Abstract

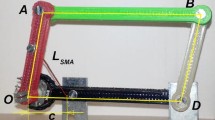

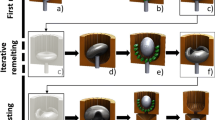

Nickel–titanium (NiTi) shape memory alloy (SMA) actuated electromechanical applications are becoming widespread in many mechatronics systems. In the thermal overload electromechanical relays (EMRs), the bimetallic strips which provide one-dimensional linear motion are used for activation. In this study, the actuation of the thermal overload EMR system is provided using the NiTi SMAs with novel EMR designs instead of traditional bimetallic strips. Two different nickel–titanium shape memory alloy-actuated thermal overload relays are designed to provide thermal overload protection for varied mechatronics systems. The displacement parameter of the designs is extracted from the established constitutive model for the NiTi SMA-actuated thermal overload relay. The developed antagonistic design structures provide functionality which is convenient for the thermal overload relays. Additionally, the developed NiTi SMA-actuated thermal overload relay designs can function in varied electrical current ranges compared to the traditional bimetallic EMRs which need to be produced separately for different electrical current ranges.

Similar content being viewed by others

References

Elahinia M, Shayesteh Moghaddam N, Taheri Andani M, Amerinatanzi A, Bimber B.A, Hamilton R.F (2016) Fabrication of NiTi through additive manufacturing: a review. Progress in Materials Science

Leng J, Yan X, Zhang X, Huang D, Gao Z (2016) Design of a novel flexible shape memory alloy actuator with multilayer tubular structure for easy integration into a confined space. Smart Mater Struct 25:2

Schneider D, Lauer M, Voigt I, Drossel WG (2016) Development and examination of switchable heat pipes. Appl Thermal Eng 99:857–865

Hartl D, Lagoudas CD (2007) Aerospace applications of shape memory alloys. J Aerosp Eng 221(4):535–552

Dilibal S (2013) Investigation of nucleation and growth of detwinning mechanism in martensitic single crystal NiTi using digital image correlation. Metallogr Microstruct Anal 2:242–248

Nespoli A, Besseghini S, Pittaccio S, Villa E, Viscuso S (2010) The high potential of shape memory alloys in developing miniature mechanical devices: a review on shape memory alloy mini-actuators. Sensor Actuat A-Phys 158:149–160

Browne A, Johnson N, Wittorf M (2012) Energy harvesting, storing, and conversion utilizing shape memory activation, patent US 8.104.278 B2

Sreekumar M, Nagarajan T, Singaperumal M, Zoppi M, Molfino R (2007) Critical review of current trends in shape memory alloy actuators for intelligent robots. Indus Robot 34:285–294

Hegana A, Hariharan SI, Engeberg E (2016) Electromechanical conversion of low temperature waste heat via helical shape memory alloy actuators. IEEE/ASME Trans Mechatron 21:1434–1444

Pierce M, Mascaro S (2013) A biologically inspired wet shape memory alloy actuated robotic pump. IEEE/ASME Trans Mechatron 18:536–546

Mazzolai B, Margheri L, Cianchetti M, Dario P, Laschi C (2012) Soft-robotic arm inspired by the octopus: II. from artificial requirements to innovative technological solutions. Bioinspiration & Biomimetics

Engeberg E, Dilibal S, Vatani M, Choi J, Lavery J (2015) Anthropomorphic finger antagonistically actuated by SMA plates. Bioinspiration & Biomimetics

Dilibal S., Engeberg E.D. (2015) Finger-like manipulator driven by antagonistic NiTi shape memory alloy actuators, IEEE Int. Conference on Advanced Robotics, Istanbul

Silva A, Santos A, Souto C, Araujo C, Silva S (2013) Artificial biometric finger driven by shape-memory alloy wires. Artif Organs 37:965–972

Andrianesis K, Tzes A (2014) Development and control of a multifunctional prosthetic hand with shape memory alloy actuators. J Intell Robot Syst 78:257–289

Lu Y, Chung JL (2013) Detecting and solving the coordination curve intersection problem of overcurrent relays in subtransmission systems with a new method. Electric Power Syst Res J 95:19–27

Elmitwally A, Gouda E, Eladawy S (2015) Optimal allocation of fault current limiters for sustaining overcurrent relays coordination in a power system with distributed generation. Alex Univ Eng J 54:1077–1089

http://www.teledynerelays.com/hi-rel.asp, accessed 15 May 2016

Mahaffey TR (2002) Electromechanical relays versus solid-state: each has its place. Electronic Design 50:19

Mengshoel OJ, Darwichse A, Cascio K, Chavira M, Poll S, Uckun S (2008) Diagnosing faults in electrical power systems of spacecraft and aircraft, IAAI’08 Proceedings of the 20th national conference on Innovative applications of artificial intelligence, 31699-1705

Venkataraman B, Godsey B, Premerlani W, Shulman E, Thakur M, Midence R (2005) Fundamentals of a motor thermal model and its applications in motor protection. In: Pulp and Paper Industry Technical Conference

Khosravifard A, Ebrahimi R (2010) Investigation of parameters affecting interface strength in Al/Cu clad bimetal rod extrusion process 31–1:493–499

Kyriakides E, Hadjistassou C, Georgiou J (2012) A new memristor based on NiTi smart alloys, IEEE International Symposium on Circuits and Systems, 1403–1406

Liangliang G, Yong L, Teng YN (2014) An investigation on the crystal structure of Ti\(_{50}\)Ni\(_{50-{\rm x}}\)Cu\(_{\rm {x}}\) shape memory alloys based on density functional theory calculations. Intermatalics 53:20–25

Bhattacharya K (2003) Microstructure of martensite. Oxford Series on Materials Modeling, Oxford

Mohamed B (2010) Mathematical modeling and control of nonlinear oscillators with shape memory alloys. Dissertation, Wilfrid Laurier University

Guoa Z, Pana Y, Weeb LB, Yu H (2015) Design and control of a novel compliant differential shape memory alloy actuator. Sens Actuator A-Phys 225:71–80

Piccirillo V, Goes LCS, Balthazar JM (2009) A shape memory alloy oscillator: regular and chaotic behavior, using basin of attractions approach. In: Proceedings of COBEM 2009

Paiva A, Savi MA (2006) An overview of constitutive models for shape memory alloys. Mathematical problems in engineering 1–30

Ashish K, Vidyashankar B (2009) Models for shape memory alloy behavior: an overview of modeling approaches. Int J Struct Changes Solids Mech Appl 1:111–148

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dilibal, S., Sahin, H., Dursun, E. et al. Nickel–titanium shape memory alloy-actuated thermal overload relay system design. Electr Eng 99, 923–930 (2017). https://doi.org/10.1007/s00202-016-0458-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00202-016-0458-2