Abstract

Integrating preventive maintenance (PM) scheduling and production planning efficiently remains challenging for researchers and practitioners alike, owing to complex component interdependencies. Existing studies often lack practicality due to oversimplified assumptions. In this paper, we propose a two-stage solution for the integrated PM scheduling and production planning problem within multi-parallel component manufacturing systems, accounting for diverse interdependencies. These interdependencies encompass stochastic, structural, economic, and resource-related interdependencies, all while accounting for the resultant degradation. The primary objective is jointly optimizing costs associated with holding, backorders, production, setup, and maintenance. Initially, we employ an Ordinary Differential System to compute a realistic production capacity. Additionally, we analyze the effects of interdependence-induced degradation on system availability and failures. Subsequently, we formulate the problem as an integer programming model to determine an optimal joint plan. The effectiveness of our approach is validated through numerical examples and sensitivity analysis, providing insightful guidance for efficient PM scheduling and production planning, particularly in large-scale production systems.

Similar content being viewed by others

References

Weinstein L, Chung CH (1999) Integrating maintenance and production decisions in a hierarchical production planning environment. Comput Oper Res 26(10–11):1059–1074. https://doi.org/10.1016/S0305-0548(99)00022-2

Keizer MCO, Flapper SDP, Teunter RH (2017) Condition-based maintenance policies for systems with multiple dependent components: A review. Eur J Oper Res 261(2):405–420. https://doi.org/10.1016/j.ejor.2017.02.044

Bahou Z, Krimi Lemnaouar MRI (2023) A dynamic availability analysis of an N-component production system with interdependency effects: a fractional-order approach. Prod Eng Res Devel. https://doi.org/10.1007/s11740-023-01216-4

Xu M, Jin X, Kamarthi S, Noor-E-Alam M (2018) A failure-dependency modeling and state discretization approach for condition-based maintenance optimization of multi-component systems. J Manuf Syst 47:141–152. https://doi.org/10.1016/j.jmsy.2018.04.018

Van Horenbeek A, Pintelon L (2013) A dynamic predictive maintenance policy for complex multi-component systems. Reliab Eng & Syst Saf 120:39–50. https://doi.org/10.1016/j.ress.2013.02.029

Haimes YY (2018) Modeling and managing interdependent complex systems of systems. John Wiley & Sons

Dinh DH, Do P, Iung B (2020) Degradation modeling and reliability assessment for a multi-component system with structural dependence. Comput & Ind Eng 144:106443. https://doi.org/10.1016/j.cie.2020.106443

Taji J, Farughi H, Rasay H (2022) A new approach to preventive maintenance planning considering non-failure stops and failure interdependence between components. Adv Ind Eng 56(2):231–249. https://doi.org/10.22059/aie.2022.344909.1843

Keedy E, Feng Q (2013) Reliability analysis and customized preventive maintenance policies for stents with stochastic-dependent competing risk processes. IEEE Trans Reliab 62(4):887–897. https://doi.org/10.1109/TR.2013.2285045

Igba J, Alemzadeh K, Henningsen K, Durugbo C (2015) Effect of preventive maintenance intervals on reliability and maintenance costs of wind turbine gearboxes. Wind Energy 18(11):2013–2024. https://doi.org/10.1002/we.1801

Shahin A, Labib A, Emami S, Karbasian M (2018) Improving Decision-Making Grid based on interdependence among failures with a case study in the steel industry. The TQM J 31(2):167–182. https://doi.org/10.1108/TQM-03-2018-0043

Kobbacy KA, Murthy DP, Nicolai RP, Dekker R (2008) Optimal maintenance of multi-component systems: a review, pp 263–286. Springer, London. https://doi.org/10.1007/978-1-84800-011-7_11

Wildeman RE, Dekker R, Smit ACJM (1997) A dynamic policy for grouping maintenance activities. Eur J Oper Res 99(3):530–551. https://doi.org/10.1016/S0377-2217(97)00319-6

Borkar S (2005) Designing reliable systems from unreliable components: the challenges of transistor variability and degradation. Ieee Micro 25(6):10–16. https://doi.org/10.1109/MM.2005.110

Cadi AAE, Hachemi NE, Jamali MA, Artiba A, Rousseau LM (2022) An exact approach to the integration of non-cyclical preventive maintenance scheduling and production planning for a series-parallel production system. Int J Oper Res 44(3):401–414. https://doi.org/10.1504/IJOR.2022.124104

Gharoun H, Hamid M, Torabi SA (2022) An integrated approach to joint production planning and reliability-based multi-level preventive maintenance scheduling optimization for a deteriorating system considering due-date satisfaction. Int J Syst Sci Oper Logist 9(4):489–511. https://doi.org/10.1080/23302674.2021.1941394

Merghem M, Haoues M, Mouss KN, Dahane M, Senoussi A (2023) Integrated production and maintenance planning in hybrid manufacturing-remanufacturing system with outsourcing opportunities. Procedia Comput Sci 217:1487–1496. https://doi.org/10.1016/j.procs.2022.12.348

Bahou Z, Krimi I, Elhachemi N, El cadi AA (in press) Integrating non-cyclical preventive maintenance scheduling and production planning for a series-parallel production line with stochastic dependence. Int J Ind Syst Eng. https://doi.org/10.1504/IJISE.2022.10053547

Aguilar H, García-Villoria A, Pastor R (2020) A survey of the parallel assembly lines balancing problem. Comput Oper Res 124:105061. https://doi.org/10.1016/j.cor.2020.105061

Xi W et al (2018) Type synthesis of coordinated multi-robot system based on parallel thought. Trans Can Soc Mech Eng 42(2):164–176. https://doi.org/10.1139/tcsme-2017-0053

Yang H, Lu L, Zhou W (2007) A novel optimization sizing model for hybrid solar-wind power generation system. Solar Energy 81(1):76–84. https://doi.org/10.1016/j.solener.2006.06.010

Chen Z, Turng LS (2005) A review of current developments in process and quality control for injection molding. Adv Polym Technol J Polym Process Inst 24(3):165–182. https://doi.org/10.1002/adv.20046

Gackowiec P (2019) General overview of maintenance strategies-concepts and approaches. Multidisciplinary Aspects of Production Engineering 2(1):126–139. https://doi.org/10.2478/mape-2019-0013

Liu X, Wang W, Zhang T, Zhai Q, Peng R, (2015) An integrated non-cyclical preventive maintenance and production planning model for a multi-product production system. In, (2015) IEEE International conference on industrial engineering and engineering management (IEEM), pp 494–498. IEEE. https://doi.org/10.1109/IEEM.2015.7385696

DerakhshanHoreh S, Bijari M (2023) Integrated production and non-cyclical maintenance planning in flow-shop environment with limited buffer. Int J Ind Syst Eng 45(3):291–320. https://doi.org/10.1504/IJISE.2023.134718

Xia T, Jin X, Xi L, Ni J (2015) Production-driven opportunistic maintenance for batch production based on MAM-APB scheduling. Eur J Oper Res 240(3):781–790. https://doi.org/10.1016/j.ejor.2014.08.004

Biel K, Glock CH (2016) Systematic literature review of decision support models for energy-efficient production planning. Comput & Ind Eng 101:243–259. https://doi.org/10.1016/j.cie.2016.08.021

Allahverdi A (2015) The third comprehensive survey on scheduling problems with setup times/costs. Eur J Oper Res 246(2):345–378. https://doi.org/10.1016/j.ejor.2015.04.004

Allahverdi A (2016) A survey of scheduling problems with no-wait in process. Eur J Oper Res 255(3):665–686. https://doi.org/10.1016/j.ejor.2016.05.036

Carlson JG, Yao AC (2008) Simulating an agile, synchronized manufacturing system. Int J Prod Econ 112(2):714–722. https://doi.org/10.1016/j.ijpe.2007.06.008

Ekin T (2018) Integrated maintenance and production planning with endogenous uncertain yield. Reliab Eng Syst Saf 179:52–61. https://doi.org/10.1016/j.ress.2017.07.011

Glawar R, Karner M, Nemeth T, Matyas K, Sihn W (2018) An approach for the integration of anticipative maintenance strategies within a production planning and control model. Procedia CIRP 67:46–51. https://doi.org/10.1016/j.procir.2017.12.174

Liu Y, Zhang Q, Ouyang Z, Huang HZ (2021) Integrated production planning and preventive maintenance scheduling for synchronized parallel machines. Reliab Eng Syst Saf 215:107869. https://doi.org/10.1016/j.ress.2021.107869

Dehghan Shoorkand, H., Nourelfath, M., and Hajji, A. (2023). A deep learning approach for integrated production planning and predictive maintenance. Int J Prod Res, pp 1–20. https://doi.org/10.1080/00207543.2022.2162618

Kolus A, El-Khalifa A, Al-Turki UM, Duffuaa SO (2020) An integrated mathematical model for production scheduling and preventive maintenance planning. Int J Qual Reliab Manag 37(6/7):925–937. https://doi.org/10.1108/IJQRM-10-2019-0335

Qiu S, Ming X, Sallak M, Lu J (2021) Joint optimization of production and condition-based maintenance scheduling for make-to-order manufacturing systems. Comput Ind Eng 162:107753. https://doi.org/10.1016/j.cie.2021.107753

Majdouline I, Dellagi S, Mifdal L, Kibbou EM, Moufki A (2022) Integrated production-maintenance strategy considering quality constraints in dry machining. Int J Prod Res 60(9):2850–2864. https://doi.org/10.1080/00207543.2021.1905193

Aghezzaf EH, Khatab A, Le Tam P (2016) Optimizing production and imperfect preventive maintenance planning’ s integration in failure-prone manufacturing systems. Reliab Eng Syst Saf 145:190–198. https://doi.org/10.1016/j.ress.2015.09.017

Kang K, Subramaniam V (2018) Joint control of dynamic maintenance and production in a failure-prone manufacturing system subjected to deterioration. Comput Ind Eng 119:309–320. https://doi.org/10.1016/j.cie.2018.03.001

Khatab A (2018) Maintenance optimization in failure-prone systems under imperfect preventive maintenance. J Intell Manuf 29:707–717. https://doi.org/10.1007/s10845-018-1390-2

Alimian M, Saidi-Mehrabad M, Jabbarzadeh A (2019) A robust integrated production and preventive maintenance planning model for multi-state systems with uncertain demand and common cause failures. J Manuf Syst 50:263–277. https://doi.org/10.1016/j.jmsy.2018.12.001

Bampoula X, Siaterlis G, Nikolakis N, Alexopoulos K (2021) A deep learning model for predictive maintenance in cyber-physical production systems using lstm autoencoders. Sensors 21(3):972. https://doi.org/10.3390/s21030972

Gan J, Zhang W, Wang S, Zhang X (2022) Joint decision of condition-based opportunistic maintenance and scheduling for multi-component production systems. Int J Prod Res 60(17):5155–5175. https://doi.org/10.1080/00207543.2021.1951447

BAHOU Z, KRIMI I, ELHACHEMI N, El Cadi AA (2022) Assessing the stochastic dependence effect on the integrated preventive maintenance scheduling and production planning

Bakir I, Yildirim M, Ursavas E (2021) An integrated optimization framework for multi-component predictive analytics in wind farm operations and maintenance. Renew Sust Energ Rev 138:110639. https://doi.org/10.1016/j.rser.2020.110639

Maher H, Aly MF, Afefy IH, Abdelmaguid TF (2022) A maintenance optimisation approach based on genetic algorithm for multi-component systems considering the effect of human error. Int J Ind Syst Eng 40(1):51–78. https://doi.org/10.1504/IJISE.2022.120803

Zhang C, Qi F, Zhang N, Li Y, Huang H (2022) Maintenance policy optimization for multi-component systems considering dynamic importance of components. Reliab Eng Syst Saf 226:108705. https://doi.org/10.1016/j.ress.2022.108705

Zhang W, Gan J, Hou Q (2022) Joint decision of condition-based maintenance and production scheduling for multi-component systems. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture 236(6–7):726–740. https://doi.org/10.1177/09544054211043759

Yang DY, Tsao CL (2019) Reliability and availability analysis of standby systems with working vacations and retrial of failed components. Reliab Eng Syst Saf 182:46–55. https://doi.org/10.1016/j.ress.2018.09.020

Gao S, Wang J (2021) Reliability and availability analysis of a retrial system with mixed standbys and an unreliable repair facility. Reliab Eng Syst Saf 205:107240. https://doi.org/10.1016/j.ress.2020.107240

Yang DY, Wu CH (2021) Evaluation of the availability and reliability of a standby repairable system incorporating imperfect switchovers and working breakdowns. Reliab Eng Syst Saf 207:107366. https://doi.org/10.1016/j.ress.2020.107366

Lazakis I, Kougioumtzoglou MA (2019) Assessing offshore wind turbine reliability and availability. Proceedings of the Institution of Mechanical Engineers, Part M: Journal of Engineering for the Maritime Environment 233(1):267–282. https://doi.org/10.1177/1475090217735413

Lotovskyi E, Teixeira AP, Soares Guedes C (2020). Availability analysis of an offshore oil and gas production system subjected to age-based preventive maintenance by Petri Nets. Eksploatacja i Niezawodność, 22(4). https://doi.org/10.17531/ein.2020.4.6

Gao P, Xie L, Pan J (2019) Reliability and availability models of belt drive systems considering failure dependence. Chin J Mech Eng 32(1):1–12. https://doi.org/10.1186/s10033-019-0342-x

Mishra S (2016) Optimal availability analysis of brake drum manufacturing system by using markovian approach (Doctoral dissertation)

Danjuma MU, Yusuf I, Sufi NA (2022). Reliability availability maintainability dependability analysis of mirrored distributed system. Journal of Industrial Engineering International. https://doi.org/10.30495/JIEI.2022.1941704.1166

Yusuf I, Usman NM, Bala SI (2020). Availability analysis of hybrid systems consisting of main units and cold standby processors. J Reliab Stat Stud, pp 429–460. https://doi.org/10.13052/jrss0974-8024.132411

Zhang N, Yang Q (2015) Optimal maintenance planning for repairable multi-component systems subject to dependent competing risks. IIE Transactions 47(5):521–532. https://doi.org/10.1080/0740817X.2014.974115

Jafari L, Naderkhani F, Makis V (2018) Joint optimization of maintenance policy and inspection interval for a multi-unit series system using proportional hazards model. J Oper Res Soc 69(1):36–48. https://doi.org/10.1057/s41274-016-0160-9

Lai MT, Yan H (2016) Optimal number of minimal repairs with cumulative repair cost limit for a two-unit system with failure rate interactions. Int J Syst Sci 47(2):466–473. https://doi.org/10.1080/00207721.2014.886749

Bahou Z, Krimi I, Cadi AAE, Hachemi NE (2023) Availability modelling and analysis of a two-component parallel system under stochastic dependence. Int J Math Oper Res 26(3):327–356. https://doi.org/10.1504/IJMOR.2023.134836

Bannert V, Tschirky H (2004) Integration planning for technology intensive acquisitions. R &d Management 34(5):481–494. https://doi.org/10.1111/j.1467-9310.2004.00356.x

Wakiru J, Pintelon L, Muchiri PN, Chemweno PK (2021) Integrated remanufacturing, maintenance and spares policies towards life extension of a multi-component system. Reliab Eng Syst Saf 215:107872. https://doi.org/10.1016/j.ress.2021.107872https://doi.org/10.1016/j.ress.2021.107872

Obrecht TP, Jordan S, Legat A, Saade MRM, Passer A (2021) An LCA methodolody for assessing the environmental impacts of building components before and after refurbishment. J Clean Prod 327:129527. https://doi.org/10.1016/j.jclepro.2021.129527https://doi.org/10.1016/j.jclepro.2021.129527

Mifdal L, Hajej Z, Dellagi S, Rezg N (2013) An optimal production planning and maintenance policy for a multiple-product and single machine under failure rate dependency. IFAC Proceedings Volumes 46(9):507–512. https://doi.org/10.3182/20130619-3-RU-3018.00246

Fitouhi MC, Nourelfath M (2012) Integrating noncyclical preventive maintenance scheduling and production planning for a single machine. Int J Prod Econ 136(2):344–351. https://doi.org/10.1016/j.ijpe.2011.12.021

Kouedeu AF, Kenné JP, Dejax P, Songmene V, Polotski V (2014) Production planning of a failure-prone manufacturing/remanufacturing system with production-dependent failure rates. Appl Math. https://doi.org/10.4236/am.2014.510149

Orcun S, Uzsoy R, Kempf KG (2009) An integrated production planning model with load-dependent lead-times and safety stocks. Comput & Chem Eng 33(12):2159–2163. https://doi.org/10.1016/j.compchemeng.2009.07.010

Hu J, Sun Q, Ye ZS (2020) Condition-based maintenance planning for systems subject to dependent soft and hard failures. IEEE Trans Reliab 70(4):1468–1480. https://doi.org/10.1109/TR.2020.2981136

Vu HC, Do P, Barros A, Bérenguer C (2015) Maintenance planning and dynamic grouping for multi-component systems with positive and negative economic dependencies. IMA J Manag Math 26(2):145–170. https://doi.org/10.1093/imaman/dpu007

Pahl J, Vob S, Woodruff DL (2007) Production planning with load dependent lead times: an update of research. Ann Oper Res 153:297–345. https://doi.org/10.1007/s10479-007-0173-5

Strogatz SH (2000) Nonlinear dynamics and chaos: with applications to physics, biology, chemistry, and engineering, 1st pbk

Bashirov AE, Mısırlı E, Tandoğdu Y, Özyapıcı A (2011) On modeling with multiplicative differential equations. Appl Math-A J Chinese Universities 26:425–438. https://doi.org/10.1007/s11766-011-2767-6

McConville K (2018) Trophic and ecological implications of the gelatinous body form in zooplankton (Doctoral dissertation, University of Plymouth)

Lemnaouar MR, Khalfaoui M, Louartassi Y, Tolaimate I (2019) Harvesting of a prey-predator model fishery in the presence of competition and toxicity with two effort functions. Commun Math Biol Neurosci, 2019, Article-ID

Hattaf K, El Karimi MI, Mohsen AA, Hajhouji Z, El Younoussi M, Yousfi N (2023) Mathematical modeling and analysis of the dynamics of RNA viruses in presence of immunity and treatment: A case study of SARS-CoV-2. Vaccines 11(2):201. https://doi.org/10.3390/vaccines11020201

Manna K, Hattaf K (2022) A generalized distributed delay model for hepatitis B virus infection with two modes of transmission and adaptive immunity: A mathematical study. Math Methods Appl Sci 45(17):11614–11634. https://doi.org/10.1002/mma.8470

Louartassi Y, Alla A, Hattaf K, Nabil A (2019) Dynamics of a predator-prey model with harvesting and reserve area for prey in the presence of competition and toxicity. J Appl Math Comput 59:305–321. https://doi.org/10.1007/s12190-018-1181-0

Vanlier J, Tiemann CA, Hilbers PAJ, Van Riel NAW (2013) Parameter uncertainty in biochemical models described by ordinary differential equations. Math Biosci 246(2):305–314. https://doi.org/10.1016/j.mbs.2013.03.006

Frenkel I, Lisnianski A, Khvatskin L (2012) Availability assessment for aging refrigeration system by using Lz-transform. J Reliab Stat Stud, pp 33–43

Daichman S, Frenkel I, Khvatskin L, Lisnianski A (2013) On aging components impact on multi-state water cooling system: L z-transform application for availability assessment. In: The international conference on digital technologies 2013 (pp 156–161). IEEE. https://doi.org/10.1109/DT.2013.6566304

Meenakshi K, Singh SB (2016) Availability assessment of multi-state system by hybrid universal generating function and probability intervals. Int J Perform Eng 12(4)

Biswas BN, Chatterjee S, Mukherjee SP, Pal S (2013) A discussion on Euler method: A review. Electron J Math Anal Appl 1(2):294–317

Jaber AA, Bicker R (2014) The state of the art in research into the condition monitoring of industrial machinery. Int J Curr Eng Technol

Nourelfath M, Châtelet E (2012) Integrating production, inventory and maintenance planning for a parallel system with dependent components. Reliab Eng Syst Saf 101:59–66. https://doi.org/10.1016/j.ress.2012.02.001

Nourelfath M, Fitouhi MC, Machani M (2010) An integrated model for production and preventive maintenance planning in multi-state systems. IEEE Trans Reliab 59(3):496–506. https://doi.org/10.1109/TR.2010.2056412

Fitouhi MC, Nourelfath M (2014) Integrating noncyclical preventive maintenance scheduling and production planning for multi-state systems. Reliab Eng Syst Saf 121:175–186. https://doi.org/10.1016/j.ress.2013.07.009

Puik E, van Moergestel L (2010) Agile multi-parallel micro manufacturing using a grid of equiplets. In: Precision assembly technologies and systems: \(5th\) IFIP WG \(5.5\) international precision assembly seminar, IPAS 2010, Chamonix, France, February \(14-17\), 2010. Proceedings 5 , pp 71–282. Springer Berlin Heidelberg

Kececioglu D (2002) Reliability engineering handbook (Vol. 1). DEStech Publications, Inc

Yong T (2004) Extended Weibull distributions in reliability engineering

Lawless JF (2011) Statistical models and methods for lifetime data. John Wiley and Sons

Johnson NL, Kotz S, Balakrishnan N (1995) Continuous univariate distributions, volume 2 (Vol. 289). John Wiley and sons

Birkoff G, Rota GC (1982) Ordinary Differential Equations. Ginn, Boston

Louartassi Y, El Mazoudi E, Elalami N (2012) A new generalization of lemma Gronwall-Bellman. Appl Math Sci 6(13):621–628

Funding

This research was supported by Abu Dhabi University under the grant number 19300779.

Author information

Authors and Affiliations

Contributions

All the authors have contributed equally to this paper.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 A.1 Basic model properties

To guarantee that our model (1) is well posed, we prove its solutions’ nonnegativity and boundedness.

Theorem 7.1

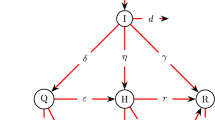

Under the condition (2), for all \(t\ge 0\), the solutions of our model (1) exhibit the following non-negative properties: \(S(t)\ge 0\), \(E(t)\ge 0\), \(I(t)\ge 0\), \(Q(t)\ge 0\), \(H(t)\ge 0\), \(R(t)\ge 0\) and \(S_t(t)\ge 0\).

Proof

If the condition (2) is realized, the following inequalities can be established from the ten equations in our model (1).

When we apply the theory of differential inequalities [93, 94], we find:

\(\square \)

Theorem 7.2

The solution of our model (1), with the initial conditions specified in (2), is positive in the following set:

where \(N=S+E+I+Q+H+R+S_t.\)

Proof

Letting \(N=S+E+I+Q+H+R+S_t,\) then

Then, the solution of differential equation (27) is:

\(N(t)= N(0)e^{-dt}+\frac{m}{d}\left( 1-e^{-dt}\right) .\) If \(t\rightarrow \infty \), we have \(N\le \frac{\Lambda }{d}\). \(\square \)

1.2 A.2 Equilibrium points and stability analysis

This section determines the equilibrium point \(P_0\) in the absence of failure and the equilibrium point \(P^*\) in the presence of failure with failure. Finally, we discuss the local stability of \(P_0\) and \(P^*\).

We need to resolve the following system of equations to obtain the coordinates of equilibrium \(P_0(S_0,E_0, I_0,Q_0,H_0, \) \( R_0,St_0)\):

The equilibrium point \(P_0\) is achieved if \(E_0=I_0=Q_0=H_0=R_0=St_0=0\). In the absence of failure, we have \(\beta _1=0\). As a result, the first system (1) is: \(\frac{dS}{dt}=m-dS_0=0\). Therefore, the system (1) admit failure-free equilibrium point \(P_{0}(\frac{m}{d},0,0,0,0,0,0)\).

To determine the coordinates of the equilibrium point \(P^*(S^*,E^*,I^*,Q^*,H^*,R^*,S_t^*)\). We resolve the system (28). Then we get:

where \(a=\beta _1+d\), \(b=\beta _2\), \(c=\sigma \), \(e=\theta \), \(f=\eta +\gamma +d+\delta \), \(g=\delta \), \(h=\varepsilon +d+\Upsilon \), \(i=\eta \), \(j=\varepsilon \), \(k=\nu +r+d\), \(l=\gamma \), \(n=d+\sigma \), \(p=\zeta \), \(q=\Upsilon \), \(s=\zeta +d\), \(t=b+e+d\) and \(z=\beta _1\).

1.3 A.3 Local stability

This section determines the conditions for local stability of the two equilibrium points \(P_0\) and \(P^*\).

Lemma 7.3

The condition (30) guarantees the local asymptotic stability of the equilibrium points \(P_0\) and \(P^*\).

Proof

The Jacobian matrix of our system (1) is determined as follows:

Solving this equation \(det(J-\lambda I_7)= 0\) leads to the determination of the eigenvalues of the matrix J. Then:

We have \(\lambda _{i}<0\) for \(i=1,\dots 6\). If the condition \(\beta _1(\beta _2+\theta +d)+\beta _{2}d+d\theta +d\theta +d^2>\beta _{2}^2\) is fulfilled. Then \(\lambda _7<0\). Therefore, all eigenvalues are negative real parts. The proof is completed. \(\square \)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bahou, Z., Lemnaouar, M.R. & Krimi, I. Integrated non-cyclical preventive maintenance scheduling and production planning for multi-parallel component production systems with interdependencies-induced degradation. Int J Adv Manuf Technol 130, 4723–4749 (2024). https://doi.org/10.1007/s00170-024-12975-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-12975-4