Abstract

For kinetic studies of protein nitration reactions, we have developed a method for the quantification of nitrotyrosine residues in protein molecules by liquid chromatography coupled to a diode array detector of ultraviolet-visible absorption. Nitrated bovine serum albumin (BSA) and nitrated ovalbumin (OVA) were synthesized and used as standards for the determination of the protein nitration degree (ND), which is defined as the average number of nitrotyrosine residues divided by the total number of tyrosine residues in a protein molecule. The obtained calibration curves of the ratio of chromatographic peak areas of absorbance at 357 and at 280 nm vs. nitration degree are nearly the same for BSA and OVA (relative deviations <5%). They are near-linear at low ND (< 0.1) and can be described by a second-order polynomial fit up to \( {\hbox{ND}} = 0.5\left( {{R^2} > 0.99} \right) \). A change of chromatographic column led to changes in absolute peak areas but not in the peak area ratios and related calibration functions, which confirms the robustness of the analytical method. First results of laboratory experiments confirm that the method is applicable for the investigation of the reaction kinetics of protein nitration. The main advantage over alternative methods is that nitration degrees can be efficiently determined without hydrolysis or digestion of the investigated protein molecules.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The nitration of biomolecules, including proteins, deoxyribonucleic acid (DNA), and lipids, plays an important role in biological systems and human diseases. It can trigger cellular responses ranging from subtle modulations of cell signaling to oxidative injury, committing cells to necrosis or apoptosis [1, 2]. For example, the reaction between free radicals nitrogen oxide (NO•) and superoxide (O •–2 ) under physiological conditions can form strong oxidizing and nitrating intermediates such as peroxynitrite (ONO −2 ), which can nitrate tyrosine residues in proteins [3–6]. Peroxynitrite-mediated damage has been implicated in a wide range of disease pathologies [1, 7], and nitrotyrosine has been established as a footprint of nitro-oxidative damage in vivo both in animal models and human diseases and as a biomarker of disease progression and severity in conditions such as acute and chronic inflammatory processes [7].

Franze et al. [8] found that nitration of proteins can also occur upon exposure to nitrogen oxides and ozone in synthetic gas mixtures and polluted urban air (summer smog), and they proposed that protein nitration may be a molecular rationale for the promotion of allergies by traffic-related air pollution [9, 10]. This hypothesis was supported by Gruijthuijsen et al. [11], who showed in immunological experiments with cells, mice, and human sera that nitration indeed enhances the allergenic potential of proteins. Thus, further investigations of protein nitration by air pollutants are under way, and suitable analytical techniques are required. In particular, laboratory studies characterizing the reaction kinetics of protein nitration under a wide range of well-defined experimental conditions require efficient ways of quantifying nitrotyrosine in protein molecules.

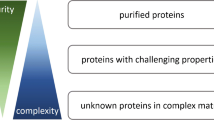

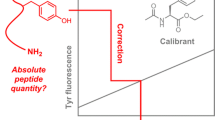

The detection and quantification methods reported for nitrotyrosine can be generally categorized into the following groups: immunochemistry, ultraviolet-visible (UV-Vis) photometry, gas chromatography (GC) coupled to a thermal energy analyzer or mass spectrometer, and high-performance liquid chromatography (HPLC) coupled to UV-Vis absorption, fluorescence, electrochemical, and mass spectrometric detectors [12–14]. Immunochemistry has been applied extensively but is generally regarded as semiquantitative [7, 13, 15, 16]. UV-Vis photometry enables the detection of nitrotyrosine as a free amino acid as well as in peptides and proteins. As illustrated in Fig. 1, tyrosine and nitrotyrosine both exhibit an absorption peak at 280 nm, and nitrotyrosine has an additional peak at ∼357 nm in acidic solutions (pH ≤3.5) or at ∼430 nm in basic solutions (pH ≥9.5) [17]. Due to low sensitivity and low specificity, the application of simple photometry is restricted to relatively pure and large amount of substance [15, 16, 18].

UV-visible spectra of tyrosine and nitrotyrosine (reprinted from Crow and Beckman [15], with permission from Elsevier)

The advantages and disadvantages of various GC and HPLC methods and related sample preparation techniques have been reviewed by Duncan [13] and Herce-Pagliai et al. [12]. In the reported GC and HPLC methods, proteins had to undergo hydrolysis or enzymatic digestion to release nitrotyrosine as a free amino acid, whereby artificial formation or loss of nitrotyrosine are of concern. Methods that account for artificial formation or loss of nitrotyrosine have been developed, but they tend to be highly labor and cost intensive. For example, Yi et al. [19] developed gas phase HCl hydrolysis followed by liquid chromatography–tandem mass spectrometry (LC–MS–MS) analysis using isotopomeric [13C6]-tyrosine as an internal standard. Walcher et al. [14] characterized nitrated proteins by LC–MS–MS analysis of oligopeptides obtained by tryptic digestion, which provides insight into the spatial distribution of nitrotyrosine residues in the protein molecule but is less suitable for efficient quantification.

In this study, we develop and present a simple, inexpensive, and robust HPLC–UV-Vis–DAD method for the determination of the protein nitration degree (ND), which is defined as the average number of nitrotyrosine residues divided by the total number of tyrosine residues in a protein molecule. Our method is based on the one developed by Crow and Beckman [17] for free nitrotyrosine. As demonstrated below, it is applicable for characterizing the reaction kinetics of protein nitration by nitrogen oxides and ozone.

Materials and methods

Materials

Bovine serum albumin (BSA; A7638-5G), ovalbumin (Grade V, A5503-5G), tetranitromethane (T25003-5G), phosphate-buffered saline (PBS) tablet (P4417-50TAB), and bicinchoninic acid assay (BCA) kit (BCA1-1KT) were obtained from Sigma-Aldrich, Schnelldorf, Germany. l-3-Nitrotyrosine (ALX-106-020-G001) was obtained from Alexis, Grünberg, Germany. Acetonitrile (ACN; ROTISOLV HPLC Gradient Grade) was obtained from Carl Roth GmbH + Co. KG, Karlsruhe, Germany. Water for chromatography (LiChrosolv) and water with 0.1% (v:v) trifluoroacetic acid (LiChrosolv) were obtained from Merck KGaA, Darmstadt, Germany. For all other purposes, high-purity water (18.2 MΩ m) was taken from an ELGA LabWater system (PURELAB Ultra, ELGA LabWater Global Operations, UK). Synthetic air, nitrogen (99.9995%), and ∼5 ppmv NO2 in N2 (99.9995%) were obtained from AIR LIQUIDE Deutschland GmbH, Germany.

Size exclusion chromatography columns PD-10 Sephadex G-25 M (17-0851-01) and PD MiniTrap G-25 (28-9180-08) were obtained from GE Healthcare, Freiburg, Germany. UV microcuvettes (Brand, 612-5688) were obtained from VWR International GmbH, Darmstadt, Germany. Syringe filters (cellulose acetate membrane, 1.2-μm pore size, 30-mm diameter, sterile. FP 30) were obtained from Whatman GmbH, Dassel, Germany. Ninety-six-well plates (Product #9017) were from Corning Incorporated, Corning, NY 14831, USA. Sealing films (SealPlate®) were from EXCEL Scientific, Inc., Wrightwood, CA 92397, USA.

Preparation of nitrated protein standards

The preparation of nitrated protein standards basically followed the optimized nitration procedure described by Franze et al. [15]. Briefly, the protein was dissolved in PBS (50 mg/ml BSA or 10 mg/ml OVA). Aliquots of the protein solution (2.5 ml) were pipetted into 20-ml glass vials with screw caps. Tetranitromethane (TNM) dissolved in methanol (4% v/v) was added in different amounts corresponding to the TNM/tyrosine ratios listed in Table 1. The reaction mixtures were stirred with Teflon-coated magnetic bars at room temperature (∼25 °C), and the reaction times were varied in the range of 35–230 min (Table 1). Each reaction mixture was then pipetted onto a PD-10 size exclusion chromatography column and eluted with water. The columns had been prewashed with 40 ml of water, and upon elution of the reaction mixtures the first 2.5 ml of the flow through was discarded, and the subsequent ∼3.5 ml of the eluate was collected. Two aliquots of the eluate were taken to determine the protein concentration (50 µl) and the concentration of nitrotyrosine residues (150 µl), respectively. The remaining eluate was dried under a high-purity N2 stream or in a freeze-drier (ALPHA 2-4 LDplus, Martin Christ Gefriertrocknungsanlagen GmbH, Germany) and stored in a refrigerator at ∼4 °C.

The protein concentration in the eluate was determined with a BCA assay. The 50 µl eluate aliquot was diluted with water to 2 ml to a concentration in the range of 200–1,000 µg/ml, and 0.1 ml of this diluted solution was then mixed with 2 ml of the BCA working reagent. After incubation at room temperature for 3–6 h, the absorbance of the solution was measured at 562 nm (UV-Vis Spectrometer, Perkin Elmer, Lambda 25) with a statistical uncertainty of ∼1.5% (relative standard deviation of triplicate measurements). The measured protein concentration was used to calculate the total amount of protein in the eluate and subsequently the recovery of protein from the nitration reaction.

The concentration of nitrotyrosine residues in the eluate was determined by dilution of the 150 µl eluate with 0.05 N NaOH into 1.5 ml solution and measurement of absorbance at 425 nm calibrated against 3-nitrotyrosine in 0.05 N NaOH (Perkin Elmer, Lambda 25) with a statistical uncertainty of ∼0.4% (relative standard deviation of triplicate measurements). The nitrotyrosine residue number per protein molecule (NTN) was then determined from the amount of substance (mol) of nitrotyrosine divided by the amount of substance of protein. For the statistical uncertainty of the calculated NTN values, we obtained an estimate of ∼1.6% by propagation of the relative uncertainties of the nitrotyrosine and protein concentration measurements (NIST reference on constants, units, and uncertainty, http://physics.nist.gov/cuu/Uncertainty/index.html). Based on the NTN value, the nitrated protein standards were designated as nitro-(NTN)-BSA or nitro-(NTN)-OVA (Table 1). The ND was calculated by dividing the NTN through the total number of tyrosine residues in a protein molecule (21 for BSA and 10 for OVA).

HPLC–DAD system and operation

The dilute protein solutions applied in the BCA assay were also analyzed with the HPLC–DAD system (Agilent Technologies 1200 Series) consisting of a binary pump (G1312B), a four-channel microvacuum degasser (G1379B), a column thermostat (G1316B), an autosampler with thermostat (G1330B), and a photo-diode array detector (DAD, G1315C). Chemstation software (Version B.03.01, Agilent) was used for system control and data analysis.

A monomerically bonded C18 column (Vydac 238TP, 250 mm × 2.1 mm i.d., particle size 5 µm, Grace Vydac, Alltech) was used for the chromatographic separation. Gradient elution was applied with 0.1% (v/v) trifluoroacetic acid in water and ACN at the flow rate of 300 µl/min. The chromatographic run started with 0.1% (v/v) trifluoroacetic acid in water, and then the ACN content was increased to 100% within 20 min. The mobile phase composition was reset to initial conditions within 10 min, and the column was equilibrated for 2 min before the next run. The absorbance was monitored with the DAD at 280 and 357 nm. The sample injection volume was 100 µl. The separation of peaks between native and nitrated proteins was not observed in our analysis. Native and nitrated proteins were eluted out as one peak. The retention time is between 12.5 and 14 min for native/nitrated BSA and 15 and 16 min for native/nitrated OVA.

Exposure of protein samples to synthetic gas mixtures

Syringe filters were prewashed with autoclaved high-purity water (18.2 MΩ m) and freeze-dried. One hundred microliters of BSA aqueous solution (∼5 mg/ml) was pipetted onto the prewashed filter and freeze-dried (∼0.2 mbar for 40∼60 min). The BSA-loaded syringe filters were then exposed to a synthetic gas flow containing variable amounts of nitrogen dioxide, ozone, and water vapor. NO2 was supplied from a gas cylinder (∼5 ppmv NO2 in N2 99.9995%) at a flow rate of 10–70 ml/min. Ozone was produced from synthetic air passing through a mercury vapor lamp (Jelight Company, Inc., Irvine, USA) at ∼1.5 l/min. At the end of a dark flow tube (∼ 4 l), inside which NO2 in N2 and O3 in synthetic air have been mixed (residence time ∼2.5 min), water vapor was introduced by passing an N2 flow at ∼1.0 l/min through a washing bottle filled with autoclaved high-purity water. The relative humidity achieved in the gas mixtures was between 30% and 50%. The concentrations of the trace gases and water vapor were measured with commercial monitoring systems (NO x analyzer, 42i-TL, Thermo SCIENTIFIC; ozone analyzer, 49i, Thermo SCIENTIFIC; the humidity detector, ALMEMO 2390-3, AHLBORN, Mess und Regelungstechnik GmbH, Germany).

The BSA-loaded syringe filters were exposed to the gas mixtures for 1–7 days and then extracted with water (6 ml). The extract was freeze-dried (∼0.8 mbar for ∼24 h until dry), redissolved in 0.5 ml of water, and pipetted onto a PD MiniTrap G-25 column that had been prewashed with 8 ml of water. The flow through was discarded, and the column was eluted with 1 ml of water. The eluate was collected and used for analysis with HPLC–DAD to determine nitration degree values for the products of the exposure experiments and for determination of protein concentration by BCA assay to subsequently calculate the protein recovery rate. Because the amount of the sample is small, BCA assay based on 96-well plate was employed. Briefly, three portions of 25-µl solution were taken for every standard or sample and pipetted into a 96-well plate for triplicate measurements. Two hundred microliters of BCA working reagent was then added. The 96-well plate was sealed with a sealing film; the samples were incubated for 3–6 h at room temperature (∼25 °C), and the absorbance of the solutions was measured with MULTISKAN EX (Thermo Electron Corporation) at 560 nm.

Results and discussion

Characterization of nitrated protein standards

Nitrated protein standards were prepared by reaction of BSA and OVA with TNM at different molar ratios and reaction times, and their ND was determined by UV-Vis photometry as detailed above (“Preparation of nitrated protein standards”). Within the investigated range of experimental conditions (Table 1), the ND values exhibited only a weak dependence on reaction time but a strong dependence on the molar ratio of TNM to tyrosine residues (TNM/Tyr). As illustrated in Fig. 2, with increasing TNM/Tyr ratio up to ∼14, the observed increase of ND was near-logarithmic for BSA and near-linear for OVA. The nitration of tyrosine residues within a protein depends on three main factors: the protein structure, the nitration mechanism, and the chemical environment of the protein [20]. As the nitration of both BSA and OVA was carried out in vitro with TNM and the reaction conditions were essentially the same, the different dependencies of ND on the TNM/Tyr ratio for BSA and OVA are likely due to the different protein structures of BSA and OVA.

Nitration degree vs. molar ratio of TNM to tyrosine residues (TNM/Tyr) for nitrated protein standards of bovine serum albumin (BSA) and ovalbumin (OVA) synthesized by reaction with TNM in liquid phase. The error bars represent the statistical uncertainty of the analytical method (±3 s). They do not include uncertainty due to the variability of reaction conditions. The lines are least-square fits (logarithmic for BSA, linear for OVA)

The average recovery rates of the protein standards after nitration by TNM and cleanup with size exclusion chromatography column were 73.1 ± 14.3% for nitrated BSA (n = 17) and 94.8 ± 9.2% for nitrated OVA (n = 25; arithmetic mean ± standard deviation). At higher TNM/Tyr ratios, we observed precipitation of yellowish solids from the reaction mixture, which is likely due to a cross-linking of protein molecules as a result of the reaction of two TyrO˙ radicals [20].

Determination of nitration degrees by HPLC–DAD

Figure 3 shows the HPLC–DAD calibration curves obtained with the nitrated protein standards. The relations between nitration degree and the ratio of absorbance peak areas at 357 and 280 nm (A357/A280) can be described by second-order polynomials (R 2 > 0.99). At low nitration degrees (ND <0.2), they are near-identical for BSA and OVA (relative deviations <2%). Even at high nitration degrees (ND ∼ 0.5), the relative deviations between the BSA and OVA calibration curves (∼5% at ND = 0.5) are not much higher than the statistical uncertainty of A357/A280 (∼2% relative standard deviation of nine replicate measurements), suggesting that one single calibration curve can be applied for determining the nitration degrees of different types of nitrated proteins.

Calibration curves plotting the ratio of absorbance peak areas at 357 and 280 nm (A357/A280) against the nitration degree of nitrated protein standards for BSA (red), OVA (blue), and all samples (dark), respectively. The error bars are relative standard deviations (±3 s). The solid lines are quadratic least-square fits

At the low nitration degrees that are most relevant for kinetic experiments with nitrating gas mixtures (ND ≤0.1; “Exemplary application in kinetic experiments”), the calibration curves can be fitted by linear regression (R 2 > 0.99, Fig. 4a).

Calibration lines plotting the ratio of absorbance peak areas at 357 and 280 nm (A357/A280, a) or just the absorbance peak area at 357 nm (A357, b) against the nitration degree (ND) of nitrated BSA standards measured with different chromatographic columns and at different time. The error bars are relative standard deviations (±3 s), and the lines are linear least-squares fits

As illustrated in Fig. 4a, the calibration curve of absorbance peak area ratio A357/A280 vs. ND remained essentially unchanged when the chromatographic column of the HPLC system was exchanged, which demonstrates high robustness of our method. In contrast, an alternative calibration approach using the peak area A357 instead of the peak area ratio A357/A280 was strongly influenced by the change of chromatographic column (Fig. 4b).

With regard to ND, the detection limit of our method is 0.0005 based on the standard deviation of nine consecutive replicate measurements with unnitrated BSA (3-s method). This corresponds to a concentration of 0.054 pmol/µl of nitrotyrosine residues in the investigated protein solution samples (4.3 pmol in 80 µl), which is comparable to the detection limit of 16 pmol nitrotyrosine per 80-µl injection volume reported by Crow and Beckmann for free nitrotyrosine [15]. The statistical uncertainty of the ND values determined by our method is 2.5% (relative standard deviation of nine replicate measurements).

Exemplary application in kinetic experiments

Exemplary applications of the analytical method in our kinetic studies of protein nitration are illustrated in Figs. 5 and 6. Figure 5 shows two series of experiments in which BSA was exposed to synthetic gas mixtures of NO2 and O3 for 1–7 days. In one series, protein samples were exposed to 102 ± 1.9 ppb NO2 and 110 ± 3.5 ppb O3; in the other series, they were exposed to 212 ± 8.5 ppb NO2 and 209 ± 5.7 ppb O3 (arithmetic mean ± standard deviation). The relative humidities in the two experiments were 41 ± 0.8% and 37 ± 0.4%, respectively (arithmetic mean ± standard deviation). The exposures were carried out at room temperature (∼22 and ∼21 °C, respectively).

Nitration degrees plotted against exposure time for BSA exposed to synthetic gas mixtures of NO2 and O3 at ∼40% relative humidity. The error bars represent the statistical uncertainty of the analytical method (±3 s). They do not include uncertainty due to the variability of reaction conditions. The lines are least-square fits with a pseudo-first-order kinetic rate equation \( {\hbox{ND}} = {\hbox{N}}{{\hbox{D}}_{{ \max }}}\left( {{1} - {{\hbox{e}}^{ - kt}}} \right) \) as discussed in the text

Nitration degrees plotted against exposure time for OVA exposed to synthetic gas mixtures of NO2 and O3 at ∼40% relative humidity. The error bars represent the statistical uncertainty of the analytical method (±3 s). They do not include uncertainty due to the variability of reaction conditions. The analytical uncertainties for OVA are higher compared to BSA in this case because the solubility of OVA decreased significantly after being exposed to the gases and thus caused extra uncertainties during the analysis by LC–DAD. The solid line is a least-square fit with a pseudo-first-order kinetic rate equation \( {\hbox{ND}} = {\hbox{N}}{{\hbox{D}}_{{ \max }}}\left( {1 - {e^{ - kt}}} \right) \) as discussed in the text

At ∼100 ppb NO2 + O3, the ND of BSA was ∼0.01 after 1 day of exposure and continued to increase steadily up to ∼0.04 after 5 days. At ∼200 ppb NO2 + O3, the ND was ∼0.025 after 1 day and reached a nearly constant plateau level of ∼0.055 after 4 days. Both curves can be fitted with a pseudo-first-order kinetic rate equation \( {\hbox{ND}} = {\hbox{N}}{{\hbox{D}}_{{ \max }}}\left( {{1} - {{\hbox{e}}^{ - kt}}} \right) \), where NDmax is the maximum nitration degree, k is a pseudo-first-order rate coefficient, and t stands for reaction time. The fitted pseudo-first-order rate coefficient k is 0.0053 ± 0.0039 h−1 (coefficient values ±95% confidence interval) at ∼100 ppb NO2 + O3 and 0.0249 ± 0.0061 h−1 at ∼200 ppb NO2 + O3. The maximum nitration degree achieved upon exposure of BSA to NO2 and O3 (∼0.055) is by an order of magnitude lower than upon nitration with TNM in aqueous solution (∼0.5). The differences can be attributed to the different reactants, conditions, and mechanisms [18], which will be further investigated in follow-up studies.

Figure 6 shows a series of experiments in which OVA was exposed to synthetic gas mixtures of NO2 and O3 for 1–7 days. In this experiment, protein samples were exposed to 208 ± 0.9 ppb NO2 and 207 ± 4.3 ppb O3 (arithmetic mean ± standard deviation). The relative humidity in the experiment was 41 ± 0.3% (arithmetic mean ± standard deviation). The exposures were carried out at room temperature (∼22 °C).

At ∼200 ppb NO2 + O3, the ND of OVA was ∼0.03 after 1 day of exposure and continued to increase steadily up to ∼0.07 after 5 days. A curve was also fitted with the same pseudo-first-order kinetic rate equation as for BSA. The fitted pseudo-first-order rate coefficient k is 0.0175 ± 0.0103 h−1 (coefficient values ± 95% confidence interval) at ∼200 ppb NO2 + O3. The maximum nitration degree achieved upon exposure of OVA to NO2 and O3 (∼200 ppb) is ∼25% higher than that of BSA. Recovery of OVA after the exposure experiments is lower compared to BSA at the same NO2 + O3 concentration, likely due to cross-linking of OVA molecules during exposure to the gases. The higher ND and lower recovery seem to indicate that OVA is more reactive to NO2 + O3 than BSA.

At this point, the exemplary applications illustrate that the developed analytical method is suitable for efficient determination of the nitration degree of the products formed upon exposure of proteins to gaseous nitrating agents.

Conclusions

Nitrated protein standards of BSA and OVA were synthesized by reaction with TNM in liquid phase. The NDs of the protein standards were determined by UV-Vis photometry and exhibited a pronounced dependence on the TNM/tyrosine molar ratio. For BSA, the dependence was steeper and near-logarithmic, for OVA, it was less steep and near-linear. The differences in reactivity are likely due to the different molecular structures of the proteins. The standards were used to develop an HPLC–DAD method for direct determination of the nitration degree of proteins. The calibration curves of A357/A280 vs. ND were nearly the same for nitrated BSA and OVA and did not change upon exchange of the chromatographic column. The applicability of the analytical method for kinetic investigations of protein nitration was demonstrated by exemplary experiments in which BSA or OVA was exposed to synthetic gas mixtures of NO2, O3, and water vapor. The increase of ND observed upon gas exposure could be described by a pseudo-first-order rate equation. The maximum values of ND (∼0.055 and 0.07 for BSA and OVA, respectively) were by an order of magnitude lower than upon nitration with TNM (∼0.5), which can be attributed to the different reactants, conditions, and mechanisms.

References

Pacher P, Beckman JS, Liaudet L (2007) Physiol Rev 87:315–424

Halliwell B, Whiteman M (2004) Br J Pharmacol 142:231–255

Beckman JS, Beckman TW, Chen J, Marshall PA, Freeman BA (1990) Proc Natl Acad Sci U S A 87:1620–1624

Beckman JS, Ischiropoulos H, Zhu L, Vanderwoerd M, Smith C, Chen J, Harrison J, Martin JC, Tsai M (1992) Arch Biochem Biophys 298:438–445

Beckmann JS, Ye YZ, Anderson PG, Chen J, Accavitti MA, Tarpey MM, White CR, Beckman JS (1994) Biol Chem Hoppe Seyler 375:81–88

Ischiropoulos H, Zhu L, Chen J, Tsai M, Martin JC, Smith CD, Beckman JS (1992) Arch Biochem Biophys 298:431–437

Greenacre SAB, Ischiropoulos H (2001) Free Radic Res 34:541–581

Franze T, Weller MG, Niessner R, Poschl U (2005) Environ Sci Technol 39:1673–1678

Pöschl U (2005) Angew Chem Int Edit 44:7520–7540

Traidl-Hoffmann C, Thilo J, Heidrun B (2009) J Allergy Clin Immun 123:558–566

Gruijthuijsen YK, Grieshuber I, Stoecklinger A, Tischler U, Fehrenbach T, Weller MG, Vogel L, Vieths S, Poschl U, Duschl A (2006) Int Arch Allergy Immunol 141:265–275. doi:10.1159/000095296

Herce-Pagliai C, Kotecha S, Shuker DEG (1998) Nitric Oxide 2:324–336

Duncan MW (2003) Amino Acids 25:351–361

Walcher W, Franze T, Weller MG, Poschl U, Huber CG (2003) J Proteome Res 2:534–542

Franze T, Weller MG, Niessner R, Pöschl U (2003) Analyst 128:824–831

Franze T, Weller MG, Niessner R, Poschl U (2004) Analyst 129:589–596

Crow JP, Beckman JS (1995) Methods (Orlando) 7:116–120

Crow JP, Ischiropoulos H (1996) Nitric oxide, Pt B. Academic, San Diego, pp 185–194

Yi D, Ingelse BA, Duncan MW, Smythe GA (2000) J Am Soc Mass Spectrom 11:578–586

Bartesaghi S, Ferrer-Sueta G, Peluffo G, Valez V, Zhang H, Kalyanaraman B, Radi R (2007) Amino Acids 32:501–515

Acknowledgements

This study has been funded by the Max Planck Society (MPG). YZ is supported by International Max Planck Research School for Atmospheric Chemistry and Physics. The authors gratefully acknowledge support by M. O. Andreae and W. Elbert.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Yang, H., Zhang, Y. & Pöschl, U. Quantification of nitrotyrosine in nitrated proteins. Anal Bioanal Chem 397, 879–886 (2010). https://doi.org/10.1007/s00216-010-3557-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-010-3557-3