Abstract

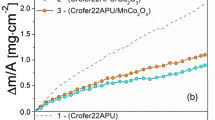

Equipment failure brought on by corrosion is one of the biggest issues the chemical and petrochemical industry are challenged with. Coating is a useful strategy to address this problem on mild steel, and the superhydrophobic coating produced by the electroplating process is particularly noteworthy. Zinc bars serve as the anode, mild steel substrates as the cathode, and a sulphate bath solution as the electrolyte in the electrodeposition coating procedure. With the aid of a DC rectifier, the coating is applied to each sample for 15 min at a voltage range of 1.4–1.5 V and an average current density of 0.2816–0.353 A/cm2. Using a magnetic stirrer and a temperature of 40 °C, the procedure is carried out. Investigating the electrochemical and microstructural characteristics of Zn-TiO2-starch coatings electrodeposited on mild steel substrates was the study’s main goal. Each coated sample served as the working electrode during the electrochemical corrosion investigation, while graphite served as the counter electrode and KCl solution as the reference electrode. 3.65% NaCl solution was the electrolytic solution that was employed. The unaltered Zn-TiO2 (control sample) was found to corrode at a rate of 0.00067197 mm/year. The corrosion rates of Zn-TiO2-starch coatings, on the other hand, ranged from 0.00041902 to 0.0002418 mm/year depending on the degree of starch modification. These findings suggest that the highly modified starch coatings provide increased corrosion resistance. The XRD pattern displayed sharp peaks corresponding to Al(ZnSO4) and Fe(Mn,Ti) crystallites on the TiO2 samples, with high diffracting intensity exceeding 2000 c.p.a., suggesting the presence of the most stable phase in those coatings. Microstructural imaging through SEM/EDS revealed a higher dispersion of starch granules in the sample with 4.5 g starch concentration than in the sample with 1.5 g starch concentration.

Similar content being viewed by others

Data availability

Not applicable.

References

Owunna IB, Ikpe AE (2022) Hardness characteristics of AISI 1020 low carbon steel Weldment produced by Tungsten Inert Gas Welding. Nigerian Journal of Engineering 29(1):36–36

Kutz, M. (2018). Handbook of environmental degradation of materials. William Andrew

Palanisamy G (2019) Corrosion inhibitors. Corrosion inhibitors, 24

Cao M, Guo D, Yu C, Li K, Liu M, Jiang L (2016) Water-repellent properties of superhydrophobic and lubricant-infused “slippery” surfaces: a brief study on the functions and applications. ACS Appl Mater Interfaces 8(6):3615–3623

Chester AM, Castillo‐Blas C, Wondraczek L, Keen DA, Bennett TD (2022) Materials Formed by Combining Inorganic Glasses and Metal‐Organic Frameworks. Chemistry–A European Journal 28(38):e202200345

Ates M, Eker AA, Eker B (2017) Carbon nanotube-based nanocomposites and their applications. J Adhes Sci Technol 31(18):1977–1997

Ma M, Li H, Xiong Y, Dong F (2021) Rational design, synthesis, and application of silica/graphene-based nanocomposite: a review. Mater Des 198:109367

Okonkwoa EG, Aigbodiona VS, Akinlabib ET, Daniel-Mkpumea CC (2020) Starch-based composites and their applications. Adv Appl Polysaccharides Compos 73:198

Khodair ZT, Khadom AA, Jasim HA (2019) Corrosion protection of mild steel in different aqueous media via epoxy/nanomaterial coating: preparation, characterization and mathematical views. J Market Res 8(1):424–435

Akinfenwa OD, Fayomi OS, Atiba JO, Anyaegbuna BE (2023) Chemical and microstructural investigation of starch modified zinc oxide paired as a composite superhydrophobic coating for mild steel protection. Chemical Papers 1–9

Jayakrishnan DS (2012) Electrodeposition: the versatile technique for nanomaterials. In Corrosion protection and control using nanomaterials (pp. 86–125). Woodhead Publishing

Kumar V, Balasubramanian K (2016) Progress update on failure mechanisms of advanced thermal barrier coatings: a review. Prog Org Coat 90:54–82

Visakh PM, Markovic G, and Pasquini D (2017) Recent developments in polymer, macro micro and nano blends. Recent Developments in Polymer Macro, Micro and Nano Blends; Elsevier: Amsterdam, The Netherlands

Arunadevi N, Kirubavathy SJ (2022) Metal oxides: Advanced inorganic materials. Inorganic Anticorrosive Materials 21–54

Ma CY, Zhao DQ, Xia FF, Xia H, Williams T, Xing HY (2020) Ultrasonic-assisted electrodeposition of Ni-Al2O3 nanocomposites at various ultrasonic powers. Ceram Int 46(5):6115–6123

Joseph OO, Afolalu AS, Abioye AA, Agbo SE, Olatunde SF, Omotehinwa OS (2021) Effect of TiC addition on the mechanical properties and microstructure of Al-Si alloy. Mater Today: Proc 38:784–788

Dutta A, Saha SK, Adhikari U, Banerjee P, Sukul D (2017) Effect of substitution on corrosion inhibition properties of 2-(substituted phenyl) benzimidazole derivatives on mild steel in 1 M HCl solution: a combined experimental and theoretical approach. Corros Sci 123:256–266

Lgaz H, Masroor S, Chafiq M, Damej M, Brahmia A, Salghi R, ... and Chung IM (2020) Evaluation of 2-mercaptobenzimidazole derivatives as corrosion inhibitors for mild steel in hydrochloric acid. Metals 10(3):357

Akpan BJ, Akande IG, Fayomi OSI, Oluwasegun KM (2022) Investigation of hardness, microstructure and anti-corrosion properties of Zn-ZnO composite coating doped unripe plantain peel particles. Case Stud Chem Environ Eng 5:100187

Wang L, Yang J, Zhu Y, Li Z, Sheng T, Hu YM, Yang DQ (2016) A study of the mechanical and chemical durability of ultra-ever dry superhydrophobic coating on low carbon steel surface. Colloids Surf A 497:16–27

Abd El-Rahman M, Mohamed LA, Said NM (2021) Effect of high gamma irradiation doses on structure and morphology properties for epoxy resins. Optik 226:165674

Author information

Authors and Affiliations

Contributions

D.O.A.: Writing of manuscript and figures.

O.S.I.F.: Research supervision.

J.O.A.: Writing of manuscript and tables.

B.E.A.: Writing of manuscript .

Corresponding author

Ethics declarations

Ethical approval

Not applicable to this paper.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Akinfenwa, O.D., Fayomi, O.S.I., Atiba, J.O. et al. Development of starch-modified titanium oxide paired with zinc powder using the electrodeposition technique as a composite superhydrophobic coating for mild steel. Int J Adv Manuf Technol 130, 2847–2854 (2024). https://doi.org/10.1007/s00170-023-12852-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12852-6