Abstract

Free-form surfaces generated by non-uniform rational B-splines (NURBS) are evolving to face turbomachinery component requirements, such as turbine blades to enhanced efficiency. Super abrasive machining (SAM) is presented as a potential process for high-added value components using custom-shaped tools to be adapted to any surface. The adaptability and flexibility of these tool concepts are specifically designed to fit these complex surfaces. This paper presents an innovative manufacturing approach for blade type components using a custom-shaped tool designed through an optimization process that simultaneously optimizes both the shape of the tool and its motion. The proposed method with SAM finishing using a custom-shaped tool is compared against a standard tool and traditional machining process. The result obtained on the blade test case shows that the custom-shaped tools need fewer paths, yet produce more accurate surface finish.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The aerospace industry has undergone a significant transformation, becoming a leading field. For the aerospace industry to thrive, innovation must be at the forefront of its priorities, which includes optimizing manufacturing processes. Nevertheless, as surface finish specifications tighten, the geometries of the aeronautical industry components become more complex [1]. Analytical representations exist for many of these aeronautical components; however, there are also surfaces for which there are no such analytical descriptions. Optimal shape for these complex components is governed by, typically non-linear, partial differential equations (PDE) for which only an approximate solution exists. Consequently, significant effort is dedicated to mathematical modelling and the optimization of parameters for machining these type of complex parts, especially those with free-form surfaces [2].

A free-form object typically consists of a compilation of control points that are blended by a set of basis functions, typically polynomial or rational, in order to form the desired shape. In the case of surfaces, a network of control points, known as a control mesh, is used to model the desired shape.

A significant step forward in modelling of smooth shapes came with the so-called Bézier curves and surfaces that became standards for modelling of curved objects and initiate a lot of follow-up research. One of the limitations of the Bézier surfaces, however, is that each control point globally affects the whole geometry. In contrast, B-splines possess the advantage of local control, which offers a huge advantage to model complex shapes [3]. The most natural generalization from B-spline curves to B-spline surfaces is via the tensor product construction, which transfers the 1D parametric entities, such as the parametric domain, knot vectors, and basis functions, into 2D. This construction inherits the local property from 1D, giving the surface the possibility to model important features. B-spline surfaces find their application in many areas; e.g., in aeronautics, they are used for aerodynamic optimization [4].

Modelling with B-splines presents several ways to get more degrees of freedom. For instance, the polynomial degree can be increased, the knot vector(s) can be refined, or each control point can be associated with a positive number, a weight, which intuitively signals the importance of the particular point (and consequently the basis function) in the curve or surface construction. This construction leads to more expensive rational basis functions; on the other hand, it gives an extra degree of freedom over traditional B-splines. In fact, these non-uniform rational B-spline curves and surfaces found its application, e.g., in computer graphics and geometric modelling for engineering [5].

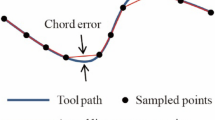

To face this challenge, advances in computers’ performance and the adoption of open architecture in CNC machines enable the direct machining of contoured geometry using NURBS curves derived from the free-form surfaces of CAD/CAM models. Empirical experiments substantiate that NURBS cutting notably leads to improve machining accuracy, increase product quality, and significantly reduce machining time, effectively meeting the demands of high-speed, high-precision machining [6].

Considering the statements mentioned above, certain aeronautical components are being designed using free-form surfaces. For instance, many researches focus on the rotating components of turbomachinery, such as turbine blades and impellers, due to their design complexity because of their free-form nature [7,8,9]. These elements play a crucial role in the transfer of energy between flow of a gas and a mechanical component. The geometric development of the flow passage, determined by the inner and outer surfaces of adjacent blades, is responsible for performing this function. Hence, functional requirements dictated by mechanical, hydraulic, and machining principles limit the design of these surfaces [10]. The impellers bring a decent challenge to design and manufacturing capabilities of five-axis machining. This is attributed to the intricate design of the impeller’s surface, characterized by a highly twisted profile and blades that significantly overlap with each other [11].

Identifying the optimal CNC machining approach for a specific free-form object continues to pose an ongoing and notably demanding objective to achieve [12]. Presented a literature review defining different conventional and non-conventional manufacturing processes for IBR manufacturing, focusing on conventional five-axis milling process and super abrasive machining. Moreover, various studies analyse a given free-form rational surface approximation by ruled surfaces [7, 13]. The primary goal is to enhance the machining process by minimizing tool deflection and vibrations. Other studies indicate that machining these aeronautical components is strongly correlated with cutting forces, which should be low. This is because operational failures of heavily loaded impellers often stem from blade breakage caused by dynamic overloading of the blade material [14].

There are also some other crucial factors, such as optimizing tool trajectories and geometry [15]. Conical tools are commonly used for the finishing of complex surfaces. Cylindrical cutters, considering them as a special case of conical ones, allow for the straightforward resolution of various real-world industrial challenges. Nevertheless, in scenarios demanding flank milling within confined spaces, opting for a conical cutter might be more advantageous due to its smaller tip and stronger shank [16].

From the point of view of approximation of two geometric entities, it is very difficult to approximate a curved (free-form) geometry by a motion of a straight (conical, cylindrical) tool. Therefore, a curved, custom-shaped, tool can be considered, to match better a given curved geometry, and simultaneously optimize the shape of the tool and its trajectories [17]. The developed algorithm ensures that the resultant envelope is a highly accurate approximation of the input free-form surface. Furthermore, similar approach was applied to create a super abrasive machining (SAM) tool considering a blade surface generatrix [18], where it is shown that this new technology of custom-shaped tools is advantageous in terms of both accuracy and manufacturing time. Therefore, SAM serves as a solution to improve machining efficiency in the production of aeronautical components, due to the fact that it offers the precision of a grinding process with comparable feeds and costs to single-point machining. In the study [19], cutting forces, surface finishing, and dimension accuracy are analysed by comparing SAM technologies with the conventional milling process for IBR blades. The comparison involves the use of oil emulsions instead of mineral cutting oils.

The novelty of the proposed work lies in an innovative approach of manufacturing a custom-shaped SAM tool and its motion used for super abrasive machining applied on a complex blade type surface. Two blade samples are manufactured, one using conventional tools and machining process, and, the other one, incorporating a custom-shaped SAM tool and motion. Results are analysed taking into account dimensional deviations and surface roughness values.

2 Blade definition

This work presents the manufacturing process of two blisk blades with the same geometry, represented by free-form surfaces. The manufacturing process of the first blade was performed with standard tools. In the case of the second blade, the roughing and semi-finishing operations were manufactured using the very same conditions as the first blade; however, the finishing operation was manufactured with a custom-shaped SAM tool. This comparison was performed on the finishing operation, due to the fact that it is considered the most critical part of the machining process.

2.1 Work piece design

The manufacturing process of these blades started from a solid block of 60 × 50 × 85 mm. The final geometry was designed in the Siemens® NX Software, as it can be seen in Fig. 1. The blade dimensions are 59.09 mm high and a maximum and minimum thickness of 2.29 mm and 0.38 mm respectively.

2.2 Workpiece material

AISI 1045 material was selected for the turbine blades, which is a medium carbon steel that is in great demand for applications requiring higher stresses and hardness, and it is a steel similar in machinability to titanium alloy. Using steel allows us not to consider the effect of tool wear that could make interpretation of the result difficult.

2.3 Tools design-manufacture for the blade manufacturing

The custom-shaped SAM tool was designed and manufactured in four process stages. First, the tool was designed and optimized to approach the geometry of the blade during its whole motion. Secondly, theoretical simulations were carried out to check the accuracy of the tool path in relation to the blade free-form surfaces of the blade. Then, the tool core was manufactured, and, finally, the tool’s cutting edge was coated with abrasive grains.

2.3.1 Tool and motion design and optimization

In the presented development, the custom-shaped tool and its motion were designed and optimized. The approach consisted of two stages, namely the initialization and the optimization.

Initialization

The user-driven initialization was applied, where the ruled surface R was initialized by manually sketching a few lines on the reference surface. These lines represented the contact curves between the tool and the reference surface S. The endpoints were lifted in the direction of surface normal. The lifting distance was related to the desired tool’s size. Initially, a preliminary tool axis length was determined based on the intended number of tool paths for surface machining. Subsequently, a practical range for the tool radius was established to avoid issues such as fragility or motion instability. Finally, the lifting distance was set to align with the determined reasonable tool radius. Then, a ruled surface R was generated taking the end points of the line segments as control points, which was defined by the following equation:

where a(t) and b(t) were cubic B-spline curves for the two boundary curves of the surface. The distance of the endpoint (length of the axis of the tool) was not constant at this point and was optimized in the optimization stage.

The tool was a rotational body, and its shape was conceptualized as an envelope of a one-parameter family of spheres centred along the axis \(l\). Each sphere was represented by its centre (point on the cutter axis) and the radius. In the discrete setup, n = 20 spheres were used and their radii were stored in a vector d = [d1, d2, …, dn], with sphere centres being uniformly sampled points on \(l\). The initial profile of the tool was estimated by computing the footpoints of the sampled points on the axis and by averaging the corresponding radii of the spheres.

The user-driven initialization was opted as it avoids computationally expensive search for lines and also controls better the motion. The blade geometry had strong constraints on the motion of the tool due to the collisions with the neighbouring blades, recall Fig. 1.

Optimization

The optimization took the ruled surface R and the initial profile of the custom-shaped tool as the input and optimized simultaneously both. The unknowns in the optimization were the control points of two boundary B-spline curves, a(t) and b(t), that define R, and the vector of radii d.

There are several objectives that the optimization aims to achieve:

-

Rigidity of the tool. Since the tool is a rigid rotational body, the length L of the axis had to be constant throughout the motion. This was expressed by a distance constraint on the corresponding endpoints of axis, a(ti) and b(ti), at time instant ti. The rigidity constraint was defined by the following equation:

$${F}_{rigid}\left({\varvec{a}},{\varvec{b}}\right)=<{\varvec{a}}\left({t}_{i}\right)-{\varvec{b}}\left({t}_{i}\right),{\varvec{a}}\left({t}_{i}\right)-{\varvec{b}}\left({t}_{i}\right)>-{L}^{2}=0$$(2) -

Approximation quality. The motion of the tool had to approximate, as good as possible, the reference surface S. This was expressed in terms of the distance differences between the point-footpoint distance and the corresponding radius of the inscribed sphere. Let S denote the surface to machine. During the motion of a rigid rotary cutting tool, each point along the cutter axis \(l\) must maintain its distance to S. The point \({{\varvec{p}}}_{ij}=R({s}_{i},{t}_{j})\) on \(l\) remained the distance \({d}_{j}\) to S in motion. \({{\varvec{p}}}_{ij}^{\perp }\) was denoted as the footpoints on S for \({{\varvec{p}}}_{ij}\), and \({{\varvec{n}}}_{ij}\) the unit normals at \({{\varvec{p}}}_{ij}^{\perp }\) oriented towards \({{\varvec{p}}}_{ij}\).

Two distance sub-terms were considered; namely, the distance to the footpoint on S (Fpoint) and to the tangent plane of S at the footpoint (Fplane) were defined as follows:

-

Motion fairness. To avoid high acceleration and jerk values, a fairness term (Ffair) was applied to the triplets of three consecutive positions of the endpoints on either of the boundary curves (a and b), defined as follows:

$${F}_{fair}\left({\varvec{a}},{\varvec{b}}\right)=\frac{1}{m}{\sum }_{i=2}^{m-1}{\left({\varvec{a}}\left({t}_{i-1}\right)-2{\varvec{a}}\left({t}_{i}\right)+{\varvec{a}}\left({t}_{i+1}\right)\right)}^{2}+\frac{1}{m}{\sum }_{i=2}^{m-1}{\left({\varvec{b}}\left({t}_{i-1} \right)-2{\varvec{b}}\left({t}_{i}\right)+{\varvec{b}}\left({t}_{i+1}\right)\right)}^{2}$$(5)

The final objective function was built as follows:

with the weights the weights μ1 = 1, μ2 = μ4 = 0.1, and μ3 = 0.001 and the Gauss–Newton method was used for the optimization.

2.3.2 Virtual verification

A batch of 18 simulations were run to test the impact of the parameters that affect the final approximation quality. In particular, it was tested varying the number of parameters within the algorithm, such as the number of points and vectors of the path, the number of vertical passes needed to finish the workpiece, or the approximate diameter of the tool.

This batch can be divided into four main groups, as there were variations among the simulations focusing on achieving the optimum geometry. First, the parameters were set to approach the blade geometry as closely as possible. Then, the number of patches was reduced, and the number of points and vectors needed to calculate the trajectories was analysed. Subsequently, in the third group of simulations, a bigger diameter tool was selected, and for the last group, the value of the tool diameter was again increased. Thereafter, in this section not only are the variations presented but also the results obtained regarding the tool geometry and the expected theoretical deviations.

In Table 1, the experiments of the first group are presented.

In the first experiment (1), with the objective to achieve an accurate approximation, the surface was divided into 11 patches of free-form surfaces on which the flank SAM could be performed. However, the tool holder collided with the workpiece, so although the motion of the tool was a geometrically valid solution, from a machining point of view, it was not physically feasible. For this reason, the values are not shown in Table 1. In the second experiment (2.1), the direction and rotation of the tool axis were programmed to be in the opposite direction to the workpiece. The result obtained was satisfactory over the whole surface, except for the overlap between patches 9 and 10, due to the fact that the tool did not machine in that small area, as can be seen in the brown area of Fig. 2.

Considering the results obtained in the experiment 2.1, the same theoretical simulation was carried out with the same tool (experiment 2.2). Nonetheless, on this occasion, the number of points and vectors of the trajectory was increased from 300 to 600, obtaining a very similar result in terms of dimensional deviation, as can be seen in Fig. 2.

After seeing that the blade surface can be very well approximated with a large number of patches, group 2 of the batch was executed reducing the number of patches as is shown in Table 2. The objective was to maintain a similar quality of finishing, but to reduce the machining time and the number of overlaps between the paths, so increase the efficiency of the process.

In the experiment number 3, the dimensional deviation error increased as the number of patches decreased, as a consequence of covering a larger area with a larger tool. It can be observed that the tool approaches more accurately in the lower area of the patches, while it leaves an excess of material in the upper area. Afterwards, the fourth experiment was carried out, presenting overall better results; however, there were some areas where the dimensional deviation was bigger, as shown in Fig. 3.

Subsequently, a new experiment (5.1) was run with the intention of testing if there could be a further reduction in the number of patches. The number was reduced to 2, and admissible results were obtained on more than three quarters of the surface area, notwithstanding the fact that there was an overmachining of about 0.08 mm in the contact zone at the entrance as it is shown in Fig. 3. Consequently, with the object to analyse the influence of the number of points and vectors, they were doubled to 600 (experiment 5.2), and divided to 100 (experiment 5.3). In the first case, the result was slightly improved in certain areas of the surface, but nothing changed in absolute terms. The same happened with the one with fewer points; the result was similar, with slightly worse results.

Experiments 6 and 7.1 were then conducted to refine the geometry of the tool, in the first case with two patches and in the second with four. The results of the 7.1 experiment were the best (− 0.03/ + 0.02), as seen in Fig. 3. Finally, another experiment was run with the data from 7.1 (experiment 7.2), in which the points and vectors were doubled to 600, obtaining very similar results.

Reasonable results were acquired with a reduced number of patches. The experiments of the group 3, shown in Table 3, were decided to use a number of four patches and to gradually increase the diameter of the desired tool, due to the fact that the four or five diameters are too small to withstand the forces of SAM.

Considering the results of the eighth experiment, they show a repetitive pattern of excess non-machining across the entire surface, which was not admissible. Then, a new experiment (9.1) was performed, in which very good results were obtained (− 0.03/ + 0.01). As in the previous stage, it was simulated doubling the number of points, obtaining the same results, as shown in Fig. 4.

Finally, the value of the tool diameter was increased to 12 mm reducing the number of patches to two. In total, four experiments (10–13) were performed in this fourth group, improving the dimensional deviation as shown in Table 4. This group simulations according to the expected dimensional deviation are represented in Fig. 5.

Once it was verified that the results obtained with different tools, number of patches, and number of points and vectors met the expected theoretical dimensional deviation values, which were set at ± 50 µm according to [9], the geometry calculation part of the tool geometry algorithm was considered valid. The tool with the parameters of the thirteenth experiment was applied to the demonstrator of this work, as will be explained in the following sections.

2.3.3 Tool core manufacturing

Considering the custom-shaped tool geometry according to the algorithm described in Sect. 2.3.1, a cylinder of 40 mm of diameter was the initial raw block. AISI 1055 steel was used as a constitutive material for this custom-shaped tool, which presents a high electrical conductivity among wrought carbon or non-alloy steels, with a ductility and a high tensile strength. Moreover, it is essential to mention that this steel is easily electroplated with abrasive grains.

The manufacturing process was defined by three different operations: roughing, semi-finishing, and finishing. The first one was performed with a manual turning centre, Pinacho S-90/260, for the removal of the maximum amount of material. With this objective, a square roughing CNMG 12 04 12-PR 4225 (Sandvik Coromant®) was used performing five turning passes with a depth of cut of about 2 mm, reducing the initial diameter to 20 mm.

The second and third operations were programmed by the Siemens®NX Software. In these operations, a CAM programme was needed because a combination of different patches was used to create the cutting zone, obtaining the free-form surface. Both operations were performed in the CNC turning centre (CMZ TC25 BTY with FANUC 31iT numerical control) equipped with four axes, X, Y, Z, and the rotary axis C.

Then, the semi-finishing operation was done to bring the surface closer to the final size, reducing surface irregularities. Taking this into account, a square CNMG 120408EN-M34 CTPX710 (Ceratizit) tool was chosen to carry out the operation.

Finally, for finishing operation, a rhombic VBMT 16 04 08-PR 4225 (Sandvik Coromat®) was selected to obtained the final geometry of the core of the tool as it is shown in Fig. 6.

Summarizing the tool manufacturing process, the cutting speed (Vc), feed per tooth (fz), cutting depth (ap), and the tools used in each machining operation are listed in Table 5.

2.3.4 Electrodeposition operation

To give the tool the cutting condition, abrasive grains were added to the tool core by electroplating in a single layer. SK-16–20-R1,2, grains were selected to be distributed among the surface (see Fig. 7), due to their capacity to preserve their inherent structure and size throughout their functional life. Moreover, it is crucial to mention that electroplating facilitates the emergence of diamond particles from the bonding matrix, enhancing cutting speed while minimizing heat production.

3 Experimental set-up

Both blisk blades were manufactured using a five-axis milling centre Kondia HS1000, being numerically controlled by Heidenhain iTNC530. It has spindle speed capacity of 25,000 rpm and a spindle motor power capacity of 18 KW.

Concerning machining processes, the roughing and semi-finishing operations were performed under the same cutting tools and the same cutting parameters. Finally, in order to compare the two approaches, finishing operations were carried out: conventional manufacturing and SAM.

In the case of the roughing operation, a solid carbide end-mill top-cut tool was used, FRANKEN A1916A.018, because it allows low-vibration machining. In Fig. 8a, the trajectories of the roughing operation are represented, whereas in Fig. 8b, the turbine blade surface after machining can be seen.

Regarding the semi-finishing operation, a tapered solid carbide ball nose end mill turbine tool, FRANKEN 3440L.06030B, was utilized, which has three slots and various taper angles design, and is considered ideal for semi-finishing and finishing turbine or other complex components. In Fig. 9a, the trajectories of these semi-finishing operations can be seen, whereas in Fig. 9b, the turbine blade surface after machining is shown.

Finally, according to the blade rounding, it was achieved with a solid carbide ball nose end mill top-cut “Lollipop” tool, FRANKEN 1935A.003, which is characterized by its ball nose with a cutting range of up to 240° and allows machining below the cutting line.

Tool characteristics and cutting conditions like cutting speed (Vc), feed per tooth (fz), and cutting depth (ap) are summarized in Table 6.

According to the finishing operations, the first blade was finished with the tapered solid carbide ball nose end mill turbine tool, with a cutting speed of 100 m/min, a feed of 0.0047 mm/rev, and a cutting depth of 0 mm. On the other hand, the second blade was finished with the custom-shaped SAM tool with a cutting speed of 376.992 m/min, a feed per tooth of 0.0167 mm/rev, and a cutting depth of 0.1 mm.

In Fig. 10, both blades are shown after the finishing operations. The left image shows the blade manufactured with conventional tools, while the right image illustrates the blade finished with the custom-shaped SAM tool.

4 Results and discussions

4.1 Dimensional deviation

The workpieces were measured using a laser scanner and a Mitutoyo® Coordinate Measuring Machine. In order to ensure measurement repeatability a stable temperature of 20 °C, with a specific fixture was used.

The results obtained were analysed with the GOM®Inspect Software. Thus, profile deviations produced during manufacturing are observed in Fig. 11. The blade manufactured with the custom-shaped SAM tool presents better results than the blade manufactured with standard tools (deviations under 48 μm). It should be noted that a deviation of 50 μm is tolerated for these blade components, and in this instance, the deviations recorded are below this threshold [9].

4.2 Roughness

Additionally, roughness measurements were performed in Leica®DCM3D. This system combines confocal technology with interferometry for high-speed measurements with excellent resolution down to 0.1 nm. Figure 12 demonstrates that even that the blade manufactured with conventional tools presents a uniform surface, the blade manufactured with the custom-shaped SAM tool presents less roughness deviation. In fact, the blade manufactured with conventional tools has an average roughness (Ra) of 6.21 μm, whereas with the custom-shaped SAM tool, it presents a Ra of 2.67 μm. It was presented an improvement in the majority of the roughness parameters that the mean values of five consecutive maximum heights between peak-valley (Rz) are halved, from 30 to 12.5 μm.

4.3 Discussion

Before moving to the concluding remarks, it is important to consider the developed solution and discuss the key identified advantages. The integration of the proposed custom-shaped tools for SAM manufacturing processes brings significant benefits for productivity, time-consuming reduction, and waste of material. The main findings include the following:

On the one hand, the use of a customized SAM tool is expected to provide a better dimensional finish than conventional machining due to the abrasive nature of the process. The SAM process implies a suitable and controllable machining that improves the production of high added value components in terms of roughness, microhardness, white layer, and residual stresses [20]. On the other hand, it should be noted that the optimized design of a custom-shaped tool surface allows a better adaptation to the surface to be manufactured, reducing the marks resulting from machining and the number of passes required to obtain the same surface [21].

In terms of both the dimensional deviation and the roughness values obtained, the advantages of combining SAM with customized tooling can be appreciated. It should be noted that the solution presented here is suitable for parts with low machinability, high added value, and complex geometries, in order to achieve a balance between the manufacture of custom-shaped tools instead of standard tools and the machining time, as well as the reduction of possible subsequent finishing operations to eliminate intrinsic machining marks. Moreover, from an economic point of view, it is also important to consider that the manufacture of the custom-shaped tool core reduces costs by 55.2% compared to the use of standard tools.

5 Conclusions

This research studies an efficient design of the custom-shaped tool and its motion, designed, and optimized for a blade type component, using a custom-shaped SAM tool. The study insights that:

-

(a)

The proposed approach uses a custom-shaped tool that is designed and optimized such that its shape fits the target blade geometry, globally throughout its paths. The tool is used then in the finishing stage of five-axis flank CNC machining.

-

(b)

The motion developed for the tools was tested with computer simulations and was validated with real machining scenarios, which were further compared against a workpiece manufactured with conventional tools.

-

(c)

Combining the results obtained in relation to the dimensional results, where the blade manufactured with the custom-shaped SAM tool presents better results than the blade manufactured with standard tools, deviation in tolerances, under 48 μm, and the surface roughness results, where the blade manufactured with the custom-shaped SAM tool presents a smaller deviation (2.67 μm Ra), it is proved that this custom-shaped SAM tool is suitable for the blade components.

Therefore, future research points to incorporating physical machining objectives like forces and vibrations analysis. Another venue for future research is testing and analysing the wear of this tool on this type of surfaces.

Abbreviations

- NURBS:

-

Non-uniform rational B-splines

- SAM:

-

Super abrasive machining

- CMM:

-

Coordinate measuring machining

- IBR:

-

Integrally bladed rotors

- CNC:

-

Computer numerical control

- CAD:

-

Computer-aided design

- CAM:

-

Computer-aided manufacturing

References

Valdés RMA, Burmaoğlu S, Tucci V, Da Costa Campos LMB, Mattera L, Comendador FG (2019) Flight path 2050 and ACARE goals for maintaining and extending industrial leadership in aviation: a map of the aviation technology space. Sustainability 11(7):2065. https://doi.org/10.3390/su11072065

Wang G, Li W, Rao F, He Z, Yin Z (2019) Multi-parameter optimization of machining impeller surface based on the on-machine measuring technique. Chin J Aeronaut 32(8):2000–2008. https://doi.org/10.1016/j.cja.2018.09.005

Farin G, Hoschek J, Kim MS (2002) Handbook of computer aided geometric design. Elsevier

Lee C, Koo D, Zingg DW (2017) Comparison of B-spline surface and free-form deformation geometry control for aerodynamic optimization. AIAA J 55(1):228–240. https://doi.org/10.2514/1.j055102

Rogers D (2001) An introduction to NURBS. Elsevier. https://doi.org/10.1016/b978-1-55860-669-2.x5000-3

Yau H, Kuo ML (2001) NURBS machining and feed rate adjustment for high-speed cutting of complex sculptured surfaces. Int J Prod Res 39(1):21–41. https://doi.org/10.1080/00207540010002360

Qi R, Liu W, Bian H, Li L (2009) Five-axis rough machining for impellers. Front Mech Eng China 4(1):71–76. https://doi.org/10.1007/s11465-009-0010-4

Kumar S, Mani V, Devraj N (2014) Production planning and process improvement in an impeller manufacturing using scheduling and OEE techniques. Proc Mater Sci 5:1710–1715. https://doi.org/10.1016/j.mspro.2014.07.360

Klocke F, Schmitt R, Zeis M, Heidemanns L, Kerkhoff J, Heinen D, Klink A (2015) Technological and economical assessment of alternative process chains for Blisk Manufacture. Procedia CIRP 35:67–72. https://doi.org/10.1016/j.procir.2015.08.052

Chaves-Jacob J, Poulachon G, Duc E (2011) Optimal strategy for finishing impeller blades using 5-axis machining. Int J Adv Manuf Technol 58(5–8):573–583. https://doi.org/10.1007/s00170-011-3424-1

Chuang L, Young H (2006) Integrated rough machining methodology for centrifugal impeller manufacturing. Int J Adv Manuf Technol 34(11–12):1062–1071. https://doi.org/10.1007/s00170-006-0675-3

González-Barrio H, Calleja-Ochoa A, Lamikiz A, López de Lacalle LN (2020) Manufacturing processes of integral blade rotors for turbomachinery, processes and new approaches. Appl Sci 2020(10):3063. https://doi.org/10.3390/app10093063

Wang CCL, Elber G (2014) Multi-dimensional dynamic programming in ruled surface fitting. Comput Aided Des 51:39–49. https://doi.org/10.1016/j.cad.2014.02.004

Sonthipermpoon K, Bohez ELJ, Hasemann H, Rautenberg M (2009) The vibration behavior of impeller blades in the five-axis CNC flank milling process. Int J Adv Manuf Technol 46(9–12):1171–1177. https://doi.org/10.1007/s00170-009-2182-9

Calleja A, Bo P, Martı́Nez, S., Bartoň, M., & De Lacalle, L. N. L. (2018) Highly accurate 5-axis flank CNC machining with conical tools. Int J Adv Manuf Technol 97(5–8):1605–1615. https://doi.org/10.1007/s00170-018-2033-7

Li C, Bedi S, Mann S (2005) Flank milling of a ruled surface with conical tools—an optimization approach. Int J Adv Manuf Technol 29(11–12):1115–1124. https://doi.org/10.1007/s00170-005-0002-4

Bo P, Bartoň M, Plakhotnik D, Pottmann H (2016) Towards efficient 5-axis flank CNC machining of free-form surfaces via fitting envelopes of surfaces of revolution. Comput Aided Des 79:1–11. https://doi.org/10.1016/j.cad.2016.04.004

Escudero GG, Martı́Nez S, Bartoň M, Bo P, Fernández-Lucio P, De Lacalle NL, Calleja A (2019) Free-form tools design and fabrication for flank super abrasive machining (FSAM) non developable surfaces. MM Sci J 2019(04):3093–3098. https://doi.org/10.17973/mmsj.2019_11_2019056

González H, Calleja A, Pereira O, Ortega N, López de Lacalle LN, Barton M (2018) Super abrasive machining of integral rotary components using grinding flank tools. Metals 8:24. https://doi.org/10.3390/met8010024

González H, Pereira O, Fernández-Valdivieso A, de López LLN, Calleja A (2018) Comparison of flank super abrasive machining vs. flank milling on Inconel 718 surfaces. Material 11(9):1638. https://doi.org/10.3390/ma11091638

Bo P, González H, Calleja A, de López LLN, Barton M (2020) 5-axis double-flank CNC machining of spiral bevel gears via custom-shaped milling toos-Part I: modeling and simulation. Precision Engineeing 62:204–212. https://doi.org/10.1016/j.precisioneng.2019.11.015

Acknowledgements

The authors owe deeply thanks to Basque Government university group IT 1573, High performance machining, MiCINN PDC2021-121792-I00 New cutting tools production for manufacturing high added-value turbomachinery components with acronym: HCTAYLOR. In addition, the authors thanked the vice chancellor of innovation, social compromise, and cultural action from UPV/EHU (Bizialab program from Basque Government).

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. The authors received Grant PID2019-109340RB-I00 funded by MCIN/AEI/https://doi.org/10.13039/501100011033. The research was also financially supported by the National Natural Science Foundation of China (No. 62072139); by the Basque Government BERC 2022–2025 program; by the Spanish Ministry of Science, Innovation and Universities, grant No. PID2019-104488RB-I00; by BCAM “Severo Ochoa” accreditation CEX2021-001142-S; and by the European Union’s Horizon 2020 program under grant agreement no. 862025.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception, design, material preparation, data collection, and analysis. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Martinez-Aguirre, M., Gómez, G., Bo, P. et al. Design, motion-planning, and manufacturing of custom-shaped tools for five-axis super abrasive machining of a turbomachinery blade type component. Int J Adv Manuf Technol 133, 655–669 (2024). https://doi.org/10.1007/s00170-024-13774-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13774-7