Abstract

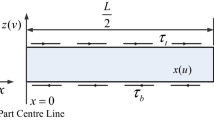

In this paper, a theoretical model of the contact characteristics for layers on irregular surfaces is established by analyzing the contact deformation and slip ratio at the placement path points. Based on this model, a numerical algorithm for calculating the contact characteristics at any path point is proposed. The normal stress field, tangential stress field, and contact status of the contact area at four path points on the double-curved surface mold are obtained using the algorithm and verified through experiments. The results indicate that the model can be used to predict the contact characteristics at any placement path point, and the possible defects at points P3 and P4 are initially identified by analyzing the contact characteristics. In addition, compared to the 8-h computational time required for simulation calculation, this numerical algorithm takes only 20 ms to compute, which shows that the developed model has greatly reduced the calculation time.

Similar content being viewed by others

References

Gushchina MO, Kuzminova YO, Dubinin ON, Evlashin SA, Vildanov AM, Klimova-Korsmik OG, Turichin GA (2023) Multilayer composite ti-6al-4 v/cp-ti alloy produced by laser direct energy deposition. Int J Adv Manuf Technol 3-4(124):907–918

Freschi M, Di Virgilio M, Haiko O, Mariani M, Andena L, Lecis N, Kömi J, Dotelli G (2022) Investigation of second phase concentration effects on tribological and electrical properties of cu–ws2 composites. Tribol Int 166:107357

Vasanth Kumar R, Keshavamurthy R, Perugu CS, Alipour M, Siddaraju C (2021) Influence of hot rolling on friction and wear behaviour of al6061-zrb2 in-situ metal matrix composites. J Manuf Process 69:473–490

Yadav R, Lee H, Lee J, Singh RK, Lee H (2023) A comprehensive review: physical, mechanical, and tribological characterization of dental resin composite materials. Tribol Int 179:108102

Lu S, Evans A, Turner T (2023) Analysis of roller compaction pressure distribution in automated dry fibre placement. Compos Struct 316:117048

Brasington A, Sacco C, Halbritter J, Wehbe R, Harik R (2021) Automated fiber placement: a review of history, current technologies, and future paths forward. Compos Prt C: Open Access 6:100182

Boon YD, Joshi SC (1951) Bhudolia SK (2021) Review: filament winding and automated fiber placement with in situ consolidation for fiber reinforced thermoplastic polymer composites. Polymers-Basel 12(13)

Rudberg T, Purvis AJ, Faubion G (2011) One Piece AFP Spar Manufacture. SAE Int J Aerosp 4(2):965–972

Xie N, Smith RA, Mukhopadhyay S, Hallett SR (2018) A numerical study on the influence of composite wrinkle defect geometry on compressive strength. Mater Design 140:7–20

Budelmann D, Schmidt C, Meiners D (2020) Prepreg tack: a review of mechanisms, measurement, and manufacturing implication. Polym Compos 9(41):3440–3458

Elhajjar RF, Shams SS (2014) Compression testing of continuous fiber reinforced polymer composites with out-of-plane fiber waviness and circular notches. Polym Test 35:45–55

Bakhshi N, Hojjati M (2019) Time-dependent wrinkle formation during tow steering in automated fiber placement. Compos Part B 165:586–593

Belhaj M, Hojjati M (2018) Wrinkle formation during steering in automated fiber placement: modeling and experimental verification. J Reinf Plast Compos 6(37):396–409

Lichtinger R, Lacalle J, Hinterhölzl R, Beier U, Drechsler K (2015) Simulation and experimental validation of gaps and bridging in the automated fiber placement process. Sci Eng Compos Mater 2(22):131–148

Rajan S, Sutton MA, Sockalingam S, McMakin W, Gurdal Z, Kidane A (2020) Simulations and experiments for automated fiber placement of prepreg slit tape: wrinkle formation and fundamental observations. Compos Part B 201:108287

Aized T, Shirinzadeh B (2011) Robotic fiber placement process analysis and optimization using response surface method. Int J Adv Manuf Technol 1-4(55):393–404

Zhao C, Xiao J, Huang W, Huang X, Gu S (2016) Layup quality evaluation of fiber trajectory based on prepreg tow deformability for automated fiber placement. J Reinf Plast Compos 21(35):1576–1585

Jiang J, He Y, Ke Y (2019) Pressure distribution for automated fiber placement and design optimization of compaction rollers. J Reinf Plast Compos 18(38):860–870

Budelmann D, Detampel H, Schmidt C, Meiners D (2019) Interaction of process parameters and material properties with regard to prepreg tack in automated lay-up and draping processes. Compos A: Appl Sci Manuf 117:308–316

Wang YJ, Huang Y, Chen YX, Yang ZS (2016) Model of an abrasive belt grinding surface removal contour and its application. Int J Adv Manuf Technol 9-12(82):2113–2122

Wang Z, Liu X (2018) Adhesion of large-deformation elastic spherical contact. Tribol Int 119:559–566

Wu YZ, Zhu YP, Dui GS (2011) Influence of small-strain and large-strain methods on mechanical behaviors in shape memory alloys. Adv Mater Res 328-330:1556–1559

Xie KH, Leo CJ (2004) Analytical solutions of one-dimensional large strain consolidation of saturated and homogeneous clays. Comput Geotech 4(31):301–314

Goryacheva I, Sadeghi F (1995) Contact characteristics of a rolling/sliding cylinder and a viscoelastic layer bonded to an elastic substrate. Wear 2(184):125–132

Peng X (2019) Quality characterization and regulation of prepreg tow steering based on automatic placement process. Zhejiang University (Master thesis)

Khajeh Salehani M, Irani N, Müser MH, Nicola L (2018) Modelling coupled normal and tangential tractions in adhesive contacts. Tribol Int 124:93–101

Li Y (2010) Mechanics of materials. Tongji University Press

Freakley PK (1978) Theory and practice of engineering with rubber. Applied Science Publishers

Lindley PB (1978) Engineering design with natural rubber. The Malaysian Rubber Producers Research Association

Fu HY, Li WQ, Sun SZ, Han ZY (2017) Experimental study on relationship between processing parameters and stress wave propagation during automated fiber placement process. IOP conference series. Mater Sci Eng 1(213):12031

Johnson KL (1985) Contact mechanics. Cambridge University Press

Gent AN (2012) Engineering with rubber: how to design rubber components. Carl Hanser Verlag GmbH Co KG

Lukaszewicz DHA, Potter K (2012) Through-thickness compression response of uncured prepreg during manufacture by automated layup. Proc Inst Mech Eng B J Eng Manuf 2(226):193–202

Guo J, Wang S (2021) Multiphase flow coupling behavior of bubbles based on computational fluid dynamics during afp process: the behavior characteristics of bubbles during afp process. Adv Mater Sci Eng 2021:1–12

Khudiakova A, Brunner AJ, Wolfahrt M, Wettemann T, Godec D, Pinter G (2021) On the investigation of quasi-static crack resistance of thermoplastic tape layered composites with multiple delaminations: approaches for quantification. Compos A: Appl Sci Manuf 149:106484

Funding

The work was s financially supported by “Pioneer” and “Leading Goose” R&D Program of Zhejiang, No. 2022C01134, the National Natural Science Foundation of China (51975520), and the fundamental research project (JCKY2021205B110).

Author information

Authors and Affiliations

Contributions

Yan Li: methodology, algorithms, writing—original draft, review and editing. Yuxiao He: formal analysis. Junxia Jiang: writing—review and editing. Han Wang: formal analysis, review and editing. Weidong Zhu: supervision, funding acquisition. Qing Wang: supervision. Liang Cheng: supervision.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Y., He, Y., Jiang, J. et al. Modeling and experimental validation of the contact characteristics for laying during automated fiber placement. Int J Adv Manuf Technol 131, 5997–6011 (2024). https://doi.org/10.1007/s00170-024-13333-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13333-0