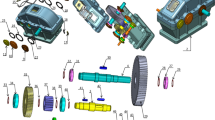

A feature-based assembly model is proposed for disassembly sequence planning, and establishing a correct and practical disassembly path for the part in the product, based on geometric reasoning and knowledge. The fundamental assembly modelling strategy for a product is based on the mating features of its parts.

An algorithm is introduced which uses the information provided by the mating features of parts in the product to find the candidate parts for disassembly and to carry out disassembly path planning. A complete and accurate interference checking approach is used to ensure no global collision while disassembling a part.

In some cases, it cannot be implemented by geometric reasoning alone, so a set of criteria and heuristic rules based on knowledge, constraints, relationships among parts, and quantitative disassemblability assessment are used. It can also be carried out interactively by the user when necessary.

The proposed method is integrated with the CAD model of the product. The user can visually disassemble the product while planning, so it is easier to carry out the disassembly planning and generate an optimal sequence.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hu, D., Hu, Y. & Li, C. Mechanical Product Disassembly Sequence and Path Planning Based on Knowledge and Geometric Reasoning. Int J Adv Manuf Technol 19, 688–696 (2002). https://doi.org/10.1007/s001700200114

Issue Date:

DOI: https://doi.org/10.1007/s001700200114