Abstract

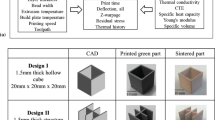

Building end-use functional metal parts by metal fused filament fabrication (MF3) is an emerging topic in additive manufacturing. MF3 involves extrusion of polymer filaments that are highly filled with metal powder to print three-dimensional parts, followed by debinding and sintering to eliminate the polymer binder and get a fully dense metal part, respectively. Material properties, part design and processing conditions have a significant influence on the quality of MF3 printed parts. Part distortion and dimensional variations are significant quality challenges that hinder the acceptance of printed parts in potential functional applications. Trial-and-error experiments to find the best conditions are commonly used for defect avoidance, though they are time-consuming and expensive. Hence, computational simulation and design solutions are required for MF3 to enable a virtual analysis of the process outcome and reduce dependency on experimental methods. This paper investigates the applicability of a thermo-mechanical model for finite element simulation of the MF3 printing process. The quantitative influence of material properties on MF3 printed part quality was estimated using a simulation platform. The simulation results of two materials, a Ti-6Al-4V filled polymer and an unfilled ABS copolymer, were compared to experiments. It was determined that the unfilled polymer showed greater shrinkage and warpage than the Ti-6Al-4V filled polymer in simulations and experiments. Further, the trend in the distribution of warpage was consistent between experiments and simulation results for both materials. Finally, warpage compensation algorithms showed improvement in dimensional control for both materials in simulations and were consistent with experimental results.

Similar content being viewed by others

References

J.G. Gutierrez, S. Cano, S. Schuschnigg, C. Kukla, J. Sapkota and C. Holzer, Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives, Materials, 2018, 11(5), p 840.

H.A. Hegab, Design for Additive Manufacturing of Composite Materials and Potential Alloys: A Review, Manuf. Rev., 2016, 3, p 11.

W. Lengauer, I. Duretek, M. Fürst, V. Schwarz, J.G. Gutierrez, S. Schuschnigg, C. Kukla, M. Kitzmantel, E. Neubauer, C. Lieberwirth and V. Morrison, Fabrication and Properties of Extrusion-Based 3D-Printed Hardmetal and Cermet Components, Int. J. Refract. Metal Hard Mater., 2019, 82, p 141–149.

Y. Thompson, J.G. Gutierrez, C. Kukla and P. Felfer, Fused Filament Fabrication, Debinding and Sintering as a Low Cost Additive Manufacturing Method of 316L Stainless Steel, Addit. Manuf., 2019, 30, p 100861.

G. Wu, N.A. Langrana, R. Sadanji and S. Danforth, Solid Freeform Fabrication of Metal Components Using Fused Deposition of Metals, Mater. Des., 2002, 23(1), p 97–105.

Y. Zhou, G. Xiong, T. Nyberg, and D. Liu, Temperature Analysis in the Fused Deposition Modeling Process, 3rd International Conference on Information Science and Control Engineering (ICISCE), Beijing, China, 2016, p 678-682. https://doi.org/10.1109/ICISCE.2016.150.

A. Cattenone, S. Morganti, G. Alaimo and F. Auricchio, Finite Element Analysis of Additive Manufacturing Based on Fused Deposition Modeling (FDM): Distortions Prediction and Comparison with Experimental Data, J. Manuf. Sci. Eng., 2019, 141(011010), p 1–17.

A. Armillotta, M. Bellotti and M. Cavallaro, Warpage of FDM Parts: Experimental Tests and Analytic Model, Robot. Comput.-Integr. Manuf., 2018, 50, p 140–152.

N. Watanabe, M.L. Shofner, N. Treat, and D.W. Rosen, A Model for Residual Stress and Part Warpage Prediction in Material Extrusion with Application to Polypropylene. Int Solid Freeform Fabrication Symposium, 2016, Austin, 27th Edition: p.2437-2455

D. Croccolo, M. DeAgostinis and G. Olmi, Experimental Characterization and Analytical Modelling of the Mechanical Behaviour of Fused Deposition Processed Parts Made of ABS-M30, Comput. Mater. Sci., 2013, 79, p 506–518.

D.D. Phan, J.S. Horner, Z.R. Swain, Z.R. Swain, A.N. Berisa and M.E. Mackay, Computational Fluid Dynamics Simulation of the Melting Process in the Fused Filament Fabrication Additive Manufacturing Technique, Addit. Manuf., 2020, 33, p 101161.

J. Zhang, X.Z. Wang, W.W. Yu and H.D. Yu, Numerical Investigation of the Influence of Process Conditions on the Temperature Variation in fused Deposition Modeling, Mater. Design, 2017, 130, p 59–68.

B. Brenken, E. Barocio, A. Favaloro, V. Kunc and R.B. Pipes, Development and Validation of Extrusion Deposition Additive Manufacturing Process Simulations, Addit. Manuf., 2019, 25, p 218–226.

C. Li, J.F. Liu, X.Y. Fang and Y.B. Guo, Efficient Predictive Model of Part Distortion and Residual Stress in Selective Laser Melting, Addit. Manuf., 2017, 17, p 157–168.

J. Song, W. Wu, L. Zhang, H. Beibei, L. Lin, N. Xiaoqing, L. Qianlei and Z.L. Guoliang, Role of Scanning Strategy on Residual Stress Distribution in Ti-6Al-4V Alloy Prepared by Selective Laser Melting, Optik—Int. J. Light Electron. Optics, 2018, 170, p 342–352.

J. Abel, U. Scheithauer, T. Janics, S. Hampel, S. Cano, A. Müller-Köhn, A. Günther, C. Kukla and T. Moritz, Fused Filament Fabrication (FFF) of Metal-Ceramic Components, J. Vis. Exp, 2019, 143, p e57693.

M. Nikzad, S.H. Masood and I. Sbarski, Thermo-Mechanical Properties of a Highly Filled Polymeric Composites for Fused Deposition Modeling, Mater. Des., 2011, 32(6), p 3448–3456.

P. Singh, Q. Shaikh, V.K. Balla, S.V. Atre and K.H. Kate, Estimating Powder-Polymer Material Properties Used in Design for Metal Fused Filament Fabrication (DfMF3), J. Miner., Metals Mater. Soc., 2020, 72, p 485–495.

P. Singh, V.K. Balla, A. Tofangchi, S.V. Atre and K.H. Kate, Printability Studies of Ti-6Al-4 V by Metal Fused Filament Fabrication (MF3), Int. J. Refract Metal Hard Mater., 2020, 91, p 105249.

e-Xstream, Digimat-AM Simulation Solution for Additive Manufacturing, https://www.e-xstream.com/product/digimat-am. Accessed 10 September 2020

Y. Zhang and Y.K. Chou, 3D FEA Simulations of Fused Deposition Modeling Process, Int. Manuf. Sci. Eng. Conf., 2006, 47624, p 1121–1128.

M. Domingo-Espin, J.M. Puigoriol-Forcada, A.A. Garcia-Granada, L. Jordi, B. Salvador and R. Guillermo, Mechanical Property Characterization and Simulation of Fused Deposition Modeling Polycarbonate Parts, Mater. Des., 2015, 83, p 670–677.

A.E. Moumen, M. Tarfaoui and K. Lafdi, Modelling of the Temperature and Residual Stress Fields During 3D Printing of Polymer Composites, Int. J. Adv. Manuf. Technol., 2019, 104, p 1661–1676.

S.F. Costa, F.M. Duarte and J.A. Covas, Thermal Conditions Affecting Heat Transfer in FDM/FFE: A Contribution Towards the Numerical Modelling of the Process, Virtual Physical Prototyping, 2015, 10(1), p 35–46.

R.Q. de Macedo, R.T.L. Ferreira and K. Jayachandran, Determination of Mechanical Properties of FFF 3D Printed Material by Assessing Void Volume Fraction, Cooling Rate and Residual Thermal Stresses, Rapid Prototyping J., 2019, 25(10), p 1661–1683.

Q. Sun, G.M. Rizvi, C.T. Bellehumeur and P. Gu, Effect of Processing Conditions on the Bonding Quality of FDM Polymer Filaments, Rapid Prototyping J., 2008, 14(2), p 72–80.

C. Bellehumeur, L. Li, Q. Sun and P. Gu, Modeling of Bond Formation Between Polymer Filaments in the Fused Deposition Modeling Process, SME J. Manuf. Process., 2004, 6(2), p 170–178.

Acknowledgements

The authors acknowledge the funding from the Minority Business Development Agency (MBDA) and the National Aeronautics and Space Administration (NASA) that supported this research work. The Digimat simulation platform was provided by MSC Software/Hexagon. KEYENCE Corp. provided support with VR-5000 for surface profilometry.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Additive Manufacturing. The issue was organized by Dr. William Frazier, Pilgrim Consulting, LLC; Mr. Rick Russell, NASA; Dr. Yan Lu, NIST; Dr. Brandon D. Ribic, America Makes; and Caroline Vail, NSWC Carderock.

Rights and permissions

About this article

Cite this article

Shaikh, M.Q., Singh, P., Kate, K.H. et al. Finite Element-Based Simulation of Metal Fused Filament Fabrication Process: Distortion Prediction and Experimental Verification. J. of Materi Eng and Perform 30, 5135–5149 (2021). https://doi.org/10.1007/s11665-021-05733-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05733-0