Abstract

Canada possesses significant potential in harnessing renewable energy from its vast and diverse geography, which can generate clean electricity. This paper presents a model that replaces fossil fuels used in a proposed thermal power plant in Point Aconi, Nova Scotia, with photovoltaic and wind turbine units based on the region’s climate conditions. The research results are based on evaluating multiple thermal power plants worldwide and examining various wind turbines and PV panels from different companies to ensure accuracy. The chosen units that best suit the location’s geographical and biological conditions, transmission, and operation costs demonstrate that the power plant currently consumes approximately 47 tons of coal and petroleum coke per hour. Replacing these materials with the proposed green units makes it possible to reduce environmental pollution by eliminating almost 165 tons of CO2 and other pollutants per hour while increasing the plant’s efficiency and independence from fossil fuel price variations. The presented structure’s ROI is approximately 20 years, which is reasonable compared to the economic and environmental benefits of utilizing such a structure and converting the thermal power plant to green units.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

1.1 General background of the research study

Modern life has led to a continuous increase in electricity demand [1, 2]. As a result of the observed increase, there has been a corresponding escalation in environmental pollution emissions and climate change, largely attributed to the impact of greenhouse gas emissions [3,4,5]. Thermal power plants play a critical role in powering our societies. However, their reliance on fossil fuels, such as coal, petroleum, and natural gas, has released pollutants into the environment. Despite these concerns, thermal power plants remain essential for meeting the increasing demand for electricity, thanks to their significant output capacity. The various types of thermal power plants include coal, petroleum, nuclear, geothermal, waste incineration plants, and natural gas power plants [6, 7]. The thermal power plant operates by heating water within a boiler, resulting in the evaporation of said water. This evaporation induces turbine blades’ movement through high-pressure steam [8, 9]. The Rankine cycle is a well-established thermal power plant process that comprises four essential components: a boiler, turbine, condenser, and pump. This process is widely used in the energy industry due to its simplicity and efficiency in generating power. The system works by converting heat energy into mechanical energy, which can then be used to generate electricity. Each component plays a vital role in the overall process, and the system’s efficiency depends on the proper functioning of all parts.

Overall, the Rankine cycle remains a critical process in the energy industry, and its continued use ensures reliable and sustainable power generation [10, 11]. The boiler plays a critical role in providing superheated steam to the turbine stage through heat input. Recent research endeavors have explored various aspects of the boiler section, including an in-depth analysis of mathematical models and simulations. Several recent studies have also presented comprehensive surveys of these models and simulations to enhance our understanding of this crucial component [12,13,14]. Recent investigations have led to attempts to improve the performance and efficiency of boilers. This has been achieved by ensuring that the superheated steam maintains constant pressure and temperature. As a result, the boiler and power plant’s overall safety and efficiency have significantly improved [15,16,17]. It is worth noting that the conventional design and construction of thermal power plants have traditionally centered around the first law of thermodynamics, with a key focus on energy conservation. However, in recent times, the discovery of the exergy criterion, which is grounded in the second law of thermodynamics, has gained widespread acceptance in the design and enhancement of thermal power plant units, with an emphasis on energy quality [18, 19].

During the early part of the nineteenth century, discourse surrounding climate change emerged following the discovery of the inherent greenhouse effect. As humanity’s comprehension of the various aspects and ramifications of global warming on the planet’s ecological system expanded, apprehension regarding the unregulated consumption of fossil fuels grew [20,21,22]. The burning of coal has been identified as a primary source of carbon dioxide (CO2), sulfur dioxide (SO2), nitrogen oxides (NOx), mercury, and heavy metals such as fly ash and bottom ash. These harmful substances have prompted international agreements and guidelines to reduce greenhouse gas emissions. In order to achieve this goal, it is imperative to decrease or eliminate the use of thermal power plants, which are significant contributors to environmental pollution. A recent report by Carbon Brief indicates that approximately 80 countries across the globe rely on coal power plants, which generate nearly 40% of the world’s total electricity output [23,24,25]. Canada currently runs a fleet of 16 coal-fired power plants that generate approximately 10,000 MW of electricity [26]. The following sections review the latest research studies to declare the most significant findings and work in this field. Moreover, the main key points are presented to help the presented paper’s novelty for understanding future readers.

1.2 Survey on the recent research studies

Several recent studies have addressed the issues of assessing the life span of thermal power plants. Steinmann et al. determined the uncertainty of CO2 and CH4 emissions for 364 United States (US) coal power plants via Monte Carlo simulation. As a result, they could implement a framework for separating variability and uncertainty in the CO2 trace of coal-fired power plants. It helps to reduce the uncertainty in the range of non-predicted emissions [27]. Ren et al. used previous studies and experiments on coal-fired power plants to determine the spatial and temporal distribution of SO3 emissions. Also, the effect of dust collectors and desulfurization systems on the amount of SO3 emissions was investigated [28].

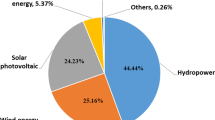

Moreover, various methods were implemented to reduce the pollution of thermal power plants, including the combined cycle power plant, which involved some gas turbines and steam turbines. The exhaust gases of the steam turbines, which can reach temperatures of up to 600 °C, were used as a heat or preheat source requirement for the steam turbine boiler [29]. The growth of industrial societies, besides the growing need for energy on the one hand, and the limited and unequal distribution of fossil fuels (oil, gas, coal) energy worldwide on the other hand, along with the environmental concerns of excessive consumption of fossil fuels, has led governments to think about alternative energies. The most important features of green energies are purity, availability, and renewability [30]. Therefore, using alternative energies, such as energy generated by wind, solar, biomass, geothermal, and water (hydropower or waves), is at the forefront of government planning. According to the International Energy Agency (IEA), the contribution of renewable energies in providing diverse countries’ needs for electricity by 2018 has been about 11% of total energy consumption [31]. Although renewable energies seem to have a long way to go in competing with other energies, many countries are planning to expand the use of these resources shortly, and therefore, they have invested dramatically in technical research and expert planning in this area.

The utilization of wind turbines as a source of green energy has been on the rise, with an annual increase of over 25%. Wind power is highly accessible and widely available; however, it only contributes a small fraction of the global energy supply [32, 33]. Wind energy is commonly harnessed through towering turbines that can reach heights of up to 600 feet, each equipped with three lengthy blades [34]. Improvement and development of wind turbines are continuing, and researchers have investigated this field [35]. Mishnaevsky et al. considered applications of composite materials like natural composites, hybrid, and nano-engineered composites with their modeling and testing approaches in the manufacturing of wind turbines in a review paper [36]. Hansen analyzed the shape mode of the particular turbine and found differences in the blades’ backward and forward whirling modes [37]. Azadeh et al. developed a computer program for optimizing wind turbine blades according to several criteria [38]. Chiu et al. quantified and investigated the impact of aerodynamic performance, structural performance, and reduced aerodynamic loads of biplane wind turbine blades.

Moreover, optimal mass and mass-driving constraints in realistic loads were considered [39]. Kusiak and Song presented a model to capture the maximum wind energy of wind farms based on the wind distribution function. The model considered wake losses based on wind turbine locations and wind direction [40]. Charhouni et al. optimized the wind farm using the genetic algorithm (GA) for different wind turbine types [41]. Rumsey and Paquette investigated structural health monitoring and NDT system setups for monitoring wind turbine structures from a fatigue test of a carbon-epoxy and glass–epoxy wind turbine blade [42]. Feng et al. examined gearbox failure modes and detection methods of incipient gearbox failures by the supervisory control and data acquisition (SCADA) and condition monitoring system (CMS) [43]. Kusiak and Verma used the power, rotor, and blade pitch curves to monitor the wind farm’s performance [44]. Liu et al. utilized decision trees to predict the wind turbine voltage output based on online information and show prediction results by lights to help operators in wind farms understand intuitive risk levels [45].

Solar energy is a prevalent form of renewable energy that is widely accessible and found in most regions worldwide. Several technologies are utilized to convert solar irradiation into usable energy, with one such technology being solar cells or photovoltaic cells. These cells are responsible for converting sunlight into electrical energy and are predominantly composed of silicon. The efficiency and cost of these cells vary depending on the type—non-crystalline, polycrystalline, or crystalline. Assembled in a specific configuration, panels comprise a collection of cells. Manufacturers have developed panels with varying attributes and qualities, such as nominal maximum power, module efficiency, and nominal module operating temperature, to suit various applications, including residential, commercial, and utility-scale photovoltaics [46]. Kabir et al. discussed the advantages and disadvantages of solar technology and analyzed the future of solar energy according to the regulation policy frameworks. Results depict that research projects should decrease solar usage costs and improve efficiency and competitiveness with conventional resources and other renewable energies [47]. Vorobiev et al. investigated semiconductor materials at high temperatures with two different options and different band-gap quantities that could be suitable and efficient [48]. Peng and Lee reviewed silicon nanowires (SNW) for photovoltaics and assessed recent developments in SNW to obtain an SNW with high performance and reasonable cost [49]. Zhu et al. studied the potential applications of various carbon materials in photovoltaic cells (PVCs), such as silicon-based solar cells, organic solar cells, and dye-sensitized solar cells. Results show that carbon utilization in PVCs still needs more investigation to enhance efficiency [50]. Skoplaki and Palyvos surveyed the effective and appropriate performance temperature of silicon-based photovoltaic panels and provided an appropriate tabulation that helps the modeling and design process according to the solar energy’s potential [51]. Ghiassi-Farrokhfal et al. assessed allocating a specific budget to solar panels and storage to maximize expected income. Their results show that allocating the budget for storage reduces the funding for solar panels, and storage devices are incomplete.

Furthermore, they present a power commitment approach for problem optimization [52]. Mallor et al. presented a new method to detect outliers or faults in PV solar farms. Data from this method were created based on two stages: the first stage, by outlier detection methods and functional principal component analysis, and in the second stage, parametric methods and three nonparametric methods [53]. Zhou et al. analyzed hybrid solar–wind energy systems’ simulation, control, and optimization. This study evaluated new research methods and developments by considering the performance of combined solar and wind systems [54]. Yang et al. optimized the annual cost and losses of hybrid solar–wind systems by five decision variables: the PV’s module number, module slope angle, wind turbine number, wind turbine installation height, and battery capacity [55].

1.3 The main research hypothesis and critical points

This paper investigates a techno-economic analysis and modeling for substituting the inlet fossil fuels of a thermal power plant by combining solar and wind power plants (hybrid solar–wind) according to Nova Scotia (Canada) geographical and biological conditions. The case study of this research is Point Aconi’s thermal power plant, with a capacity of about 171 MW. Many thermal power plants worldwide are examined, and the one with the best conditions and the ability to exert and reach the assumed aims is selected. Therefore, the output power generated by renewable resources (instead of coal and petroleum coke) is applied and delivered to electrical boilers designed and considered concerning the requirements and consumption. Many factors, such as solar irradiance and wind speed of the site in different months of the year, the possibility of wind turbines shut down due to bird migration, flicker, and noise issues, as well as land issues for construction wind and solar farms, participate in the proposed study. Furthermore, various turbines and panels of several companies with different characteristics are checked and evaluated to show precision and select the best concerning the critical factors for the presented research study.

According to the above, the main key points and novelties of the paper are proposed as follows:

-

Using RERs as the input sector of thermal power plants instead of coal and petro coke.

-

Planning has been done by considering the geographical and environmental conditions of Nova Scotia.

-

Various turbines and panels of several companies with different characteristics have been examined.

-

Environmental pollution and expansion planning costs have decreased.

-

The return on investment has been reasonably acceptable compared to the amount of pollution reduction.

-

The penetration of clean energies to overcome climate change has grown.

1.4 The arrangement of the presented paper

The rest of the paper is organized as follows: Point Aconi’s power plant details and the site’s regional climate and characteristics are explained in parts 2 and 3, respectively. Section 4 expresses the equations, equipment selection, and proposed model of the renewable-thermal power plant. Section 5 dedicates to the numerical results, discussion, and diverse analyses, and eventually, in Sect. 6, the conclusion is brought.

2 Point Aconi power plant specifications

Nova Scotia is a thin peninsula on Canada’s southeast coast, and its maximum distance from the sea is 34 miles. The Point Aconi Generating Station (shown in Fig. 1), which burns a mix of coal and petroleum coke, is placed on the shores of the Cabot Strait at the northeastern tip of Boularderie Island (Latitude: 46.32, Longitude: − 60.32). PAGS started work four years after construction in January 1990, and it is the largest generating unit in Nova Scotia and Cape Breton province. PAGS has one 171 MW unit (nameplate capacity) and uses a circulating fluidized bed (CFB), which Finland’s Ahlstrom Pyropower drew to reduce emissions of NOx and SO2 [56]. PAGS’s boiler was the world’s largest CFB plant and the first in North America [57]. PAGS burns 22 tons of bituminous coal and 25 tons of petroleum coke per hour, and the drum-type reheat of the CFB boiler has been designed to provide 1,207,150 lb/hr of steam (maximum continuous rating) at 1800 psi and 1000 F [58]. Also, it accounts for approximately 15% of total coal power plants in the province and emits 1,188,377 tons of CO2 (roughly 17% of the total emission of Nova Scotia), according to the 2017 annual report [59].

3 Regional climate

3.1 Temperature and climate conditions

According to meteoblue’s latest 30-year data, January and February have the lowest temperatures of the year; in return, June and August have the highest temperatures. The average annual temperature variation is shown in Fig. 2 [60].

According to Solar Atlas’s Normal irradiation data, the average vertical radiation of about 7 months a year is approximately the same, but the difference is in the number of effective daily hours. It should be noted that hours with an average irradiation of less than 80 Wh/m2 have been ignored when designing solar power plants for the proposed study. The average direct normal irradiation and the number of days’ efficient hours in different months are shown in Fig. 3 [61].

3.2 Wind conditions

Based on the Global Wind Atlas’s information, wind speed variation over the month each day changes between 6.3 and 10.5 m/s. The change rate for each month is almost the same, as shown in Fig. 4 [62]. Moreover, hourly wind speed data in 2019 show that wind speeds are higher at higher altitudes and at night, which helps to generate more power.

3.3 Bird migration

Despite the development in utilizing wind energy, the side effects of wind turbines should be noted. In other words, one of the issues in the planning that should be included in the design of wind farms concerns the birds’ migration and the period of the wind turbine’s blackout. According to bird life data, there are nine major routes of intercontinental bird migrations. The closest to the Point Aconi site is the Atlantic American Flyway, which is almost the appropriate distance from the study area [63], as illustrated in Fig. 5. Special attention has been paid to details to obtain valid results. In other words, it can generate continuous power throughout the year and does not require the compulsory shutdown of wind turbines.

4 Main equipment selection

According to the climate and local potentials, panels and wind turbines are selected to provide the required power for the inlet fuel, substituting the thermal power plant. Figure 6 shows the proposed model of the combined power plant. Critical characteristics and features of the selected panels and turbines are shown in Table 1.

The panel’s output power depends on various parameters such as ambient temperature, cell temperature, humidity, and irradiation level. Equations (1) and (2) are utilized to calculate the output power of PV panels [30, 64].

where.

\({P}_{\text{PV}.\text{STC}}, {G}_{T,\text{STC}}, \gamma , {N}_{\text{PV}s}, {N}_{\text{PV}p}, {T}_{\text{amp}}\), and NOCT are maximum test power in STC (standard test conditions), solar radiation in STC (standard test conditions) (kW/m2), power-temperature coefficient, the numeral of series cells in the PV module, the numeral of parallel cells in PV module, environmental temperature (°C), and normal operating cell temperature (°C), respectively. The wind turbine output power is calculated based on Vestas’s standard chart, as illustrated in Fig. 7.

5 Numerical results evaluation and discussion

This section is divided into various subsections in which numerical results evaluation and many analyzing approaches related to the research study are explained.

5.1 The numerical results analyzing of the proposed study

Given that one of the purposes of this paper is to replace the fossil fuels needed by thermal power plants; initially, the amount of energy input of PAGS has been calculated by using heating values of 22 tons of bituminous coal and 25 tons of petroleum coke per hour, as are shown in Table 2.

According to the total inlet power calculated based on Table 2, two optimal combined solar and wind power plants with a minimal actual output power of 405 MW have been designed. According to Table 3, the output power of the panels for three temperature ranges of the mean daily maximum and the mean daily minimum temperature based on Eqs. (1) and (2) have been computed and expressed. Figure 8 shows that May, June, and April have had the most monthly energy production because of more daily hours with more effective radiation levels.

As shown in Fig. 9 and according to the 2019 temperature data of the Point Aconi region, the probability of mean daily minimum temperature occurrence has been much higher than the probability of mean daily maximum temperature. Therefore, the proposed model design has been considered based on the worst-case scenario to ensure that the appropriate design of the solar power plant has been done. In other words, other scenarios could generate more energy than expected.

The amount of energy produced has been calculated according to the turbine selection (Table 2) and wind characteristics, which are shown in Fig. 10. Calculations have illustrated that wind energy generation is higher in cold seasons and at night, which can compensate for the shortage of energy production by solar power plants during these seasons. Figure 11 depicts that the probability of appropriate wind conditions and speeds exceeding 7.5 (m/s) during the day was about 16% in August. However, based on Fig. 10, the minimum wind speed was about 6.3 (m/s) during the year, and in August, the performance of solar energy generation was acceptable, which compensated for the shortage of wind energy generation.

After determining the environmental information and selecting the main and proper equipment, the optimal dimensions of the combined power plant, the total cost, and the fuel-substituting effects of the power plant by renewable energies on environmental pollution reduction have been analyzed. The cost function of the new hybrid-thermal power plant has been defined by (3).

where \({\lambda }_{1}\) and \({\lambda }_{2}\) are the total installation cost of solar and wind energy, respectively, and \({W}_{\text{name} \text{plate}.S}\) and \({W}_{\text{name} \text{plate}.W}\) are the designed nameplate capacity of solar and wind power plants. The price variations of bituminous coal and petroleum coke are shown in Fig. 12. Analysis of long-time variations in the price of petroleum coke and coal fuels has demonstrated that these constantly change according to global conditions; however, these do not fall from their overall average price. The total installation costs have been based on reported data from the International Renewable Energy Agency (IRENA), which have been considered for determining the total cost in this paper (Table 4). As shown in Table 4, the reserve margin for increasing the system’s overall reliability has been considered in the design of the proposed renewable-thermal power plant. The reserve margin has been assumed to be about 10% (405 + 40 MW).

According to Fig. 12, coal and petroleum coke combustion costs are 60 $/ton and 220 $/ton, respectively. This means that the total cost could be around 60 million dollars per year for the consumption of fossil fuels for the PAGS. In other words, over a period of about 20 years, it can compensate for the construction cost of its renewable power plants just by removing fossil fuels. Moreover, eliminating or reducing the fossil fuels needed by thermal power plants (especially coal-fired plants) can help to reduce greenhouse gas emissions and advance the Paris Agreement in 2016. Furthermore, Fig. 13 shows the results and positive impacts of substituting inlet fuels (with renewable resources) to reduce GHG emissions of the proposed PAGS.

The thermal power plant’s total emission of various pollutants [67]

Regarding the efficiency of the proposed model and based on all explanations and evaluations, the total efficiency of renewable energy resources has always been high. At least during the last decade, moral progress has been made. In other words, the technologies utilized all these years ensure good yield (wind and solar). In return, fossil fuel-based units have not been very efficient. The critical and significant problem that should not be ignored is their emissions and their consequences (lung and cardiac issues, the destruction of construction structures over time due to acid rainfall, global warming, climate change, and much worse problems). Some of the reasons that fossil fuels are still used have been their lower price, the lack of investors’ attention (for investing in RERs), and the insignificance of environmental issues in governments’ thoughts and public beliefs.

In conclusion, the technologies utilized for RERs during these years have made significant progress, and therefore, the efficiency of RERs, especially the common ones (solar, wind), has been acceptable; however, it can always be better. Furthermore, when each wind, solar, and electric boiler’s efficiency has been proper, their combination can also be appropriate and more efficient than fossil fuel-based units. In other words, an efficient system can be achieved if the planners choose the most efficient technology for each of them, considering the geographical, environmental, and economic conditions.

5.2 Life cycle assessment explanation and analysis (LCA)

The life cycle assessment (LCA) is a technique used to assess the environmental impact of a model, product, or service throughout its entire life cycle. It looks at the whole system, from the initial raw material extraction and manufacturing to the use, repair, maintenance, final disposal, or recycling. LCA is a holistic approach that quantifies the environmental impact of a model, product, or service. The LCA process is divided into four key steps:

-

1.

Goal and Scope Definition: This step involves defining the purpose and boundaries of the assessment. This includes selecting the functional unit, the product system, the life cycle stages, and the impact categories to be included in the assessment.

-

2.

Inventory Analysis: This step involves collecting data about the product system, such as the energy and raw materials consumed, the air, water, and solid waste generated, and the emissions released into the environment.

-

3.

Impact Assessment: This step includes assessing the environmental impact of the product system. This involves quantifying emissions and resource use, as well as the evaluation of effects on human health and the environment.

-

4.

Interpretation: This step involves interpreting the results of the assessment. This includes evaluating the environmental impact and identifying opportunities for improving the environmental performance of the product system.

As mentioned, life cycle thinking is an important concept in sustainability. It encourages considering the entire life cycle of a system or model, from raw material extraction to disposal, when assessing its environmental and social impacts; this allows for a better understanding of the potential impacts of a proposed model or service and making informed decisions that are environmentally and socially responsible. Life cycle thinking helps to consider the full scope of impacts associated with actions and to develop strategies that reduce the environmental and social impacts of the models and services. The potential benefits of conducting an LCA include identifying opportunities for reducing environmental impacts, reporting model design decisions, improving environmental performance, and increasing public awareness of environmental issues. LCA can also support environmental policies and regulations and provide evidence for environmental claims. Therefore, by looking at the proposed model and numerical results, based on the mentioned explanation, it can be understood that the impacts of exerting such a system positively affect the environmental aspects; therefore, it has avoided emitting about 165 tons of CO2 and other pollutants. Figure 14 demonstrates the LCA’s different steps and their relations.

5.3 The return on investment explanations and analysis (ROI)

Return on investment (ROI) measures the profit or loss generated from an investment. It is calculated by taking the total net income from the investment and dividing it by the total cost of the investment (Fig. 15). The resulting figure is expressed as a percentage, which is the ROI. ROI is a valuable metric for assessing the profitability and efficiency of an investment. It can be used to compare investments and determine the potential return on a proposed investment. According to the numerical results, the cost of burning coal and petroleum coke per year for the PAGS has been estimated to be around 60 million dollars. Over the period of 20 years, this cost could be used to offset the construction costs of renewable power plants by substituting fossil fuels with renewable energy sources. The higher the return on investment, the more profitable the investment.

5.4 The energy analysis and definition

Energy analysis is understanding how energy is used in a system (proposed model), typically focusing on energy flow into, through, and out of the system. The analysis involves understanding the sources of energy, how energy is utilized, and how energy is wasted. The analysis results can be used to identify improvement opportunities and assess the system’s environmental impact. Energy analysis is an important tool for reducing operational costs and promoting sustainability. Since the presented model has utilized RERs and electric boilers for its purposes, and the operating and maintenance costs have been lower, it could demonstrate positive results if the energy analysis is performed. In other words, as the whole system’s efficiency has enhanced compared to the conventional unit, the energy analysis results can also be satisfying by considering this type of modeling.

5.5 General pros and cons of this approach

Using electric boilers supplied by renewable energy resources in a thermal power plant in Nova Scotia, Canada, instead of burning coal and oil, has several advantages and disadvantages. From a positive point of view,

-

1-

Environmental benefits: By using renewable energy sources to power electric boilers, the thermal power plant can significantly reduce its carbon footprint and greenhouse gas emissions. This can help combat climate change and improve air quality in the region.

-

2-

Energy efficiency: Electric boilers are generally more efficient than traditional coal or oil-fired boilers, leading to lower energy consumption and operating costs.

-

3-

Renewable energy integration: By incorporating renewable energy sources into the power generation process, the thermal power plant can contribute to the growth of the clean energy sector and support sustainable development.

-

4-

Energy security: Using electric boilers powered by renewable energy sources can enhance energy security by reducing dependence on fossil fuels that are subject to price fluctuations and supply disruptions. On the other side, it also has limitations and constraints that could impact this type of planning; in other words,

-

1-

Cost implications: The initial investment required to install electric boilers and renewable energy infrastructure may be higher compared to traditional coal or oil-fired boilers. This could potentially increase electricity prices for consumers.

-

2-

Reliability concerns: Renewable energy sources such as wind and solar power are intermittent, which could lead to fluctuations in electricity generation and potential reliability issues for the thermal power plant.

-

3-

Grid integration challenges: Integrating a large amount of renewable energy into the grid can pose technical challenges related to grid stability, voltage control, and frequency regulation.

-

4-

Limited capacity: The capacity of electric boilers powered by renewable energy sources may be limited compared to traditional coal or oil-fired boilers, which could impact the overall output of the thermal power plant.

-

5-

Briefly, while using electric boilers supplied by renewable energy resources in a thermal power plant in Nova Scotia has several environmental and economic benefits, there are also challenges related to cost, reliability, grid integration, and capacity limitations that need to be carefully considered before implementing this approach. Policymakers and stakeholders need to weigh these pros and cons carefully when making decisions about transitioning toward cleaner energy solutions in the region.

5.6 Inertia in the power system by this approach

In the context of a thermal power plant transitioning from burning coal and oil to using electric boilers powered by renewable energy resources in Nova Scotia, Canada, it is essential to understand the concept of inertia in the power system. Inertia in a power system refers to its ability to maintain stable operation in the face of disturbances, such as sudden changes in load or generation. Traditional thermal power plants, like those using coal and oil, inherently possess a significant amount of inertia due to the rotating mass of turbines and generators. This inertia helps stabilize the system by resisting sudden changes in frequency caused by fluctuations in supply or demand. However, when transitioning to electric boilers powered by renewable energy sources like wind or solar, the inertia of the system can be affected. A decrease in system inertia can impact the stability of the power grid, as it may become more susceptible to frequency deviations caused by sudden changes in generation or load. Without sufficient inertia, the grid may experience frequency fluctuations that can lead to instability or even blackouts if not properly managed. In order to address this challenge, grid operators must implement measures to enhance the inertia of the system. This can include integrating energy storage systems or utilizing advanced control algorithms to mimic the stabilizing effects of inertia. Moreover, maintaining a diverse mix of generation sources, including those with high levels of inertia, can help ensure grid stability during the transition to renewable energy. Overall, while the transition to electric boilers powered by renewable energy resources offers significant environmental benefits, it is crucial to consider the impact on system inertia and implement appropriate measures to maintain grid stability.

5.7 Power system infrastructure and expansion planning

Transitioning to electric boilers supplied by renewable energy resources would require significant upgrades to the existing power system infrastructure. Firstly, the transmission and distribution network would need to be expanded and upgraded to accommodate the increased demand for electricity from the electric boilers. This may involve building new transmission lines, substations, and distribution networks to ensure that the electricity generated from renewable sources can be efficiently delivered to the thermal power plant. In terms of handling a large number of solar panels and wind turbines, the power system would need to be equipped with advanced grid management technologies such as smart meters, energy storage systems, and demand response programs. These technologies can help balance the intermittent nature of renewable energy sources and ensure a reliable supply of electricity to the thermal power plant. The impact on the whole power system would be significant but ultimately positive. By transitioning to electric boilers supplied by renewable energy resources, the thermal power plant would reduce its carbon emissions and reliance on fossil fuels. This would help Nova Scotia meet its climate goals and contribute to a more sustainable energy future.

6 Conclusions

In this paper, we have presented a new approach to using local renewable energy to substitute the inlet fossil fuels of thermal power plants. The case study is Point Aconi’s power plant in Canada, which has a capacity of 171 MW, and its consumption fuel is bituminous coal and petroleum coke. PAGS was the first CFB thermal power plant in the region and North America, accounting for about 15% of the region’s coal-fired power plant. The renewable-thermal power plant that we designed based on renewable sources’ local potential and the combination of wind and solar power plants to increase the model’s reliability, which helped compensate for each power plant’s shortage at specific times. The renewable-thermal power plant reduced fossil fuel emissions; therefore, about 1.45 million tons of environmental pollutants can be removed yearly (eliminating almost 165 tons of CO2 and other pollutants per hour). Also, over nearly 20 years, it could compensate for the construction cost of its renewable power plants. In other words, the return on investment was reasonably acceptable compared to the amount of pollution reduction. The plan presented in this study prevents the closure of newly established thermal power plants due to laws and prohibitions on the continued release of environmental pollutants. The superiority of renewable-thermal power plants over biomass power plants is to release lower pollution and the lack of harmful chemicals due to burning various materials and preventing deforestation. Due to the use of electric boilers in the renewable-thermal power plant, the boiler’s efficiency could be much higher than that of the standard boiler, which was close to 98%. Electric heating could be steadier than combustion, which caused the production of better quality steam and reduced the moisture content of the steam; as a result, lower maintenance costs were achieved, and less damage was done to the turbine’s blades.

Abbreviations

- CMS:

-

Condition monitoring system

- CO2 :

-

Carbon dioxide

- CFB:

-

Circulating fluidized bed

- DER:

-

Distributed energy resources

- DG:

-

Distributed generation

- GA:

-

Genetic algorithm

- GHG:

-

Greenhouse GAS

- IRENA:

-

International Renewable Energy Agency

- IEA:

-

International Energy Agency

- LCA:

-

Life cycle assessment

- NOCT:

-

Normal operating cell temperature

- NOx :

-

Nitrogen oxide

- PVC:

-

Polyvinyl chloride

- PAGS:

-

Point Aconi Generating Station

- PV:

-

Photovoltaic

- ROI:

-

Return on investment

- RER:

-

Renewable energy resources

- STC:

-

Standard test condition

- SO2 :

-

Sulfur dioxide

- SNW:

-

Silicon nanowires

- SCADA:

-

Supervisory control and data acquisition

- WT:

-

Wind turbine

References

Firoozi H et al (2022) Active building as an electricity network service provider. Active building energy systems: operation and control. Springer, Berlin, pp 273–293

Shaterabadi M, Mehrjerdi H, Jirdehi MA (2023) How INVELOX can affect the perspective of renewable energy exploitation: demand response and multilateral structure planning outlook. Sustain Cities Soc 91:104421

Jirdehi MA, Shaterabadi M (2020) Incentive programs caused by the carbon capture utilization and storage technology profit’s effect: optimal configuration and energy planning of hybrid microgrid involving INVELOX turbine. Energ Technol 8(10):2000398

Jirdehi MA, Shaterabadi M (2021) A low-carbon strategy using INVELOX turbines in the presence of real-time energy price uncertainty. Greenhouse Gases: Sci Technol 11(3):461–482

Shaterabadi M, Sadeghi S, Jirdehi MA (2024) The role of green hydrogen in achieving low and net-zero carbon emissions: climate change and global warming. Green hydrogen in power systems. Springer, Berlin, pp 141–153

Khattak M et al (2016) Common types of fuels in steam power plant: a review. J Adv Res Fluid Mech Thermal Sci 23:1–24

Jirdehi MA et al (2022) Impact of diverse penetration levels of thermal units on a hybrid microgrid energy management considering the time of use and function priority. Appl Therm Eng 217:119164

Ishigai S (1999) Steam power engineering: thermal and hydraulic design principles. Cambridge University Press, Cambridge

Lin X et al (2020) Thermo-economic analysis of typical thermal systems and corresponding novel system for a 1000 MW single reheat ultra-supercritical thermal power plant. Energy 201:117560

Sonntag RE, Van Wylen GJ, Borgnakke C (2008) Fundamentals of thermodynamics. Wiley, Hoboken

Kler AM, Potanina YM, Marinchenko AY (2020) Co-optimization of thermal power plant flowchart, thermodynamic cycle parameters, and design parameters of components. Energy 193:116679

Maffezzoni C (1997) Boiler-turbine dynamics in power-plant control. Control Eng Pract 5(3):301–312

Ul Haq E et al (2016) Modeling and simulation of an industrial steam boiler. Int J Comput Eng Inform Technol 8(1):7

Madejski P, Żymełka P (2020) Calculation methods of steam boiler operation factors under varying operating conditions with the use of computational thermodynamic modeling. Energy 197:117221

Taler J et al (2019) Mathematical model of a supercritical power boiler for simulating rapid changes in boiler thermal loading. Energy 175:580–592

Trojan M (2019) Modeling of a steam boiler operation using the boiler nonlinear mathematical model. Energy 175:1194–1208

Chauhan SS, Khanam S (2019) Enhancement of efficiency for steam cycle of thermal power plants using process integration. Energy 173:364–373

Razzaq M, Hossain S, Ahamed J (2019) Energy and Exergy investigation of a thermal power plant boiler.

Feng Z-K et al (2019) A mixed integer linear programming model for unit commitment of thermal plants with peak shaving operation aspect in regional power grid lack of flexible hydropower energy. Energy 175:618–629

Maity JP et al (2014) Microalgae for third generation biofuel production, mitigation of greenhouse gas emissions and wastewater treatment: present and future perspectives–A mini review. Energy 78:104–113

Shaterabadi M et al (2022) Energy management systems of grid-connected active buildings. Active building energy systems: operation and control. Springer, Berlin, pp 251–271

Shaterabadi M, Jirdehi MA, Amiri N (2022) Impact of fuel price increasing policies on fuel smuggling and acceptance of green cars: a case study of Iran. J Eng 2022(12):1239–1248. https://doi.org/10.1049/tje2.12181

Akbari-Dibavar A et al (2021) Economic-emission dispatch problem in power systems with carbon capture power plants. IEEE Trans Ind Appl 57(4):3341–3351

Ye L-C, Lin HX, Tukker A (2019) Future scenarios of variable renewable energies and flexibility requirements for thermal power plants in China. Energy 167:708–714

Shaterabadi M, Jirdehi MA (2021) Smart scheduling of transmission line switching: optimization of multi-objective microgrid’s day-ahead energy scheduling with considering high penetration of green energies and INVELOX. Electr Eng 103:1753–1767

Kumar TS et al. (2018) Experimental analysis of glazed windows for green buildings. In: 2018 2nd international conference on green energy and applications (ICGEA). IEEE.

Steinmann ZJ et al (2014) A methodology for separating uncertainty and variability in the life cycle greenhouse gas emissions of coal-fueled power generation in the USA. Int J Life Cycle Assess 19(5):1146–1155

Ren Y et al (2020) Sulfur trioxide emissions from coal-fired power plants in China and implications on future control. Fuel 261:116438

Goebel K (1974) Combined gas-steam power plant.

Shaterabadi M et al (2020) Enhancement the economical and environmental aspects of plus-zero energy buildings integrated with INVELOX turbines. Renew Energy 153:1355–1367. https://doi.org/10.1016/j.renene.2020.02.089

Reddy S et al (2016) Modeling of carbon capture technology attributes for unit commitment in emission-constrained environment. IEEE Trans Power Syst 32(1):662–671

Amiri N et al (2021) A comprehensive review on design, monitoring, and failure in fixed offshore platforms. J Marine Sci Eng 9(12):1349

Shaterabadi M et al (2023) Green roof positive impact on changing a Plus-ZEB to drastic Plus-ZEB: The multi-objective energy planning and audit in real condition outlook. Energy Build 287:112983

Abdulqader NAW (2018) Simple environmental treatments for heat transfer of building ceilings. In: 2018 international conference on advanced science and engineering (ICOASE). IEEE.

Shaterabadi M, Jirdehi MA (2020) Multi-objective stochastic programming energy management for integrated INVELOX turbines in microgrids: a new type of turbines. Renew Energy 145:2754–2769

Mishnaevsky L et al (2017) Materials for wind turbine blades: an overview. Materials 10(11):1285

Hansen M (2003) Improved modal dynamics of wind turbines to avoid stall-induced vibrations. Wind Energy: Int J Progr Appl Wind Power Convers Technol 6(2):179–195

Azadeh A, Maghsoudi A, Sohrabkhani S (2009) An integrated artificial neural networks approach for predicting global radiation. Energy Convers Manage 50(6):1497–1505

Chiu PK, Roth-Johnson P, Wirz RE (2020) Optimal structural design of biplane wind turbine blades. Renew Energy 147:2440–2452

Kusiak A, Song Z (2010) Design of wind farm layout for maximum wind energy capture. Renew Energy 35(3):685–694

Charhouni N, Sallaou M, Mansouri K (2019) Realistic wind farm design layout optimization with different wind turbines types. Int J Energy Environ Eng 10(3):307–318

Rumsey MA, Paquette JA (2008) Structural health monitoring of wind turbine blades. In: Smart sensor phenomena, technology, networks, and systems 2008. International Society for Optics and Photonics.

Feng Y et al (2013) Monitoring wind turbine gearboxes. Wind Energy 16(5):728–740

Kusiak A, Verma A (2012) Monitoring wind farms with performance curves. IEEE Trans Sustain Energy 4(1):192–199

Liu P et al (2017) Design of wind turbine dynamic trip-off risk alarming mechanism for large-scale wind farms. IEEE Trans Sustain Energy 8(4):1668–1678

Soga T (2006) Nanostructured materials for solar energy conversion. Elsevier, Amsterdam

Kabir E et al (2018) Solar energy: potential and future prospects. Renew Sustain Energy Rev 82:894–900

Vorobiev Y et al (2006) Thermal-photovoltaic solar hybrid system for efficient solar energy conversion. Sol Energy 80(2):170–176

Peng KQ, Lee ST (2011) Silicon nanowires for photovoltaic solar energy conversion. Adv Mater 23(2):198–215

Zhu H et al (2009) Applications of carbon materials in photovoltaic solar cells. Sol Energy Mater Sol Cells 93(9):1461–1470

Skoplaki E, Palyvos JA (2009) Operating temperature of photovoltaic modules: a survey of pertinent correlations. Renewable Energy 34(1):23–29

Ghiassi-Farrokhfal Y et al (2015) Optimal design of solar PV farms with storage. IEEE Trans Sustain Energy 6(4):1586–1593

Mallor F et al (2017) A method for detecting malfunctions in PV solar panels based on electricity production monitoring. Sol Energy 153:51–63

Zhou W et al (2010) Current status of research on optimum sizing of stand-alone hybrid solar–wind power generation systems. Appl Energy 87(2):380–389

Yang H, Wei Z, Chengzhi L (2009) Optimal design and techno-economic analysis of a hybrid solar–wind power generation system. Appl Energy 86(2):163–169

Xuan A et al (2022) Two-stage planning for electricity-gas coupled integrated energy system with carbon capture, utilization, and storage considering carbon tax and price uncertainties. IEEE Trans Power Syst 38:2553

Kralovic P (2011) North American natural gas market dynamics: shale gas plays in North America: a Review. CERI.

Bevilacqua P et al. (2018) Water-energy related aspect of extensive green roofs: the role of evapotranspiration. In: 2018 IEEE international conference on environment and electrical engineering and 2018 IEEE industrial and commercial power systems Europe (EEEIC/I&CPS Europe). IEEE.

Lu X, Lai J, Yu X (2020) A novel secondary power management strategy for multiple AC microgrids with cluster-oriented two-layer cooperative framework. IEEE Trans Industr Inf 17(2):1483–1495

Saeed MH et al (2021) A review on microgrids’ challenges & perspectives. IEEE Access 9:166502–166517

Ju C et al (2017) A two-layer energy management system for microgrids with hybrid energy storage considering degradation costs. IEEE Trans Smart Grid 9(6):6047–6057

Choobineh M, Silva-Ortiz D, Mohagheghi S (2018) An automation scheme for emergency operation of a multi-microgrid industrial park. IEEE Trans Ind Appl 54(6):6450–6459

Arciniega PJ et al. (2021) An energy management system for power exchange between multiple residential neighborhood microgrids. In: IECON 2021–47th Annual Conference of the IEEE Industrial Electronics Society. IEEE.

Tabar VS, Jirdehi MA, Hemmati R (2017) Energy management in microgrid based on the multi objective stochastic programming incorporating portable renewable energy resource as demand response option. Energy 118:827–839

Li F et al (2020) Decentralized cooperative optimal power flow of multiple interconnected microgrids via negotiation. IEEE Trans Smart Grid 11(5):3827–3836

Nabavi SA et al (2021) Deep learning in energy modeling: Application in smart buildings with distributed energy generation. IEEE Access 9:125439–125461

Zhang W, Xu Y (2018) Distributed optimal control for multiple microgrids in a distribution network. IEEE Trans Smart Grid 10(4):3765–3779

Funding

Open Access funding provided by the Qatar National Library.

Author information

Authors and Affiliations

Contributions

Nima Amiri: “Methodology, Software, Formal analysis.” Mohammad Shaterabadi: “Supervision, Visualization, Software, Reviewing, and Editing.” Lazhar Ben-Brahim: “Writing – review & editing, Formal analysis, Conceptualization.” Mehdi Ahmadi Jirdehi: “Investigation, Validation, Data Analyzing.”

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Amiri, N., Shaterabadi, M., Ben-Brahim, L. et al. Assessing the eco-environmental aspects of fossil fuels-based units substitution of Point Aconi thermal power plant by green-based energies: a case study of Canada. Electr Eng (2024). https://doi.org/10.1007/s00202-024-02482-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00202-024-02482-w