Abstract

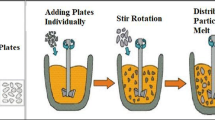

In the past, aluminium alloys greatly influenced the aerospace, automotive, and medical fields, particularly in biomedical applications. However, in contemporary times, magnesium alloys have emerged as highly promising materials for biomedical applications and casting processes. This study focuses primarily on magnesium metal matrix composites, utilizing ZE41 magnesium alloy as the base material. ZE41 possesses a high ductile nature, excellent mechanical strength, and impressive wear and corrosion resistance properties. In this experimental work, nanographene is employed as reinforcement particles. The investigation employs the stir casting methodology to create magnesium metal matrix nanocomposites. The responses considered in this work are compressive strength and microhardness. Both responses undergo Taguchi statistical analysis with varying process parameters. A Taguchi L16 orthogonal array is utilized to assess the optimization parameters of the stir casting process. The parameters include reinforcement percentage (3, 6, 9, and 12%), stirring speed (300, 400, 500, and 600 rpm), melting temperature (700, 750, 800, and 850 °C), and stirring time (15, 20, 25, and 30 min). The mechanical properties, specifically compressive strength and microhardness, are thoroughly examined. The highest compressive strength, reaching 276.66 MPa, was achieved with 12% reinforcement, a stirring speed of 400 rpm, a melting temperature of 800 °C, and a stirring time of 15 min. Similarly, the maximum microhardness, recorded at 172 VHN, was influenced by 6% reinforcement, a stirring speed of 600 rpm, a melting temperature of 800 °C, and a stirring time of 20 min.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Saberi A, Bakhsheshi-rad HR, Karamian E, Kasiri-Asgarani M, Ghomi H (2020) Magnesium-graphene nano-platelet composites: corrosion behaviour, mechanical and biological properties. J Alloys Compd 821:153379. https://doi.org/10.1016/j.jallcom.2019.153379

Tun KS, Wong WLE, Nauyen QB, Gupta M (2013) Tensile and compressive responses of ceramic and metallic nanoparticle reinforced Mg composites. Compos Sci Technol 67:2657–2664. https://doi.org/10.3390/ma6051826

Chandradass J, Thirugnanasambandham T, Baskarasethupathi P (2020) Liquid state stir cast processing and characteristics study of AZ91D/SiCp composites. Mater Today Proc 45(7):6507–6511. https://doi.org/10.1016/j.matpr.2020.11.450

Aravindan S, Rao PVPK (2015) Evaluation of physical and mechanical properties of AZ91/SiC composites by two-step stir casting process. J Magnes Alloys 3:52–62. https://doi.org/10.1016/j.jma.2014.12.008

Xiao P, Gao Y, Xu F, Yang C, Li Y, Liu Z, Zheng Q (2018) Tribological behaviour of in-situ nanosized TiB2 particles reinforced AZ91matrix composite. Tribol Int 128:130–139. https://doi.org/10.1016/j.triboint.2018.07.003

Soorya Prakash K, Balasundar P, Nagaraja S, Gopal PM, Kanimani V (2016) Mechanical and wear behaviour of Mg–SiC–Gr hybrid composites. J Magnes Alloys 4:197–206. https://doi.org/10.1016/j.jma.2016.08.001

Chandran S, Maridurai T, Baskar S, Shankar NS (2022) Magnesium alloy machining and its methodology: a systematic review and analyses. AIP Conf Proc 2473:020003. https://doi.org/10.1063/5.0096398

Krishnan AM, Mohan N, Venkatesh R (2022) Evaluation of mechanical strength of the stir casted aluminium metal matrix composites (AMMCs) using Taguchi method. Mater Today: Proc 62(4):1943–1946. https://doi.org/10.1016/j.matpr.2022.02.036

Anilkumar S, Krishna N, Mukhopadhyay YA, Sinha DK (2022) Effect of TiC reinforcement on mechanical and wear properties ofAZ91 matrix composites. Int J Met 16:2128–2143. https://doi.org/10.1007/s40962-021-00747-9

Ezatpour HR, Parizi MT, Ebrahimi GR (2021) The effects and improvements of GNPs+CNTs on the mechanical properties and microstructure of AZ80 matrix composite. Int J Lightw Mater Manuf 4(3):323–338. https://doi.org/10.1016/j.ijlmm.2021.03.002

Li H, Fan J, Geng X, Li B, Liang C, Wang H, Li Y, Qiao Z, Kang J (2014) Alumina powder-assisted carbon nanotubes reinforced Mg matrix composites. Mater Des 60:637–642. https://doi.org/10.1016/j.matdes.2014.04.017

Emadi P, Andilab B, Ravindran C (2022) Processing and properties of magnesium-based composites reinforced with low levels of Al2O3. Int Metalcast 16:1680–1692. https://doi.org/10.1007/s40962-021-00738-w

Shen MJ, Ying T, Chen FY et al (2017) Effects of hybrid SiCp on the microstructures and mechanical properties of AZ31B Alloy. Int Metalcast 11:266. https://doi.org/10.1007/s40962-016-0050-6

Marode RV, Awang M, Lemma TA, Pedapati SR, Hassan A, Janga VSR, Alam MA, Loyte A, Devarajan Y (2024) Friction stir processing of AZ91 hybrid composites with exfoliated multi-layered graphene: a Taguchi-Grey relational analysis. J Alloys Compd 972:172703. https://doi.org/10.1016/j.jallcom.2023.172703

Zhou D, Zheng C, Niu Y, Feng D, Ren H, Zhang Y, Huimin Yu (2024) Hydrogen storage property improvement of ball-milled Mg2. 3Y0. 1Ni alloy with graphene. Int J Hydrogen Energy 50:123–135. https://doi.org/10.1016/j.ijhydene.2023.06.255

Chen L, Zhao Y, Jing J, Hou H (2023) Microstructural evolution in graphene nanoplatelets reinforced magnesium matrix composites fabricated through thixomolding process. J Alloy Compd 940:168824. https://doi.org/10.1016/j.jallcom.2023.168824

Wang T, Dong Y, Yingchao Xu, Li G, Guo Y, Lian J, Zhang Z, Ren L (2023) A calcium phosphate coating improving corrosion resistance of the biodegradable magnesium alloy with graphene oxide modifying the deposition. Ceram Int 49(8):11926–11935. https://doi.org/10.1016/j.ceramint.2022.12.041

Acknowledgements

The author thanks the management of Saveetha School of Engineering, SIMATS, for their support and encouragement.

Author information

Authors and Affiliations

Contributions

Sathish Thanikodi: conceptualization, formal analysis, investigation, methodology, writing original draft, writing, review, and editing.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent to publication

Not applicable.

Conflict of interest

The author declares no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Thanikodi, S. Effect of graphene nanoparticle reinforcement on the mechanical properties of ZE41/graphene nanocomposites prepared by stir casting route. Int J Adv Manuf Technol (2024). https://doi.org/10.1007/s00170-024-13508-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00170-024-13508-9