Abstract

Impellers must have no defects to endure vibration and centrifugal force. The shell for producing the impeller is located at tilt and the runner/riser system is optimized to obtain good quality casting and increase the casting yield. Sprue is adopted as riser to increase casting yield and ProCAST is employed to analyze solidification behavior of molten metal according to dimensions of the riser and gate. Although the diameter of riser was decreased from 133 to 66 mm through the simulation, no shrinkage defect was occurred in the castings due to the proper size and location of the runner/riser system. The occurring of the gas and non-metal inclusion defects was evaluated in castings by tilting the shell at 0°, 5°, 10°, 15° and 20°. The ultrasonic detecting results show that the proper design of the runner/riser systems and mold tiling eliminated the casting defects such as shrinkage, gas and non-metal inclusion. In addition, the casting yield was increased from 41.5 to 65.2%.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within this article.

Code availability

The code that support the findings of this study are available from the corresponding author [Yu-Chol Kim], upon a reasonable request.

References

Khan Muhammad AA, Sheikh Anwar K, Muhammad A (2020) Mold design and casting of an impeller using MAGMASoft. Int J Mech Eng Rob Res 9(12):1579–1583

Adiaconitei A, Vintila IS, Mihalache R, Paraschiv A, Frigioescu TF, Popa IF, Pambaguian L (2021) Manufacturing of closed impeller for mechanically pump fluid loop systems using selective laser melting additive manufacturing technology. Materials. https://www.mdpi.com/journal/materials. Accessed 9 Oct 2021

Yingjie Y, Xingmao Y (2013) The casting process optimization of the impellor of 65KZL slurry pump. Appl Mech Mater 268–270:518–521

Smirnov VV, Barzali VV, Khairullina AM, Ganeev AA (2014) Aspects of modelling the centrifugal casting of intermetallic titanium alloys in the ProCAST software. Metallurgist 57(3):1073–1075

Abdullin AD (2013) Computer modelling of a large casting in the software package ProCAST. Metallurgist 56(1):721–726

Abdullin AD (2013) Detecting microporocity defects in steel castings by computer modelling of the casting operation in ProCAST. Metallurgist 57(7):167–171

Erdakov IN, Karpinskii AV, Novokreshchenov VV (2014) Analysis of pore formation and impeded shrinkage of an alloy in the system ProCAST. Metallurgist 58(7):243–249

Kang MD, Gao HY, Wang J, Ling LSB, Sun BD (2013) Prediction of microporosity in complex thin-wall castings with the dimensionless Niyama criterion. Materials 6:1789–1802

Li JL, Chen RS, Ma YQ, Ke W (2014) Characterization and prediction of microporosity defect in sand cast WE54 alloy castings. J Mater Sci Technol 30(10):991–997

Hojjat MS, Christoph B (2018) Effect of pouring conditions and gating system design on air entrainment during mold filling. Int J Met Cast. https://doi.org/10.1007/s40962-018-0272-x

Alireza M, Azim S, Sedigh NAM, Naser H, Mostafa MS (2017) Gating system design and simulation of gray iron casting to eliminate oxide layers caused by turbulence. Int J MetalCast 11(2):328–339

Ignaszak Z (2017) Discussion on usability of the Niyama criterion for porosity predicting in cast iron castings. Arch Foundry Eng 17(3):196–204

Thammachot N, Dulyapraphant P, Bohez ELJ (2013) Optimal gating system design for investment casting of sterling silver by computer-assisted simulation. Int J Adv Manuf Technol 67:797–810

Zhang XP, Xiong SM, Xu QY (2006) Numerical methods to improve the computational efficiency of solidification simulation for the investment casting process. J Mater Proc Technol 173:70–74

Huang PH, Lin CJ (2015) Computer-aided modeling and experimental verification of optimal gating system design for investment casting of precision rotor. Int J Adv Manuf Technol 79:997–1006

Huang PH, Huang WJ (2018) Preventing shrinkage defects in investment casting of SUS310 stainless steel feather keys. Earth Environ Sci. https://doi.org/10.1088/1755-1315/186/2/012001

Sabau AS (2006) Alloy shrinkage factors for the investment casting process. Metall Mater Trans B 37(2):131–140

Xu MZ, Lekakh SN, Richards VL (2016) Thermal property database for investment casting shells. Int J MetalCast 10(3):329–337

Huang PH, Kuo JK, Fang TH, Wu WR (2018) Numerical simulation and design of casting system for stainless steel exhaust manifold. MATEC Web Conf. https://doi.org/10.1051/matecconf/201818500008

Sun F, Fang Y, Zhou JX, Hu J (2014) Optimal design with good quality and high yield of exhaust manifold investment casting. Int J Cast Met Res 27(4):207–212

Leushin IO, Ul’yanov VA, Leushina LI (2013) Predicting gas defect formation on changing the investment casting technology. Steel Transl 43(11):681–683

Tao P, Shao H, Jib ZJ, Nan H, Xua QY (2018) Numerical simulation for the investment casting process of a large-size titanium alloy thin-wall casting. Prog Nat Sci: Mater Int. https://doi.org/10.1016/j.pnsc.2018.06.005

Kuo JK, Huang PH, Lai HY, Chen JR (2017) Optimal gating system design for investment casting of 17–4PH stainless steel enclosed impeller by numerical simulation and experimental verification. Int J Adv Manuf Technol 92:1093–1103

Huang PH, Guo MJ (2015) A study on the investment casting of 17–4PH stainless steel helical impeller of centrifugal pump. Mater Res Innov 19(S9):77–81

Zhang Y, Li XY, He LC, Ma CL, Liu XY, Mao YH (2019) Research for process on investment casting of impeller based on 3D printing. ICEEMS. https://doi.org/10.1088/1755-1315/332/4/042047

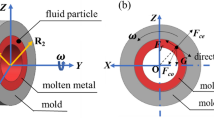

Wang H, Djambazov G, Pericleous KA, Harding RA, Wickins M (2011) Modelling the dynamics of the tilt-casting process and the effect of the mold design on the casting quality. Comput Fluids 42:92–101

Wang H, Djambazov G, Pericleous K, Harding RA, Wickins M (2012) Numerical modelling of tilt casting process for γ-TiAl alloys. Int J Cast Met Res 25(2):65–75

Birsan G, Ashtari P, Shankar S (2011) Valid mold and process design to cast tensile and fatigue test bars in tilt pour casting process. Int J Cast Met Res 24(6):378–384

Kilinc E, Akbalik S, Birol Y (2018) Optimization of the strontium modification process in gravity permanent mold tilt cast AlSi6Cu4 cylinder heads. Int J Metalcast 12(2):266–274

Cox M, Harding RA (2007) Influence of tilt filling on Weibull modulus of 2L99 aluminium investment castings. Mater Sci Technol 23(2):214–224

Hamzaha E, Dody P, Ghazali MZM (2002) Effect of mold tilt angle on the mechanical properties of as-cast aluminum alloy. Mater Des 23:189–194

Ransing RS, Savino S, Lewis RW (2005) Numerical optimisation of tilt casting process. Int J Cast Met Res 18(2):109–118

ProCast 2016 User’s Guide, ESI group. www.esi-group.com

Acknowledgements

The authors would like to express their gratitude to the editors, the authors of the references and the reviewers for their helpful suggestions for improvement and publication of this paper.

Funding

This research work was not funded.

Author information

Authors and Affiliations

Contributions

Yu Chol Kim presented the idea to enhance the quality and casting yield by optimizing runner/riser system and tilting the shell mold, and established the optimal casting process plan for the investment casting of centrifugal pump impeller.

Nong I Paek determined the process parameters for investment casting and the properties of thermo-physical properties of GX12Cr12 stainless steel used for the simulation of impeller, and tested the impeller castings.

Bok Gyu Ri calculated the gating system and ventilator to ensure the stable flow, and determined the size of riser to feed the shrinkage of impeller casting sufficiently for investment casting.

Rim Hyok O simulated the flow of molten metal in the shell mold and predicted the shrinkage formation probability by using ProCAST software to optimize the runner/riser system, and determined the mold tilt angle for the investment casting of pump impeller.

Corresponding author

Ethics declarations

Ethics declarations

The authors approve to observe the ethics standard of this journal.

Conflict of interest

The authors declare that they have no conflict of interest.

Open access

No open access.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kim, YC., Paek, NI., Ri, BG. et al. Improvement of quality and yield for investment casting of centrifugal pump impeller by tilting mold and optimizing runner/riser system. Int J Adv Manuf Technol 130, 2369–2379 (2024). https://doi.org/10.1007/s00170-023-12839-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12839-3