Abstract

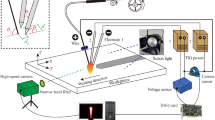

Twin tungsten electrode-wire electrode indirect arc welding (TTW-IAW) is a new welding method, in which the twin tungsten electrodes are connected to the power source together with the welding wire, while the base metal is not connected to the power source, so that the indirect arc is formed between the twin tungsten electrodes and the welding wire. Currently, only the arc characteristics and the droplet transition behavior have been studied, which limits the application of this process in practical welding. In this paper, the thin-plate butt welding process is applied for the first time in TTW-IAW, and the effects of process parameters on weld formation, microstructure, and its hardness are investigated. Additionally, the formation mechanisms of burn-through and hump defects are revealed by the static model and hydraulic jump model of the molten pool, respectively. The results show that TTW-IAW achieves stable weld formation at a maximum welding speed of 600 mm/min, a fourfold increase compared to conventional cold-wire single-TIG welding (conventional cold-wire STW), which reflects its advantages of large deposition rate and high welding efficiency. The degree of influence of the welding current on the penetration of base metal is greater than the welding speed, and the increase in welding current is conducive to the increase in the base metal penetration and the heat-affected zone (HAZ) width, while the increase in welding speed can reduce the convex height of the weld. However, excessive welding currents cause the downward component of arc force and droplet impact to be increased and the upward component of surface tension to be decreased, which results in destabilization of the molten pool, leading to the formation of burn-through defects. Excessive welding speed causes the flow rate of the liquid in the molten pool to be increased and the critical value for the occurrence of a hydraulic jump is exceeded, leading to the formation of a hump.

Similar content being viewed by others

Data availability

All the data have been presented in the manuscript.

References

Liu LM, Yu SB, Song G, Hu CH (2019) Analysis of arc stability and bead forming with high-speed TW-GIA welding. J Manuf Process 46:67–76

Chen S, Wang L, Xiao J, Wei P (2018) Arc behavior and droplet dynamics of AC GTAW-GMAW hybrid indirect arc. Weld J 97:91–98

Liu G, Han S, Tang X, Cui H (2021) Effects of torch configuration on arc interaction behaviors and weld defect formation mechanism in tandem pulsed GMAW. J Manuf Process 62:729–742

Liu GC, Xiong J, Tang L (2020) Microstructure and mechanical properties of 2219 aluminum alloy fabricated by double-electrode gas metal arc additive manufacturing. Addit Manuf 35:101375

Zhang ZH, Wu DT, Zou Y (2018) Effect of bypass coupling on droplet transfer in twin-wire indirect arc welding. J Mater Process Technol 262:123–130

Liu LM, Zhu YL, Liu RT (2022) Influence of cusp external magnetic field on deposition rate of two-electrode TIG welding. Int J Adv Manuf Tech 119:6549–6558

Huang Y, Liu RL, Hao YZ (2018) Gas pool coupled activating TIG welding method with coupling arc electrode. Chin J Mech Eng 31:96

Voigt AL, Cunha TV, Niño CE (2020) Conception, implementation and evaluation of induction wire heating system applied to hot wire GTAW (IHW-GTAW). J Mater Process Technol 281:116615

Han QL, Li DY, Sun HJ, Zhang GJ (2019) Forming characteristics of additive manufacturing process by twin electrode gas tungsten arc. Int J Adv Manuf Tech 104:4517–4526

Chen JS, Lu Y, Li XR, Zhang YM (2012) Gas tungsten arc welding using an arcing wire. Weld J 91(10):261s–269s

Miao Y, Xu XF, Wu BT, Han DF, Zeng Y, Wang T (2015) Effects of bypass current on arc characteristics and metal transfer behaviour during MIG–TIG double sided arc welding. J Mater Process Technol 224:40–48

Wang J, Wu D, Liao P, Tian C, Li M, Feng J (2013) Metal transfer and arc behaviour of novel consumable and non-consumable electrode indirect arc droplet welding. Sci Technol Weld Join 18:261–270

Wang J, Huang Y, Xiao J, Feng J, Tian CY, Wang J (2015) Metal transfer with force analysis in consumable and nonconsumable indirect arc welding process. Weld J 93:431S–438S

Zhu YL, Wang ZL, Liu RT, Liu LM (2022) Study on arc behavior and droplet transfer in twin-electrode TIG-MIG indirect arc welding. Int J Adv Manuf Tech 120:6821–6831

Wu XY, Zhao XY, Chen J, Zhang ZY, Wu CS (2022) Simulation of the influence of welding parameters on weld pool behavior during a TIG-MIG hybrid welding process. J Manuf Process 79:460–475

Kim C, Zhang W, Debroy T (2003) Modeling of temperature field and solidified surface profile during gas metal arc fillet welding. J Appl Phys 94:2667–2669

Zong R, Chen J, Wu C, Lou D (2021) Numerical analysis of molten metal behavior and undercut formation in high-speed GMAW. J Mater Process Technol 297:117266

Huang J, Pan W, Yang W, Xue C, Shi Y, Fan D (2019) The influence of bypass current on metal transfer in dual-bypass gas metal arc welding. J Manuf Process 38:179–186

Lakemeyer P, Schöppner V (2019) Simulation-based investigation on the temperature influence in laser transmission welding of thermoplastics. Weld World 63(2):221–228

Huang JK, He XY, Guo YN, Zhang ZP, Shi Y, Fan D (2017) Joining of aluminum alloys to galvanized mild steel by the pulsed DE-GMAW with the alternation of droplet transfer. J Manuf Process 25:16–25

Wu D, An Q, Matsuda K, Zhang Y (2020) Characteristics of bypass coupling twin-wire indirect arc welding with high-speed welding mode. J Mater Process Technol 291:116995

Chen J, Wu CS (2009) Numerical simulation of forming process of humping bead in high speed GMAW. Acta Metall Sin 45(9):1070–1076

Savage WF, Nippes EF, Agusa K (1979) Effect of arc force on defect formation in GTA welding. Weld J 58:212–224

Shimada W, Hoshinouchi S (1982) A study on bead formation by low pressure TIG arc and prevention of under-cut bead. J Jpn Weld Soc 51(3):280–286

Schempp P, Rethmeier M (2015) Understanding grain refinement in aluminium welding. Weld World 59:767–784

Li ZY, Yu G, He XL, Li SX, Li HM, Li QY (2019) Study of thermal behavior and solidification characteristics during laser welding of dissimilar metals. Results in Physics 12:1062–1072

Kohlhorst NM, Faraone KM, Miller RG, Muralidharan G, Ulrich GB, Zhao JC (2023) A technique for the quantitative characterization of weld microstructure and application to Mo welds. Metall Mater Trans B 54:1434–1448

Funding

This work was supported by the National Key Research and Development Program of China (2022YFB4600900), and the National Natural Science Foundation of China (No.52175290).

Author information

Authors and Affiliations

Contributions

Liming Liu: conceptualization, writing—review and editing.

Runtao Liu: writing-original draft, methodology, formal analysis.

Yanli Zhu: supervision, validation.

Corresponding author

Ethics declarations

Ethics approval

The paper follows the guidelines of the Committee on Publication Ethics (COPE).

Consent to participate

The authors declare that they all consent to participate this research.

Consent for publication

The authors declare that they all consent to publish the manuscript.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, L., Liu, R. & Zhu, Y. Study on the influence of process parameters in twin tungsten electrode-wire electrode indirect arc welding. Int J Adv Manuf Technol 130, 5547–5561 (2024). https://doi.org/10.1007/s00170-024-12944-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-12944-x