Abstract

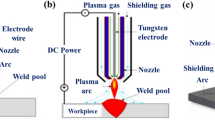

In response to the demands of high-efficient welding, twin-arc integrated cold wire hybrid welding technology was proposed in this paper. In order to realize a stable welding process, the research was focused on the effect of welding electrical parameters on the metal transfer process of simultaneous arcing to find a proper range of process parameters. In addition, the experimental research found a new factor to affect the metal transfer mode, i.e., arcing mode, and its effect mechanism was discussed in greater detail. The results showed that both the leading wires kept simultaneous arcing with in-phase pulse currents supplied to two wires. The metal transfer modes were divided into two types: one is one droplet per pulse, and the other is one droplet multiple pulses, which highly depended on arc voltage. At first, the main metal transfer was one droplet multiple pulses at lower arc voltage. Then the metal transfer mode started to change to one droplet per pulse with the increase of arc voltage. Finally, when arc voltage continuously increased to a certain value, one droplet multiple pulses once again occurred. This was mainly because the great increase of arc length restricted the expansion of arc root. What is more important, through the comparison between the metal transfer processes of simultaneous arcing and alternative arcing, it was found that the arcing mode had a significant effect on the metal transfer mode, and the main reason was the arcing mode affected the electric field intensity of arc column.

Similar content being viewed by others

References

Tusek J (2004) Mathematical modelling of melting rate in arc welding with a triple-wire electrode. J Mater Process Technol 146(3):415–423

Layus P, Kah P, Martikainen J, Gezha VV, Bishokov RV (2014) Multi-wire SAW of 640 MPa Arctic shipbuilding steel plates. Int J Adv Manuf Technol 75(5–8):771–782

Bajcer B, Hrzenjak M, Pompe K, Jez B (2007) Improvement of energy and materials efficiencies by introducing multiple-wire welding. Metalurgija 46(1):47–52

Meng XM, Qin GL, Zhang YQ, Fu BL, Zou ZD (2014) High speed TIG–MAG hybrid arc welding of mild steel plate. J Mater Process Technol 214(11):2417–2424

Wahba M, Mizutani M, Katayama S (2015) Hybrid welding with fiber laser and CO2 gas shielded arc. J Mater Process Technol 221:146–153

Cai C, Feng JC, Li LQ, Chen YB (2016) Influence of laser on the droplet behavior in short-circuiting, globular, and spray modes of hybrid fiber laser-MIG welding. Optics Laser Technol 83:108–118

Kiran DV, Cho DW, Song WH, Na SJ (2015) Arc interaction and molten pool behavior in the three wire submerged arc welding process. Int J Heat Mass Transf 87:327–340

Li YB, Huang MH, Lu XJ (2011) Improvement in Ovality of pipeline steel X80 with weld power under multi-wire SAW welding process. Adv Mater Res 239-242:1823–1831

Kah P, Suoranta R, Martikainen J (2013) Advanced gas metal arc welding processes. Int J Adv Manuf Technol 67(1–4):655–674

Qin GL, Meng XM, BL F (2015) High speed tandem gas tungsten arc welding process of thin stainless steel plate. J Mater Process Technol 220:58–64

Kiran DV, Cho DW, Song WH, Na SJ (2014) Arc behavior in two wire tandem submerged arc welding. J Mater Process Technol 214(8):1546–1556

Yao P, Xue JX, Zhou K, Wang XJ, Zhu Q (2016) Symmetrical transition waveform control on double-wire MIG welding. J Mater Process Technol 229:111–120

Yokota Y, Shimizu H, Nagaoka S, Ito K, Arita H (2012) Development and application of the 3-electrode MAG high-speed horizontal fillet welding process. Weld World 56(1–2):43–47

Arita H, Morimoto T, Nagaoka S, Nakano T (2009) Development of advanced 3-electrode MAG high-speed horizontal fillet welding process. Weld World 53(5–6):35–43

Raudsepp H (2015) Integrated cold electrode—latest advancement in submerged arc welding. Electr Weld Mach 45(5):28–32

Xiang T, Li H, Wei HL, Gao Y (2015) Effects of filling status of cold wire on the welding process stability in twin-arc integrated cold wire hybrid welding. Int J Adv Manuf Technol 83(9–12):1583–1593

Xiang T, Li H, Wei HL, Gao Y (2016) Arc characteristics and metal transfer behavior of twin-arc integrated cold wire hybrid welding. Int J Adv Manuf Technol Article in press. doi: 10.1007/s00170-016-8663-8

Scotti A, Ponomarev V, Lucas W (2012) A scientific application oriented classification for metal transfer modes in GMA welding. J Mater Process Technol 212(6):1406–1413

Yin SY (2008) Basic and application of gas metal arc welding. China Machine Press, Bei Jin

Chen DS, Chen MA, Wu CS (2015) Effects of phase difference on the behavior of arc and weld pool in tandem P-GMAW. J Mater Process Technol 225:45–55

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Xiang, T., Li, H., Huang, C.Q. et al. The metal transfer behavior and the effect of arcing mode on metal transfer process in twin-arc integrated cold wire hybrid welding. Int J Adv Manuf Technol 90, 1043–1050 (2017). https://doi.org/10.1007/s00170-016-9451-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9451-1