Abstract

Currently, there is a notable attraction within the industry towards biocomposites, driven by the increasing fascination with natural fiber-reinforced composites (NFRCs). These NFRCs offer remarkable benefits, including cost-effectiveness, biodegradability, eco-friendliness, and favorable mechanical properties. As a result, the manufacturing processes of natural fiber reinforced polymer (NFRP) composites have garnered attention from both industrial professionals and scientists. The emergence of these eco-friendly materials in the automotive and aerospace industries has sparked interest in understanding their production techniques. However, the machining processes of NFRP composites pose significant challenges due to the complex structure of natural fibers, necessitating thorough studies to address these issues effectively. This research paper presents a comprehensive investigation on surface roughness during the milling process of Alfa/epoxy biocomposites. A set of 100 experimental trials was conducted to test the surface roughness, and analysis of variance (ANOVA) was used to assess the impact of cutting parameters and chemical treatment on surface quality.

To develop a predictive model for surface roughness, a hybrid approach called ANN-GA (artificial neural networks-genetic algorithms) is proposed in this research. This approach combines ANN and GA to determine an optimal neural network architecture. The performance of the ANN-GA model is compared to the Levenberg–Marquardt backpropagation (LM) algorithm.

ANOVA results show that the feed per revolution have a significant influence on surface roughness, followed by the chemical treatment of fibers, while machining direction has a smaller effect. The ANN-GA model demonstrates good accuracy in surface roughness prediction compared to the LM algorithm.

Similar content being viewed by others

Data availability

All data presented in this paper are available.

Code availability

Can be made available upon request.

References

Behera RR et al (2016) Simultaneous prediction of delamination and surface roughness in drilling GFRP composite using ANN. Int J Plast Technol 20:424–450

Mohammed NH, Wolla DW (2022) Optimization of machining parameters in drilling hybrid sisal-cotton fiber reinforced polyester composites. AIMS Mater Sci 9(1):119–134. https://doi.org/10.3934/matersci.2022008

Sivam R (2009) Symposium on fibre reinforced composites, Port Elizabeth – South Africa 24 – 25 February

Lovins AB, Cramer DR (2004) Hypercars, hydrogen, and the automotive transition. Int J Veh Des 35(1–2):50–85

Chauhan V, Kärki T, Varis J (2022) Review of natural fiber-reinforced engineering plastic composites, their applications in the transportation sector and processing techniques. J Thermoplast Compos Mater 35(8):1169–1209

Christophe B (2013) Fibres naturelles de renfort pour matériaux composites. Éditions Techniques de l’Ingénieur 249. https://doi.org/10.51257/a-v3-am5130

Taallah B, Guettala A, Kriker A (2014) Effet de la teneur en fibres de palmier dattier et de la contrainte de compactage sur les propriétés des blocs de terre comprimée. Courrier du Savoir 18:45–51

Abdelaziz S et al (2013) Valorisation des tiges de dattiers dans la formulation des mortiers: propriétés physiques et mécaniques. AUGC, Mai 2013, LMT Cachan, France

Madhavan V et al (2015) Fiber orientation angle effects in machining of unidirectional CFRP laminated composites. J Manuf Process 20:431–442

Nayak D, Bhatnagar N, Mahajan P (2005) Machining studies of uni-directional glass fiber reinforced plastic (UD-GFRP) composites part 1: effect of geometrical and process parameters. Mach Sci Technol 9(4):481–501

Chakladar ND, Pal SK, Mandal P (2012) Drilling of woven glass fiber-reinforced plastic—an experimental and finite element study. Int J Adv Manuf Technol 58:267–278

Sorrentino L, Turchetta S (2014) Cutting forces in milling of carbon fibre reinforced plastics. Int J Manuf Eng 2014:439634. https://doi.org/10.1155/2014/439634

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15:25–33

George M et al (2014) Characterization of chemically and enzymatically treated hemp fibres using atomic force microscopy and spectroscopy. Appl Surf Sci 314:1019–1025

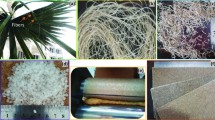

El-Abbassi FE et al (2020) A review on alfa fibre (Stipatenacissima L.): From the plant architecture to the reinforcement of polymer composites. Compos Part A: Appl Sci Manuf 128:105677

Gares M, Hiligsmann S, KacemChaouche N (2020) Lignocellulosic biomass and industrial bioprocesses for the production of second generation bio-ethanol, does it have a future in Algeria? SN Appl Sci 2:1–19

Sun X-F et al (2013) Hemicellulose-based pH-sensitive and biodegradable hydrogel for controlled drug delivery. Carbohyd Polym 92(2):1357–1366

Zoghlami A, Paës G (2019) Lignocellulosic biomass: understanding recalcitrance and predicting hydrolysis. Front Chem 7:874

Kim S, Dale BE (2004) Global potential bioethanol production from wasted crops and crop residues. Biomass Bioenerg 26(4):361–375

Semhaoui I et al (2017) Bioconversion of Moroccan Alfa (Stipa Tenacissima) by thermomechanical pretreatment combined to acid or alkali spraying for ethanol production. J Mater 8:2619–2631

Labidi K et al (2019) Alfa fiber/polypropylene composites: influence of fiber extraction method and chemical treatments. J Appl Polym Sci 136(18):47392

Paiva M et al (2007) Alfa fibres: mechanical, morphological and interfacial characterization. Compos Sci Technol 67(6):1132–1138

Brahim BS, Cheikh RB, Baklouti M (2001) The alfa fibres in composite materials. In: Proceedings of ICCM-13 conference, 2001. ICCM, Beijing, China

Campos AR, Cunha AM, Cheikh RB (2003) Injection molding of a starch based polymer reinforced with natural fibres. In: Proceedings of SPE-ANTEC conference. SPE, Nashville, USA

Salim MH et al (2022) Alfa fibers, their composites and applications. Plant fibers, their composites, and applications. Elsevier, pp 51–74

Brahim SB, Cheikh RB (2007) Influence of fibre orientation and volume fraction on the tensile properties of unidirectional Alfa-polyester composite. Compos Sci Technol 67(1):140–147

Abdallah Y, Ben Cheikh R, Paiva M (2019) Could alfa fibers substitute glass fibers in composite materials? Int Polym Process 34(1):133–142

Bledzki A, Gassan J (1999) Composites reinforced with cellulose based fibres. Prog Polym Sci 24(2):221–274

Chafra M, Chevalier Y (2005) Directional damage and failure of composite materials under cyclic loading. Int J Veh Des 39(1–2):163–172

Zrida M, Laurent H, Rio G (2016) Numerical study of mechanical behaviour of a polypropylene reinforced with Alfa fibres. J Compos Mater 50(21):2883–2893

Arrakhiz F et al (2012) Mechanical and thermal properties of polypropylene reinforced with Alfa fiber under different chemical treatment. Mater Des 35:318–322

Rajesh M, Kandasamy J, Mallikarjuna Reddy D, Mugeshkannan V, Kar VR (2021) Experimental Characterization for Natural Fiber and Hybrid Composites. In: Jawaid M, Hamdan A, Hameed Sultan MT (eds) Structural Health Monitoring System for Synthetic, Hybrid and Natural Fiber Composites. Composites Science and Technology. Springer, Singapore. https://doi.org/10.1007/978-981-15-8840-2_6

Benyamina B et al (2021) Study and modeling of thermomechanical properties of jute and Alfa fiber-reinforced polymer matrix hybrid biocomposite materials. Polym Bull 78:1771–1795

El-Abbassi FE et al (2015) Effect of alkali treatment on Alfa fibre as reinforcement for polypropylene based eco-composites: Mechanical behaviour and water ageing. Compos Struct 133:451–457

Chegdani F, Mezghani S, El Mansori M (2016) On the multiscale tribological signatures of the tool helix angle in profile milling of woven flax fiber composites. Tribol Int 100:132–140

Chegdani F et al (2020) Effect of flax fiber orientation on machining behavior and surface finish of natural fiber reinforced polymer composites. J Manuf Process 54:337–346

Kumaran ST et al (2017) Prediction of surface roughness in abrasive water jet machining of CFRP composites using regression analysis. J Alloy Compd 724:1037–1045

John R et al (2021) Effects of machining parameters on surface quality of composites reinforced with natural fibers. Mater Manuf Processes 36(1):73–83

Vinayagamoorthy R, Rajeswari N (2012) Analysis of cutting forces during milling of natural fibered composites using fuzzy logic. Int J Compos Mater Manuf 2(3):15–21

Babu GD, Babu KS, Gowd BUM (2013) Effect of machining parameters on milled natural fiber-reinforced plastic composites. J Adv Mech Eng 1(1):1–12

bin Harun A et al (2015) Study the effect of milling parameters on surface roughness during milling kenaf fibre reinforced plastic. Adv Environ Biol 9(13):46–53

Benyettou R, Amroune S, Slamani M, Kiliç A (2023) Investigation of machinability of biocomposites: modeling and ANN optimization. Academic J Manuf Eng 21(1):97–104

Tran DS et al (2020) Effects of reinforcements and cutting parameters on machinability of polypropylene-based biocomposite reinforced with biocarbon particles and chopped miscanthus fibers. Int J Adv Manuf Technol 110:3423–3444

Tran DS, Songmene V, Ngo AD (2021) Regression and ANFIS-based models for predicting of surface roughness and thrust force during drilling of biocomposites. Neural Comput Appl 33:11721–11738

Belaadi A et al (2022) Drilling performance prediction of HDPE/Washingtonia fiber biocomposite using RSM, ANN, and GA optimization. Int J Adv Manuf Technol 123(5–6):1543–1564

Nouioua M et al (2022) Evaluation of: MOSSA, MOALO, MOVO and MOGWO algorithms in green machining to enhance the turning performances of X210Cr12 steel. Int J Adv Manuf Technol 120(3–4):2135–2150

Benyahia A, Merrouche A, Rokbi M, Kouadri Z (2013) Study the effect of alkali treatment of natural fibers on the mechanical behavior of the composite unsaturated Polyester-fiber Alfa. Composites 2(3):69–73

Laouissi A et al (2021) Machinability study and ANN-MOALO-based multi-response optimization during Eco-Friendly machining of EN-GJL-250 cast iron. Int J Adv Manuf Technol 117(3–4):1179–1192

Laouissi A et al (2019) Investigation, modeling, and optimization of cutting parameters in turning of gray cast iron using coated and uncoated silicon nitride ceramic tools. Based on ANN, RSM, and GA optimization. Int J Adv Manuf Technol 101(1–4):523–548

Muoi PQ et al (2016) Descent gradient methods for nonsmooth minimization problems in ill-posed problems. J Comput Appl Math 298:105–122

Senov A, Granichin O (2017) Projective approximation based gradient descent modification. IFAC-PapersOnLine 50(1):3899–3904

Singh BK, Verma K, Thoke A (2015) Adaptive gradient descent backpropagation for classification of breast tumors in ultrasound imaging. Procedia Comput Sci 46:1601–1609

Møller MF (1993) A scaled conjugate gradient algorithm for fast supervised learning. Neural Netw 6(4):525–533

Moré JJ (1978) The Levenberg-Marquardt algorithm: implementation and theory. In: Watson GA (eds) Numerical Analysis. Lecture Notes in Mathematics, vol 630. Springer, Berlin, Heidelberg. https://doi.org/10.1007/BFb0067700

Sun Z et al (2017) A Bayesian regularized artificial neural network for adaptive optics forecasting. Opt Commun 382:519–527

Heydecker BG, Wu J (2001) Identification of sites for road accident remedial work by Bayesian statistical methods: an example of uncertain inference. Adv Eng Softw 32(10–11):859–869

Laouissi A et al (2022) Heat treatment process study and ANN-ga based multi-response optimization of C45 steel mechanical properties. Met Mater Int 28(12):3087–3105

Funding

This work was funded by the Ministry of Higher Education and Scientific Research of Algeria (MESRS) (grant # PRFU Project-N A11N01UN280120220003).

Author information

Authors and Affiliations

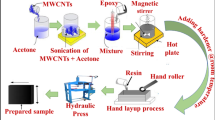

Contributions

The paper was collaboratively authored by a team of individuals, each making unique contributions. MG conducted the literature study, experiments, and data analysis and also wrote the paper. MS acted as the project supervisor, providing the research idea, technical guidance, and ongoing support. He also participated in data analysis and took responsibility for finalizing the article. AL contributed to the modeling approach, while MA conducted the experiments. MR focused on the elaboration of composite materials. J-FC played a key role in the discussions and significantly contributed to the final draft of the article. All authors carefully reviewed and approved the final manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

All authors contribute and participate in the work carried out in this paper.

Consent for publication

The authors of this paper agree to publish this work in the International Journal of Advanced Manufacturing Technology.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Grine, M., Slamani, M., Laouissi, A. et al. Enhanced investigations and modeling of surface roughness of epoxy/Alfa fiber biocomposites using optimized neural network architecture with genetic algorithms. Int J Adv Manuf Technol 130, 3115–3132 (2024). https://doi.org/10.1007/s00170-023-12866-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12866-0