Abstract

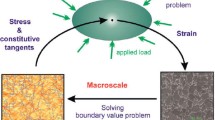

Morphology and dynamics at the mesoscale play crucial roles in the overall macro- or system-scale flow of heterogeneous materials. In a multi-scale framework, closure models upscale unresolved sub-grid (mesoscale) physics and therefore encapsulate structure–property (S–P) linkages to predict performance at the macroscale. This work establishes a route to S–P linkage, proceeding all the way from imaged microstructures to flow computations in one unified level-set-based framework. Level sets are used to: (1) define embedded geometries via image segmentation; (2) simulate the interaction of sharp immersed boundaries with the flow field; and (3) calculate morphological metrics to quantify structure. Mesoscale dynamics is computed to calculate sub-grid properties, i.e., closure models for momentum and energy equations. The S–P linkage is demonstrated for two types of multi-material flows: interaction of shocks with a cloud of particles and reactive meso-mechanics of pressed energetic materials. We also present an approach to connect local morphological characteristics in a microstructure containing topologically complex features with the shock response of imaged samples of such materials. This paves the way for using geometric machine learning techniques to associate imaged morphologies with their properties.

Similar content being viewed by others

References

Welle, E.J., Molek, C.D., Wixom, R.R., Samuels, P.: Microstructural effects on the ignition behavior of HMX. J. Phys Conf. Ser. 500, 052049 (2014). https://doi.org/10.1088/1742-6596/500/5/052049

Tarver, C.M., Chidester, S.K., Nichols, A.L.: Critical conditions for impact- and shock-induced hot spots in solid explosives†. J. Phys. Chem. 100(14), 5794–5799 (1996). https://doi.org/10.1021/jp953123s

Zhang, J., Jackson, T.L.: Effect of microstructure on the detonation initiation in energetic materials. Shock Waves 29(2), 327–338 (2017). https://doi.org/10.1007/s00193-017-0796-7

Rai, N.K., Schmidt, M.J., Udaykumar, H.S.: High-resolution simulations of cylindrical void collapse in energetic materials: effect of primary and secondary collapse on initiation thresholds. Phys. Rev. Fluids 2(4), 043202 (2017). https://doi.org/10.1103/PhysRevFluids.2.043202

Boiko, V.M., Kiselev, V.P., Kiselev, S.P., Papyrin, A.N., Poplavskii, S.V., Fomin, V.M.: Interaction of a shock wave with a cloud of particles. Combust. Explos. Shock Waves 32(2), 191–203 (1996). https://doi.org/10.1007/bf02097090

Tay, T.E.: Characterization and analysis of delamination fracture in composites: an overview of developments from 1990 to 2001. Appl. Mech. Rev. 56(1), 1–32 (2003). https://doi.org/10.1115/1.1504848

Vyas, B., Preece, C.: Cavitation-induced deformation of aluminum. In: Thiruvengadam, A. (ed.) Erosion, Wear, and Interfaces with Corrosion, pp. 77–101. ASTM International, West Conshohocken, PA (1974). https://doi.org/10.1520/stp32221s

Zaefferer, S., Ohlert, J., Bleck, W.: A study of microstructure, transformation mechanisms and correlation between microstructure and mechanical properties of a low alloyed TRIP steel. Acta Mater. 52(9), 2765–2778 (2004). https://doi.org/10.1016/j.actamat.2004.02.044

Davies, G.A.O., Hitchings, D., Ankersen, J.: Predicting delamination and debonding in modern aerospace composite structures. Compos. Sci. Technol. 66(6), 846–854 (2006). https://doi.org/10.1016/j.compscitech.2004.12.043

de Brauer, A., Rai, N.K., Nixon, M.E., Udaykumar, H.S.: Modeling impact-induced damage and debonding using level sets in a sharp interface Eulerian framework. Int. J. Numer. Methods Eng. 115(9), 1108–1137 (2018). https://doi.org/10.1002/nme.5837

Liu, Y.J., Li, S.J., Wang, H.L., Hou, W.T., Hao, Y.L., Yang, R., Sercombe, T.B., Zhang, L.C.: Microstructure, defects and mechanical behavior of beta-type titanium porous structures manufactured by electron beam melting and selective laser melting. Acta Mater. 113, 56–67 (2016). https://doi.org/10.1016/j.actamat.2016.04.029

Li, W., Hahn, E.N., Yao, X., Germann, T.C., Zhang, X.: Shock induced damage and fracture in SiC at elevated temperature and high strain rate. Acta Mater. 167, 51–70 (2019). https://doi.org/10.1016/j.actamat.2018.12.035

Lieberman, E.J., Lebensohn, R.A., Menasche, D.B., Bronkhorst, C.A., Rollett, A.D.: Microstructural effects on damage evolution in shocked copper polycrystals. Acta Mater. 116, 270–280 (2016). https://doi.org/10.1016/j.actamat.2016.06.054

Callister, W.D., Rethwisch, D.G.: Materials Science and Engineering: An Introduction. Wiley, New York (2007)

Olson, G.B.: Computational design of hierarchically structured materials. Science 277(5330), 1237–1242 (1997). https://doi.org/10.1126/science.277.5330.1237

Nassar, A., Rai, N.K., Sen, O., Udaykumar, H.S.: Modeling mesoscale energy localization in shocked HMX, part I: machine-learned surrogate models for the effects of loading and void sizes. Shock Waves 29(4), 537–558 (2018). https://doi.org/10.1007/s00193-018-0874-5

Sen, O., Rai, N.K., Diggs, A.S., Hardin, D.B., Udaykumar, H.S.: Multi-scale shock-to-detonation simulation of pressed energetic material: a meso-informed ignition and growth model. J. Appl. Phys. 124(8), 085110 (2018). https://doi.org/10.1063/1.5046185

Roy, S., Rai, N.K., Sen, O., Hardin, D.B., Diggs, A.S., Udaykumar, H.S.: Modeling mesoscale energy localization in shocked HMX, Part II: training machine-learned surrogate models for void shape and void–void interaction effects. Shock Waves 30(4), 349–372 (2019). https://doi.org/10.1007/s00193-019-00931-1

Rai, N.K., Udaykumar, H.S.: Three-dimensional simulations of void collapse in energetic materials. Phys. Rev. Fluids 3(3), 033201 (2018). https://doi.org/10.1103/PhysRevFluids.3.033201

Sen, O., Gaul, N.J., Choi, K.K., Jacobs, G., Udaykumar, H.S.: Evaluation of kriging based surrogate models constructed from mesoscale computations of shock interaction with particles. J. Comput. Phys. 336, 235–260 (2017). https://doi.org/10.1016/j.jcp.2017.01.046

Zhao, L., Choi, K.K., Lee, I.: Metamodeling method using dynamic Kriging for design optimization. AIAA J. 49(9), 2034–2046 (2011). https://doi.org/10.2514/1.J051017

Sen, O., Gaul, N.J., Choi, K.K., Jacobs, G., Udaykumar, H.S.: Evaluation of multifidelity surrogate modeling techniques to construct closure laws for drag in shock–particle interactions. J. Comput. Phys. 371, 434–451 (2018). https://doi.org/10.1016/j.jcp.2018.05.039

Kapahi, A., Mousel, J., Sambasivan, S., Udaykumar, H.S.: Parallel, sharp interface Eulerian approach to high-speed multi-material flows. Comput. Fluids 83, 144–156 (2013). https://doi.org/10.1016/j.compfluid.2012.06.024

Baer, M.: Modeling heterogeneous energetic materials at the mesoscale. Thermochim. Acta 384(1–2), 351–367 (2002)

Provatas, N., Grant, M., Elder, K.R.: Phase-field model for activated reaction fronts. Phys. Rev. B: Condens. Matter 53(10), 6263–6272 (1996). https://doi.org/10.1103/physrevb.53.6263

Osher, S., Sethian, J.A.: Fronts propagating with curvature-dependent speed: algorithms based on Hamilton-Jacobi formulations. J. Comput. Phys. 79(1), 12–49 (1988). https://doi.org/10.1016/0021-9991(88)90002-2

Dillard, S., Buchholz, J., Vigmostad, S., Kim, H., Udaykumar, H.S.: Techniques to derive geometries for image-based Eulerian computations. Eng. Comput. (Swansea) 31(3), 530–566 (2014). https://doi.org/10.1108/EC-06-2012-0145

Dillard, S.I., Mousel, J.A., Shrestha, L., Raghavan, M.L., Vigmostad, S.C.: From medical images to flow computations without user-generated meshes. Int. J. Numer. Method Biomed. Eng. 30(10), 1057–1083 (2014). https://doi.org/10.1002/cnm.2644

Rai, N.K., Udaykumar, H.S.: Mesoscale simulation of reactive pressed energetic materials under shock loading. J. Appl. Phys. 118(24), 245905 (2015). https://doi.org/10.1063/1.4938581

Rai, N.K., Kapahi, A., Udaykumar, H.S.: Treatment of contact separation in Eulerian high-speed multimaterial dynamic simulations. Int. J. Numer. Methods Eng. 100(11), 793–813 (2014). https://doi.org/10.1002/nme.4760

Kapahi, A., Sambasivan, S., Udaykumar, H.S.: A three-dimensional sharp interface Cartesian grid method for solving high speed multi-material impact, penetration and fragmentation problems. J. Comput. Phys. 241, 308–332 (2013). https://doi.org/10.1016/j.jcp.2013.01.007

Das, P., Sen, O., Jacobs, G., Udaykumar, H.S.: A sharp interface Cartesian grid method for viscous simulation of shocked particle-laden flows. Int. J. Comput. Fluid Dyn. 31(6–8), 269–291 (2017). https://doi.org/10.1080/10618562.2017.1351610

Bostanabad, R., Zhang, Y., Li, X., Kearney, T., Brinson, L.C., Apley, D.W., Liu, W.K., Chen, W.: Computational microstructure characterization and reconstruction: review of the state-of-the-art techniques. Prog. Mater Sci. 95, 1–41 (2018). https://doi.org/10.1016/j.pmatsci.2018.01.005

Torquato, S.: Random Heterogeneous Materials: Microstructure and Macroscopic Properties. Springer, Berlin (2013)

Whitehouse, W.J.: The quantitative morphology of anisotropic trabecular bone. J. Microsc. 101(Pt 2), 153–168 (1974). https://doi.org/10.1111/j.1365-2818.1974.tb03878.x

Nakashima, Y., Kamiya, S.: Mathematica programs for the analysis of three-dimensional pore connectivity and anisotropic tortuosity of porous rocks using X-ray computed tomography image data. J. Nucl. Sci. Technol. 44(9), 1233–1247 (2007). https://doi.org/10.1080/18811248.2007.9711367

Royet, J.P.: Stereology: a method for analyzing images. Prog. Neurobiol. 37(5), 433–474 (1991). https://doi.org/10.1016/0301-0082(91)90009-p

Katuwal, S., Arthur, E., Tuller, M., Moldrup, P., de Jonge, L.W.: Quantification of soil pore network complexity with x-ray computed tomography and gas transport measurements. Soil Sci. Soc. Am. J. 79(6), 1577–1589 (2015). https://doi.org/10.2136/sssaj2015.06.0227

Azegrouz, H., Trucco, E., Dhillon, B., MacGillivray, T., MacCormick, I.: Thickness dependent tortuosity estimation for retinal blood vessels. In: 2006 International Conference of the IEEE Engineering in Medicine and Biology Society, New York, USA, pp. 4675–4678 (2006). https://doi.org/10.1109/IEMBS.2006.260558

Cowin, S.C.: The relationship between the elasticity tensor and the fabric tensor. Mech. Mater. 4(2), 137–147 (1985). https://doi.org/10.1016/0167-6636(85)90012-2

Gundersen, H.J.G., Jensen, E.B.: Particle sizes and their distributions estimated from line- and point-sampled intercepts. Including graphical unfolding. J. Microsc. 131(3), 291–310 (1983). https://doi.org/10.1111/j.1365-2818.1983.tb04256.x

Odgaard, A.: Three-dimensional methods for quantification of cancellous bone architecture. Bone 20(4), 315–328 (1997). https://doi.org/10.1016/s8756-3282(97)00007-0

Odgaard, A., Jensen, E.B., Gundersen, H.J.: Estimation of structural anisotropy based on volume orientation. A new concept. J. Microsc. 157(Pt 2), 149–162 (1990). https://doi.org/10.1111/j.1365-2818.1990.tb02955.x

Wang, M.Y., Wang, X., Guo, D.: A level set method for structural topology optimization. Comput. Methods Appl. Mech. Eng. 192(1–2), 227–246 (2003). https://doi.org/10.1016/s0045-7825(02)00559-5

Wang, M.Y., Wang, X.: A level set based variational method for design and optimization of heterogeneous objects. Comput. Aided Des. 37(3), 321–337 (2005). https://doi.org/10.1016/j.cad.2004.03.007

Schmähling, J.: Statistical characterization of technical surface microstructure. PhD Thesis, Heidelberg University (2006). https://archiv.ub.uni-heidelberg.de/volltextserver/6792/1/schmaehling_06_statistical.pdf

Jørgensen, P.S., Hansen, K.V., Larsen, R., Bowen, J.R.: High accuracy interface characterization of three phase material systems in three dimensions. J. Power Sources 195(24), 8168–8176 (2010). https://doi.org/10.1016/j.jpowsour.2010.06.083

Moës, N., Cloirec, M., Cartraud, P., Remacle, J.-F.: A computational approach to handle complex microstructure geometries. Comput. Methods Appl. Mech. Eng. 192(28–30), 3163–3177 (2003)

Sambasivan, S., Kapahi, A., Udaykumar, H.S.: Simulation of high speed impact, penetration and fragmentation problems on locally refined Cartesian grids. J. Comput. Phys. 235, 334–370 (2013). https://doi.org/10.1016/j.jcp.2012.10.031

Sen, O., Davis, S., Jacobs, G., Udaykumar, H.S.: Evaluation of convergence behavior of metamodeling techniques for bridging scales in multi-scale multimaterial simulation. J. Comput. Phys. 294, 585–604 (2015). https://doi.org/10.1016/j.jcp.2015.03.043

Chan, T.F., Vese, L.A.: Active contours without edges. IEEE Trans. Image Process. 10(2), 266–277 (2001). https://doi.org/10.1109/83.902291

Yu, Y., Acton, S.T.: Speckle reducing anisotropic diffusion. IEEE Trans. Image Process. 11(11), 1260–1270 (2002). https://doi.org/10.1109/TIP.2002.804276

Molek, C., Welle, E., Wixom, R., Ritchey, M., Samuels, P., Horie, Y.: Microstructural characterization of pressed HMX material sets at differing densities. AIP Publ. 1793(1), 040007 (2017). https://doi.org/10.1063/1.4971501

Herrmann, M.: A parallel Eulerian interface tracking/Lagrangian point particle multi-scale coupling procedure. J. Comput. Phys. 229(3), 745–759 (2010). https://doi.org/10.1016/j.jcp.2009.10.009

Harrigan, T.P., Mann, R.W.: Characterization of microstructural anisotropy in orthotropic materials using a second rank tensor. J. Mater. Sci. 19(3), 761–767 (1984). https://doi.org/10.1007/bf00540446

Jones, K.B., Inoue, N., Tis, J.E., McCarthy, E.F., McHale, K.A., Chao, E.Y.: Quantification of the microstructural anisotropy of distraction osteogenesis in the rabbit tibia. Iowa Orthop J. 25, 118–122 (2005)

Lock, A.C.H., Brown, A.D., Blessington, R.A., Appleby-Thomas, G., Quadir, M.Z., Hazell, P.J., Escobedo, J.P.: Effect of microstructural anisotropy on the dynamic mechanical behaviour of rolled Ti-6Al-4V. In: Ikhmayies, S.J. et al. (eds.) Characterization of Minerals, Metals, and Materials 2016, pp. 3–10. Springer, Cham (2016). https://doi.org/10.1007/978-3-319-48210-1_1

Moreno, R., Borga, M., Smedby, O.: Generalizing the mean intercept length tensor for gray-level images. Med. Phys. 39(7), 4599–4612 (2012). https://doi.org/10.1118/1.4730502

Smit, Th.H., Schneider, E., Odgaard, A.: Star length distribution: a volume-based concept for the characterization of structural anisotropy. J. Microsc. 191(3), 249–257 (1998). https://doi.org/10.1046/j.1365-2818.1998.00394.x

Odgaard, A., Kabel, J., van Rietbergen, B., Dalstra, M., Huiskes, R.: Fabric and elastic principal directions of cancellous bone are closely related. J. Biomech. 30(5), 487–495 (1997). https://doi.org/10.1016/s0021-9290(96)00177-7

Moreno, R., Smedby, Ö., Borga, M.: On the Efficiency of the Mean Intercept Length Tensor. In: SSBA Symposium (2011). http://www.diva-portal.org/smash/get/diva2%3A533443/FULLTEXT01.pdf

Liu, Y., Saha, P.K., Xu, Z.: Quantitative characterization of trabecular bone micro-architecture using tensor scale and multi-detector CT imaging. Med Image Comput Comput Assist Interv. 15(1), 124–131 (2012). https://doi.org/10.1007/978-3-642-33415-3_16

Kanatani, K., Sugaya, Y., Kanazawa, Y.: Ellipse analysis and 3D computation of circles. In: Guide to 3D Vision Computation. Advances in Computer Vision and Pattern Recognition. Springer, Cham (2016)

Gander, W., Golub, G.H., Strebel, R.: Least-squares fitting of circles and ellipses. Bit 34(4), 558–578 (1994). https://doi.org/10.1007/bf01934268

Diggle, P.J., Besag, J., Gleaves, J.T.: Statistical analysis of spatial point patterns by means of distance methods. Biometrics 32(3), 659–667 (1976). https://doi.org/10.2307/2529754

Illian, J., Penttinen, A., Stoyan, H., Stoyan, D.: Statistical Analysis and Modelling of Spatial Point Patterns. Wiley, New York (2008)

Diggle, P.J.: Statistical Analysis of Spatial and Spatio-Temporal Point Patterns. Chapman and Hall/CRC, Cambridge (2013)

Bringa, E.M., Rosolankova, K., Rudd, R.E., Remington, B.A., Wark, J.S., Duchaineau, M., Kalantar, D.H., Hawreliak, J., Belak, J.: Shock deformation of face-centred-cubic metals on subnanosecond timescales. Nat. Mater. 5(10), 805–809 (2006). https://doi.org/10.1038/nmat1735

de Brauer, A., Udaykumar, H.S.: Influence of bulk and interfacial properties on shock compression of metal powders. I. Interaction of a pair of particles. J. Appl. Phys. 124(13), 134903 (2018). https://doi.org/10.1063/1.5030212

Clennell, M.B.: Tortuosity: a guide through the maze. Geol. Soc. Lond. Spec. Publ. 122(1), 299–344 (1997). https://doi.org/10.1144/gsl.Sp.1997.122.01.18

Zhang, T., Suen, C.Y.: A fast parallel algorithm for thinning digital patterns. Commun. ACM 27(3), 236–239 (1984). https://doi.org/10.1145/357994.358023

Jain, R., Kasturi, R., Schunck, B.G.: Machine Vision. McGraw-Hill, New York (1995)

Hinde, A.L., Miles, R.E.: Monte Carlo estimates of the distributions of the random polygons of the Voronoi tessellation with respect to a Poisson process. J. Stat. Comput. Simul. 10(3–4), 205–223 (2007). https://doi.org/10.1080/00949658008810370

Tanaka, H., Hayashi, T., Nishi, T.: Digital image analysis of droplet patterns in polymer systems: point pattern. J. Appl. Phys. 65(12), 4480–4495 (1989). https://doi.org/10.1063/1.343266

Tschopp, M., Wilks, G., Spowart, J.: Multi-scale characterization of orthotropic microstructures. Modell. Simul. Mater. Sci. Eng. 16(6), 065009 (2008). https://doi.org/10.1088/0965-0393/16/6/065009

MATLAB and Statistics Toolbox Release 2015b. The MathWorks, Inc., Natick, Massachusetts

Okabe, A., Boots, B., Sugihara, K., Chiu, S.N.: Spatial Tessellations: Concepts and Applications of Voronoi Diagrams. Wiley, New York (2009)

Kosinski, P.: On shock wave propagation in a branched channel with particles. Shock Waves 15(1), 13–20 (2006). https://doi.org/10.1007/s00193-005-0001-2

Ling, Y., Wagner, J.L., Beresh, S.J., Kearney, S.P., Balachandar, S.: Interaction of a planar shock wave with a dense particle curtain: modeling and experiments. Phys. Fluids 24(11), 113301 (2012). https://doi.org/10.1063/1.4768815

Parmar, M., Haselbacher, A., Balachandar, S.: Modeling of the unsteady force for shock–particle interaction. Shock Waves 19(4), 317–329 (2009). https://doi.org/10.1007/s00193-009-0206-x

Yang, J., Kubota, T., Zukoski, E.E.: Applications of shock-induced mixing to supersonic combustion. AIAA J. 31(5), 854–862 (1993). https://doi.org/10.2514/3.11696

Li, Y., Zhang, J., Fan, L.-S.: Numerical simulation of gas–liquid–solid fluidization systems using a combined CFD-VOF-DPM method: bubble wake behavior. Chem. Eng. Sci. 54(21), 5101–5107 (1999). https://doi.org/10.1016/s0009-2509(99)00263-8

Shuai, W., Tianyu, Z., Guodong, L., Huilin, L., Liyan, S.: Multi-scale heat transfer in fluidized bed reactors by Eulerian CFD modeling. Fuel 139, 646–651 (2015). https://doi.org/10.1016/j.fuel.2014.09.027

Mehta, Y., Neal, C., Salari, K., Jackson, T.L., Balachandar, S., Thakur, S.: Propagation of a strong shock over a random bed of spherical particles. J. Fluid Mech. 839, 157–197 (2018). https://doi.org/10.1017/jfm.2017.909

Mehta, Y., Neal, C., Jackson, T.L., Balachandar, S., Thakur, S.: Shock interaction with three-dimensional face centered cubic array of particles. Phys. Rev. Fluids 1(5), 054202 (2016). https://doi.org/10.1103/PhysRevFluids.1.054202

Sen, O., Gaul, N.J., Davis, S., Choi, K.K., Jacobs, G., Udaykumar, H.S.: Role of pseudo-turbulent stresses in shocked particle clouds and construction of surrogate models for closure. Shock Waves 28(3), 579–597 (2018). https://doi.org/10.1007/s00193-017-0801-1

Barua, A., Zhou, M.: A Lagrangian framework for analyzing microstructural level response of polymer-bonded explosives. Modell. Simul. Mater. Sci. Eng. 19(5), 055001 (2011). https://doi.org/10.1088/0965-0393/19/5/055001

Jackson, T.L., Jost, A.M.D., Zhang, J., Sridharan, P., Amadio, G.: Multi-dimensional mesoscale simulations of detonation initiation in energetic materials with density-based kinetics. Combust. Theor. Model. 22(2), 291–315 (2017). https://doi.org/10.1080/13647830.2017.1401121

Moulard, H., Delclos, A., Kury, J.: The effect of RDX particle size on the shock sensitivity of cast PBX formulations: 2, Bimodal compositions. International Symposium on Pyrotechnics and Explosives, Beijing, China. United States: N. p. (1987). https://www.osti.gov/biblio/6079610-effect-rdx-particle-size-shock-sensitivity-cast-pbx-formulations-bimodal-compositions

Borne, L., Patedoye, J.C., Spyckerelle, C.: Quantitative characterization of internal defects in RDX crystals. Propellants Explos. Pyrotech. 24(4), 255–259 (1999). https://doi.org/10.1002/(SICI)1521-4087(199908)24:4%3C255::AID-PREP255%3E3.0.CO;2-2

van der Heijden, A.E.D.M., Bouma, R.H.B.: Crystallization and characterization of RDX, HMX, and CL-20. Cryst. Growth Des. 4(5), 999–1007 (2004). https://doi.org/10.1021/cg049965a

Levesque, G.A., Vitello, P.: The effect of pore morphology on hot spot temperature. Propellants Explos. Pyrotech. 40(2), 303–308 (2015). https://doi.org/10.1002/prep.201400184

Rai, N.K., Schmidt, M.J., Udaykumar, H.S.: Collapse of elongated voids in porous energetic materials: effects of void orientation and aspect ratio on initiation. Phys. Rev. Fluids 2(4), 043201 (2017). https://doi.org/10.1103/PhysRevFluids.2.043201

Lee, E.L., Tarver, C.M.: Phenomenological model of shock initiation in heterogeneous explosives. Phys. Fluids 23(12), 2362–2372 (1980). https://doi.org/10.1063/1.862940

Garcia, F., Vandersall, K.S., Tarver, C.M.: Shock initiation experiments with ignition and growth modeling on low density HMX. J. Phys. Conf. Ser. 500(5), 052048 (2014). https://doi.org/10.1088/1742-6596/500/5/052048

Kumar Rai, N., Udaykumar, H.S.: An Eulerian level set-based framework for reactive meso‐scale analysis of heterogeneous energetic materials. In: Lanbert, D.E. et al. (eds.) Dynamic Damage and Fragmentation, pp. 387–416. Wiley (2019). https://www.wiley.com/en-us/Dynamic+Damage+and+Fragmentation-p-9781786304087

Akiki, G., Jackson, T.L., Balachandar, S.: Pairwise interaction extended point-particle model for a random array of monodisperse spheres. J. Fluid Mech. 813, 882–928 (2017). https://doi.org/10.1017/jfm.2016.877

Lee Perry, W., Clements, B., Ma, X., Mang, J.T.: Relating microstructure, temperature, and chemistry to explosive ignition and shock sensitivity. Combust. Flame 190, 171–176 (2018). https://doi.org/10.1016/j.combustflame.2017.11.017

Rai, N.K., Udaykumar, H.S.: Void collapse generated meso-scale energy localization in shocked energetic materials: non-dimensional parameters, regimes, and criticality of hotspots. Phys. Fluids 31(1), 016103 (2019). https://doi.org/10.1063/1.5067270

Nichols, A., Tarver, C.M.: A statistical hot spot reactive flow model for shock initiation and detonation of solid high explosives. In: 12th International Detonation Symposium, San Diego, CA, UCRL-JC-145031. Lawrence Livermore National Lab, Livermore (2002)

Menikoff, R.: Hot spot formation from shock reflections. Shock Waves 21(2), 141–148 (2011). https://doi.org/10.1007/s00193-011-0303-5

Roy, S., Rai, N.K., Udaykumar, H.S.: Effect of local void morphology on the reaction initiation mechanism in the case of pressed HMX. In: Abstracts of 20th Biennial Conference of the APS Topical Group on Shock Compression of Condensed Matter, St. Louis, Missouri (2017). http://meetings.aps.org/link/BAPS.2017.SHOCK.M9.30

Kondo, R., Yamakawa, S., Masuoka, Y., Tajima, S., Asahi, R.: Microstructure recognition using convolutional neural networks for prediction of ionic conductivity in ceramics. Acta Mater. 141, 29–38 (2017). https://doi.org/10.1016/j.actamat.2017.09.004

Cecen, A., Dai, H., Yabansu, Y.C., Kalidindi, S.R., Song, L.: Material structure-property linkages using three-dimensional convolutional neural networks. Acta Mater. 146, 76–84 (2018). https://doi.org/10.1016/j.actamat.2017.11.053

Menikoff, R., Sewell, T.D.: Constituent properties of HMX needed for mesoscale simulations. Combust. Theor. Model. 6(1), 103–125 (2006). https://doi.org/10.1088/1364-7830/6/1/306

Shu, C.-W., Osher, S.: Efficient implementation of essentially non-oscillatory shock-capturing schemes, II. J. Comput. Phys. 83(1), 32–78 (1989). https://doi.org/10.1016/0021-9991(89)90222-2

Fedkiw, R.P., Aslam, T., Merriman, B., Osher, S.: A non-oscillatory Eulerian approach to interfaces in multimaterial flows (the ghost fluid method). J. Comput. Phys. 152(2), 457–492 (1999). https://doi.org/10.1006/jcph.1999.6236

Kapahi, A., Udaykumar, H.S.: Three-dimensional simulations of dynamics of void collapse in energetic materials. Shock Waves 25(2), 177–187 (2015). https://doi.org/10.1007/s00193-015-0548-5

Acknowledgements

The authors gratefully acknowledge the financial support from the Air Force Research Laboratory Munitions Directorate (AFRL/RWML), Eglin AFB, under Contract Number FA8651-16-1-0005 (Program Manager: Angela Diggs).

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by D. Frost.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

1.1 Governing equations and numerical method for mesoscale computations

The hyperbolic conservation laws for mass, momentum, and energy are solved:

Here, the density and velocity components of the material are denoted by \( \rho \) and \( u_{i} \), respectively. The total specific energy is \( E = e + \frac{1}{2}u_{i} u_{i} \), where \( e \) is the specific internal energy. The source term \( \dot{\varepsilon } \) in (34) is the rise in specific internal energy of the system due to heat released in the decomposition of solid HMX into gaseous reaction products. The quantity \( \sigma_{ij} \) is the Cauchy stress tensor and is given differently for the particle-laden gas flow computations and pressed energetic materials.

The stress tensor \( \sigma_{ij} \) is:

where \( p \) is the pressure and \( \varSigma_{ij} \) refers to the deviatoric components of the stress tensor. For the gas, the deviatoric components \( \varSigma_{ij} \) of the stress tensor are zero and an ideal gas equation of state is used to calculate the pressure:

where \( \gamma \) is the specific heat ratio with a value of 1.4. For the solid energetic materials, the deviatoric stress tensor \( S_{ij} \) is evolved using the following evolution equation:

where \( D_{ij}^{\text{d}} \) is the deviatoric component of the strain rate tensor, \( \varOmega_{ij} \) is the spin tensor, \( D_{ij}^{{{\text{d}},{\text{p}}}} \) is the plastic component of the deviatoric strain rate tensor, and G is the shear modulus of the material. The component \( D_{ij}^{{{\text{d}},{\text{p}}}} \) is obtained using the radial return algorithm [41].

Pressure is obtained from the Birch–Murnaghan equation of state [105], which can be written in the general Mie-Gruneisen form as:

where

The Birch–Murnaghan equation of state is solved to obtain the dilatational response, and the deviatoric response of HMX is obtained by modeling perfectly plastic response under shock loading (Table 3) [105]. Thermal softening caused due to melting of HMX under shock loading is modeled using the Kraut–Kennedy relation [105], \( T_{\text{m}} = T_{\text{m}0} \left( {1 + a\frac{{\Delta V}}{{V_{0} }}} \right) \), with model parameters provided in the work of Menikoff et al. [105]. Once the temperature exceeds the melting point of HMX, the deviatoric strength terms are set to zero. Furthermore, the specific heat of HMX is known to change significantly with temperature. The variation of specific heat is modeled as a function of temperature as suggested in [105]. The specific heat as a function of temperature is obtained from [105]. A three-step chemical decomposition model is applied for the chemical reaction of HMX [2]. A detailed description of the implementation is presented in the previous work [93]. Here, a brief overview of the reaction model and its implementation is provided.

Chemical decomposition of HMX takes place in three steps involving four different species:

The solid HMX (species 1, mass fraction \( Y_{1} \)) under high temperature decomposes into fragments (species 2, \( Y_{2} \)). The fragments are further decomposed to intermediate gases (species 3, \( Y_{3} \)) which are later converted to the final gases (species 4, \( Y_{4} \)) through exothermic reactions leading to high temperatures in the hotspot. In the absence of information about the equations of state for the intermediate and the final products, in this work, it is assumed that these intermediates and the products follow the same cold curves as the bulk material.

Species formed by the chemical decomposition of HMX are evolved in time using the following species conservation equation:

where \( Y_{k} \) corresponds to the mass fraction and \( \dot{Y}_{k} \)—to the mass production rate of the kth species. The change in temperature because of the chemical decomposition of HMX is calculated by solving the evolution equation:

where \( \rho \) is the density of HMX, \( C_{p} \) is the specific heat of HMX, \( T \) is the temperature, \( k \) is the thermal conductivity of HMX, and \( \dot{Q}_{\text{R}} \) is the total heat release rate because of the chemical reaction. The values of \( C_{p} \), λ, and \( \dot{Q}_{\text{R}} \) are obtained from the work of Tarver et al. [2]. The source term in (34) is computed by setting \( \dot{\varepsilon } = C_{v} \dot{T} \), where \( C_{v} \) is the specific heat of HMX at constant volume.

Spatial discretization of the governing equations is performed on a fixed Cartesian grid using a third-order essentially non-oscillatory (ENO) scheme [106]. A third order Runge–Kutta scheme is used for explicit time marching. The computational domain contains objects in the form of particles in the case of gas–particle flows and voids in the case of pressed energetic materials. All interfaces between materials are delineated by a signed distance function or the level-set function \( \varphi \left( {\varvec{x},t} \right) \). The level set \( \varphi \left( {\varvec{x},t} \right) < 0 \) for regions in the interior of the objects and \( \varphi \left( {\varvec{x},t} \right) > 0 \) in the exterior and is defined in a narrow band for each interface [26]. If there are a total of \( N_{\text{obj}} \) objects in the domain, the level-set field for the \( l{\text{th}} \) object is given by a separate narrowband level-set field \( \varphi_{l} (\varvec{x},t) \). No-penetration boundary conditions are applied at interfaces between the gas and solid using the modified ghost fluid method (GFM) [107]; appropriate boundary conditions on free surfaces and crystal–crystal contact conditions for the pressed HMX problem are prescribed [108]. A detailed explanation of the numerical framework used for the mesoscale simulations can be found in previous works [10, 23, 29,30,31, 49].

Appendix 2

2.1 Spatial and temporal homogenization of QoIs for gas–particle flow

The spatially averaged drag \( \overline{{F_{\text{D}} }} (t^{*} ) \) is the mean drag experienced by all the particles in the domain. Details of the averaging methods can be found in previous work [86]. Here, \( t^{*} = \frac{t}{{t_{\text{ref}} }} \) and reference timescale \( t_{\text{ref}} = \frac{{l_{\text{ref}} }}{{u_{\text{s}} }} \), where \( l_{\text{ref}} \) is the reference length scale, and its value is 1.0 based on the dimensions of the square that contains the particle cluster (Fig. 9). The velocity \( u_{\text{s}} \) is the incident particle velocity of the shock. The spatially averaged drag coefficient \( \overline{{C_{\text{D}} }} (t^{*} ) \) in the cluster is:

where \( \rho_{\text{s}} \) is the density of static unshocked fluid, \( u_{\text{s}} \) is the particle velocity, and \( d_{\text{eq}} \) is the equivalent diameter of the particle cluster \( d_{\text{eq}} = \sqrt {\frac{4}{\pi }\varOmega \phi } \) in the domain with area \( \varOmega \) and volume fraction \( \phi \). The velocity fluctuations cause stresses in the gas phase, which appear as the pseudo-turbulent stress tensor, \( S_{ij} \), given by:

where \( u_{i}^{\prime } (\varvec{x},t^{*} ) \) is the velocity fluctuation field:

and the Favre-averaged gas slip velocity \( \widetilde{u}_{\text{g}} (t^{*} ) \) is calculated as follows:

where \( \rho \) and \( u_{\text{g}} \) are the fluid phase density and velocity component, respectively.

The spatially-averaged pseudo-turbulent stress tensor \( \tilde{S}_{ij} (t^{*} ) \) is:

The spatially averaged pseudo-turbulent kinetic energy (PTKE [86]), i.e., \( \widetilde{\text{PTKE}}(t^{*} ) \), is:

The temporal homogenization is performed over a time \( T^{*} \) beginning with the shock entering the cluster until the entire incident shock wave leaves the particle cluster. The spatiotemporally-averaged drag coefficient \( \left\langle {\overline{{C_{\text{D}} }} } \right\rangle \) is obtained as:

The spatiotemporally-averaged pseudo-turbulent stress tensor \( \tilde{S}_{ij} \) is given by:

And the spatiotemporal average of the PTKE, \( \left\langle {\widetilde{\text{PTKE}}} \right\rangle \), is defined as follows:

Appendix 3

3.1 Spatial homogenization of QoIs in shocked HMX

The product species mass fraction is denoted by \( Y_{4} (x,t) \) and is evolved using the conservation equations for species (43). The rate of chemical decomposition of HMX within the entire domain is calculated by accumulating the mass of the final gaseous products via:

\( M_{\text{reacted}} \) is calculated for the entire domain of area \( \varOmega \), and \( \rho \) is the local density. The burned fraction of HMX, \( F \), is the mass of the solid converted to reaction product gaseous species denoted by \( F \) which is useful to study the long-term behavior for a field of voids. The fraction of fully burned HMX to the total mass of HMX in the control volume is:

where \( M_{\text{HMX}} \) is the total mass of HMX present in the control volume \( \varOmega_{ } \) prior to the start of chemical reactions.

Rights and permissions

About this article

Cite this article

Roy, S., Rai, N.K., Sen, O. et al. Structure–property linkage in shocked multi-material flows using a level-set-based Eulerian image-to-computation framework. Shock Waves 30, 443–472 (2020). https://doi.org/10.1007/s00193-020-00947-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00193-020-00947-y