 10 min before use. Lactic acid (Alfa Aesar 85.0–90.0%), acetic acid (Merck Millipore, 30%), citric acid (Merck, citric acid monohydrate), succinic acid (Amresco), valeric acid (Aldrich, > 99%), oxalic acid (JT Baker, oxalic acid dihydrate) and HCl (Merck, 37%) were tested. During Soxhlet, diethyl ether (Merck) was used as extraction media.

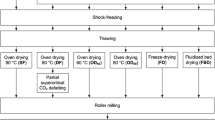

Fractionation procedure

The extraction media that were evaluated as triplicates are summarized in Table 1. Defrosted insect juice was mixed with the solvent at a liquid (w):solid (w) ratio of 17.6 ± 0.5 (200 ml assay). A concentration of 0.5-M organic acid was used, except for valeric acid which was used at 0.33 M (because of the saturation point). For some test conditions, the pH was kept at pH 2 by measuring the pH every 10 min and adjusting it with 2.5-M HCl. These conditions are indicated by ‘+ HCl’ in Table 1. The mixture was stirred for 30 min in total at 100 rpm on a shaking plate (Gerhardt laboshake) at room temperature. After swing out centrifugation (Eppendorf 5810-A-4-81 rotor) at room temperature (3220 g, 30 min), three layers were obtained (Fig. 1). The upper layer was scooped off with a spatula. The supernatant (SN1) was decanted and the pellet (pellet 1) was collected and resuspended at pH 7. The SN1 fraction was adjusted to pH 5 with NaOH (40 v% or 50 w%) and was subsequently centrifuged at room temperature (3220 g, 15 min) to obtain two fractions, being a supernatant (SN2) and a pellet (pellet 2). Both fractions were resuspended at pH 7. Selected tests were repeated at a fixed temperature of 25 °C using angled head centrifugation (Thermo Scientific, Sorvall lynx 6000—F14-14 × 50 cy rotor).

The distribution of the obtained fractions (as dry weight, DW) was evaluated by calculating non-dialyzed yield (NDY) for the different fraction using the following formula (1):

During the screening test, the upper layer (rich in oil) and pellet 2 (rich in proteins) received most attention. For a selection of well-performing conditions, a more detailed mass balance was established after dialyzing all four fractions (Spectrum™ Labs Spectra/Por™ 6 1000 D MWCO Standard RC Pre-wetted Dialysis Kits). Dialyzed yield, recovery and lipid/protein distribution were calculated using the following formulas (2), (3) and (4):

Sample characterization

Dry weight was measured either after oven drying at 105 °C (juice and upper layer) for 48 h or after freeze-drying (pellet 1, pellet 2 and SN2) (Christ, gamma 1–16 LSC) for 36 h. Ash content was determined gravimetrically after incineration (550 °C) in a muffle furnace. The crude lipid content was determined by Soxhlet extraction with diethyl ether for 6 h and expressed on dry weight. Quantification of the chitin content was performed as described by D’Hondt et al. (D’Hondt et al., submitted). Briefly, chitin was hydrolyzed to glucosamine and acetate that were subsequently quantified by LC–MS and HPLC–RID, respectively. The sample was hydrolyzed with 6 N HCl for 6 h at 110 °C. Glucosamine was determined by UPLC–MS/MS analysis (Waters UPLC BEH HILIC 2.1 × 100 mm, 1.7 µm column at 40 °C, isothermal gradient elution using water with (A) 20-mM ammoniumformiate and 0.1% formic acid (pH = 3) and acetonitrile (B) with 0.1% formic acid with gradient settings: 5–25% A (0–3 min), 25% A (3–4 min), 25–5% A (4–4.1 min), 5% A (4.1–7 min) at 0.4 ml/min at 40 °C). Peak detection and quantification were done using a triple quadrupole MS operated in multiple reaction monitoring mode. Crude protein content of the fractions was calculated based on nitrogen measurements (Dumas method, Elementar, vario EL cube) using the standard 6.25 correction factor and expressed on dry weight. pH solubility curves were measured at pH values ranging between pH 2 and pH 10. Dispersions in demineralized water were stirred at different pH for 30 min; then the pH was checked and adjusted if needed with 0.1 M NaOH or 0.1 M HCl, followed by another 30 min of stirring. Afterwards, samples were centrifuged at 4 °C for 20 min at 5910g. The total nitrogen was determined by a chemiluminescence detector (Multi N/C 3100 Analytik Jena). The sample was oxidized by catalytic combustion in an oxygen atmosphere at 800 °C, to produce nitrogen oxides as is described by EN 12260:2003 [water quality—determination of nitrogen—determination of bound nitrogen (TNb), following oxidation to nitrogen oxides]. The formed measuring gas was dried and entered the reaction chamber of the chemiluminescence detector. There, the nitrogen monoxide present in the measuring gas was oxidized with ozone into activated nitrogen dioxide. By emitting light photons (luminescence), the molecules of the nitrogen dioxide returned to their original state. The luminescence was detected using a photomultiplier and is proportional to the nitrogen monoxide concentration. Sample vials were filled with about 25-ml sample and placed into the sample carrousel. About 1000 µl of sample was injected in the system. The catalytic combustion of the sample in an oxygen atmosphere (160 mbar) was carried out at 800 °C. A linear calibration curve between 1 and 10 mg/l of nitrogen was set up using a mixture of ammonium sulfate (Merck) and potassium nitrate (Merck) at five concentration levels (1–2.5–5–7.5 and 10 mg N/l). Solubility was expressed as percent of protein in the supernatant relative to the protein content of the sample. The total protein solubility at a specific pH (of all proteins in the juice) after fractionation was determined by adding the solubilities of the different fractions according to formula (5). The fraction solubility for a certain pH was calculated based on formula (6), where ‘F’ stands for the fraction (pellet 1, pellet 2, SN2).

Results and discussion

Characterization of the BSFL juice

The BSFL juice used for this study had a dry weight of 26%. The crude protein and lipid content based on dry weight was 38% and 35%, respectively, as indicated in Table 2 along with other composition data. Chitin content of the juice was 0.52% which is much lower compared to BSFL that have a chitin content between 4.4% and 9.1% [26, 27]. The solubility curve of the proteins in the insect juice was U-form shaped (see Fig. 4), indicating that BSFL proteins have a high solubility at low and high pH (90% soluble at pH 2 and 80% at pH 9) and an isoelectric point around pH 5. Earlier, Bußler et al. [20] reported a solubility curve for BSFL with a different pattern. The protein solubility of the larvae meal was only 40% at pH 2 and pH 9 and a minimum was reached at pH 4. However, the exoskeleton (containing chitin) was included in this experiment [20]. Chitin is a non-soluble polymer containing nitrogen that may lead to underestimation of the protein solubility if not taken into account when converting nitrogen measurements into protein content. To the best of our knowledge, no solubility curves for BSFL juice (without the exoskeletons) have been described before in literature. The findings of Zielińska et al. [14] on solubility for the mealworm proteins (extracted by alkaline isoelectric point precipitation) Tenebrio molitor, the cricket Gryllodes sigillatus and grasshopper Schistocerca gregaria were more similar to the results obtained in the current study. The isoelectric point for these insects proteins (without exoskeleton) was situated around pH 5 and a solubility up to 90% was reached at pH 2 and 8 [14].

Distribution of lipids and proteins among the fractions obtained

Even though protein extractions at alkaline pH result in a high amount of soluble proteins, protein digestibility and nutritional value can decrease [28]. Hence, protein fractionation at acid pH may be a better approach. Based on the solubility curve, it can be suggested that at pH 2, proteins can be separated from other non-soluble particles with only 10% of protein loss. To separate the proteins from other soluble molecules in a subsequent step, the pH can be adjusted to 5 to precipitate about 60% of the proteins. This fractionation approach was verified using different organic acids. Since the pH of the mixtures after adding the organic acids raised and was different over all treatment (see Table 1), HCl was used to insure all treatments had the same pH.

Nine test conditions were set up to evaluate the performance of six different organic acids, being lactic acid, acetic acid, citric acid, succinic acid, valeric acid, and oxalic acid. The aim was to fractionate the juice into a lipid-enriched fraction and a protein-enriched fraction. The distribution of the lipids and proteins among the four fractions is visualized in Fig. 2. The lipids were predominantly present in the upper layer except for condition 1, 8 and 9 (Fig. 2a). For all other conditions, on average, 64% of all lipids were concentrated in this fraction with 75% for condition 6 (citric acid) and 73% for condition 4 (lactic acid). Figure 2b illustrates that the proteins were distributed over all fractions but were concentrated predominantly in pellet 2 (up to 48%, in particular for condition 2, 5 and 6) and SN2 (up to 48%). The impact of acid versus neutral pH during extraction could be evaluated by comparing the results obtained under condition 1 and 2. When working in an acidic environment, an upper layer was formed separating lipids that were first located in pellet, and more proteins could be collected in pellet 2 (13% versus 45%). This result was expected based on the solubility curve of the juice (Fig. 4). Comparison between conditions 3 and 4 also indicated that lactic acid at pH 2 was more beneficial than at pH 3.3. At pH 2 (condition 4), more lipids were collected in the upper layer and the protein distribution altered towards proteins in pellet 2 and less in the upper layer. The influence of organic acids was studied by comparing them to an inorganic acid (HCl) at the same pH (condition 2). When only inorganic acid was used (condition 2), the distribution of lipids was less in the upper layer compared to four out of six organic acids, indicating an added value of these specific acids in collecting lipids in the upper layer. The difference was less pronounced in the protein distribution. In conclusion, the results of the screening test indicate that conditions 2, 4, 5, 6 and 7 may be of interest for fragmentation of insect juice. When pure lipid fractions are desired, condition 4 (lactic acid) would be superior to condition 6 or 7 because of a lower protein distribution in the upper layer. Condition 5 (acetic acid) resulted in a lower distribution of proteins in the upper layer, same as condition 2, but still a high distribution of protein in pellet 2 was noted (48%).

Lipid (a) and protein (b) distribution of the four generated fraction (mean ± SD, n = 3). Distribution over the obtained fraction after mixture was stirred at 100 rpm for 30 min in a 17.6 liquid: solid (w:w) ratio (200 ml assay), the condition 1: water, condition 2: water + HCl, condition 3: lactic acid, condition 4: lactic acid + HCl, condition 5: acetic acid + HCl, condition 6: citric acid + HCl, condition 7: succinic acid + HCl, condition 8: valeric acid + HCl, condition 9: oxalic acid + HCl

Yield and purity

In the previous section, the impact of organic acids on the distribution of lipids and proteins among the four generated fractions was evaluated. When envisioning the use of the fractions towards certain applications, also the size of the fraction (yield) and the concentration of lipids and/or proteins in the fraction (purity) are important criteria to evaluate the added value of organic acid assisted extractions. The compilation of accurate mass balances, however, was proven to be challenging due to the acids and alkaline that were added during the extraction. These chemicals were distributed over all fractions and were partially lost via evaporation during drying of the fractions. Further, as proteins and lipids only represented 74% of DW juice, mass balances prepared based exclusively on these compounds are not accurate. Two types of mass balances were calculated to make best estimates for the yield of the different fractions. Firstly, NDYs (non-dialyzed yields) were calculated based on the dry weight amounts of the fractions after drying relative to the dry weight of juice used, which provides a realistic view of the obtained fractions. Next, for a selection of six most promising conditions (condition 2, 3, 4, 5, 6 and 7), yields based on the weight of dialyzed fractions were calculated relative to the weight of the dialyzed juice (named dialyzed yield) to verify the fate of the juice among the four fractions (see Table 3). Dialysis of the juice fraction resulted in a 79.0 ± 3.3% recovery. Conditions 1, 8 and 9 were excluded because of the poor lipid distribution. The added yields of the four fractions ranged between 107 and 270%, and between 70 and 98% for non-dialysed and dialyses fractions, respectively. The total recovery based on dialyzed yield suggested some losses during the extraction procedure. Gas development, possibly caused by for instance enzymatic or microbial activity, was noticed during the extraction procedure. This may have contributed to the losses of mass. For the upper layer, which was observed for all test conditions except for condition 1, the non-dialyzed yield varied between 12 and 39% DW of the initial juice and the dialyzed yield was slightly higher than one-third of the juice. The lipid content of the upper layer was between 66 and 85%. The highest percentage was obtained using lactic acid at pH 2 (condition 4), followed by acetic acid (condition 5), and lactic acid with no additional HCl (condition 3). In addition, condition 4 realized an upper layer with a very small protein impurity (8%). The highest yield for the lipid-rich upper layer was obtained with succinic acid (46%, condition 7) followed by citric acid (41%, condition 6). Yet, these were not the most pure fractions based on lipid content and thus not seen as an improvement of the fractionation procedure. Condition 4, on the other hand, contained a significantly higher % of lipids (73% distribution) in the upper layer compared to condition 7 (63% distribution) with a slightly lower dialyzed yield (37% versus 46%).

With respect to protein purity, an enrichment of the protein content was obtained for all conditions in pellet 2. Conditions 9, 5, 1 and 2 resulted in a protein content higher than 50%. Despite its higher protein content in pellet 2 for condition 1, water alone as extraction media is not advisable since the non-dialyzed yield was only 8%. Protein fractions with low lipid content (< 5%) were observed for conditions 2 and 5. The dialyzed yield of the protein-rich pellet 2 was on average 25% and was maximized with conditions 2, 6 and 7 to 27%. Comparing non-dialyzed and dialyzed yields for conditions 6 and 7 revealed that significant amounts of compounds smaller than 1 kDa were present. This makes these fractions, despite their high non-dialyzed yield (48% and 39%, respectively) less interesting than condition 2 for the fractionation procedure. For both pellets 1 and 2, the sum of lipid and protein content was on average ± 55%, indicating that other compounds were concentrated in these fractions.

Fraction pellet 1 contained lower amounts of lipid and protein compared to the juice. These concentrations were even lower in fraction SN2, especially for lipids. The non-dialyzed yields of SN2 were significantly higher compared to the dialyzed yield. This indicates that SN2 consisted mostly of compounds smaller than 1 kDa and that only maximum 9% of the dialyzed juice was distributed in this fraction. In addition, this effect is also notable, but less pronounced with pellet 1 (e.g., conditon 5, the yield decreased from 23.5 to 14.2%) and pellet 2 (the yield decreased from 32.7 to 23.2% for condition 5). These results indicate that a filtration step of these fractions will further purify the sample and thus also increase the protein/lipid content. Filtration would result in the removal of organic and inorganic salt which can have a positive effect on feed applications. However, also other compounds such as small peptides, amino acids on other micro-nutrients would be lost.

Comparison between conditions 3 and 4 confirms the conclusions made based on the lipid and protein distribution. A more acidic pH resulted in a higher dialyzed yield of pellet 2 (24% versus 18%) with a lower lipid content (8% versus 12%), whereas the protein content was similar. In addition, the results for these conditions also indicate that a low pH favored lipid fractionation since the lipid content was higher in the upper layer at pH 2 (85% versus 78%). Literature on the BSFL reports the presence of a large amount of free fatty acids, depending on the killing method [29, 30]. Ushakova et al. [29] reported 87% of lipids to be free fatty acids when the larvae were killed by freezing. Caligiani et al. [30] found a free fatty acid content of 78% in larvae that were frozen. However, they stated that the storage length influenced the free fatty acids content (35% immediately after freezing, 90% after 2 months in frozen storage). Larvae that were first killed by blanching only showed traces of free fatty acids. The larvae in the current study were not frozen but mechanically killed. During this treatment, it cannot be excluded that lipases were activated and free fatty acids were formed, but based on TLC analyses, they were not found to be dominant (data not shown). A possible explanation for a better separation in a more acidic environment is that these free fatty acids may become protonated and thus become less soluble in water. In addition, the acid environment will change the structure of proteins and perhaps decrease emulsifying properties making separation more easily. Focusing on the added value of organic acids assisted extraction of lipids, the dialyzed yields demonstrate that all organic acids (at pH 2) except for acetic acid (condition 5) increased the upper layer yield compared to HCl (condition 2). The inorganic acid (HCl) treatment at pH 2 resulted in a lipid content of 75%. For most organic acids, a similar or slightly lower lipid content was obtained, except for lactic acid (condition 4). Here, an increased lipid content (85%) and as such an increased purity (lower protein content) was observed. A similar observation was stated by Liang and Hultin [32] where organic acid had a beneficial effect on separating phospholipids from soluble fish proteins. A better phospholipid removal was noticeable compared to a water treatment (both adjusted to the same pH with HCl). Malic acid gave the best results for phospholipid removal, followed by citric acid and lactic acid. In search for an explanation of the added value of the organic acids, Liang and Hulting hypothesized that the carboxylic groups of the acid were involved in the separation. Phospholipids may interact under the applied conditions (pH3) with proteins via the basic amino acid residues and the polyanionic groups of the phospholipids. The presence of the carboxylic group of the organic acids may compete with the polyanionic groups of phospholipids [31]. However, in the present study, multiple lipid classes were present. Tzompa-Sosa et al. [31] showed by TLC analysis that insect lipids consist mainly of triglycerides [31]. These insects were killed rapidly (30 min at − 20 °C followed by nitrogen immersion). The same results were obtained after blanching (98% triglycerides) [30]. TLC analysis in the current study (data not shown) also indicated a major presence of triglycerides (no polyanionic group), thus implying that the interaction between proteins and lipids in this study is different. Although the specific context is different, both studies observe an added value of organic acids for separating the lipids present in biomass. Since the current study indicates lactic acid to be better than citric acid in removing the lipids, it could be stated that lactic acid has a higher preference toward neutral lipids. In addition, under the applied conditions (pH 2), it is more likely that the acids were protonated (pKa of lactic acid is 3.08) and thus not negatively charged. The acidic pH may have stimulated the release of lipids from remaining tissue (located in pellet 1 when fractionating at neutral pH) by, for example, changing the structure of bounded proteins. Nevertheless, pH cannot be the only explanation, as lactic acid was proven to be beneficial compared to the use of inorganic acids or other organic acids. This indicates that lactic acid has another beneficial effect in separating neutral lipids from other insect biomass components.

For the protein-enriched fraction (pellet 2), the use of organic acid did not increase the protein or lipid content in the fractions compared to water (condition 1) or HCl (condition 2). In comparison with condition 2, there was no added value of the organic acids. The purity of the pellet 2 factions was maximal about 60% proteins, which is comparable to other protein extractions of the BSFL. For example, Bußler et al. [20] performed a hexane defatting resulting in a protein meal (still containing chitin) with a protein content of 44.9% and a crude fat content of 8.8%. Osborne’s fractionation after solvent lipid extraction created multiple fractions with a protein content range from 3 to 13% [27]. Low-pressure defatting without the use of solvents resulted in a protein fraction containing 55% proteins and 18% fat and high-pressure defatting resulted in a fraction with 67% crude proteins and 5% crude fat [33]. For other insects such as the mealworm, for example, an aqueous extraction at pH 10 after a hexane extraction also delivered a protein fraction with 68% protein and 0.4% fat. Enzymatic extraction of proteins on crickets (Gryllodes sigillatus) did also not succeeded in obtaining a fraction higher than 70% of protein and 8% of fat [34]. Aqueous extraction of crickets (Acheta domesticus) resulted in multiple fractions comprising a fraction with 67% crude proteins and 14% crude fat [16].

Reproducibility

Extractions with HCl (condition 2), lactic acid (condition 4) and acetic acid (condition 5) were repeated in triplicate under slightly different conditions to evaluate the reproducibility. For condition 4, the first repetition was performed with freshly prepared juice; while for the second repetition, defrosted juice was used. Similar results were obtained (Fig. 3) indicating that the freezing and defrosting process does not affect the fractionation procedure. Conditions 1 and 5 were performed with a different type of centrifuge and showed the same fractionation profile for all fractions except for condition 5, fraction SN2. However, this difference can be explained by the differences in additions acid/base for pH changes and the volatility of acetic acid. Overall, all three conditions show good reproducibility of the process. In addition, the protocol was also successfully executed for another insect, viz., the lesser mealworm (data not shown).

Reproducibility: NDY distribution after fractionation for three conditions performed in duplicate with slightly different conditions (mean ± SD, n = 3). NDY distribution over the obtained fraction after mixture was stirred at 100 rpm for 30 min in a 17.6 liquid: solid (w:w) ratio (200 ml essay), condition 1: water, condition 4: lactic acid + HCl, condition 5: acetic acid + HCl, centrifuge type 1: swing out centrifuge at room temperature, centrifuge type 2: angle head centrifuge at 25 °C

Solubility curve assessment

Since most functional properties of proteins require the protein to be soluble [35, 36], the solubility was used as a criteria to evaluate potential use of the fractionated proteins as functional proteins. The total protein solubility of pellet 1, pellet 2 and SN2 are given in Fig. 4. The proteins in the upper layer were not investigated for functional properties and were, therefore, not included in the calculations. These proteins were extracted in a highly hydrophobic environment (caused by the lipids) and were assumed to be insoluble in water or trapped in micelles in the lipid-rich fraction. Based on Fig. 4, it can be concluded that the acidic water treatment and acetic acid treatment resulted in soluble proteins, although partial loss in solubility was observed. At pH 2 and 9, ± 35% of proteins were probably denatured or lost in the upper layer resulting in a lower solubility. At pH 5, no losses were measured for the inorganic acid treatment, and at pH 6.5–7 a loss of approximately 13–15% was recorded. No similar protein extractions of the BSFL were found in literature; however, data on extracted protein from the yellow mealworm were found. Protein extraction at pH 10 after a defatting with ethanol resulted in 40% solubility at pH 7 [12], similar to the results discussed here (Fig. 4). Bußler et al. [20] obtained a higher solubility, up to 60% at pH 7, after alkaline extraction at 60 °C and hexane defatting. The solubility of the separate fractions indicated that SN2 was most soluble (around 80% for pH 2–5 and 7). The protein-enriched fraction (P2) had a high solubility at pH 2 (60%) but extremely low at pH 5 and 7 (around 10%). Yet, solubility experiment of SN1 indicated a solubility of 53% at pH7. This leads to the hypothesis that the acid environment did cause structural changes of the proteins but did not cause denaturation. Only when the pH was adjusted to pH 5, the protein was denatured to a point where at neutral pH, no renaturation could occur. Further investigation of other techno-functional properties beside the solubility is needed to evaluate the effect of the treatment more in detail.

Protein solubility as function of pH of defrosted juice, and the summarized solubility after fractionation of pellet 1, pellet 2 and SN2 from the BSFL in water. Summarized solubility of the obtained fraction after mixture was stirred at 100 rpm for 30 min in a 17.6 liquid: solid (w:w) ratio (200 ml essay), condition 2: water + HCl, condition 5: acetic acid + HCl

Conclusion

The aim of this paper was to evaluate an alternative approach for fractionation of wet biomass. Organic acids were evaluated in this study to solubilize proteins. A special focus was given to additional benefits in the separation of lipids from proteins. Lipid- and protein-enriched fractions were achieved. All acids (organic and inorganic) enabled to obtain a lipid-rich fraction; however, the use of lactic acid combined with HCl proved to be the best condition to obtain a lipid fraction with a purity of 80% lipid. Multiple acids were capable to enrich the protein level in 1 fraction; however, when taking into account the yield and purity, acetic acid combined with HCl or HCl by itself gave best results. The purity of the enriched protein fraction reached ± 60%. The data also implied that pH has a significant effect on lipid separation; whereas protein separation was less affected. The process proved to be robust and proteins were still partially soluble. The total proteins solubility after fractionation was in the same order of magnitude compared to other protein extraction procedures.

References

Nelson G, Rosegrant MW, Koo J, Robertson R, Sulser T, Zhu T, Ringler C, Msangi S, Palazzo A, Batka M, Magalhães M, Santos, RA, Ewing M, Lee D (2009) Climate change: impact on agriculture and costs of adaptation. International Food Policy Research Institute (IFPRI). https://doi.org/10.2499/0896295354

van Huis A (2011) Potential of insects as food and feed in assuring food security. Annu Rev Entomol 58(2012):120928130709004

Foley JA et al (2011) Solutions for a cultivated planet. Nature 478(7369):337–342

van Huis A, Itterbeeck JV, Klunder H, Mertens E, Halloran A, Muir G, Vantomme P (2013) Edible insects: Future prospects for food and feed security. Food and Agriculture Organization of the United Nations, Rome. https://doi.org/10.1017/CBO9781107415324.004

Oonincx DGAB, Van Broekhoven S, Van Huis A, Van Loon JJA (2015) Feed conversion, survival and development, and composition of four insect species on diets composed of food by-products. PLoS One 10(12):e0144601

Spranghers T, Ottoboni M, Klootwijk C, Ovyn A, Deboosere S, De Meulenaer B, Michiels J, Eeckhout M, De Clercq P, De Smet S (2016) Nutritional composition of black soldier fly (Hermetia illucens) prepupae reared on different organic waste substrates. J Sci Food Agric. https://doi.org/10.1002/jsfa.8081

EFSA Scientific Committee (2015) Risk profile related to production and consumption of insects as food and feed. EFSA J 13(10):60

Ramachandran Nair K, Mathew P, Madhavan P, Prabhu P (1987) Chitin as a feed additive for broiler chicken. Indian J Poultry Sci 22(10):40–44

Ozimek L, Sauer WC, Kozikowski V, Ryan JK, Jorgensen H, Jelen P (1985) Nutritive value of protein extracted from honey bees. J Food Sci 50(5):1327–1329

Marono S et al (2015) In vitro crude protein digestibility of Tenebrio molitor and Hermetia illucens insect meals and its correlation with chemical composition traits. Ital J Anim Sci 14(3):338–343

Kroeckel S et al (2012) When a turbot catches a fly: evaluation of a pre-pupae meal of the black soldier fly (Hermetia illucens) as fish meal substitute—Growth performance and chitin degradation in juvenile turbot (Psetta maxima). Aquaculture 364–365:345–352

Zhao X, Vázquez-Gutiérrez JL, Johansson DP, Landberg R, Langton M (2016) Yellow mealworm protein for food purposes—extraction and functional properties. PLoS One 11(2):1–17

Nongonierma AB, FitzGerald RJ (2017) Unlocking the biological potential of proteins from edible insects through enzymatic hydrolysis: a review. Innov Food Sci Emerg Technol 43(March):239–252

Zielińska E, Karaś M, Baraniak B (2018) Comparison of functional properties of edible insects and protein preparations thereof. LWT Food Sci Technol 91:168–174

Purschke B, Tanzmeister H, Meinlschmidt P, Baumgartner S, Lauter K, Jäger H (2018) Recovery of soluble proteins from migratory locust (Locusta migratoria) and characterisation of their compositional and techno-functional properties. Food Res Int 106:271–279

Ndiritu AK, Kinyuru JN, Kenji GM, Gichuhi PN (2017) Extraction technique influences the physico-chemical characteristics and functional properties of edible crickets (Acheta domesticus) protein concentrate. J Food Meas Charact 11(4):2013–2021

Purschke B, Stegmann T, Schreiner M (2017) Pilot-scale supercritical CO2 extraction of edible insect oil from Tenebrio molitor L. larvae—influence of extraction conditions on kinetics, defatting performance and compositional properties. Eur J Lipid Sci Technol 119(2):1–12. https://doi.org/10.1002/ejlt.201600134

Wu S (2012) Supercritical carbon dioxide extraction of oil from Clanis bilineata (Lepidoptera), an edible insect. Afr J Biotechnol 11(20):4607–4610. https://doi.org/10.5897/AJB11.4102

Yi L, Lakemond CMM, Sagis LMC, Eisner-Schadler V, van Huis A, van Boekel MAJS (2013) Extraction and characterisation of protein fractions from five insect species. Food Chem 141(4):3341–3348. https://doi.org/10.1016/j.foodchem.2013.05.115

Bußler S, Rumpold BA, Jander E, Rawel HM, Schlüter OK (2016) Recovery and techno-functionality of flours and proteins from two edible insect species: Meal worm (Tenebrio molitor) and black soldier fly (Hermetia illucens) larvae. Heliyon 2(12):e00218

Ivanovs K, Blumberga D (2017) Extraction of fish oil using green extraction methods: a short review. Energy Procedia 128:477–483

Kinyuru JN, Kenji GM, Njoroge SM, Ayieko M (2010) Effect of processing methods on the in vitro protein digestibility and vitamin content of edible winged termite (Macrotermes subhylanus) and grasshopper (Ruspolia differens). Food Bioprocess Technol 3(5):778–782

L’Hocine L, Boye JI, Arcand Y (2006) Composition and functional properties of soy protein isolates prepared using alternative defatting and extraction procedures. J Food Sci 71(3):C137–C145

Sarwar-Gilani G, Wu-Xiao C, Cockell KA (2012) Impact of antinutritional factors in food proteins on the digestibility of protein and the bioavailability of amino acids and on protein quality. Br J Nutr 108(S2):S315–S332

Liang Y, Hultin HO (2005) Separation of membranes from acid-solubilized fish muscle proteins with the aid of calcium ions and organic acids. J Agric Food Chem 53(8):3008–3016

Janssen RH, Vincken JP, Van Den Broek LAM, Fogliano V, Lakemond CMM (2017) Nitrogen-to-protein conversion factors for three edible insects: Tenebrio molitor, Alphitobius diaperinus, and Hermetia illucens. J Agric Food Chem 65(11):2275–2278

Caligiani A et al (2018) Composition of black soldier fly prepupae and systematic approaches for extraction and fractionation of proteins, lipids and chitin. Food Res. Int. 105:812–820

Gilani GS, Xiao CW, Cockell KA (2012) Impact of antinutritional factors in food proteins on the digestibility of protein and the bioavailability of amino acids and on protein quality. Br J Nutr 108(Suppl. 2):S315–S332

Ushakova NA, Brodskii ES, Kovalenko AA, Bastrakov AI, Kozlova AA, Pavlov ADS (2016) Characteristics of lipid fractions of larvae of the black soldier fly Hermetia illucens. Dokl Biochem Biophys 468(1):462–465. https://doi.org/10.1134/S1607672916030145

Caligiani A et al (2019) Influence of the killing method of the black soldier fly on its lipid composition. Food Res Int 116:276–282

Tzompa-Sosa DA, Yi L, van Valenberg HJF, van Boekel MAJS, Lakemond CMM (2014) Insect lipid profile: aqueous versus organic solvent-based extraction methods. Food Res Int 62:1087–1094

Liang Y, Hultin HO (2005) Separation of muscle membrane from alkali-solubilized fish muscle proteins. J Agric Food Chem 53(26):10012–10017

Schiavone A et al (2017) Nutritional value of a partially defatted and a highly defatted black soldier fly larvae (Hermetia illucens L.) meal for broiler chickens: apparent nutrient digestibility, apparent metabolizable energy and apparent ileal amino acid digestibility. J Anim Sci Biotechnol 8(1):1–9

Hall FG, Jones OG, O’Haire ME, Liceaga AM (2017) Functional properties of tropical banded cricket (Gryllodes sigillatus) protein hydrolysates. Food Chem 224:414–422

Nakai S, Li-Chan E (1985) Structure modification and functionality of whey proteins: quantitative structure-activity relationship approach. J Dairy Sci 68(10):2763–2772

Pelegrine DHG, Gasparetto CA (2005) Whey proteins solubility as function of temperature and pH. LWT Food Sci. Technol. 38(1):77–80

Acknowledgements

The authors would like to acknowledge that this study has been funded by the BBI Joint Undertaking under the European Union’s Horizon 2020 research and innovation program under Grant agreement No. 720715 (InDirect project).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Compliance with ethics requirements

All applicable international, national, and/or institutional guidelines for handling of the animals were followed.

Informed consent

Informed consent was obtained from all individual participants included in the study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Soetemans, L., Uyttebroek, M., D’Hondt, E. et al. Use of organic acids to improve fractionation of the black soldier fly larvae juice into lipid- and protein-enriched fractions. Eur Food Res Technol 245, 2257–2267 (2019). https://doi.org/10.1007/s00217-019-03328-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-019-03328-7