Abstract

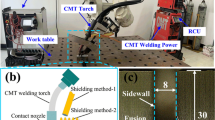

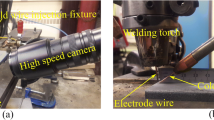

The novel hybrid cold metal transfer (CMT)–pulsed gas metal arc welding (P-GMAW) process was used to perform the narrow gap welding of mild steel plates. A systematic approach was followed to select the working values of numerous process parameters using high-speed images of the welding arc in synchronization with the welding current and voltage. Furthermore, emphasis was given to understanding the influence of pulse frequency on the complex arc and metal transfer behavior in the narrow gap and its subsequent effect on the side wall fusion and mechanical properties of weld joints. The root pass was deposited using the CMT process, while the filling and closing passes were deposited using the P-GMAW process to eliminate the incomplete fusion between the layers while keeping the overall heat input lower. A decrease in the narrow gap distance and an increase in the arc oscillation amplitude and welding voltage resulted in severe arc climbing over the facing surface, an inadequate fusion between the layers, and incomplete side wall fusion. Simultaneously decreasing the number of passes and welding speed engendered the overhead flow of the molten pool and hindered the heat transfer from the arc to the already deposited layer resulting in the lack of fusion. Pulse current and duration directly affect the welding arc lengths, resulting in higher welding arc deflections to the side walls in the case of lower pulse frequencies. The controlled welding arc deflections, molten metal transfer, and inter-pulse cooling displayed a noticeable effect on the mechanical properties of the weld joint.

Similar content being viewed by others

References

Roshan R, Kumar Naik A, Kumar Saxena K et al (2023) Effect of welding speed and wire feed rate on arc characteristics, weld bead and microstructure in standard and pulsed gas metal arc welding. J Adhes Sci Technol 0:1–18. https://doi.org/10.1080/01694243.2023.2192314

Evans GM (1982) Effect of heat input on the microstructure and properties of C-Mn all-weld-metal deposits. Weld J (Miami, Fla) 61(4):125–132

Singh V, Chandrasekaran M, Samanta S (2022) Study on the influence of heat input on mechanical property and microstructure of weld in GMAW of AISI 201LN stainless steel. Adv Mater Process Technol 8:81–91. https://doi.org/10.1080/2374068X.2020.1819732

Agrawal BP, Ghosh PK (2010) Thermal modeling of multipass narrow gap pulse current GMA welding by single seam per layer deposition technique. Mater Manuf Process 25:1251–1268. https://doi.org/10.1080/10426914.2010.489593

Shukla P, Chitral S, Kumar T, Kiran DV (2023) The influence of GMAW correction parameters on stabilizing the deposition characteristics for wire arc additive manufacturing. J Manuf Process 90:54–68. https://doi.org/10.1016/j.jmapro.2023.01.075

Shukla P, Dash B, Kiran DV, Bukkapatnam S (2020) Arc behavior in wire arc additive manufacturing process. Procedia Manuf 48:725–729. https://doi.org/10.1016/j.promfg.2020.05.105

Kumar T, Kiran DV, Arora N, Kumar PS (2022) Study of steel-aluminium joining under the influence of current waveforms using advanced CMT process variants. Mater Manuf Process 37:1578–1595. https://doi.org/10.1080/10426914.2022.2030879

Chakraborty D, Tirumala T, Chitral S et al (2022) The state of the art for wire arc additive manufacturing process of titanium alloys for aerospace applications. J Mater Eng Perform 31:6149–6182. https://doi.org/10.1007/s11665-022-07128-1

Selvi S, Vishvaksenan A, Rajasekar E (2018) Cold metal transfer (CMT) technology - an overview. Def Technol 14:28–44. https://doi.org/10.1016/j.dt.2017.08.002

Zhu L, Pan Y, Li Y (2012) Ultranarrow gap welding with constrained arc by flux strips. Adv Mater Res 472–475:2814–2818. https://doi.org/10.4028/www.scientific.net/amr.472-475.2814

Madhvacharyula AS, Pavan AVS, Gorthi S et al (2022) In situ detection of welding defects: a review. Weld World 66:611–628. https://doi.org/10.1007/s40194-021-01229-6

Bevans B, Ramalho A, Smoqi Z et al (2023) Monitoring and flaw detection during wire-based directed energy deposition using in-situ acoustic sensing and wavelet graph signal analysis. Mater Des 225:111480. https://doi.org/10.1016/j.matdes.2022.111480

Agrawal BP, Ghosh PK (2017) Characteristics of extra narrow gap weld of HSLA steel welded by single-seam per layer pulse current GMA weld deposition. J Mater Eng Perform 26:1365–1381. https://doi.org/10.1007/s11665-017-2516-y

Anant R, Ghosh PK (2017) Ultra-narrow gap welding of thick section of austenitic stainless steel to HSLA steel. J Mater Process Technol 239:210–221. https://doi.org/10.1016/j.jmatprotec.2016.08.016

Krampit AG, Krampit NY, Krampit MA (2014) Effect of the parameters of pulsed arc welding on the formation of a root layer in a narrow gap. Weld. Int. 28:629–630

Zhang G, Shi Y, Zhu M, Fan D (2017) Arc characteristics and metal transfer behavior in narrow gap gas metal arc welding process. J Mater Process Technol 245:15–23. https://doi.org/10.1016/j.jmatprotec.2017.02.006

Wang JY, Ren YS, Yang F, Guo HB (2007) Novel rotation arc system for narrow gap MAG welding. Sci Technol Weld Join 12:505–507

Silveira GMS, Filho WAS, Costa JFM et al (2020) Influence of rotation frequency and rotation diameter on mechanical properties and microstructure of weld metal produced by MCAW-RE. Int J Adv Manuf Technol 110:1789–1803. https://doi.org/10.1007/s00170-020-05961-z

Guo N, Wang MR, Guo W et al (2014) Effect of rotating arc process on molten pool control in horizontal welding. Sci Technol Weld Join 19:385–391. https://doi.org/10.1179/1362171814Y.0000000203

Guo N, Han YF, Jia CB, Du YP (2011) Effects of wire rotating frequency on metal transfer process in rotating arc narrow gap horizontal GMAW. Adv Mater Res 189–193:3395–3399. https://doi.org/10.4028/www.scientific.net/AMR.189-193.3395

Liu G, Tang X, Xu Q, Lu F, Cui H (2021) Effects of active gases on droplet transfer and weld morphology in pulsed-current NG-GMAW of mild steel. Chinese J Mech Eng (English Ed) 34:1–13. https://doi.org/10.1186/s10033-021-00583-2

Cai X, Fan C, Lin S et al (2018) Optimization of shielding gas composition in narrow gap GMA welding based on response surface methodology. Int J Adv Manuf Technol 95:2405–2412. https://doi.org/10.1007/s00170-017-1373-z

Sun J, Nie P, Feng K et al (2017) The elimination of pores in laser welds of AISI 304 plate using different shielding gases. J Mater Process Technol 248:56–63. https://doi.org/10.1016/j.jmatprotec.2017.05.011

Zhao Y, Shi X, Yan K et al (2018) Effect of shielding gas on the metal transfer and weld morphology in pulsed current MAG welding of carbon steel. J Mater Process Technol 262:382–391. https://doi.org/10.1016/j.jmatprotec.2018.07.003

Wong YR, Ling SF (2014) An investigation of dynamical metal transfer in GMAW - effects of argon shielding gas. J Mater Process Technol 214:106–111. https://doi.org/10.1016/j.jmatprotec.2013.08.003

Xu wanghui, Sanbao L, Chenglei F, Chunli Y (2012) Feasibility study on tandem narrow gap GMAW of 65 mm thick steel plate. China Weld 21(3):7–11

Wang J, Sun Q, Zhang T et al (2018) Arc characteristics in alternating magnetic field assisted narrow gap pulsed GTAW. J Mater Process Technol 254:254–264. https://doi.org/10.1016/j.jmatprotec.2017.11.042

Standard A (2008) Standard test method for determining volume fraction by systematic manual point count. ASTM E562-08:1–7

ASTM E384 (2002) Standard test method for microindentation hardness of materials ASTM E384. ASTM Stand 14:1–24

ASTM E8 (2010) ASTM E8/E8M standard test methods for tension testing of metallic materials 1. Annu B ASTM Stand 4 1–27. https://doi.org/10.1520/E0008

Selvi S, Vishvaksenan A, Rajasekar E (2018) Cold metal transfer (CMT) technology - An overview. Def Technol 14:28–44. https://doi.org/10.1016/j.dt.2017.08.002

Sharir Y, Pelleg J, Grill A (1978) Effect of arc vibration and current pulses on microstructure and mechanical properties of TIG tantalum welds. Met Technol 5:190–196. https://doi.org/10.1179/mt.1978.5.1.190

Kou S, Le Y (1988) Welding parameters and the grain structure of weld metal - a thermodynamic consideration. Metall Trans A, Phys Metall Mater Sci 19(A):1075–1082. https://doi.org/10.1007/bf02628392

Funding

This work was supported by the Naval Research Board, India (Grant number NRB/4003/PG/436) and Science and Engineering Research Board, India (Grant numbers CRG/2020/005089 and SB/S2/RJN-093/2015). Venkata Kiran Degala has received research support from the above grants.

Author information

Authors and Affiliations

Contributions

SKP: conceptualization, methodology, investigation, validation, formal analysis, writing—original draft, visualization; VN: conceptualization, writing—review and editing, resources, supervision; BB: conceptualization, writing—review and editing, resources; VD: conceptualization, writing—review and editing, resources; VKD: conceptualization, methodology, investigation, formal analysis, resources, supervision, writing—review and editing, visualization, project administration, and funding acquisition.

Corresponding author

Ethics declarations

Ethics approval

Not applicable

Consent to participate

Not applicable

Consent for publication

Not applicable

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Polamuri, S.K., Nasina, V., Biswajyoti, B. et al. Study on the arc behavior and mechanical properties of energy-efficient hybrid CMT-pulsed gas metal arc narrow gap mild steel welds. Int J Adv Manuf Technol 129, 837–854 (2023). https://doi.org/10.1007/s00170-023-12350-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12350-9