Abstract

The aim of this work is to present the results of the analysis of composition of mono-, di- and oligosaccharides, including the content of fructooligosaccharides as well as rafinose, stachyose in pseudo stalk of leek plants of the following cultivars: Shelton F1, Belton F1 and Parton F1. Leek plants were stored in cold room at the temperature 0 °C and relative humidity around 98% in the period from December to May. Fructose, glucose, saccharose, fructooligosaccharides (FOS) as well as α-galactosides were determined with the HPLC method with the application of water-alcohol extracts. It was shown that some of the studied parameters have changed during storage, i.e., the glucose content increased from 4.4 ± 0.3 to 16.2 ± 1.6, fructose from 4.7 ± 0.2 to 23.8 ± 0.4, saccharose from 5.1 ± 0.7 to 18.7 ± 0.1, depending on the cultivar and the storage period. The largest increase in the content of fructose and glucose took place between 60th and 90th day of storage which testifies to intensive hydrolysis of fructans. Leek cv. Parton F1 was characterised by the largest content of fructans and the lowest susceptibility to hydrolysis. The amount of kestose, nystose and rafinose after the period of storage changed from 0.3 ± 0.0 to 0.9 ± 0.2, 0.5 ± 0.1 to 1.8 ± 0.1, 0.8 ± 0.1 to 1.8 ± 0.2 g/100 g of dry mass, respectively. The content of stachyose, in turn, remained at a constant level and amounts to around 0.5 g/100 g of dry mass. Leek plants kept in typical refrigeration conditions are characterised by good durability and constitute a valuable merchandise. However, due to ongoing hydrolysis processes, the content of prebiotic substances decreased what lowered the health-promoting value.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Leek is a plant species belonging to the group of onion vegetables, which is derived from wild growing species: Allium ampeloprasum [1]. Leek cultivation is common in the whole Europe. In the European Union, leek cultivation covers the area of about 30 thousand hectares. The area of leek cultivation in Poland amounts to around 6–7 thousand hectares, with Mazowsze as the region of the largest leek production in Poland [1, 2]. Around 90% of harvested leek plants are sold for direct consumption, whilst 10% is stored in refrigeration conditions, frozen, dried or destined for the preparation of ready-made dishes [1].

Depending on a country leek plants are prepared for market and used by consumers in many ways. In England leek leaves are cut away and only pseudo stalks are meant for trade. In Belgium, as well as in many other countries including Poland, whole leek plants with leaves are a marketable product. Pseudo stalk is also an edible part of leek plants [3]. In Poland leek leaves are used as an addition to soups or as a component of vegetable salads.

Main components of leek are: carbohydrates 5.0–11.2 g, proteins 1.6–2.2 g, fat 0.1–0.4 g, dietary fibre 1.0–3.2 g and mineral components such as: K 248–347 mg/100 g, Ca 48–75 mg/100 g, Mg 10–11 mg/100 g, Na 5–9 mg/100 g, Cu 0.06–0.30 mg/100 g in 100 g of fresh mass as well as vitamins, i.e. Vitamin C and Vitamins of the B group [1, 4–8]. Leek (Allium porrum) is a source of nitrates as well as a rich source of sulphur volatiles like thiosulphinates and related compounds. Allium plants have high contents of inulin-type fructans—fructooligosaccharides [9, 10]. Onion contains up to 9.5 g of fructooligosaccharides in 100 g, garlic up to 6.4 g fructooligosaccharides in 100 g, [11–14] whereas leek contains from 3 to 10% of fresh mass of fructans [15].

Fructooligosaccharides stimulate the growth of specific microorganisms in the colon (e.g. bifidobacteria, lactobacilli) with generally positive health effect. A minimal daily dose of 2.5 g of fructooligosaccharides is a condition upon which a bifidogenuous effect takes place [16–18]. It shows a variety of pharmacological effects such as growth inhibition of tumour and microbial cells, reduction of cancer risk, good effects on serum lipids, blood glucose and protection against cardiovascular disease, which are attributed to fructooligosaccharides [9, 10, 19]. Apart from fructooligosaccharides, in leek there are α-galactooligosaccharides, i.e., rafinose 0.96% and stachyose 0.24% of fresh mass of leek [20]. According to Amarowicz, α-galactosides are composed of sugar chain, in which from one to four galactose molecules are connected to a saccharose molecules with a α-1,6-glicoside bond [21]. In the human digestive tract, there are no enzymes decomposing α-galactosides to monosaccharides. In an unchanged form, they are passed to the large intestine whereby they are hydrolysed under the influence of enzymes of microbiological origin, further they are metabolised by colon microflora. It is accompanied by a production of substantial quantities of gases (mainly CO2 and H2) thus disadvantageous flatulence action of rafinose and stachyose [21, 22]. On the other hand, the influence of oligosaccharides on human organism is positive because their presence in the diet stimulates the development of bifidobacteria in colon which makes them biologically active components of natural food with health-promoting activity [22, 23]. Due to its good durability under conditions of low temperature, the leek is available on the market in fresh form almost the whole year. In spite of the important position of this vegetable in human diet, there is a very limited information in the literature on the content of fructooligosaccharides and fructans (DP > 10) as well as on positive effects of these in health consumer [24].

The aim of this research was to determine the content of fructose, glucose, saccharose and low-molecule oligosaccharides in leek stored in a cold room, meant to be consumed in the autumn–winter season.

Materials and methods

The research was carried out on three leek cultivars: Belton F1, Parton F1 and Shelton F1. Leek plants cvs. Belton F1 and Parton F1 were harvested on 5th of November 2009. The storage research study was commenced on 6th of November 2009. Harvesting of Shelton F1 cultivar was carried out on 23rd of November 2009, whereas the storage research study was initiated on 24th of November 2009. Leek plants were stored at standard conditions: 0–1 °C and 98% relative humidity from November–December to May in a cold room at the Research Institute of Vegetable Crops in Skierniewice. Prior to the storage plants were prepared in the following way: roots were cut to around 1 cm length whereas whole plants were about 60 cm long. Later the plants were rinsed in water, dried and put into universal boxes lined with polyethylene liner. Plants of each cultivar were placed for storage in four repetitions, each consisting of 30 plants. Over the period of 6 months, samples were collected every month from two repetitions for the purpose of chemical analyses. Upon finishing of the storage period, the rotten external leaves of the leeks were eliminated and determined peeled from rotten external leaves and the following parameters were determined: the weight of trade leek, sick and cleared leek as well as natural shortage of weight (Table 1). The amount of leek destined for chemical analyses directly after harvesting as well as after 30, 60, 90, 120 and 150 days of storage was divided into two parts: white part (pseudo stalk) and green part (leaves) and the weight distribution of those two parts was determined. Leek pseudo stalk were was used in for this research due to its higher nutrition importance, as well as their higher oligosaccharides content in comparing with whole plant of this part of the plant as well as the richer composition of oligosaccharides. Pseudo stalk was mixed in a Zelmer mixer type 886.6 and average lab samples were prepared in order to determine the content of dry mass and saccharides.

The determination of total solids of the materials was made according to AOAC official method 920.151 [25].

Mono-, di- and oligosaccharides were extracted following the methodology described in the previous work [14]. The obtained extracts were a subject to chromatographic analysis with the application of Shodex NH2P (250 × 4 mm) column filled with aminopropyl polimer; a mobile phase acetonitryle-water mixture (72–28% v/v). The analysis was carried out using a HPLC system Knauer (Germany) equipped with a EuroChrom 2000 data control system, RI K-2301 Knauer detector (Germany). The degree of fructans hydrolysis in the researched period of leek storage was based on the increase in fructose, glucose and saccharose in 30 days’ intervals and calculated in the way described by Jamie et al. [26].

Statistics

The results were analysed using one-way ANOVA and significant differences between groups were determined by the Duncan’s Multiple Range Test. Differences were considered significant at P ≤ 0.05.

Results and discussion

The results obtained after 5 months of storage in refrigeration conditions at the temperature of 0 °C and relative humidity of 98% are presented in Table 1. Losses originated during storage process comprise: peeled leaves (rotten and sick), plants attacked by illnesses and the natural weight decreasing as a result of the plant metabolism. No significant differences were noticed in storage durability after 150 days of storage between particular leek cultivars. In spite of long storage period a high percentage of merchandise material was obtained—from 68.5% (Shelton F1 cultivar) to 71% (Belton F1 cultivar). A percentage distribution of sick plants in Parton F1 and Shelton F1 accounted for 3.7 and 5.6%, respectively, whereas for Benton F1 cultivar no sick plants were noticed. However, Benton F1 cultivar had the highest percentage of peeled leaves (27.5%) comparing with the others. Natural shortages of weight over the storage period were very low and accounted from 1.1% for Parton F1 cultivar to 1.5% for Benton F1 cultivar.

An average leek weight and calculated content of pseudo stalk in trade material of particular cultivars Belton F1, Parton F1 and Shelton F1 directly after harvesting as well as after 30, 60, 90, 120 and 150 days of storage is presented in Table 2. In case of Belton F1 and Parton F1 cultivars, the weight ratio between pseudo stalk and the whole plant after 90 days of storage increased from 54 to 70% and from 55 to 64%, respectively. In case of Shelton F1, the content of pseudo stalk in the whole plant after 120 days of storage increased from 64 to 71%. It is connected with the decrease in the weight of leaves during storage period due to decease and rotting.

The content of dry mass in pseudo stalk in three leek cultivars directly after harvesting and during storage over 150 days is presented in Table 3. There is a statistically significantly difference in dry mass content in three different leek cultivars. In leek cv. Shelton F1 the value varies from 10.6 to 14.6%, in leek cv. Belton F1 varies from 12.9 to 14.1%, whereas in leek cv. Parton F1 from 11.9 to 17.2%. In leek cv. Shelton F1 and Parton F1 the increase in dry mass by around 14% was noticed after 30 days of storage. In the later period of storage, the content of dry mass was gradually lowering. After 150 days of storage in leek of Parton F1 cv., the content of dry substance decreased by 25%, in leek Shelton F1 cv. by 18%, whereas in leek of Belton F1 cv. by 4%. It is connected with biological, chemical and physical processes taking place in stored leek.

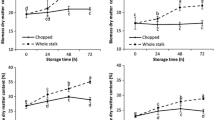

The contents of mono-, di- and oligosaccharides in leek of Shelton F1, Belton F1, Parton F1 cultivars during the storage in refrigeration conditions over the period of 5 months is shown in Table 4. Data presented in this table reveals that the content of low-molecule fructooligosaccharides, i.e., kestose and nystose as well as α-galactooligosaccharides, i.e., rafinose and stachyose varies within the range 0.2–2% calculated on dry mass of three researched cultivars during the whole storage period. The added up content of kestose and nystose differs statistically significantly taking into account both cultivars and duration of storage. The least amount of fructooligosaccharides is present in the leek of Shelton F1 cv.: from 0.9 ± 0.2 to 1.3 ± 0.4 g/100 g of dry mass, whereas the largest amount of fructooligosaccharides is present in leek of the Belton F1 cv. from 1.0 ± 0.2 to 2.7 ± 0.3 g/100 g of dry mass. A decrease in the content of kestose and nystose was noted after 90 days of storage. Average content of kestose in all three leek cultivars between 90 and 120 days of storage decreases by 43% whereas the content of nystose decreases by 34% (Fig. 1). According to Table 4 the content of rafinose in leek cv. Shelton F1 amounts from 0.8 ± 0.1 to 1.7 ± 0.2 g/100 g of dry mass, in leek cv. Belton F1 from 1.0 ± 0.1 to 1.8 ± 0.2, whereas in leek cv. Parton F1 from 1.1 ± 0.3 to 1.7 ± 0.1. However, the content of stachyose in three leek cultivars is around 50% lower and accounts to from 0.2 to 0.8 g/100 g of dry mass. (Fig. 1). Average content of kestose, nystose, rafinose and stachyose in three leek cultivars over the period of 150 days of storage amounts to 0.6 ± 0.1, 1.1 ± 0.1, 1.4 ± 0.1 and 0.8 ± 0.1 g/100 g of dry mass, respectively (Fig. 1).

The change in the content of kestose and nystose depending upon the duration of storage period is presented on Fig. 1. The presented chart indicates a slow increase in the short-chain fructooligosaccharides in the initial period of storage, relatively high level during the period of leek dormancy and a fast decrease over the period of spring activation. The presented data reveals that the content of kestose and nystose in stored leek plants is still low, in comparison with fructans of higher degree of polymerisation. According to Jane G. Muir et al. [27] leek purchased in local grocery network in Australia contain 7.1 g of fructans in 100 g of fresh mass. Figure 1 reveals a similar tendency of rafinose growth depending on the duration of storage period, whereas the content of stachyose remains at a similar level of around 0.5 g/100 g of dry mass.

On the other hand, data in Table 4 reveals that in three leek cultivars a substantial increase in the content of fructose and glucose took place during the storage period. In leek cvs. Belton F1 and Shelton F1, the increase in the content of fructose took place after 60 days of storage, respectively, from 4.7 ± 0.2 to 15.2 ± 0.3 g in 100 g of dry mass as well as from 7.2 ± 0.3 to 17.3 ± 3.7 g in 100 g of dry mass. Over the next storage periods, the increase in fructose maintained at a stable level. In leek cv. Parton F1, the increase in the fructose content took place after 90 days of storage from 7.2 ± 0.3 directly after harvesting to 15.9 ± 0.6 g in 100 g of dry mass. Over the next 60 days, the fructose content remained at a constant level and as late as after 150 days of storage the increase in the fructose content was at the level of 23.7 ± 2.5 g in 100 g of dry mass (Table 4; Fig. 2). The largest increase in the glucose content in leek of Shelton F1 and Belton F1 cultivars was observed after 60 days of storage from 6.2 ± 0.3 to 12.2 ± 2.6 and from 4.4 ± 0.3 to 10.7 ± 0.0, respectively. In the leek cv. Parton F1, the glucose content increased significantly after 90 days of storage. In three leek cultivars, the highest increase in saccharose content took place after 120 days of storage (Table 4; Fig. 2).

The increase in the fructose and glucose content over the storage period is connected with hydrolysis of fructans of DP > 3. According to literature sources in leek, there are mostly fructans of DP > 10. [12, 27, 28]. The hydrolysis of fructans takes place starting from the end of the chain. During storage of chicory roots at temperature 2–4 °C over the period of 8–9 weeks enzymes such as endohydrolase, glucosydase and egzohydrolase hydrolise, respectively, bonds of β-2,1 inuline, therminal molecule of glucose and fructose in the fructan chain [29, 30].

In stored leek, depending on the cultivar, the variable rate of increase in the fructose and glucose content is noticed, which testifies to ongoing hydrolysis of long-chain fructans to fructooligosaccharides. In leek of Shelton F1 cultivar, the increase in the content of short-chained fructooligosaccharides was noted after 30 days of storage. In the leek of Shelton F1 cultivar after 30 days of storage, the increase takes place in the content of short-chained fructooligosaccharides by 0.4 g, i.e. by 50%. In the leek of Belton F1 and Parton F1 cultivars, the largest increase in the content of kestose and nystose took place between 60 and 90 days of storage by 70 and 35%. (Table 4). Such a phenomenon is also observed in Jerusalem artichoke bulbs. During winter seasoning of bulbs in soil, a considerable part of large molecule fraction of DP > 10 is transformed into short-chained fructooligosaccharides of DP 3 ÷ 5 [31].

The calculated content of prebiotic fructans (fructooligosaccharides) as well as the degree of hydrolysis of fructans depending on the duration of the storage period is presented in Table 5. The content of fructans is variable and depends on the cultivar. The largest content of fructans was observed in leek cv. Parton F1: 5.8 g/100 g of fresh mass, whereas the least content—in cv. Belton F1: 3.8 g in 100 g of fresh mass.

During 5 months of storage, a variable degree of fructan hydrolysis in three leek cultivars was noticed. Fructans in leek of Belton F1 cultivar are subject to the fastest hydrolysis; after 30 days of storage, 26% of fructans are hydrolysed whereas after 90 days of storage 80% of fructans were subject to hydrolysis. In leek cv. Shelton F1, only after 60 days 46% of fructans were subject to hydrolysis. The leek cv. Parton F1 turned out to be the most stable towards hydrolysis of fructans, after 90 days of storage hydrolysed were 48% of fructans.

Conclusion

Leek stored in typical refrigeration conditions are characterised by good storage durability and constitute a valuable trade merchandise. In three leek cultivars stored in cold room over the period of 5 months, substantial changes in the content of fructose, glucose and saccharose as well as minor changes in the content of kestose, nystose, rafinose and stachyose were observed. Our research under storage conditions revealed a variable degree of fructan hydrolysis—from 2 to 80% of dry mass, depending on the cultivar and the duration of storage. From the nutrition point of view, leek of the selected cultivars is a good source of prebiotic fructans and fructooligosaccharides within the first 3 months of storage. In case of longer stored leek and in order to maintain a constant supply of fructans (FOS) in the diet, there is a need to increase their consumption or to use alternative prebiotics.

References

Kołota E (2004) Uprawa pora. Hortpress Sp. z o.o., Warszawa (In Polish)

De Clercq H, Peusens D, Rold′an-Ruiz I, Van Bockstaele E (2003) Euphytica 134:103–115

De Clercq H, Baert J, Van Bockstaele E (1999) Euphytica 106:101–109

Adamicki F, Czerko Z (2002) Przechowalnictwo warzyw i ziemniaka. PWRiL, Poznań (In Polish)

Byszewski W, Ostrowska D, Pala J (1978) Produkcja a jakość surowców roślinnych. PWN, Warszawa (In Polish)

Kunachowicz H, Nadolna I, Przygoda B (2005) Tabele składu i wartości odżywczej żywności. PZWL, Warszawa (In Polish)

Piekarska J, Łoś-Kuczera M (1983) Skład i wartość odżywcza produktów spożywczych. PZWL, Warszawa (In Polish)

Sánchez-Castillo CP, Dewey PJS, De Lourdes Solano M, Finney S, James WPT (1995) J Food Comp Anal 8:284–294

Magra TI, Bloukas JG, Fista GA (2006) Meat Sci 72:280–287

Irkin R, Korukluoglu M (2009) J Verbr Lebensm 4:3–6

Moshfegh AJ, Friday JE, Goldman JP, Chug Ahuja JK (1999) J Nutr 129:1407S–1411S

Praznik W, Huber A, Löppert R (2006) Characterization of Carbohydrates Occurrence and potentional of fructan plants (http://www.uni-graz.at)

Sangeetha PT, Ramesh MN, Prapulla SG (2005) Trends Food Sci Technol 16:442–457

Grzelak K, Milala J, Król B, Adamicki F, Badełek E (2009) Eur Food Res Technol 228:1001–1007

Van Bekkum H, Röper H, Voragen F (1996) Carbohydrates as organic raw materials III. CFR, The Hague, The Netherlands

Guigoz Y, Rochat F, Perruisseau-Carrier G, Rochat I, Schiffrin EJ (2002) Nutr Res 22:13–25

Rao AV (1999) J Nutr 129:1442S–1445S

Griffiths G, Trueman L, Crowther T, Thomas B, Smith B (2002) Phytother Res 16:603–615

Ngoc Ly T, Hazama C, Shimoyamada M, Ando H, Kato K, Yamauchi R (2005) J Agric Food Chem 53:8183–8189

Lee CY, Shallenberger RS, Vittum MT (1970) NY Food Life Sci Bull 1:1–12

Amarowicz R (1999) Roczn. PZH 50:89–95 (In Polish)

Wieczorek C, Lahuta LB (2007) Żywność Nauka Technologia Jakość 3(52):159–172

Darewicz M, Dziuba J, Panfil T (2003) Żywność Nauka Technologia Jakość 4(37):36–47

Brunsgaard G, Sørensen J, Kaack K, Eggum BO (1997) J Sci Food Agric 74:237–243

AOAC (2006) Official metod 920.151: solids (total) in fruits and fruit products, 16th edn. AOAC, Arlington

Jaime L, Martin-Cabrejes MA, Molla E, Lopez-Andréu FJ, Esteban RM (2001) J Agric Food Chem 49:982–988

Muir JG, Shepherd SJ, Rosella O, Rose R, Barrett JS, Gibson PR (2007) J Agric Food Chem 55:6619–6627

Darbyshire B, Henry RJ (1981) New Phytol 87:249–256

Ernest M, Chatterton NJ, Harrison PA (1995) Sci Hortic 63:251–261

Livingston DP III, Hincha DK, Heyer AG (2009) Cell Mol Life Sci 66:2007–2023

Cieślik E, Filipiak-Florkiewicz A (2000) Żywność Nauka Technologia Jakość 1(22):73–82 (In Polish)

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Grzelak-Błaszczyk, K., Kołodziejczyk, K., Badełek, E. et al. Changes in the contents of mono-, di- and oligosaccharides in leek plants stored in cold room. Eur Food Res Technol 232, 1027–1033 (2011). https://doi.org/10.1007/s00217-011-1476-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-011-1476-y