Abstract

To establish factors affecting the quality of gluten-free bread based on rice semolina supplemented with field bean semolina and improving its final quality, a new study with definitive screening design was conducted after an appropriate choice of six factors: agar–agar, water, two types of gums gum arabic and locust bean gum, and two types of starches tapioca starch and corn starch. We investigated the effect of the aforementioned parameters on specific volume, hardness, chewiness, and springiness of breads. The results showed that specific volume of gluten-free breads increased significantly (p < 0.05) with the addition of gum arabic, tapioca and corn starches, and water; addition of agar–agar, gum arabic, tapioca starch and water affected the hardness. With regard to chewiness, the results showed that gum arabic and water and also the interaction between them had a significant effect. Gum arabic, tapioca and corn starches, and water affected the springiness. In addition, we observed the interactions among the additives. For all the tested parameters, water and gum arabic had statistically significant (p < 0.0001) effect and affected all the properties of examined breads. These factors were retained for process characterization of optimized gluten-free bread. The final optimum formulation of rice/field bean contained 1.5% of gum arabic and 71.5% of water. The optimum gluten-free bread with gum arabic showed high volume, good textural, structural, and sensory qualities with high acceptability compared to the gluten-free control bread without any improver.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Celiac disease is currently one of the most common gastrointestinal diseases. It affects about 1% of the world’s population [1, 2]. Because the digestive system of patients with celiac disease is sensitive to gluten present in wheat and other prolamin containing cereals such as rye, barley, and triticale, they have to exclude gluten from their diet [3, 4]. Hence, there is an urgent need to develop gluten-free products for patients with celiac disease.

In Algeria, patients with celiac disease suffer due to the nonavailability of gluten-free products, which makes it difficult for them to follow their diet restrictions. One of the methods to improve their situation to tackle the disease is the development of traditional gluten-free products [5].

Making high-quality bread requires the presence of gluten, a protein which is responsible for the final structure of bread and also helps to retain gas bubbles and imparts a pleasing volume and texture to the bread dough system [6]. Therefore, elimination of gluten from the diet of patients with celiac disease implies greater difficulties in the bread making process such as lack of cohesion and elasticity and low gas retention capacity of the gluten-free dough. Thus, a bread without gluten displays properties such as low volume, friable texture, poor flavor, and rapid firming compared to popular wheat breads [7,8,9]. Use of bread quality improvers has become an unavoidable element in improving the quality of bakery products [10].

Recently, various gluten-free formulations have been developed with the help of nongluten components such as starches and hydrocolloids to mimic the viscoelastic properties of gluten and to improve the final quality of bread [6, 11]. With respect to the ingredients in the bread making process, rice is the most commonly used ingredient, followed by corn, as these are the two most productive cereals around the world. Furthermore, supplementation of gluten-free dough with legumes has also been previously performed [5, 12]. Corn starch and starch from tubers such as potato and tapioca are most commonly used in the manufacture of gluten-free bread [8].

Due to their functional properties, thickening agents, stabilizers and enhancers of water retention, enhancers of textural properties, and various hydrocolloids are frequently used in the formulation of gluten-free breads to improve their structural properties as well as their acceptability. Among them, hydroxypropyl methylcellulose, xanthan gums, cellulose gums, pectin, guar gum, or gum arabic are most commonly used [4, 13,14,15,16].

As starches and hydrocolloids are most frequently used in the formulation of bakery products, their combinations have also been investigated by many authors [17,18,19]. In addition, synergistic interactions between starches and gums have also been studied in recent years [20,21,22].

Most gluten-free breads manufactured with rice still have weaker physical and textural qualities than those manufactured with traditional wheat breads. Therefore, supplementation of gluten-free rice bread formulation with hydrocolloids and/or additives is often required [4]. Thus, further research in the development of gluten-free rice breads with acceptable textural and sensory properties is highly warranted.

Design of experiment is a statistical model that efficiently examines multiple parameters in a minimum number of runs, thereby helping us to optimize the factors and their interactions. During the analysis of factors, screening designs must be used to select the parameters that affect the response significantly; however, such parameters are limited and generally need a more detailed study to understand the effects of interaction between such factors [23]. Therefore, a new design called definitive screening design (DSD) with three levels has been proposed by Jones and Nachtsheim [24], which allows screening of factors to obtain information that can clarify details about their effects. In this design, secondary interactions are evenly estimated so that it provides more information about the combination effect between factors.

Thus, in this study, we used DSD approach to investigate the effect of two different starches (tapioca and corn), two different gums (gum arabic and locust bean gum), and agar–agar and their possible combinations on the textural and sensory parameters of gluten-free bread based on rice and field bean semolina.

Materials and methods

Materials

Rice semolina with particle size between 200 and 500 µm was obtained after grinding long grain white rice using a laboratory mill (LMN-100 Testchem, Radlin, Poland). The long grain white rice was purchased from Makro K&K Sp. z.o.o. (Cmolas, Poland). Rice semolina was characterized with 10.33% moisture content, 0.22% ash content, 0.50% lipid content, and 7.80% protein content. Field bean semolina (Vicia faba) (10.46% moisture, 0.50% ash, 1.03% lipid, and 30.86% protein) was obtained after grinding the dehulled bean seeds purchased from Al-Amir Company (Albehera, Egypt). Instant dry yeast was purchased from Saf-Instant (France); salt, commercial sunflower oil, and fresh eggs were purchased from a local market. Tapioca starch (extracted from cassava root—Manihot esculenta) was obtained from Thailand (exotic food, Sriracha, Thailand); corn starch was obtained from Kraków (Bezgluten, Poland); agar–agar (derived from agarose–polysaccharide polymer material extracted from algae) and gum arabic (natural gum from various species of the acacia tree derived from Africa) were purchased from NatVita (Długołęka, Poland); locust bean gum (galactomannan vegetable gum extracted from carob seeds) was obtained from China (Samic Enterprise, China, Guangdong).

Thermal properties of starches and hydrocolloids by differential scanning calorimeter (DSC)

Thermal properties of tapioca and corn starches, agar–agar, gum arabic, and locust beangum were evaluated using DSC (DSC Mettler-Toledo AG, Greifensee, Switzerland). Measurements were controlled with STARe Software. Temperature was controlled by Huber high precision thermoregulation system TC100MT, with an accuracy of ±0.01 °C.

Measurements were conducted under nitrogen atmosphere. Experiments were performed in aluminum crucibles with pin (40 μL). Empty crucible was used as a reference. Samples were thermally equilibrated at 25 °C for 10 min and then heated up to 180 °C at a heating rate of 10 °C/min. Plots of heat flow versus temperature were registered. Thermal parameters (onset, peak position, final temperature, and enthalpy of transition) were calculated using evaluation mode from STARe system.

DSD

DSD was used to study the effect of six continuous factors (k = 6; X 1 agar–agar, X 2 gum arabic, X 3 locust bean gum, X 4 tapioca starch, X 5 corn starch, and X 6 water) and their possible interactions on quality characteristics of gluten-free bread presented by four responses: Y 1 specific volume (cm3/g), Y 2 hardness (N), Y 3 chewiness (N), and Y 4 springiness.

For making DSD model, three levels for each factor are necessary −1, 0, and 1 refer to the minimal, median, and maximal concentrations of factors (Table 1). For hydration, minimal and maximal water levels were selected based on our preliminary trials, which were finalized between 65 and 78 g/100 g of formula, respectively (65 g/100 g of formula is the minimum level of water necessary to make dough and 78 g/100 g of formula is the maximum level of water necessary for the bread to be with good volume and crumb after being baked). Concentrations of added starches, gums, and agar–agar ranged according to the preliminary tests of feasibility and data published previously [4, 25,26,27] from 0 to 1% for agar–agar, from 0 to 3% for gum arabic, and from 0 to 2% for carob gum, tapioca starch (0–10% w/w), and corn starch (0–20% w/w) based on rice/field bean semolina weight.

For DSD, the minimum number of required runs is one more than twice the number of factors (2k + 1) included in one center point. For the DSD generated in this study, there were six factors and, therefore, 13 runs were required. To give more power to the design, four additional extra runs were added. Runs were conducted randomly to maximize specific volume and springiness and minimize hardness and chewiness according to the control bread without any improver. Optimization was generated by DSD using the desirability function approach.

According to Šimurina et al. [28], the desirability function approach is an optimization method useful to find the best compromise between several responses. Often there are multiple responses measured and the desirability of the outcome involves several or all of these responses. D = (d 1 × d 2 × d3…× d n )1/n where d i are the desirability indices for each response (d i = 0 least desirable; d i = 1 most desirable according to the optimization method, for example, for specific volume, if the desirability indices is close to 1 or 100%, the specific volume is optimum) and n is the number of responses in the measure. The values of experimental design and levels for each factor are shown in Table 1.

Baking tests

A formula with rice semolina and field bean semolina in a ratio of 2:1 for 100 g of formula (66.66 g of rice semolina/33.33 g of field bean semolina) was used in this study, aiming to offer a better nutritional balance in amino acids [3].

The gluten-free bread making process was performed according to Bourekoua et al. [5]. A control gluten-free bread made without any additives with 75 g water/100 g of formula, fixed according to our preliminary trials, was used. Gluten-free breads were prepared using 2% salt, 2% instant dry yeast, 10 g fresh egg, and 20 mL of sunflower oil based on rice/field bean semolina weight. Water and the additives were added according to the experimental design data (Table 1). In the first step, all the ingredients were mixed (1 min) with the exception of fresh egg and additives and left to rest for 10 min. After resting, fresh egg, additives, and rest of the water were added. The mixture was kneaded for 15 min at 25 °C. The resulting dough was weighted to 80 g on four baking molds and then subjected to proofing for 45 min at 37 °C with a relative humidity of 75–80% in a fermentation cabinet. Breads were baked in an oven for 20 min at 230 °C (Sadkiewicz Instruments, Bydgoszcz, Poland). The baked breads were allowed to cool for 1 h at room temperature prior to quality evaluation process.

Quality evaluation of gluten-free bread

Properties of the gluten-free breads were measured approximately 1 h after baking. For each analysis, four samples of bread were used.

Volume of bread was determined by millet seed displacement method according to the AACC approved method 10.05 [29], and specific volume (cm3/g) of the bread was calculated by dividing its volume by weight.

Moisture content was evaluated based on ICC 110/1 method [30].

Texture profile analysis of bread crumb was performed using a texture analyzer (ZWICK Z020/TN2S strength tester, Germany). Samples of bread crumb collected from the center of the loaf with a dimension of 30 × 30 × 20 mm were double compressed using a head equipped with a 30 mm penetrator until a 50% depth at a crosshead speed of 1 mm/s was achieved [31] and then following parameters were recorded: hardness, springiness, and chewiness.

Color of bread crumb was measured using a colorimeter 4Wave CR30-16 (Planeta, Tychy, Poland) under the following conditions light D 65; space Lab; diameter 16 mm; style 8/d. Color was determined in CIE-Lab system, where L * indicated lightness. The redness +/greenness− and the yellowness+/blueness− are denoted by a * and b * values, respectively. Data from three slices per loaf were averaged.

Analysis of crumb cells was performed by Image J software according to Gonzales-Barron and Butler [32]. 10-mm thick central slices were made on four bread loaves, and their images were captured using a scanner (HP ScanJet 3530c). The number of cells and their average size were calculated.

Thermal parameters of gluten-free breads’ crumb were measured using DSC according to the methods described above. In this instance, scanning temperatures varied from 25 to 200 °C.

Structural analysis of optimum gluten-free bread obtained by analysis of desirability function and control bread was performed using a scanning electron microscopy on dry samples. Samples of bread were freeze dried prior to analysis. Dried samples were mounted on carbon disks using a silver tape and sprayed with gold in a vacuum sublimator K-550X (Emitech, RC, Ashford, England). The VEGA LMU microscope (Tescan, Warrendale, PA, USA) operating at 30 kV was used to examine the cross-section of samples at different magnifications (100× and 400×).

For sensory evaluation, the samples were sliced mechanically (1 cm thick) and divided into eight parts [33]. The panel for sensory evaluation consisted of 52 untrained consumers (23–48 years old; 28 females and 24 males) who were habitual consumers of bread. According to a nine-point hedonic scale (1 dislike extremely, 5 neither like nor dislike, 9 like extremely), the taste, aroma, texture, and the overall acceptability of gluten-free breads were evaluated [34].

Statistical analysis

The design and analysis of experiments were performed with JMP statistical software, version 13 (SAS Institute, Cary, NC, USA). p value was used to determine if a factor is significant; as a rule, this component was compared to α value of 0.05. If the value of p was less than 0.05, the factor was significant. Data were averaged and means were compared and evaluated using one-way analysis of variance followed by the Tukey’s significant differences post hoc test, performed using STATISTICA 7.0 software (StatSoft, Inc., Tulsa, OK, USA). A statistical difference at p < 0.05 was considered significant.

Results and discussion

Thermal properties of additives

DSC parameters of the starches and hydrocolloids are shown in Table 2. For corn and tapioca starches, DSC parameters were almost similar considering their values of onset, peak, end set, and enthalpy of transition. No statistical difference between the two starches was found (p > 0.05).

Considering hydrocolloids, locust bean gum and agar–agar exhibited the lowest and the highest transition temperature and enthalpy. Agar–agar demonstrated the highest enthalpy (336.96 J/g) and highest transition temperature (97.32 °C) than locust bean gum, which showed an enthalpy of 223.99 J/g and transition temperature of 94.48 °C. For gum arabic, enthalpy value and transition temperature were found to be 261.03 J/g and 94.95 °C, respectively. Gum arabic demonstrated the highest end set temperature (165.52 °C) than that of other gums (p < 0.05). DSC parameters of gums were highly variable and depended on the natural source of the gums. The values were also affected by sample preparation and operation status of the instrument. Consequently, it is often difficult to compare data obtained from various DSC studies [26].

Comparing thermal properties of starches and hydrocolloids, we observed that hydrocolloids exhibited higher thermal properties.

Effect of factors on gluten-free bread characteristics and DSD results

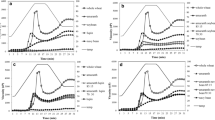

DSD model used in this study was found to be efficient because the coefficients of determination (R 2) were found to be 0.97, 0.93, 0.85, and 0.94 for Y 1, Y 2, Y 3, and Y 4, respectively, and the regression explains the phenomenon studied since the significance of the risk (p < 0.0001) is less than 0.05 for all responses.

While studying the effect of factors, a null hypothesis considering lack of difference between control and substituted bread was assumed so no observed effect on parameters. An alternative hypothesis was considered when there was a significant effect of the factors on parameters being tested. Effects were evaluated at p < 0.05. All factors that were not included in the model (p > 0.05) were screened out. The explanation for some is difficult and as it might relate to the other components of the traditional Algerian bread such as whole egg and oil that can mask the effect of some factors for different responses.

Influence of factors on specific volume

Bread loaf volume is an important parameter used in the determination and assessment of quality of bread [38]. Results in Table 3 confirm that agar–agar with a negative sign demonstrated a main significant effect (p < 0.05) on specific volume, whereas gum arabic, tapioca starch, corn starch, and water demonstrated a positive effect on specific volume. The main effect with a positive sign for a factor indicates that a high concentration of this factor is nearly optimum, and a negative sign for a factor indicates that a low concentration of this variable is nearly optimum. Gum arabic and corn starch were involved in a significant negative two-way interaction. This means that the combination of small levels of gum arabic and corn starch positively affected the specific volume of gluten-free bread.

Gum arabic showed the highest positive main effect (0.189) on specific volume indicating that the presence of this component in high concentrations in gluten-free bread can improve its volume. Asghar et al. [25] indicated that loaf volume of bread was significantly affected by the addition of gums; the maximal volume of bread was recorded at 3% of gum arabic. Agar–agar increased specific volume of bread with low levels, as indicated by Collar et al. [39]. Hydrocolloids when used in small quantities [<1% (w/w) in formula] are expected to increase water retention and loaf volume. Collar et al. [39] and Mir et al. [40] reported that the quality of gluten-free breads is primarily affected by the nature, content, and properties of hydrocolloids as these components increase dough foam stability by increasing viscosity and coalescence, preventing effects on the aqueous phase of dough and thus affecting the stability of the liquid film surrounding gas bubbles, preventing gas retention.

Positive effect of tapioca and corn starches indicates that their addition to gluten-free bread can increase its volume [4, 41]. Addition of starches to bread could help in gas retention as well as the expansion of gas bubbles during proofing and baking, and contribute to the structural architecture and mechanical strength of gluten-free bread [4].

Water showed a positive effect on specific volume of gluten-free bread. Many authors concluded that water positively affects the volume of gluten-free bread [5, 31, 42].

The combination of gum arabic and corn starch could increase the specific volume of bread significantly. Many studies referring to Mollakhalili Meybodi et al. [6] reported that the starches/gums are used in combination to improve gluten-free bread quality including volume.

Influence of factors on bread crumb texture

Hardness of bread crumb is considered as a very important quality of bread. The data from Table 4 show a range of negative effects and two-way interaction values on hardness accompanying the presence of gum arabic, tapioca starch, water at low levels, and the combination of agar–agar and gum arabic. Agar–agar and tapioca starch at low concentrations had positive effect on hardness of gluten-free bread. The only positive effect was observed for agar–agar (1.44). The presence of low levels of gum arabic and high levels of agar–agar can decrease the hardness of bread. Similarly, the presence of low levels of tapioca starch can improve the hardness of bread at high levels of agar–agar.

Mir et al. [40] reported that hydrocolloids could improve the texture of gluten-free bread. Toufeili et al. [16] also reported that incorporating gum arabic at low concentrations could decrease hardness of bread.

An interaction between gum arabic and agar–agar at low levels affects the hardness of gluten-free bread. This can be difficult to explain because as indicated by Collar et al. [39], there is a lack of information on the influence of mixtures of hydrocolloids on dough parameters and baking quality of bread. But, the interaction between agar–agar and tapioca starches can be explained by the effect of gums on rheological parameters and swelling power of tapioca, which improve bread quality [11].

According to the results presented in Table 4, only gum arabic (−1.24) and water (−0.75) showed a significant effect on chewiness of bread but with a negative sign, and the two-way interaction of both showed a positive effect which involves both the presence of gum arabic and water at high concentrations to improve chewiness of bread. Mir et al. [40] reported that hydrocolloids interact with water, reducing its diffusion and stabilizing its presence. The interaction between different dough components and water is important to the property of dough and, therefore, quality of the corresponding bread needs to be evaluated [4].

Springiness is related to aeration and elasticity of bread and high values are desired [33]. In our gluten-free bread, springiness showed different effect (Table 4). A negative effect of gum arabic indicates that improving springiness in bread requires the presence of gum arabic in small amounts. But, a positive effect of tapioca starch, corn, and water was observed which involve the addition of these factors at high concentrations to improve springiness of gluten-free bread.

For all crumb properties (hardness, chewiness, and springiness), water showed a significant effect as reported by numerous authors [5, 31].

Optimal conditions

According to the results of DSD and the results presented in Tables 3 and 4, gum arabic and water only showed a significant effect on specific volume, hardness, chewiness, and springiness at the same time. Of all the tested factors, gum arabic and water significantly affected the quality of gluten-free bread.

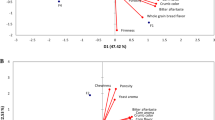

The desirability function in DSD model in the Fig. 1 shows the optimum levels of gum arabic and water to maximize specific volume and springiness and to minimize hardness and chewiness, with a desirability of 80%. Medium concentrations of these two factors were selected to improve gluten-free bread quality: 1.5% of gum arabic and 71.5 g/100 g of water.

Characteristics of optimum gluten-free bread

Characteristics of optimum gluten-free bread (specific volume, textural parameters, moisture content, and color of crumb and image analysis) are shown in Table 5 against the control bread without improver.

Specific volume of optimum gluten-free bread was higher (2.87 cm3/g) than that of control bread without improver (2.50 cm3/g). Table 5 shows that optimum gluten-free bread had an average moisture content of 28.09% which was found to be less than the control bread (32.15%). This indicates that gum arabic decreases the moisture content of bread. Textural properties of the bread supplemented with gum arabic demonstrated hardness of 14.94 N, chewiness of 4.26 N, and springiness of 0.791 for optimum gluten-free bread; however, control bread demonstrated hardness of 25.3 N, chewiness of 6.391 N, and springiness of 0.72 (p < 0.05).

Considering the color of the crumb of gluten-free optimum and control bread (Table 5), control bread appeared to be more bright because the value of L * was higher (63.37) than that of the optimum gluten-free bread (60.27) (p < 0.05). Higher value of b * of the control bread crumb may be attributed to the addition of eggs in bread recipe, thereby improving the yellow tint.

Image analysis revealed that bread with gum arabic was characterized with higher number of pores with big size compared to control bread without improvers. Optimum bread exhibited an aerated crumb structure.

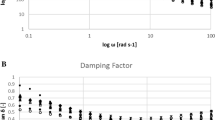

Thermal properties of gluten-free breads

The effect of addition of gum arabic on thermal properties of gluten-free bread is shown in Table 6. Regarding DSC results, control bread exhibited the highest DSC values than that of optimum bread (p < 0.05). The values of onset for control bread were higher than that of optimum bread, which means that more energy was necessary to start the gelatinization process. Lowering of onset temperature in optimum bread is important, since it implies an earlier beginning of starch gelatinization. This fact can be related to the specific interactions that take place between the different components of the optimum bread. Gum arabic as new structure-forming additive could interact with amylopectin and retard its recrystallization.

Control bread showed the highest transition temperature (115.85 °C) and the highest enthalpy (824.55 J/g) than that of optimum bread (110.61 °C transition temperature and 618.93 J/g enthalpy). The addition of gum arabic to gluten-free bread caused a decrease in enthalpy in comparison to control.

The addition of gum arabic had a significant impact on the thermal properties of gluten-free bread (p < 0.05). These results are consistent with those previously published [35, 36]. These studies reported that the addition of gums tended to lower enthalpy values. Shinoj et al. [37] reported that high transition temperatures could result from a high degree of crystallinity, which gives the starch granules a stable and more resistant structure during gelatinization. Addition of gum arabic caused a decrease in transition temperature. This phenomenon can explain the improvement of technological parameters required to prepare an optimum bread.

Microstructure of bread

Figure 2a shows the image of control bread at a magnification of 100×. Control bread demonstrated the characteristic porous structure of a baked bread with internal empty pores. Internal surface of the pores of control bread was rough and uneven as compared to smooth surface of the bread supplemented with gum arabic (Fig. 2c). Gum arabic imparted a homogenous structure to the bread (Fig. 2d), whereas control bread showed dense and compact structure (Fig. 2b). Control bread was characterized with harder structure according to the presence of visible starch particles less integrated with bread matrix than that in the optimum sample with the addition gum arabic. Swollen and ungelatinized singular starch granules were visible on rugged surface of the tested control sample (Fig. 2b) as opposed to the unified structure of the optimum bread with more amorphous and homogenous structure (Fig. 2d).

Sensory evaluation

Sensory evaluation (Table 7) showed no significant difference (p > 0.05) with respect to taste and aroma between gluten-free control bread and optimum gluten-free bread with gum arabic. Results showed that the optimum gluten-free bread showed the highest scores for appearance, texture, and overall evaluation significantly than that of the control gluten-free bread. Thus, an acceptable bread was prepared with the application of gum arabic in basic gluten-free bread recipe.

Conclusion

In this study, the effect of combination of starches/hydrocolloids on the quality of rice/field bean in gluten-free bread was evaluated using an efficient method of screening, that is, DSD. After performing statistical validation of the obtained model, we analyzed the effects of factors. DSD approach allowed the estimation of optimal conditions with significant factors such as gum arabic and water. Optimum gluten-free bread with 1.5% of gum arabic and 71.5 g/100 g of water was manufactured and tested for its characteristics. Based on the results of loaf volume, textural, structural, color, DSC, microstructure, and sensory analysis of the optimum gluten-free bread, it can be concluded that of all the selected factors (starches and hydrocolloids), gum arabic was found to be the best additive for making gluten-free rice-based bread for patients with celiac disease.

Abbreviations

- DSD:

-

Definitive screening design

- DSC:

-

Differential scanning calorimetry

References

Bellir N, Bellir MN, Rouabah L (2015) Etude de l’effet de Nigella sativa sur les manifestations cliniques de la maladie cœliaque de l’adulte. Int J Adv Res 3:880–893

Makharia GK, Verma AK, Amarchand R, Bhatnagar S, Das P, Goswami A, Bhatia V, Ahuja V, Datta Gupta S, Anand K (2011) Prevalence of celiac disease in the northern part of India: a community based study. J Gastroenterol Hepatol 26(5):894–900

Benatallah L, Zidoune MN, Michon C (2012) Optimization of HPMC and water addition for a gluten-free formula with rice and field bean based on rheological properties of doughs. Int Rev Chem Eng 4(5):474–481

Pongjaruvat W, Methacanon P, Seetapan N, Fuongfuchat A, Gamonpilas C (2014) Influence of pregelatinised tapioca starch and transglutaminase on dough rheology and quality of gluten-free jasmine rice breads. Food Hydrocolloid 36:143–150

Bourekoua H, Benatallah L, Zidoune MN, Rosell CM (2016) Developing gluten free bakery improvers by hydrothermal treatment of rice and corn flours. LWT Food Sci Technol 73:342–350

Mollakhalili Meybodi N, Mohammadifar MA, Feizollahi E (2015) Gluten-free bread quality: a review of the improving factors. J Food Qual Hazards Control 2(3):81–85

Hamaker BR (2008) Technology of functional cereal products. Woodhead Publishing Limited, Cambridge, p 538

Masure HG, Fierens E, Delcour JA (2016) Current and forward looking experimental approaches in gluten-free bread making research. J Cereal Sci 67:92–111

Sivaramakrishnan HP, Senge B, Chattopadhyay PK (2004) Rheological properties of rice dough for making rice bread. J Food Eng 62(1):37–45

Pourfarzad A, Mohebbi M, Mazaheri Tehrani M (2012) Interrelationship between image, dough and Barbari bread characteristics; use of image analysis to predict rheology, quality and shelf life. Int J Food Sci Technol 47(7):1354–1360

Singh A, Gevekea DJ, Yadav MP (2016) Improvement of rheological, thermal and functional properties of tapioca starch by using gum Arabic. LWT Food Sci Technol 80:155–162

Martinez MM, Gómez M (2016) Rheological and microstructural evolution of the most common gluten-free flours and starches during bread fermentation and baking. J Food Eng 197:78–86

Anton AA, Artfield SD (2007) Hydrocolloids in gluten-free breads: a review. Int J Food Sci Nutr 59:11–23

Gallagher E, Gormley TR, Arendt EK (2004) Recent advances in the formulation of gluten free cereal- based products. Trends Food Sci Technol 15:143–152

Rosell CM, Rojas JA, De Barber CB (2001) Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocolloid 15(1):75–81

Toufeili I, Dagher S, Shadarevian S, May Sarakbi AN, Farran MT (1994) Formulation of gluten-free pocket-type flat breads: optimization of methylcellulose, gum arabic, and egg albumen levels by response surface methodology. Cereal Chem 71(6):594–601

Kohajdová Z, Karovičová J, Schmidt Š (2009) Significance of emulsifiers and hydrocolloids in bakery industry. Acta Chim Slov 2:46–61

Lamacchia C, Camarca A, Picascia S, Di Luccia A, Gianfrani C (2014) Cereal-based gluten free food: how to reconcile nutritional and technological properties of wheat proteins with safety for celiac disease patients. Nutrients 6:575–590

Linlaud N, Puppo M, Ferrero C (2009) Effect of hydrocolloids on water absorption of wheat flour and farinograph and textural characteristics of dough. Cereal Chem 86:376–382

Chranioti C, Nikoloudaki A, Tzia C (2015) Saffron and beetroot extracts encapsulated in maltodextrin, gum Arabic, modified starch and chitosan: incorporation in a chewing gum system. Carbohydr Polym 127:252–263

Chivero P, Gohtani S, Yoshii H, Nakamura A (2016) Assessment of soy soluble polysaccharide, gum arabic and OSA-Starch as emulsifiers for mayonnaise-like emulsions. LWT Food Sci Technol 69:59–66

Sanz T, Tárrega A, Salvador A (2016) Effect of thermally inhibited starches on the freezing and thermal stability of white sauces: rheological and sensory properties. LWT Food Sci Technol 67:82–88

Fidaleo M, Lavecchia R, Petrucci E, Zuorro A (2016) Application of a novel definitive screening design to decolorization of an azo dye on boron-doped diamond electrodes. Int J Environ Sci Technol 13(3):835–842

Jones B, Nachtsheim CJ (2011) A class of three-level designs for definitive screening in the presence of second-order effects. J Qual Technol 43(1):1–15

Asghar A, Anjum FM, Tariq MW, Hussain S (2005) Effect of carboxy methyl cellulose and gum arabic on the stability of frozen dough for bakery products. Turk J Biol 29:237–241

Onyango C, Mutungi C, Unbehend G, Lindhauer MG (2011) Modification of gluten-free sorghum batter and bread using maize, potato, cassava or rice starch. LWT Food Sci Technol 44:681–686

Pahwa A, Kaur A, Puri R (2016) Influence of hydrocolloids on the quality of major flat breads: a review. J Food Process. doi:10.1155/2016/8750258

Šimurina OD, Ikonić BB, Jevtić-Mučibabić RC, Belović MM, Koprivica GB, Mišljenović NM (2012) Application of response surface methodology in the development of specialty bread with sugar beet molasses, flax seed and vital wheat gluten. Food Feed Res 39(1):11–21

AACC (2000) American Association of cereal chemists. Approved methods of the AACC, 10th ed. American Association of cereal chemists, St Paul, USA

ICC (1996) Standard methods of the International Association for cereal science and technology. Austria, Vienna

Różyło R, Dziki D, Gawlik-Dziki U, Cacak-Pietrzak G, Miś A, Rudy S (2015) Physical properties of gluten-free bread caused by water addition. Int Agrophys 29:353–364

Gonzales-Barron U, Butler F (2006) A comparison of seven thresholding techniques with the k-means clustering algorithm for measurement of bread-crumb features by digital image analysis. J Food Eng 74:268–278

Torres MD, Moreira R, Chenlo F, Morel MH (2013) Effect of water and guar gum content on thermal properties of chestnut flour and its starch. Food Hydrocolloid 33(2):192–198

Shinoj S, Viswanathan R, Sajeev MS, Moorthy SN (2006) Gelatinisation and rheological characteristics of minor millet flours. Biosyst Eng 95(1):51–59

Różyło R, Laskowski J (2011) Predicting bread quality (bread loaf volume and crumb texture). Polish J Food Nutri Sci 61:61–67

Collar C, Andreu P, Martınez JC, Armero E (1999) Optimization of hydrocolloid addition to improve wheat bread dough functionality: a response surface methodology study. Food Hydrocoll 13(6):467–475

Mir SA, Shah MA, Naik HR, Zargar IA (2016) Influence of hydrocolloids on dough handling and technological properties of gluten-free breads. Trends Food Sci Technol 51:49–57

Matos ME, Rosell CM (2012) Relationship between instrumental parameters and sensory characteristics in gluten free breads. Eur Food Res Technol 235(1):107–117

Lim HS, Park SH, Ghafoor K, Hwang SY, Park J (2011) Quality and antioxidant properties of bread containing turmeric (Curcuma longa L.) cultivated in South Korea. Food Chem 124(4):1577–1582

Larrosa VJ, Lorenzo G, Zaritzky NE, Califano AN (2012) Effect of the addition of proteins and hydrocolloids on the water mobility in gluten-free pasta formulations. Water 4:1–17

Horstmann SW, Belz MCE, Heitmann M, Zannini E, Arendt EK (2016) Fundamental study on the impact of gluten-free starches on the quality of gluten-free model breads. Foods 5(2):30. doi:10.3390/foods5020030

Schoenlechner R, Mandala I, Kiskini A, Kostaropoulos A, Berghofer E (2010) Effect of water, albumen and fat on the quality of gluten-free bread containing amaranth. Int J Food Sci Technol 45:661–669

Acknowledgements

This research was funded by the exceptional National Program. H. Bourekoua acknowledges the Financial support of Institut de la Nutrition, de l’Alimentation et des Technologies Agro-Alimentaires (INATAA). Experiments were also supported by statutory funds of Life Science University in Lublin, Poland.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Compliance with ethics requirements

The sensory evaluation was done with untrained human panel at the test room which fulfils the requirements of ISO Standards (ISO 2007). The panelists were informed about the source of the samples prior to the analysis. The samples were produced with good grade facilities.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Bourekoua, H., Różyło, R., Benatallah, L. et al. Characteristics of gluten-free bread: quality improvement by the addition of starches/hydrocolloids and their combinations using a definitive screening design. Eur Food Res Technol 244, 345–354 (2018). https://doi.org/10.1007/s00217-017-2960-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-017-2960-9