Abstract

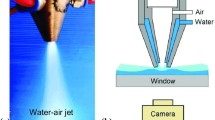

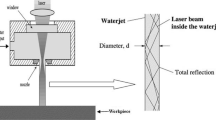

Water jet-guided laser is a novel machining technique. With the continuous emergence of high-hardness, high-strength materials and the increasing demand for efficient processing, the coupling of waterjet with high-power lasers has become an inevitable trend in developing water-guided lasers. However, the coupling and transmission of high-power laser energy with a water jet during the processing process introduce a series of issues, including transmission losses, which will emerge as crucial challenges limiting the development of this technology. Therefore, it is imperative to investigate the transmission losses of high-power laser energy guided by water jets. This study addresses this issue by employing the finite element method (FEM) to solve Maxwell's equations numerically, conducting wave optics simulations of the propagation of high-power lasers in water jets, and obtaining the electric field distribution of the laser beam within the water jet. Simultaneously, an investigation into the relationship between different laser beam diameters, waterjet diameters, lengths, and the energy loss of the laser is conducted to analyze the transmission losses of high-power lasers in waterjets. Finally, transmission efficiency measurements of laser coupled with a water jet are conducted utilizing a self-designed water-guided laser experimental platform. The effectiveness of the model is validated by comparing experimental results with simulations. The research findings will provide valuable insights into regulating the transmission efficiency of high-power lasers within water jets.

Similar content being viewed by others

Data Availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

Cao ZH, Qiao HC, Zhang YN, Chen YL, Zhao JB (2022) Study on reducing burrs of super alloy through structures in water jet guided laser ablation. J Manuf Process 77:809–818

Zhang YN, Qiao HC, Zhao JB, Cao ZH (2021) Research on water jet-guided laser micro-hole machining of 6061 aluminum alloy. Int J Adv Manuf Tech 118:1–13

Qiao HC, Cao ZH, Cui JF, Zhao JB (2021) Experimental study on water jet guided laser micro-machining of mono-crystalline silicon. Opt Laser Technol 140:107057

Perrottet D, Amorosi S, Richerzhagen B (2005) Water-jet guided fiber lasers for mask cutting. International Congress on Applications of Lasers & Electro-Optics (ICALEO) M206:77–80

Wagner F, Sibailly O, Vágó N, Romanowicz R, Richerzhagen B (2003) The Laser Microjet Technology-10 Years of Development. International Congress on Applications of Lasers & Electro-Optics (ICALEO) M401:1–9

Richerzhagen B, Kutsuna M, Okada H, Ikeda T (2003) Water-jet-guided laser processing. International Congress on Laser Advanced Materials Processing (Proceedings of SPIE) 4830:91–94

Spiegel A, Vago N, Wagner FR (2004) High efficiency Raman scattering in micrometer-sized water jets. Opt Eng 43:450–454

Vágó N, Spiegel Á, Couty P, Richerzhagen B (2003) New technique for high-speed microjet breakup analysis. Exp Fluids 35:303–309

Couty P, Spiegel Á, Vágó N, Ugurtas BI, Hoffmann P (2004) Laser-induced break-up of water jet waveguide. Exp Fluids 36:919–927

Chaja M, Laporte G, Cam P, Remund S, Neuenschwander B (2021) Ultra-short pulses at high average power in the Laser MicroJet. LAMOM 11673:1167319

Zhang GY, Zhang Z, Wang YF, Guo CH, Zhang WW (2019) Gas shrinking laminar flow for robust high-power waterjet laser processing technology. Opt Express 27:38635–38644

Huang YX, Zhao YW, Yang LF, Zhou J, Jiao H, Long YH (2019) Theoretical study of water jet guided laser technology based on non-uniform electric field deflection water jet. Opt Commun 442:31–39

Huang YX, Yang LF, Liang E, Zhong ZX, Long YH (2021) Study on the mechanisms of curved water jet fiber-guided laser technology. Int J Adv Manuf Tech 112:3137–3150

Richerzhagen B, Delacretaz G, Salathe RP (1996) Complete model to simulate the thermal defocusing of a laser beam focused in water. Opt Eng 35:2058–2066

Li CF, Johnson DB, Kovacevic R (2003) Modeling of waterjet guided laser grooving of silicon. Int J Mach Tool Manu 43:925–936

Wang Y, Li L, Yang LJ, Liu B, Wang Z (2008) Simulation and experimental research on water-jet guided laser cutting silicon wafer. International Conference on Electronic Packaging Technology & High Density Packaging (ICEPT-HDP), pp 1–6

Li CQ, Yang LJ, Wang Y, Tang J (2011) Simulation on the effects of misaligned coupling on the output intensity distribution in Water-jet guided laser. Adv Mater Res 212:400–405

Mullick S, Madhukar YK, Kumar S, Shukla DK, Nath AK (2011) Temperature and intensity dependence of Yb-fiber laser light absorption in water. Appl Optics 50:6319–6326

Mullick S, Madhukar YK, Roy S, Kumar S, Shukla DK, Nath AK (2013) Development and parametric study of a water-jet assisted underwater laser cutting process. Int J Mach Tool Manu 68:48–55

Mullick S, Madhukar YK, Roy S, Nath AK (2015) An investigation of energy loss mechanisms in water-jet assisted underwater laser cutting process using an analytical model. Int J Mach Tool Manu 91:62–75

Brecher C, Janssen H, Eckert M, Schmidt F (2016) Thermal investigation of interaction between high-power CW-laser radiation and a water-jet. Phys Procedia 83:317–327

Schmidt F, Janssen H, Brecher C (2017) Realization and first time operation of a high-power laser-water-jet system. Lasers in Manufacturing Conference, pp 1–8

Piltyay S, Bulashenko A, Herhil Y, Bulashenko O (2020) FDTD and FEM Simulation of Microwave Waveguide Polarizers. 2020 IEEE 2nd International Conference on Advanced Trends in Information Theory (ATIT), pp 357–363

Ekuakille AL (2013) Optical waveguiding and applied photonics. Springer 10:3–25

Deng C, Yeo H, Ki H (2020) Electrodynamic simulation of laser beam propagation in waterjet-guided laser processing. Opt Express 28:11128–11143

Wei MR, Zhang T, Liu Y, Wang Z, Dong ZL, Huang ZX (2023) Laser coupling in waterjets subject to jet instabilities, laser parameters, and alignment errors. Opt Express 31:12967–12985

Funding

Guangxi Natural Science Foundation (2019JJD160010, 2020JJB170048); Guangxi Science and Technology Base and Talent Project (2021AC18026); National Natural Science Foundation of China (NSFC) (62274045, 62004050, 52165056); Guangxi Key Laboratory of Manufacturing Systems and Advanced Manufacturing Technology (17–259-05-018Z); Guangxi Young Teacher Education Project (2020KY05020); the Innovation Project of Guangxi Graduate Education (YCSW2022287, YCBZ2022114, YCBZ2021073); the Guilin University of Electronic Technology Excellent Graduate Thesis Program (19YJPYBS02); the Innovation Project of Guilin University of Electronic Technology Graduate Education (2020YCXS010, 2021YCXS001).

Author information

Authors and Affiliations

Contributions

Zhen Zhao put forward research ideas, design research methods, and establish analysis models. Guanghui Zhang and Yuxing Huang was responsible for data collection, sorting, and storage in the early stage. Jia Zhou, Ze Lin and Hui Jiao was responsible for literature collection, tracking, and sorting. Tielin Shi and Xiaoqing Yang was involved in manuscript writing instruction. Yuhong Long carried out framework layout, key point analysis, and guidance for manuscript. All the authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, Z., Zhang, G., Huang, Y. et al. Water jet guided high-power laser energy transmission loss analysis. Int J Adv Manuf Technol 130, 5379–5389 (2024). https://doi.org/10.1007/s00170-024-13063-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13063-3