Abstract

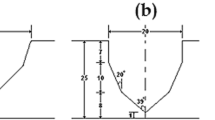

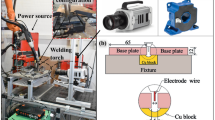

Narrow gap welding of 316L stainless steel thick plate was carried out using the cold metal transition pulsed wire-arc swing method. The effects of heat input, arc swing, and shielding mode on weld shaping and lack of fusion were investigated, and microstructure and tensile properties of welded joints were analyzed and characterized. The results indicate that arc swing amplitude was the primary factor affecting sidewall fusion. The tendency of undercut and incomplete fusion at the weld toe increased with the increase of wire feeding speed. Narrow gap weld with built-in shielding was easy to produce pores. The microstructure of welded joints was mostly represented by twin crystals in HAZ and columnar dendrites in the weld. Solidification sub-boundaries were produced between dendritic crystal clusters in the middle of the weld under high heat input, resulting in severe regional segregation and crystalline cracks that extended along subgrain boundaries. The microhardness of the weld and HAZ was greater than that of the base material. The tensile strength of welded joints was comparable to that of base material with good mechanical properties.

Similar content being viewed by others

Data Availability

Not applicable.

Code availability

Not applicable.

References

Anant R, Ghosh PK (2017) Ultra-narrow gap welding of thick section of austenitic stainless steel to HSLA steel. Journal of Materials Processing Tech 239:210–221. https://doi.org/10.1016/j.jmatprotec.2016.08.016

Yang WX, Xin JJ, Fang C, Dai WH, Wei J, Wu JF, Song YT (2019) Microstructure and mechanical properties of ultra-narrow gap laser weld joint of 100 mm-thick SUS304 steel plates. J Mater Process Tech 265:130–137. https://doi.org/10.1016/j.jmatprotec.2018.10.017

Buddu RK, Chauhan NL, Raole PM (2014) Investigations of microstructure and mechanical properties of 60-mm-thick type 316 L stainless steel welded plates by multipass tungsten inert gas welding and electron beam welding for fusion reactor applications. Fusion Sci Technol 65:248–254

Anant R, Ghosh PK (2017) Ultra-narrow gap welding of thick section of austenitic stainless steel to HSLA steel. J Mater Process Technol 239:210–221. https://doi.org/10.1016/j.jmatprotec.2016.08.016

Elmesalamy A, Francis J, Li L (2014) A comparison of residual stresses in multi pass narrow gap laser welds and gas-tungsten arc welds in AISI 316L stainless steel. Int Press Vessel Pip 113:49–59. https://doi.org/10.1016/j.ijpvp.2013.11.002

Dittrich D, Schedewy R, Brenner B (2013) Laser-multi-pass-narrow-gap welding of hot crack sensitive thick aluminum plates. Phys Procedia 41:225–233. https://doi.org/10.1016/j.phpro.2013.03.073

Wei B, Jia CB, Wu W, Fang C, Wu CS (2020) Stirring effect of the rotating arc on the molten pool during non-axisymmetric tungsten NG-GTAW. J Mater Process Technol 285:116769. https://doi.org/10.1016/j.jmatprotec.2020.116769

Rai R, Palmer TA, Elmer JW, Debroy T (2009) Heat transfer and fluid flow during keyhole mode laser welding of tantalum, Ti–6Al–4V, 304L stainless steel and vanadium. J Phys D Appl Phys 40(18):5753. https://doi.org/10.1088/0022-3727/40/18/037

Wang MQ, Wu PB, Xu K, Huang RS, Wang XX, Fang NW, Sun LB, Qin J, Ma YM, Su JH (2023) Influence of high-temperature annealing on microstructure and properties of welded joints using narrow gap laser welding of TC4 titanium with welding wire. J Mater Eng Perform. https://doi.org/10.1007/s11665-023-08629-3

Cai XY, Lin SB, Fan CL, Yang CL, Zhang W, Wang YW (2016) Molten pool behaviour and weld forming mechanism of tandem narrow gap vertical GMAW. Sci Technol Weld Joining 21(2):124–130. https://doi.org/10.1179/1362171815Y.0000000073

Benaouda OF, Mezaache M, Bouchakour M, Bendiabdellah A (2023) Estimation of the droplet detachment frequency using SSAS and PSD techniques in GMAW process under different transfer modes. Int J Adv Manuf Technol 126:1979–1996. https://doi.org/10.1007/s00170-023-11125-6

Liu HS, Xue RL, Zhou JP, Bao Y, Xu Y (2023) Applying statistical models to optimize the weld bead geometry in the vertical oscillation arc narrow gap all-position GMAW. Appl Sci 13(11):6801. https://doi.org/10.3390/app13116801

Guo N, Lin SB, Gao C, Fan CL, Yang CL (2009) Study on elimination of interlayer defects in horizontal joints made by rotating arc narrow gap welding. Sci Technol Weld Joining 14(6):584–588. https://doi.org/10.1179/136217109X456942

Ahsan MRU, Cheepu M, Ashiri R, Kim TH, Jeong C, Park YD (2017) Mechanisms of weld pool flow and slag formation location in cold metal transfer (CMT) gas metal arc welding (GMAW). Weld World 61:1275–1285. https://doi.org/10.1007/s40194-017-0512-3

Cai HY, Xu LY, Zhao L, Han YD, Pang HN, Chen W (2020) Cold metal transfer plus pulse (CMT+P) welding of G115 steel: mechanisms, microstructure, and mechanical properties. Mater Sci Eng A 843:143–156. https://doi.org/10.1016/j.msea.2022.143156

Huan PC, Wang XN, Zhang J, Hu ZR, Chen WG, Nagaumi H, Di HS (2020) Effect of wire composition on microstructure and properties of 6063 aluminium alloy hybrid synchronous pulse CMT welded joints. Mater Sci Eng A 790:139713. https://doi.org/10.1016/j.msea.2020.139713

Hu ZQ, Lin H, Qin XP, Ni M, Ji F, Wu MW (2021) Molten pool behaviors and forming appearance of robotic GMAW on complex surface with various welding positions. J Manuf Process 64:1359–1376. https://doi.org/10.1016/j.jmapro.2021.02.061

Yuan L, Pan ZX, Ding DH, He FY, Van DS, Li HJ, Li WH (2020) Investigation of humping phenomenon for the multi-directional robotic wire and arc additive manufacturing. Robot Comput Integr Manuf 63:101916. https://doi.org/10.1016/j.rcim.2019.101916

Guo W, Li L, Dong SY, Crowther D, Thompson A (2017) Comparison of microstructure and mechanical properties of ultra-narrow gap laser and gas-metal-arc welded S960 high strength steel. Opt Lasers Eng 91:1–15. https://doi.org/10.1016/j.optlaseng.2016.11.011

Yang T, Liu JF, Zhuang Y, Sun K, Chen WL (2020) Studies on the formation mechanism of incomplete fusion defects in ultranarrow gap laser wire filling welding. Opt Laser Technol 129:106275. https://doi.org/10.1016/j.optlastec.2020.106275

Li RY, Yue J, Sun R, Mi GY, Wang CM, Shao XY (2016) A study of droplet transfer behavior in ultra-narrow gap laser arc hybrid welding. Int J Adv Manuf Technol 87:2997–3008. https://doi.org/10.1007/s00170-016-8699-9

Zhang YX, Han SW, Cheon J, Na SJ, Gao XD (2017) Effect of joint gap on bead formation in laser butt welding of stainless steel. J Mater Process Technol 249:274–284. https://doi.org/10.1016/j.jmatprotec.2017.05.040

Han SY, Tang XH, Liu GQ, Xu LD, Cui HC, Shao CD (2022) Effects of arc interaction on lack-of-fusion and porosity in tandem NG-GMAW of 5083 Al-Mg alloy. J Manuf Process 81:92–106. https://doi.org/10.1016/j.jmapro.2022.06.059

Guo N, Wang MR, Wei G, Yu JB, Feng JC (2014) Study on forming mechanism of appearance defects in rotating arc narrow gap horizontal GMAW. Int J Adv Manuf Technol 75:15–20. https://doi.org/10.1007/s00170-014-6127-6

Lin X, Yang HO, Chen J, Huang WD (2006) Microstructure evolution of 316L stainless steel during laser rapid forming. Acta Metall Sin Chin Ed 42:361–368. https://doi.org/10.1360/crad20061117

Wang JY, Jiang YQ, Zhu J, Liu DS, Xu GX, Li WH (2023) Development of swing arc narrow gap GMAW process assisted by swaying wire. J Mater Process Technol 318:118004. https://doi.org/10.1016/j.jmatprotec.2023.118004

Fang C, Wei J, Liu J (2021) Solidification cracking sensibility of narrow gap laser welding on ITER-grade austenitic stainless steel. Fusion Eng Des 162:112068. https://doi.org/10.1016/j.fusengdes.2020.112068

Lippold JC, Kotecki DJ (2005) Welding Metallurgy and Weldability of Stainless Steels. John Wiley & Sons Inc., Hoboken https://doi.org/10.1080/10426910500476747

Yang F, Li CW, Li ZJ, Jiang L, Ye XX, Liu F (2020) Investigation on microstructure and hardness of UNS N10003 weld cladding on 316H with optimization of process parameters. Mater Sci Technol 28:1–8. https://doi.org/10.11951/j.issn.1005-0299.20180386

Lin X, Ren Z, Fautrelle Y, Gagnoud A, Zhang Y, Esling C (2009) Degeneration of columnar dendrites during directional solidification under a high magnetic field. Scripta Mater 60:443–446. https://doi.org/10.1016/j.scriptamat.2008.11.036

Kawahito Y, Mizutani M, Katayama S (2009) High quality welding of stainless steel with 10 kW high power fibre laser. Sci Technol Weld Joining 14(4):288–294. https://doi.org/10.1179/136217108X372531

Ravikiran K, Das G, Kumar S, Singh PK, Sivaprasad K, Ghosh M (2019) Narrow gap welding of low alloy and austenitic stainless steels using different Inconel alloys: comparison of microstructure and properties. Mater Res Express 6(9):096518. https://doi.org/10.1088/2053-1591/ab2be2

Hall EO (1970) Yield point phenomena in metals and alloys. Plenum Press, New York

Yang X, Chen H, Li MV, Bu H, Cai C (2021) Porosity suppressing and grain refining of narrow-gap rotating laser-MIG hybrid welding of 5A06 aluminum alloy. J Manuf Process 68:1100–1113. https://doi.org/10.1016/j.jmapro.2021.06.036

Funding

This work was supported by the National Natural Science Foundation of China, No. 52005007 and No. 52105312, and the Natural Science Fund of Anhui Province Education Office, No. 2022AH0S0322.

Author information

Authors and Affiliations

Contributions

Wei Meng: conceptualization, methodology, writing—review and editing.

Kai Chen: data curation, writing—original draft.

Qinyue Pan: supervision.

Kai Ye: investigation.

Zhenhua Liu: investigation, resources.

Qunshuang Ma: formal analysis.

Lei Hu: validation.

Wenbo Du: formal analysis.

Xiaohui Yin: project administration.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Wei Meng and Kai Chen are the co-first authors.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Meng, W., Chen, K., Pan, Q. et al. Narrow gap welding of 316L thick-section steel with cold metal transition pulsed arc swing. Int J Adv Manuf Technol (2024). https://doi.org/10.1007/s00170-024-13601-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00170-024-13601-z