Abstract

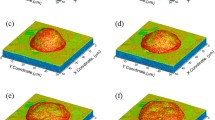

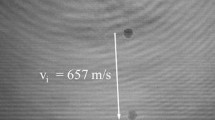

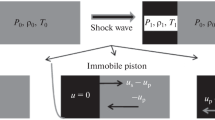

This work describes particle-resolved simulations of a single aluminum particle within a larger layer of particles that is interacting with a strong nitromethane shock. The objective is to observe how varying the particle’s volume fraction within a planar particle curtain changes the deformation of the particles as well as the fluid dynamics around them. First the isolated particle limit, when the distance between the neighbors is very large, is simulated; this is followed by simulating a single-layer of particles subjected to a planar shock propagating normal to the layer. Several initial particle volume fractions of the curtain are considered, and the results are compared and discussed. The results show that the presence and proximity of neighboring particles influence the shape and magnitude of the particle’s plastic deformation. The presence of neighboring particles also increases the initial average pressure within the particle during shock interaction as well as the average velocity of the particle afterwards. The strength of the reflected shock from the curtain of particles increases in magnitude and becomes more planar as the volume fraction increases due to neighboring particles’ individual reflections that coalesce to form a singular planar shock. The results obtained provide valuable insight into the microscale physics of shock interaction with an array of deformable particles.

Similar content being viewed by others

References

Ling, Y., Haselbacher, A., Balachandar, S., Najjar, F.M., Stewart, D.S.: Shock interaction with a deformable particle: direct numerical simulation and point-particle modeling. J. Appl. Phys. 113, 013504 (2013). https://doi.org/10.1063/1.4772744

Sun, M., Saito, T., Takayama, K., Tanno, H.: Unsteady drag on a sphere by shock wave loading. Shock Waves 14, 3–9 (2005). https://doi.org/10.1007/s00193-004-0235-4

Parmar, M., Haselbacher, A., Balachandar, S.: Modeling of the unsteady force for shock-particle interaction. Shock Waves 19, 317–329 (2009). https://doi.org/10.1007/s00193-009-0206-x

Parmar, M., Haselbacher, A., Balachandar, S.: Equation of motion for a sphere in non-uniform compressible flows. J. Fluid Mech. 699, 352–375 (2012). https://doi.org/10.1017/jfm.2012.109

Mao, C., Jin, T., Luo, K., Fan, J.: Investigation of supersonic turbulent flows over a sphere by fully resolved direct numerical simulation. Phys. Fluids 31(5), 056102 (2019). https://doi.org/10.1063/1.5092152

Lu, C., Sambasivan, S., Kapahi, A., Udaykumar, H.S.: Multi-scale modeling of shock interaction with a cloud of particles using an artificial neural network for model representation. Procedia IUTAM 3, 25–52 (2012). https://doi.org/10.1016/j.piutam.2012.03.003

Regele, J.D., Rabinovitch, J., Colonius, T., Blanquart, G.: Unsteady effects in dense, high speed, particle laden flows. Int. J. Multiph. Flow 61, 1–13 (2014). https://doi.org/10.1016/j.ijmultiphaseflow.2013.12.007

Sridharan, P., Jackson, T.L., Zhang, J., Balachandar, S.: Shock interaction with one-dimensional array of particles in air. J. Appl. Phys. 117, 075902 (2015). https://doi.org/10.1063/1.4913217

Mehta, Y., Neal, C., Jackson, T.L., Balachandar, S., Thakur, S.: Shock interaction with three-dimensional face centered cubic array of particles. Phys. Rev. Fluids 1, 054202 (2016). https://doi.org/10.1103/PhysRevFluids.1.054202

Mehta, Y., Jackson, T.L., Zhang, J., Balachandar, S.: Numerical investigation of shock interaction with one-dimensional transverse array of particles in air. J. Appl. Phys. 119(10), 104901 (2016). https://doi.org/10.1063/1.4943616

Hosseinzadeh-Nik, Z., Subramaniam, S., Regele, J.D.: Investigation and quantification of flow unsteadiness in shock-particle cloud interaction. Int. J. Multiph. Flow 101, 186–201 (2018). https://doi.org/10.1016/j.ijmultiphaseflow.2018.01.011

Mehta, Y., Neal, C., Salari, K., Jackson, T.L., Balachandar, S., Thakur, S.: Propagation of a strong shock over a random bed of spherical particles. J. Fluid Mech. 839, 157–197 (2018). https://doi.org/10.1017/jfm.2017.909

Theofanous, T.G., Mitkin, V., Chang, C.H.: Shock dispersal of dilute particle clouds. J. Fluid Mech. 841, 732–745 (2018). https://doi.org/10.1017/jfm.2018.110

Osnes, A.N., Vartdal, M., Omang, M.G., Reif, B.A.P.: Computational analysis of shock-induced flow through stationary particle clouds. Int. J. Multiph. Flow 114, 268–286 (2019). https://doi.org/10.1016/j.ijmultiphaseflow.2019.03.010

Mehta, Y., Salari, K., Jackson, T.L., Balachandar, S.: Effect of Mach number and volume fraction in air-shock interacting with a bed of randomly distributed spherical particles. Phys. Rev. Fluids 4(1), 014303 (2019). https://doi.org/10.1103/PhysRevFluids.4.014303

Osnes, A.N., Vartdal, M., Omang, M.G., Reif, B.A.P.: Particle-resolved simulations of shock-induced flow through particle clouds at different Reynolds numbers. Phys. Rev. Fluids 5(1), 014305 (2020). https://doi.org/10.1103/PhysRevFluids.5.014305

Shallcross, G.S., Fox, R.O., Capecelatro, J.: A volume-filtered description of compressible particle-laden flows. Int. J. Multiph. Flow 122, 103138 (2020). https://doi.org/10.1016/j.ijmultiphaseflow.2019.103138

Xiao, W., Mao, C., Jin, T., Luo, K., Fan, J.: Fully resolved simulation of a shockwave interacting with randomly clustered particles via a ghost-cell immersed boundary method. Phys. Fluids 32(6), 066105 (2020). https://doi.org/10.1063/5.0002088

Ripley, R.C., Zhang, F., Lien, F.: Acceleration and heating of metal particles in condensed matter detonation. Proc. R. Soc. A 468, 1564–1590 (2012). https://doi.org/10.1098/rspa.2011.0595

Di Felice, R.: The voidage function for fluid-particle interaction systems. Int. J. Multiph. Flow 20, 153–159 (1994). https://doi.org/10.1016/0301-9322(94)90011-6

Chauvin, A., Daniel, E., Chinnayya, A., Massoni, J., Jourdan, G.: Shock waves in sprays: numerical study of secondary atomization and experimental comparison. Shock Waves 26, 403–415 (2016). https://doi.org/10.1007/s00193-015-0593-0

Enwald, H., Peirano, E., Almstedt, A.-E.: Eulerian two-phase flow theory applied to fluidization. Int. J. Multiph. Flow 22, 21–66 (1996). https://doi.org/10.1016/S0301-9322(96)90004-X

Ferry, J., Balachandar, S.: A fast Eulerian method for disperse two-phase flow. Int. J. Multiph. Flow 27, 1199–1226 (2001). https://doi.org/10.1016/S0301-9322(00)00069-0

Ferry, J., Balachandar, S.: Equilibrium Eulerian approach for predicting the thermal field of a dispersion of small particles. Int. J. Heat Mass Transf. 48, 681–689 (2005). https://doi.org/10.1016/j.ijheatmasstransfer.2004.07.047

Gonthier, K.A., Powers, J.M.: A high-resolution numerical method for a two-phase model of deflagration-to-detonation transition. J. Comput. Phys. 163, 376–443 (2000). https://doi.org/10.1006/jcph.2000.6569

Kapila, A.K., Menikoff, R., Bdzil, J.B., Son, S.F., Stewart, D.S.: Two-phase modeling of deflagration-to-detonation transition in granular materials: reduced equations. Phys. Fluids 13(10), 3002–3024 (2001). https://doi.org/10.1063/1.1398042

Papalexandris, M.V.: Numerical simulation of detonations in mixtures of gases and solid particles. J. Fluid Mech. 507, 95–142 (2004). https://doi.org/10.1017/S0022112004008894

Baer, M.R., Nunziato, J.W.: A two-phase mixture theory for the deflagration-to-detonation transition (DDT) in reactive granular materials. Int. J. Multiph. Flow 12, 861–889 (1986). https://doi.org/10.1016/0301-9322(86)90033-9

Rogue, X., Rodriguez, G., Haas, J.F., Saurel, R.: Experimental and numerical investigation of the shock-induced fluidization of a particles bed. Shock Waves 8, 29–45 (1998). https://doi.org/10.1007/s001930050096

Saurel, R., Lemetayer, O.: A multiphase model for compressible flows with interfaces, shocks, detonation waves and cavitation. J. Fluid Mech. 431, 239–271 (2001). https://doi.org/10.1017/S0022112000003098

Saurel, R., Favrie, N., Peptitpas, F., Lallemand, M.-H., Gavrilyuk, S.L.: Modelling dynamic and irreversible powder compaction. J. Fluid Mech. 664, 348–396 (2010). https://doi.org/10.1017/S0022112010003794

McGrath, T.P., II., St. Clair, J.G., Balachandar, S.A.: Compressible two-phase model for dispersed particle flows with application from dense to dilute regimes. J. Appl. Phys. 119, 104901 (2016). https://doi.org/10.1063/1.4948301

McGrath, T.P., II., St. Clair, J.G., Balachandar, S.: Modeling compressible multiphase flows with dispersed particles in both dense and dilute regimes. Shock Waves 28, 533–544 (2018). https://doi.org/10.1007/s00193-017-0726-8

Harris, G., Luton, J.A., McGrath, T.P., II., McKeown, R.M., St. Clair, J.S., Babcock, W., Wardlaw Jr., A.B.: Overview of the Dynamic System Mechanics Advanced Simulation Code (DYSMAS). Technical Report No. IHSP 14-04. Naval Surface Warfare Center Indian Head EOD Technology Division (2014)

Mi, X., Michael, L., Ioannou, E., Nikiforakis, N., Higgins, A.J., Ng, H.D.: Meso-resolved simulations of shock-to-detonation transition in nitromethane with air-filled cavities. J. Appl. Phys. 125, 245901 (2019). https://doi.org/10.1063/1.5093990

Saurel, R., Abgrall, R.: A multiphase Godunov method for compressible multifluid and multiphase flows. J. Comput. Phys. 150, 425–467 (1999). https://doi.org/10.1006/jcph.1999.6187

Benson, D.J.: Computational methods in Lagrangian and Eulerian hydrocodes. Comput. Methods Appl. Mech. Eng. 98, 235–394 (1992). https://doi.org/10.1016/0045-7825(92)90042-I

Godunov, S.K., Romenskii, E.: Elements of Continuum Mechanics and Conservation Laws. Springer, Boston, MA (2003)

Das, P., Sen, O., Jacobs, G., Udaykumar, H.S.: A sharp interface Cartesian grid method for viscous simulation of shocked particle-laden flows. Int. J. Comput. Fluid Dyn. 31(6–8), 269–291 (2017). https://doi.org/10.1080/10618562.2017.1351610

Michael, L., Nikiforakis, N.: A multi-physics methodology for the simulation of reactive flow and elastoplastic structural response. J. Comput. Phys. 367, 1–27 (2018). https://doi.org/10.1016/j.jcp.2018.03.037

Kumar Rai, N., Udaykumar, H.S.: A Eulerian level set-based framework for reactive meso-scale analysis of heterogeneous energetic materials. In: Dynamic Damage and Fragmentation, pp. 387–416 (2018). https://doi.org/10.1002/9781119579311.ch13

Miller, G.H., Collela, P.: A conservative three-dimensional Eulerian method for coupled solid-fluid shock capturing. J. Comput. Phys. 183, 26–82 (2002). https://doi.org/10.1006/jcph.2002.7158

Fedkiw, R.: Coupling an Eulerian fluid calculation to a Lagrangian solid calculation with the ghost fluid method. J. Comput. Phys. 175, 200–224 (2002). https://doi.org/10.1006/jcph.2001.6935

Collela, P., Graves, D., Keen, B., Modiano, D.: A Cartesian grid embedded boundary method for hyperbolic conservation laws. J. Comput. Phys. 211, 347–366 (2006). https://doi.org/10.1016/j.jcp.2005.05.026

Udaykumar, H.S., Mittal, R., Rampunggoon, P., Khanna, A.: A sharp interface cartesian grid method for simulating flows with complex moving boundaries. J. Comput. Phys. 174, 345–380 (2001). https://doi.org/10.1006/jcph.2001.6916

Schneiders, L., Hartmann, D., Meinke, M., Schröder, W.: An accurate moving boundary formulation in cut-cell methods. J. Comput. Phys. 235, 786–809 (2013). https://doi.org/10.1016/j.jcp.2012.09.038

Forbes, J.: Shock Wave Compression of Condensed Matter. Springer, Berlin, Heidelberg (2012)

Steinberg, D.J.: Equation of State and Strength Properties of Selected Materials. Technical Report No. UCRL-MA-106439. Lawrence Livermore National Laboratory (1991)

Zywicz, E., Lin, J.I.: DYNA3D: A Nonlinear, Explicit, Three-Dimensional Finite Element Code for Solid and Structural Mechanics User Manual—Version 17. Technical Report No. LLNL-SM-740518. Lawrence Livermore National Laboratory (2017)

Steinberg, D.J., Guinan, M.W.: A High-Strain-Rate Constitutive Model for Metals. Technical Report No. UCRL-80465. University of California, Lawrence Livermore National Laboratory (1978)

Fujisawa, K., Jackson, L.T., Balachandar, S.: Influence of baroclinic vorticity production on unsteady drag coefficient in shock-particle interaction. J. Appl. Phys. (2019). https://doi.org/10.1063/1.5055002

Annamalai, S., Balachandar, S.: Faxén form of time-domain force on a sphere in unsteady spatially varying viscous compressible flows. J. Fluid Mech. 816, 381–411 (2017). https://doi.org/10.1017/jfm.2017.77

Ling, Y., Haselbacher, A., Balachandar, S.: Importance of unsteady contributions to force and heating for particles in compressible flows Part 1: modeling and analysis for shock-particle interaction. Int. J. Multiph. Flow 37, 1026–1044 (2011). https://doi.org/10.1016/j.ijmultiphaseflow.2011.07.001

Annamalai, S., Balachandar, S., Sridharan, P., Jackson, T.L.: Pressure evolution equation for the particulate phase in inhomogeneous compressible disperse multiphase flows. Phys. Rev. Fluids 2(2), 056102 (2017). https://doi.org/10.1103/PhysRevFluids.2.024301

LS-DYNA Theory Manual. Technical Report No. ISBN 0-9778540-0-0. Livermore Software Technology Corporation (2006)

Anderson, C.: An overview of the theory of hydrocodes. Int. J. Impact Eng. 5(1), 33–59 (1987). https://doi.org/10.1016/0734-743X(87)90029-7. Hypervelocity Impact Proceedings of the 1986 Symposium

Ponthot, J.P.: Unified stress update algorithms for the numerical simulation of large deformation elasto-plastic and elasto-viscoplastic processes. Int. J. Plast. 18, 91–126 (2002)

Belytschko, T., Liu, W.K., Moran, B.: Non-Linear Finite Elements for Continua and Structures. Wiley (2000)

Hallquist, J.O.: Theoretical manual for DYNA3D. https://www.osti.gov/biblio/6290765

Toro, E.F.: Riemann Solvers and Numerical Methods for Fluid Dynamics, 2nd edn. Springer, Berlin, Heidelberg (1999)

Collela, P.: A direct Eulerian MUSCL scheme for gas dynamics. SIAM J. Sci. Stat. Comput. 6, 104–117 (1985). https://doi.org/10.1137/0906009

Wardlaw, A.B., Jr., Luton, J.A., Renzi, J.R., Kiddy, K.C., McKeown, R.M.: The Gemini Euler Solver for the Coupled Simulation of Underwater Explosions. Technical Report No. 2500. Naval Surface Warfare Center Indian Head Division (2003)

Hirsch, C.: Numerical Computation of Internal and External Flows, vol. 2. Wiley (1990)

Van Leer, B.: Towards the ultimate conservative difference scheme. V. A second order sequel to Godunov’s method. J. Comput. Phys. 32, 101–136 (1979). https://doi.org/10.1016/0021-9991(79)90145-1

Muralidharan, B., Menon, S.: Simulation of moving boundaries interacting with compressible reacting flows using a second-order adaptive Cartesian cut-cell method. J. Comput. Phys. 357, 230–262 (2018). https://doi.org/10.1016/j.jcp.2017.12.030

Khalili, M.E., Larsson, M., Muller, B.: Immersed boundry method for viscous compressible flows around moving bodies. Comput. Fluids 170, 77–92 (2018). https://doi.org/10.1016/j.compfluid.2018.04.033

Gokhale, N., Nikiforakis, N., Klein, R.: A dimensionally split Cartesian cut cell method for hyperbolic conservation laws. J. Comput. Phys. 364, 186–208 (2018). https://doi.org/10.1016/j.jcp.2018.03.005

Acknowledgements

This work was supported by the Office of Naval Research under the In-House Laboratory and Independent Research (ILIR) Program; the document is approved for public release, Distribution A (21-016). The authors wish to thank the ILIR program management and review boards for their support and guidance of this research. Additionally, this work benefited from the U.S. Department of Energy, National Nuclear Security Administration, Advanced Simulation and Computing Program, as a Cooperative Agreement to the University of Florida under the Predictive Science Academic Alliance Program, under Contract No. DE-NA0002378 and from the Defense Threat Reduction Agency Basic Research Award No. HDTRA1-14-1-0028 to the University of Florida.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by D. Frost.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Mesh resolution

To ensure the computational mesh size of 40 cells through the diameter of the particle was sufficient, a mesh resolution study was performed with the \(\alpha = 0.33\) particle layer. Both the finite volume (fluid) and element (particle) meshes were varied to the same computational cell sizes for the study. The average particle pressure and velocity obtained with various grid resolutions are plotted in Fig. 16. From the results, it appears that 40 cells through the diameter of the particle is more than sufficient towards attaining a converging solution.

Appendix 2: Computational methods

The computational methods used in this paper are well established in the literature. The purpose of this appendix is to present the basic governing equations and material models, briefly describe the solution method, and provide references for interested readers.

1.1 Lagrangian finite element solution

Solid materials are represented within an explicit finite element framework developed and maintained by Lawrence Livermore National Laboratory (LLNL) [49]. The general finite element method applied for transient analysis is presented in [37, 55, 56]. The governing equations for mass, momentum, and energy, cast in the Lagrangian framework, are:

Here \(\rho _\mathrm {0}\) is the initial density, \(\rho \) is the density, V is the volume of the element relative to its initial volume, u is the velocity, \(\sigma \) is the Cauchy stress tensor, f is a body or external force per unit mass, e is the internal energy per unit mass, and \({\dot{\epsilon }}\) is the strain rate tensor. The dot above a variable represents the total derivative: \(\dot{( )}=D( )/Dt\).

For large deformation calculations, the stress tensor is separated into a deviatoric stress (s) and pressure (P) components:

where \(\delta \) is the Kronecker delta. Pressure is calculated via an equation of state, and the deviatoric stress rate is defined using the Jaumann rate:

Here \(\mu \) is the shear modulus, \(\omega \) is the spin tensor, \({\dot{\epsilon }}\) is the strain rate tensor, and \({\dot{\epsilon }}'\) is the deviatoric strain rate tensor:

For elastic-plastic materials, the integration of (7) results in an elastic estimate (\(s^{\mathrm {est}}\)) which may exceed the yield condition imposed by the constitutive model. If so, a radial return method is used to return the stress to the yield surface. To assess this, the effective stress is calculated as:

Finally, the effective stress is compared to the yield stress, \(\sigma _\mathrm {y}\), and the stress tensor is scaled if necessary:

Additional information on the stress update methodology and radial return algorithms can be found in [55, 57, 58].

Transient integration is accomplished using a central difference scheme in which velocity is saved at the half-step. Spatial derivatives are computed via central differencing, with the application of artificial viscosity to avoid numerical oscillations near discontinuities. See [37, 55, 59] for presentation of these methods.

1.2 Eulerian finite volume solution

The fluid domain is modeled using an Eulerian finite volume method. The fluid is compressible and assumed to be inviscid, so that the Euler equations apply. The governing equations are solved with dimensional splitting [60] via a series of 1D sweeps. The one-dimensional Euler equations are:

where

where E is the total energy per unit mass and \(\nu \) is a convected variable. Off-sweep velocities are treated as convected variables in this methodology.

A Monotonic Upwind Scheme for Conservation Laws (MUSCL) method is applied. The specific scheme used was proposed by Collela [61] and applied by Wardlaw [62]. This is a higher-order scheme that attains second order accuracy in both time and space in smooth flow regions, but reduces to first order accuracy at shocks. Interested readers are directed to [60, 63, 64] for further information.

1.3 Fluid-solid coupling

The finite element and finite volume solutions are coupled at the fluid-solid interface. A mechanical coupling consistent with the goverining equations for the solid and fluid are applied. Momentum and energy are exchanged due to pressure and the associated work, while viscous effects, heat and mass transfer are assumed to be negligible during the early times of shock-particle interaction. Coupling of the solvers at the solid-fluid interface is accomplished with an embedded boundary approach. The finite volume solver employs a ghost-fluid method to account for the boundary conditions at the solid particle surface while pressures from the fluid are mapped onto the exposed interface segments of the finite element mesh. Methods of this type are common in the literature [43,44,45,46, 65,66,67].

The external fluid applies a force boundary condition to the solid surface. The finite element solver calculates internal forces based on stress gradients and body forces. For the subset of nodes existing on the solid-fluid interface, coupling forces exerted from fluid pressure (\(f^\mathrm {cpl}\)) augment any other forces (e.g., body forces) existing in solution (\(f^\mathrm {fem}\)). The momentum, (4) and energy, (5) become:

A ghost-fluid method [43] is used to represent the solid body within the finite volume solver. Internal ghost cells are inserted into the dimensional sweeps. State values are assigned to enforce the cutting element velocity and position, in a manner consistent with MUSCL limited slopes. As discussed by Fedkiw [43], the interface normal velocity is defined as the finite element node velocity. Pressure equilibrium is not rigourously enforced at the interface, rather pressure differences in the Eulerian and Lagrangian solutions drive interface motion through (14), which leads to pressure equilibration. Further details of ghost fluid state construction and the overall coupling scheme are given in [62].

1.4 Steinberg-Guinan constitutive model

The constitutive model utilized for the aluminum particle was the Steinberg-Guinan high rate elastic-plastic model [48,49,50]. This model is applicable to metals at high strain rates, where plastic strain and pressure hardening, as well as thermal softening, may occur. The yield stress is defined as:

Equation (16) is applicable for when the material’s internal energy, e, has not exceeded the melting energy, \(e_\mathrm {m}\), which is a function of the cold compression energy, \(e_\mathrm {c}\), and the melting temperature of the material. In the above, \(\gamma _\mathrm {i}\) is the initial plastic strain of the material, and \(\sigma _\mathrm {0}\) is the base yield stress. \(\beta , n, h, b,\) and f are constant parameters of the material model that define the yield stress as a function of effective plastic strain, \(\epsilon ^\mathrm {p}_\mathrm {eff}\), pressure and energy. R is the universal gas constant and \(\mathrm {Aw}\) is the atomic weight of the material. Model parameters used in this study are defined in Table 3.

1.5 Mie–Gruneisen EOS

The Mie–Gruneisen equation of state assumes separate forms for compression and tension [49]. The excess compression is defined as: \(\mu =\rho / \rho _\mathrm {0} -1\). For compressed material (\(\mu \ge 0\)):

For an expanded material (\(\mu < 0\)):

The material parameters \(\rho _\mathrm {0}\), C, \(\gamma _\mathrm {0}\), \(S_\mathrm {1}\), and \(S_\mathrm {2}\) are defined in Table 2.

Rights and permissions

About this article

Cite this article

St. Clair, J., McGrath, T. & Balachandar, S. Fully resolved coupled solid-fluid simulations of shock interaction with a layer of deformable aluminum particles. Shock Waves 32, 161–178 (2022). https://doi.org/10.1007/s00193-021-01059-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00193-021-01059-x