Abstract

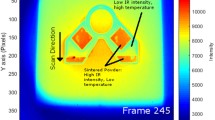

The estimation and control of the substrate temperature in the Metal Organic Chemical Vapor Deposition (MOCVD) of superconductor tape manufacturing is investigated. In the advanced MOCVD (AMOCVD) for High-Temperature Superconductor (HTS) tape manufacturing developed at the University of Houston, Ohmic resistance heating is implemented to heat the rolling tape at a reference temperature. Control of the electric current through the tape is proposed to ensure substrate temperature uniformity that is essential for reducing nanoscale defect growth. The substrate temperature measurement is corrupted by the continuous deposition of precursor gas material on the crystal rods of the pyrometers in the reaction chamber challenging the real-time control process. The proposed approach for model-based substrate temperature control is based on the real-time estimation of the states of the substrate temperature model dynamics, and the sensor drift and drift rate, using an extended Kalman filter (EKF) combined with particle swarm optimization (PSO) to optimally tune the process and measurement noise covariance matrices. Experimental data from the AMOCVD facility are used to validate the model parameter and the sensor drift estimation process. The estimated temperature is used in a simulation study of a PSO-tuned LQR controller with adjustable gains designed to ensure uniform heating along the tape by controlling the electric current, and the results are compared with those of a PI controller. Precise temperature regulation in Ohmic heating is critical within a multitude of manufacturing and material processes, and the proposed methods constitute a systematic framework for model-based temperature estimation and control.

Similar content being viewed by others

Change history

23 May 2024

A Correction to this paper has been published: https://doi.org/10.1007/s00170-024-13778-3

References

Miller LM, Coleman JJ (2006) Metalorganic chemical vapor deposition. Crit Rev Solid State Mater Sci 15:1–26. https://doi.org/10.1080/10408438808244623

Yang FH (2014) 2-Modern metal-organic chemical vapor deposition (MOCVD) reactors and growing nitride-based materials. Adv Mater Technol, pp 27–65. https://doi.org/10.1533/9780857099303.1.27

Selvamanickam V, Xie Y, Reeves J, Chen Y (2004) MOCVD-based YBCO-coated conductors. MRS Bull 29:579–582. https://doi.org/10.1557/mrs2004.164

Majkic G, Pratap R, Galstyan E, Xu A, Zhang Y, Selvamanickam V (2017) Engineering of nanorods for superior in field performance of 2G-HTS conductor utilizing advanced MOCVD reactor. IEEE Trans Appl Supercond 27:1–5. https://doi.org/10.1109/TASC.2016.2637328

Pratap R, Majkic G, Galstyan E, Mohanasundaram G, Chakradhar S, Selvamanickam V (2019) Growth of high-performance thick film REBCO tapes using advanced MOCVD. IEEE Trans Appl Supercond 29:1–5. https://doi.org/10.1109/TASC.2019.2899244

Chen S, Majkic G, Jain R, Pratap R, Mohan V, Goel C, Selvamanickam V (2021) Scale up of high-performance REBCO tapes in a pilot-scale advanced MOCVD tool with in-line 2D-XRD system. IEEE Trans Appl Supercond 31:1–5. https://doi.org/10.1109/TASC.2021.3058868

Selva research group https://selva.me.uh.edu/facilities/

Selvamanickam V (2019) Advanced manufacturing of high performance superconductor wires for next generation electric machines. https://www.energy.gov/sites/prod/files/2019/07/f65/Projects19%20-%20Advanced%20Manufacturing%20of%20Superconducting%20Wires%20for%20NGEM_U%20of%20Houston.pdf

Laamari Y, Chafaa K, Athamena B (2015) Particle swarm optimization of an extended Kalman filter for speed and rotor flux estimation of an induction motor drive. Electr Eng 97:129–138. https://doi.org/10.1007/s00202-014-0322-1

Bian X, Wei Z, He J, Yan F, Liu L (2021) A two-step parameter optimization method for low-order model-based state-of-charge estimation. IEEE Trans Transp Electrif 7:399–409. https://doi.org/10.1109/TTE.2020.3032737

Jatoth RK, Kumar TK (2009) Particle swarm optimization based tuning of extended Kalman filter for maneuvering target tracking. IEEE J Circuits Systems and Signal Proc 3:127–136

Batista J, Souza D, dos Reis L, Barbosa A, Rios C (2023) Identification of a robotic manipulator using RLS-PSO and control LQI with metaheuristics. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-023-12187-2

Li X, Liu S, Wan S, Hong J (2020) Active suppression of milling chatter based on LQR-ANFIS. Int J Adv Manuf Technol 111:2337–2347. https://doi.org/10.1007/s00170-020-06279-6

Yu GR, Hsieh PH (2019) Optimal design of helicopter control systems using particle swarm optimization. IEEE International Conference on Industrial Cyber Physical Systems, pp 346–351. https://doi.org/10.1109/ICPHYS.2019.8780133

Wang M, Wang K, Zhao Q, Zheng X, Gao H, Yu J (2023) LQR control and optimization for trajectory tracking of biomimetic robotic fish based on unreal engine. Biomimetics 8:236. https://doi.org/10.3390/biomimetics8020236

Varghese KS, Pandey MC, Radhakrishna K, Bawa AS (2014) Technology, applications and modelling of ohmic heating: a review. J Food Sci Technol 51:2304–17. https://doi.org/10.1007/s13197-012-0710-3

Silva DLM, Santos LMNBF, Silva AMS (2017) Ohmic heating: an emerging concept in organic synthesis. Chem Eur J 23:7853–7865. https://doi.org/10.1002/chem.201700307

Joseph C, Viney C (2000) Electrical resistance curing of carbon-fibre/epoxy composites. Compos Sci Technol 60:315–319. https://doi.org/10.1016/S0266-3538(99)00112-8

Zhang MH, Li CH, Zuo JL (2022) A variable stiffness adhesive enabled by joule heating effect. Chem Eng J 433:133840. https://doi.org/10.1016/j.cej.2021.133840

Liu F, Zhao Z, Ma Y, Gao Y, Li J, Hu X, Ye Z, Ling Y, Dong D (2022) Robust joule-heating ceramic reactors for catalytic CO oxidation. J Adv Ceram 11:1163–1171. https://doi.org/10.1007/s40145-022-0603-5

Chui CK, Chen G (2017) Kalman filtering with real-time applications. Springer

Bozic SM (2018) Digital and Kalman filtering: an introduction to discrete-time filtering and optimum linear estimation, 2nd edn. Dover Publications

Wang D, Tan D, Liu L (2017) Particle swarm optimization algorithm: an overview. Soft Comput 22:387–408. https://doi.org/10.1007/s00500-016-2474-6

Shami TM, Saleh AA, Alswaitti M, Tashi Q, Summakieh MA, Mirjalili S (2022) Particle swarm optimization: a comprehensive survey. IEEE Access 10:10031–10061. https://doi.org/10.1109/ACCESS.2022.3142859

Jordehi AR, Jasni J (2012) Parameter selection in particle swarm optimisation: a survey. J Exp Theor Artif Intell 25:527–542. https://doi.org/10.1080/0952813X.2013.782348

Akhlaghi S, Zhou N, Huang Z (2017) Adaptive adjustment of noise covariance in Kalman filter for dynamic state estimation. IEEE Power & Energy Society General Meeting, pp 1–5. https://doi.org/10.1109/PESGM.2017.8273755

Cetenovic D, Rankovic A, Zhao J, Jin Z, Wu J, Terzija V (2021) An adaptive method for tuning process noise covariance matrix in \(EKF\)-based three-phase distribution system state estimation. Int J Electr Power Energy Syst 132. https://doi.org/10.1016/j.ijepes.2021.107192

Mironova A, Haus B, Zedler A, Mercorelli P (2020) Extended Kalman filter for temperature estimation and control of peltier cells in a novel industrial milling process. IEEE Trans Ind Appl 56:1670–1678. https://doi.org/10.1109/TIA.2020.2965058

Acknowledgements

We gratefully acknowledge the assistance of University of Houston graduate students Siwei Chen and Chirag Goel in sharing their expert knowledge on the AMOCVD superconductor manufacturing process and experimental data. We also gratefully acknowledge financial support from the Advanced Manufacturing Institute (AMI) at the University of Houston.

Funding

This research was supported by the University of Houston Advanced Manufacturing Institute.

Author information

Authors and Affiliations

Contributions

Amal chebbi: data analysis, investigation, method proposed, simulations, writing, review and editing. Karolos Grigoriadis: investigation, writing, review and editing. Matthew Franchek: investigation, review and editing. Marzia Cescon: review and editing.

Corresponding author

Ethics declarations

Consent to participate

The authors have consent to participate.

Consent for publication

The authors have consent to publish.

Competing interests

The authors declare no competing interests.

Additional information

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g., a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: Acknowledgements has been revised.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chebbi, A., Grigoriadis, K., Franchek, M. et al. Substrate temperature estimation and control in advanced MOCVD process for superconductor manufacturing. Int J Adv Manuf Technol (2024). https://doi.org/10.1007/s00170-024-13699-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00170-024-13699-1