Abstract

Real-time chatter detection is crucial for avoiding damage to machine tools and workpieces. Time–frequency analysis methods have been extensively adopted in the feature extraction of chatter detection, especially the variational mode decomposition (VMD) has a solid theoretical basis and outstanding decomposition performance. Nevertheless, the performance of VMD is highly dependent on the decomposition parameters (number of modes and penalty factor). In this article, a novel real-time chatter detection method based on fast recursive variational mode decomposition (FRVMD) is proposed. Unlike the optimization algorithm-based VMD, which is time-consuming, the proposed FRVMD extracts the modes one by one in a recursive framework and adaptively adjusts the penalty factor according to the iterative information. FRVMD exhibits higher computational efficiency and better decomposition performance, which is suitable for real-time chatter detection. After the adaptive extraction of chatter-sensitive component by FRVMD, two chatter indicators, namely energy ratio (ER) and dispersion entropy (DE), are introduced to characterize the machining state. Finally, a chatter identification model is established by utilizing the support vector machine (SVM). The simulation and experimental findings verify the effectiveness of the proposed method.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

Quintana G, Ciurana J (2011) Chatter in machining processes: a review. Int J Mach Tools Manuf 51:363–376. https://doi.org/10.1016/j.ijmachtools.2011.01.001

Ma H, Guo J, Wu J, Xiong Z, Lee K-M (2020) An active control method for chatter suppression in thin plate turning. IEEE Trans Ind Inf 16:1742–1753. https://doi.org/10.1109/tii.2019.2924829

Sun YX, Xiong ZH (2016) An optimal weighted wavelet packet entropy method with application to real-time chatter detection. IEEE/ASME Trans Mechatron 21:2004–2014. https://doi.org/10.1109/Tmech.2016.2547481

Shi F, Cao HR, Zhang XW, Chen XF (2020) A reinforced k-nearest neighbors method with application to chatter identification in high-speed milling. IEEE Trans Ind Electron 67:10844–10855. https://doi.org/10.1109/TIE.2019.2962465

Cao HR, Zhou K, Chen XF (2015) Chatter identification in end milling process based on EEMD and nonlinear dimensionless indicators. Int J Mach Tools Manuf 92:52–59. https://doi.org/10.1016/j.ijmachtools.2015.03.002

Cao H, Lei Y, He Z (2013) Chatter identification in end milling process using wavelet packets and Hilbert-Huang transform. Int J Mach Tools Manuf 69:11–19. https://doi.org/10.1016/j.ijmachtools.2013.02.007

Lu YZ, Ma HF, Sun YX, Liu ZQ, Song QH (2022) An early chatter detection method based on multivariate variational mode decomposition and chatter correlation factor. IEEE/ASME Trans Mechatron 27:5724–5735. https://doi.org/10.1109/TMECH.2022.3188680

Zhang Z, Li HG, Meng G, Tu XT, Cheng CM (2016) Chatter detection in milling process based on the energy entropy of VMD and WPD. Int J Mach Tools Manuf 108:106–112. https://doi.org/10.1016/j.ijmachtools.2016.06.002

Liu CF, Zhu LD, Ni CB (2018) Chatter detection in milling process based on VMD and energy entropy. Mech Syst Signal Process 105:169–182. https://doi.org/10.1016/j.ymssp.2017.11.046

Sun Y, He J, Ma H, Yang X, Xiong Z, Zhu X, Wang Y (2023) Online chatter detection considering beat effect based on inception and LSTM neural networks. Mech Syst Signal Process 184:109723. https://doi.org/10.1016/j.ymssp.2022.109723

Huda F, Darman D, Rusli M (2020) Chatter detection in turning process using sound signal and simple microphone. IOP Conf Ser Mater Sci Eng 830:042027. https://doi.org/10.1088/1757-899X/830/4/042027

Hao Y, Zhu L, Yan B, Qin S, Cui D, Lu H (2022) Milling chatter detection with WPD and power entropy for Ti-6Al-4V thin-walled parts based on multi-source signals fusion. Mech Syst Signal Process 177:109225. https://doi.org/10.1016/j.ymssp.2022.109225

Wang RQ, Song QH, Liu ZQ, Ma HF, Liu ZJ (2022) Multi-condition identification in milling Ti-6Al-4V thin-walled parts based on sensor fusion. Mech Syst Signal Process 164:109225. https://doi.org/10.1016/j.ymssp.2021.108264

Aslan D, Altintas Y (2018) On-line chatter detection in milling using drive motor current commands extracted from CNC. Int J Mach Tools Manuf 132:64–80. https://doi.org/10.1016/j.ijmachtools.2018.04.007

Vashisht RK, Peng QJ (2021) Online chatter detection for milling operations using LSTM neural networks assisted by motor current signals of ball screw drives. J Manuf Sci Eng 143:011008. https://doi.org/10.1016/j.ymssp.2022.109723

Zheng X, Arrazola P, Perez R, Echebarria D, Kiritsis D, Aristimuño P, Sáez-de-Buruaga M (2023) Exploring the effectiveness of using internal CNC system signals for chatter detection in milling process. Mech Syst Signal Process 185:109812. https://doi.org/10.1016/j.ymssp.2022.109812

Wang WK, Wan M, Zhang WH, Yang Y (2022) Chatter detection methods in the machining processes: A review. J Manuf Process 77:240–259. https://doi.org/10.1016/j.jmapro.2022.03.018

Zhu L, Liu C (2020) Recent progress of chatter prediction, detection and suppression in milling. Mech Syst Signal Process 143:106840. https://doi.org/10.1016/j.ymssp.2020.106840

Yesilli MC, Khasawneh FA, Otto A (2020) On transfer learning for chatter detection in turning using wavelet packet transform and ensemble empirical mode decomposition. CIRP J Manuf Sci Technol 28:118–135. https://doi.org/10.1016/j.cirpj.2019.11.003

Ji YJ, Wang XB, Liu ZB, Wang HJ, Jiao L, Wang DQ, Leng SY (2018) Early milling chatter identification by improved empirical mode decomposition and multi-indicator synthetic evaluation. J Sound Vib 433:138–159. https://doi.org/10.1016/j.jsv.2018.07.019

Yang K, Wang GF, Dong Y, Zhang QB, Sang LL (2019) Early chatter identification based on an optimized variational mode decomposition. Mech Syst Signal Process 115:238–254. https://doi.org/10.1016/j.ymssp.2018.05.052

Wang Y, Zhang M, Tang X, Peng F, Yan R (2021) A kMap optimized VMD-SVM model for milling chatter detection with an industrial robot. J Intell Manuf 33:1483–1502. https://doi.org/10.1007/s10845-021-01736-9

Liu XL, Wang ZX, Li MY, Yue CX, Liang SY, Wang LH (2021) Feature extraction of milling chatter based on optimized variational mode decomposition and multi-scale permutation entropy. Int J Adv Manuf Technol 114:2849–2862. https://doi.org/10.1007/s00170-021-07027-0

Liu T, Deng Z, Luo C, Li Z, Lv L, Zhuo R (2022) Chatter detection in camshaft high-speed grinding process based on VMD parametric optimization. Measurement 187:110133. https://doi.org/10.1016/j.measurement.2021.110133

Mou W, Zhu S, Jiang Z, Song G (2022) Vibration signal-based chatter identification for milling of thin-walled structure. Chinese J Aeronaut 35:204–214. https://doi.org/10.1016/j.cja.2020.09.029

Chen QZ, Zhang CR, Hu TL, Zhou Y, Ni HP, Wang T (2021) Online chatter detection in robotic machining based on adaptive variational mode decomposition. Int J Adv Manuf Technol 117:555–577. https://doi.org/10.1007/s00170-021-07769-x

Wang P, Bai Q, Cheng K, Zhang Y, Zhao L, Ding H (2023) Investigation on an in-process chatter detection strategy for micro-milling titanium alloy thin-walled parts and its implementation perspectives. Mech Syst Signal Process 183:109617. https://doi.org/10.1016/j.ymssp.2022.109617

Huang NE, Shen Z, Long SR, Wu MLC, Shih HH, Zheng QN, Yen NC, Tung CC, Liu HH (1998) The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc Roy Soc London A: Math Phys Eng Sci 454:903–995. https://doi.org/10.1098/rspa.1998.0193

Dragomiretskiy K, Zosso D (2014) Variational mode decomposition. IEEE Trans Signal Process 62:531–544. https://doi.org/10.1109/TSP.2013.2288675

Zhang M, Jiang Z, Feng K (2017) Research on variational mode decomposition in rolling bearings fault diagnosis of the multistage centrifugal pump. Mech Syst Signal Process 93:460–493. https://doi.org/10.1016/j.ymssp.2017.02.013

Tang G, Wu Y, Li C, Wong PK, Xiao Z, An X (2020) A novel wind speed interval prediction based on error prediction method. IEEE Trans Ind Inf 16:6806–6815. https://doi.org/10.1109/TII.2020.2973413

Zhang Q, Tu XT, Li FC, Hu Y (2020) An effective chatter detection method in milling process using morphological empirical wavelet transform. IEEE Trans Instrum Meas 69:5546–5555. https://doi.org/10.1109/TIM.2019.2958470

Fu Y, Zhang Y, Zhou H, Li D, Liu H, Qiao H, Wang X (2016) Timely online chatter detection in end milling process. Mech Syst Signal Process 75:668–688. https://doi.org/10.1016/j.ymssp.2016.01.003

Yao ZH, Mei DQ, Chen ZC (2010) On-line chatter detection and identification based on wavelet and support vector machine. J Mater Process Technol 210:713–719. https://doi.org/10.1016/j.jmatprotec.2009.11.007

Chen D, Zhang XJ, Zhao H, Ding H (2021) Development of a novel online chatter monitoring system for flexible milling process. Mech Syst Signal Process 159:107799. https://doi.org/10.1016/j.ymssp.2021.107799

Pérez-Canales D, Álvarez-Ramírez J, Jáuregui-Correa JC, Vela-Martínez L, Herrera-Ruiz G (2011) Identification of dynamic instabilities in machining process using the approximate entropy method. Int J Mach Tools Manuf 51:556–564. https://doi.org/10.1016/j.ijmachtools.2011.02.004

Nair U, Krishna BM, Namboothiri VNN, Nampoori VPN (2009) Permutation entropy based real-time chatter detection using audio signal in turning process. Int J Adv Manuf Technol 46:61–68. https://doi.org/10.1007/s00170-009-2075-y

Li K, He SP, Li B, Liu HQ, Mao XY, Shi CM (2020) A novel online chatter detection method in milling process based on multiscale entropy and gradient tree boosting. Mech Syst Signal Process 135:106385. https://doi.org/10.1016/j.ymssp.2019.106385

Rostaghi M, Ashory MR, Azami H (2019) Application of dispersion entropy to status characterization of rotary machines. J Sound Vib 438:291–308. https://doi.org/10.1016/j.jsv.2018.08.025

Rostaghi M, Azami H (2016) Dispersion entropy: a measure for time-series analysis. IEEE Signal Process Lett 23:610–614. https://doi.org/10.1109/LSP.2016.2542881

Wang H, Sun W, He L, Zhou J (2022) Intelligent fault diagnosis method for gear transmission systems based on improved multi-scale reverse dispersion entropy and swarm decomposition. IEEE Trans Instrum Meas 71:1–13. https://doi.org/10.1109/TIM.2021.3115207

Chen SQ, Yang Y, Peng ZK, Dong XJ, Zhang WM, Meng G (2019) Adaptive chirp mode pursuit: Algorithm and applications. Mech Syst Signal Process 116:566–584. https://doi.org/10.1016/j.ymssp.2018.06.052

Funding

This work was supported by the Natural Science Foundation of China under Grant 52375450, Natural Science Foundation of Shandong Province under Grant ZR2022ZD06 and Shandong Provincial Key Research and Development Program (Major Scientific and Technological Innovation Project) under grant 2020CXGC010204.

Author information

Authors and Affiliations

Contributions

Yezhong Lu was responsible for the design of the algorithm and the analysis and validation of the experimental data. Haifeng Ma was responsible for conducting all the experiments and collecting the data. Yuxin Sun, Zhen Zhang, and Liping Jiang helped with data analysis and visualization. Qinghua Song and Zhanqiang Liu were responsible for the discussion of ideas and methods, review of the manuscript, and financial support.

Corresponding author

Ethics declarations

Ethical approval

The authors declare that there are no ethical implications of this study.

Consent to participate

All authors agree to submit the manuscript to IJAMT.

Consent to publish

All authors agree to publish this study. There are no potential copyright/plagiarism issues involved in this study.

Competing interests

All authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

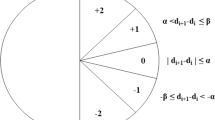

Please see Fig. 16.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lu, Y., Ma, H., Zhang, Z. et al. Real-time chatter detection based on fast recursive variational mode decomposition. Int J Adv Manuf Technol 130, 3275–3289 (2024). https://doi.org/10.1007/s00170-023-12832-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12832-w