Abstract

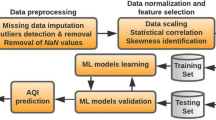

This paper presents an investigation into the optimization of petroleum coke mill or petcoke mill processes, to improve efficiency and reduce waste in the heavy industry within the cement plant where our study is conducted. Our mission was to create a robust algorithm that could properly anticipate the mill’s performance and improve its operations. To accomplish this, we started by performing a comprehensive data analysis. Next, we built numerous regression models, and then assessed the effectiveness of each model using four crucial metrics. The suggested model is a multi-regression XGBoost (eXtreme gradient boosting) model, performing with a 90% score. Finally, the model will then be used to build an algorithm that can optimize the input values to accomplish the intended results.

Similar content being viewed by others

References

Hasanbeigi A, Price L, Lu H, Lan W (2010) Analysis of energy-efficiency opportunities for the cement industry in Shandong Province, China: a case study of 16 cement plants. Energy 35:3461–3473. https://doi.org/10.1016/j.energy.2010.04.046

Agrawal V, Panigrahi BK, Subbarao PMV (2015) Review of control and fault diagnosis methods applied to coal mills. J Process Control 32:138–153. https://doi.org/10.1016/j.jprocont.2015.04.006

Tontu M (2021) An investigation of performance characteristics and energetic efficiency of vertical roller coal mill. Int J Coal Prep Util 41:248–262. https://doi.org/10.1080/19392699.2020.1799200

Sligar J (1996) Component wear in vertical spindle mills grinding coal. Int J Miner Process 44–45:569–581. https://doi.org/10.1016/0301-7516(95)00066-6

Parejo Guzmán M, Navarrete Rubia B, Mora Peris P, Alfalla-Luque R (2022) Methodological development for the optimisation of electricity cost in cement factories: the use of artificial intelligence in process variables. Electr Eng 104:1681–1696. https://doi.org/10.1007/s00202-021-01409-z

Grudziak Ł, Magdalena Z, Lipiński M (2021) The identification method of the coal mill motor power model with the use of machine learning techniques. In: The identification method of the coal mill motor power model with the use of machine learning techniques. pp 1–9

Fatahi R, Nasiri H, Dadfar E, Chehreh Chelgani S (2022) Modeling of energy consumption factors for an industrial cement vertical roller mill by SHAP-XGBoost: a “conscious lab” approach. Sci Rep 12:7543. https://doi.org/10.1038/s41598-022-11429-9

Wang C, Liu Y, Jiang A (2022) A modeling and optimizing method for electricity current intensity of coal mills. Sci Program 2022:1–5. https://doi.org/10.1155/2022/3250896

Batta M (2019) Machine learning algorithms -a review. https://www.researchgat344717762_machine_learning_algorithms_-a_review. 9:381–386. https://doi.org/10.21275/ART20203995

Hao J, Ho TK (2019) Machine learning made easy: a review of scikit-learn package in Python programming language. J Ed Behav Stat 44:348–361. https://doi.org/10.3102/1076998619832248

Gullì A, Pal S (2017) Deep learning with Keras: implement neural networks with Keras on Theano and TensorFlow. Packt Publishing, Birmingham Mumbai

Tosi S (2009) Matplotlib for python developers: build remarkable publication quality plots the easy way. Packt Publ, Birmingham

Bisong E (2019) Building machine learning and deep learning models on Google Cloud platform: a comprehensive guide for beginners. Apress, Berkeley, CA

Chai T, Draxler RR (2014) Root mean square error (RMSE) or mean absolute error (MAE)? – Arguments against avoiding RMSE in the literature. Geosci Model Dev 7:1247–1250. https://doi.org/10.5194/gmd-7-1247-2014

Botchkarev A (2018) Performance metrics (error measures) in machine learning regression, forecasting and prognostics: properties and typology. https://doi.org/10.48550/ARXIV.1809.03006

Emmanuel T, Maupong T, Mpoeleng D et al (2021) A survey on missing data in machine learning. J Big Data 8:140. https://doi.org/10.1186/s40537-021-00516-9

Harrison M (2019) Machine learning pocket reference: working with structured data in Python, First edition. O’Reilly, Beijing ; Boston

Asst. Professor, Dept. of Computer Science, MITS School of Biotechnology, Utkal University, Bhubaneswar, India., Sahoo* K, Samal AK, et al (2019) Exploratory data analysis using Python. IJITEE 8:4727–4735. https://doi.org/10.35940/ijitee.L3591.1081219

Benchekroun MT, Zaki S, Hezzem B, Laacha H (2023) Kiln process fan vibrations prediction based on machine learning models: application to the raw mill fan. In: The 3rd International Day on Computer Science and Applied Mathematics. MDPI, p 6

Toum Benchekroun M, Zaki S, Aboussaleh M (2023) Kiln predictive modelization for performance optimization. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-023-11563-2

Benchekroun MT, Zaki S, Aboussaleh M (2023) Cement kiln safety and performance improvement based on machine learning predictive analytics. Int J Adv Manuf Technol 125:5267–5277. https://doi.org/10.1007/s00170-023-10813-7

Acknowledgements

The authors would like to thank all the stakeholders of this project and particularly the engineers and technicians of the cement plant where our research was conducted.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. Material preparation, data collection, and analysis were performed by M.T. Benchekroun, S. Zaki, M. Aboussaleh, H. Belrhiti, and F. Diassana. The first draft of the manuscript was written by M.T. Benchekroun, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Benchekroun, M.T., Zaki, S., Aboussaleh, M. et al. Development of a kiln petcoke mill predictive model based on a multi-regression XGBoost algorithm. Int J Adv Manuf Technol 130, 3373–3386 (2024). https://doi.org/10.1007/s00170-023-12689-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12689-z