Abstract

Flux-cored arc welding (FCAW) is a universal group of welding methods in terms of the scope of application and automation possibilities, the share of which in various industries in many countries is still increasing. The paper presents the results of bibliographic analyses (scientometric analysis with the use of VOSviewer, Bibliometrix and CitNetExplorer tools) of a data set of 993 publications indexed in the Web of Science database on the subject of FCAW for all types of flux-cored wires. An objective and unbiased approach to analysis resulted in a relatively neutral assessment of the state of knowledge in the field of FCAW and allowed for the identification of research directions carried out in the world, the dynamics of their changes as well as research gaps and needs. The scientometric analysis approach provided a holistic picture of the development of FCAW over the last 58 years, pointing to the geographical areas where this process has been and is most intensively researched, the agencies funding this research, the most active research teams, as well as the journals that have most often published articles on this topic. The most current research directions in relation to FCAW include underwater welding, hardfacing and cladding purposes, health and safety issues, and more general topic: properties and weldability of ferrous alloys. However, among the most urgent research needs the following topics: fatigue analysis of welded joints, environmental degradation of flux-cored wires, properties and weldability of nickel alloys, development of hybrid and combined welding procedures can be listed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Flux-cored arc welding (FCAW) is a group of arc welding processes that use a consumable, tubular (filled with a flux) electrode with continuous feeding and gas protection of welding pool [1]. In industrial practice, two main types of the processes are used: shielding gas welding (FCAW-G, 136 according to EN ISO 4063:2023 standard classification of welding processes), which is a modification of gas metal arc welding (GMAW), and self-shielded FCAW (FCAW-S, 114 according to EN ISO 4063:2023 standard classification of welding processes), similar from the metallurgical point of view to welding with covered electrodes (shielded metal arc welding—SMAW) [2, 3]. Although technically similar, both groups of processes have different application fields. Process 136 (rutile and basic cored wires) is often used to make steel and nickel alloy-welded joints as well as for surfacing to ensure corrosion-resistant properties [4, 5]. On the other hand, process 114 found two main directions of development: regeneration and cladding as well as underwater welding and cutting [6,7,8,9,10]. Separate areas of application of flux-cored wires are, for example, cases of their use as consumables for brazing, gas tungsten arc welding (GTAW), laser welding, and additive manufacturing. Cai et al. describe that with the use of Al-Si12 filler wire rotating laser welding-brazing technology was developed to fabricate sound aluminum alloy and steel joint [11]. The work [12] describes the results for a hardfacing layer made by the TIG process using flux-cored wire with pulsed current. This innovative approach allowed to increase the wear resistance of duplex steel substrate. TIG welding with the use of flux-cored wire was also the subject of research work on improving the worn properties of high-strength titanium alloy intended for the aviation industry [13]. Laser welding of titanium alloys supported by the use of a self-developed flux-cored wire was presented in the article [14]. Based on the results of the morphology and properties of welded joints, the authors concluded that such technology is suitable for high-quality welding of titanium alloy. The aim of the research presented by Pańcikiewicz [2] was to verify the possibility of producing a maraging steel part using the WAAM process with flux-cored wire. The author stated that the proposed procedure allows the production of elements with a martensitic structure and favorable properties, without welding imperfections.

The growing share of FCAW in the welded structures fabrication market results from many advantages, among which the most important are the following: high efficiency, ease of welder training (semi-automatic process), material and technological versatility, high quality of welded joints, as well as the possibility of automation and robotization [15, 16]. The few disadvantages include the need to provide protection against the wind during welding in the open air, good ventilation in closed rooms, and the need to remove slag from welds [17]. It is also necessary to ensure appropriate transport and storage conditions for flux-cored wires by the manufacturers’ requirements [18,19,20]. These features make FCAW a process that effectively displaces and replaces traditional methods: SMAW, GMAW, and SAW (submerged arc welding) in many areas of welded construction production [21, 22].

The key stage in the selection of the appropriate FCAW procedure is the selection of the appropriate consumable electrode. The wires differ in manufacturing technology—there are wires produced with a seam (rolled profile, with no continuous connection between the edges of the tape being wound) and seamless (the tape edges are joined together). Thanks to this, seamless wires are widely used in difficult conditions, with an increased risk of core moisture, while seamed wires are used due to the small thickness of the metallic sheath guaranteeing high current densities during welding [23,24,25]. In addition, seamless wires are often copper-plated, and wires with the seam usually do not have an additional layer of copper on the surface. The possibility of using a metallic sheath made of many different construction materials and the use of fluxes of various compositions and properties guarantees a wide range of applications and continuous development of the FCAW process [26,27,28].

Web of Science (WOS) is a classic bibliographic database indexing publications from literature sources verified with strict criteria for reliability and high scientific level. As one of the major bibliographic databases, it is often (next to Scopus, PubMed, and Dimensions) used e.g., by scientists, staff of libraries, and publishing houses for analyses aimed at assessing the publication situation, which facilitates decision-making related to publishing activity [29].

Software VOSviewer developed by van Eck and Waltman is an application with a free license that enables creating, visualizing, and exploring bibliometric networks [30]. VOSviewer offers preparation of three viewing modes: network visualization, network overlay (most often with a time scale), and two types of density visualization. The application can be used to create networks based on given criteria. The distances between the points reflect the strength of relations between them, and the diameter of the circle (node) indicates their number in the examined data set. CitNetExplorer, created by the same authors, can be used to supplement, and significantly extend the possibilities of interpreting the publication citation network [31]. Both applications are recommended by many scientists as excellent tools for scientometric analysis [32, 33]. Bibliometrix is an R programming statistical system package that enables advanced quantitative scientometric analyses along with the visualization of their results [34]. The use of this tool does not require knowledge of programming in R, because analyses can be performed in Biblioshiny, a web-based application [34]. Biblioshiny supports many types of analyses representing both the state of knowledge at a given time: current research landscape as well as research trends, e.g., tabular and graphical summaries of data, principal components analysis, and Sankey charts [34, 35].

Despite the growing share of the FCAW process in various industries, the systematic increase in sales of consumables and publications describing various aspects of the use of flux-cored wires in the world literature, a review article that would summarize the state of knowledge and indicate current research directions has not yet been published. According to data from WOS, six review articles have been published since 1965; however, after verifying the content of these works, it was found that two of them had an incorrectly assigned article type in WOS and in fact, they were standard research papers. At the same time, these works describe issues that only marginally touch the subject of FCAW: hot cracking of duplex steel weldments [36], health and safety during welding [37], welding of railway rails by aluminothermic welding [38], and the effectiveness of the temper bead technique [39]. This justifies conducting a bibliometric analysis of the state of the art of FCAW processes.

The review of FCAW processes was conducted based on scientometric analysis methodology [40]. This unbiased approach, devoid of the authors’ subjective view of the content of the publication, is considered the most reliable. In order to ensure an objective analysis of the state of the art, the database of publications should be universal, complete, inclusive, effective, and unprejudiced [41].

In the face of such a situation, the main objectives of this work were as follows: to conduct an objective assessment of the current state of knowledge about FCAW processes as of June 2023 and to identify gaps in research directions in terms of potential opportunities to use processes based on the use of flux-cored wires. An additional contribution of the content of this article to the scientific community may be an indication of the possibilities of potential cooperation and sources of funding for scientific work. In particular, our work answers the following research question: “What were and are the research trends, and which countries, institutions, scientists, and journals play leading roles in the analyzed field of knowledge?”.

2 Scientometric analyses

2.1 Methodology

An analysis of world literature that is not limited in time was conducted using the WOS indexing database. To obtain the widest possible collection of literature (articles from reputable journals and conference proceedings) well suited to the subject of the article, the following terms in the search engine were introduced: “flux cored arc welding,” “FCAW,” and “flux cored wire.” As a result, a collection of 1002 publications from the years 1965–2023 was obtained (as of June 16, 2023). This data set was saved and prepared for further analysis: based on the abstracts and keywords, their thematic correctness was verified so that retracted publications and corrections were removed. Since the main purpose of this work is not a substantive assessment of the content of the analyzed publications, articles in languages other than English were not removed from the collected data set, if the title, abstract, and keywords were translated into English. The distribution of languages in which the considered works were published is presented in Table 1.

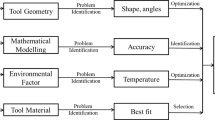

Analyses of 993 publications included in the prepared thematic collection, directly related to various applications of flux-cored wires, were carried out using the tools available in WOS, Microsoft Excel, VOSviewer 1.6.19, Biblioshiny 4.1.2, and CitNetExplorer 1.0.0 software. In the case of maps and word cloud charts, online generators from websites were also used: https://www.jasondavies.com/wordcloud/ and https://www.datawrapper.de/maps/choropleth-map. The methodological diagram showing the sequence of research works and the tools used is presented in Fig. 1. Figure 2 shows the range of analyses made in WOS, VOSviewer, Biblioshiny, and CitNetExplorer.

2.2 Publication and citation trends

Since 1965, when the first article indexed in WOS was published [42], for 40 years, the number of papers published annually did not exceed 14 (Fig. 3). A significant increase has taken place since 2005, and since then, the number of papers published annually has been steadily increasing, reaching over 60 per year in 2016–2022. Almost 79% of these publications are regular research articles, while over 19% are conference proceedings (Table 2). The low number of review papers is striking—there were only six review papers (0.60%); however, as mentioned earlier, it was found that there were only four of them. The share of works from the Data paper group is similarly noticeable—there is only one such paper [43]. It seems that this may be a severe limitation in the possibility of effective application of Data mining techniques for FCAW processes.

Table 3 presents information on the mode of access to the analyzed works. More than 73% of publications do not have an access mode, which suggests that these are works that have been published in a subscription-based model. The topic of open access modes of journals and their detailed characteristics are presented elsewhere [44, 45].

Works from this collection were cited 7522 times in 4754 publications, which gives an average number of citations: 7.58. Treemap charts showing the shares of individual countries and journals in the citation of works from the analyzed set are shown in Fig. 4a and b. Most citations come from papers written by authors from Asian countries (China, India, South Korea, Iran), North America (USA and Canada), and Europe (Poland, England, and Germany) and published in journals issued by three publishing houses: Springer Nature, MDPI, and Elsevier.

2.3 Research areas

Subject areas for FCAW processes were determined in three ways: based on keywords, according to WOS categories, and quantitative analysis of publications terms in titles and abstracts. Figure 5 shows a summary of analyses performed in VOSviewer and word cloud chart. Based on Fig. 5a, it can be concluded that the subject of FCAW processes can be grouped primarily into three main research directions: underwater welding (microstructure, droplet transfer), hardfacing and surfacing (wear phenomena), and various aspects of the performance and quality assessment of welded joints (mechanical properties, diffusible hydrogen, residual stress). The fourth and distinguishing issue is the cluster including mainly health and safety (welding fumes, manganese, nanoparticles, hexavalent chromium) and stainless steels. Relatively often, the study of the considered process is conducted in comparison with another arc welding process: SMAW, SAW (submerged arc welding), GTAW, or GMAW. This means that the FCAW process can often be considered an alternative to other arc welding methods. Thanks to such comparative studies, it is possible to expand the scope of application of this method. In terms of methodology, the frequent use of modeling with statistical methods (response surface methodology, ANOVA) is noteworthy. An identical network of connections, which, however, takes into account the topicality of the relationship data is shown in Fig. 5b. Lighter yellow indicates the latest research trends (wear, underwater welding). Similar conclusions can be drawn by analyzing the density map of keywords (Fig. 5c).

The word cloud chart is a modern tool for text analysis—graphical presentation of the frequency of words in texts, also for bibliometric purposes [46, 47]. Using this tool (Fig. 6) allowed for a clear identification of the most popular keywords. The larger the font obtained during the analysis, the more important a given word is in the examined set. They indicate thematic areas clearly related to FCAW. Since this type of chart shows the most important keywords out of hundreds, this is an indicator that the most researched subjects in the studies in the field of FCAW, instead of the name of the process, are as follows: “steel,” “microstructure,” “behavior”. At the same time, it is clear that there is no single main research trend that dominates in frequency over others. It can be assumed that the presence of each word in the word cloud chart indicates an important branch of development and research conducted in the field of FCAW.

Keywords word cloud chart (https://www.jasondavies.com/wordcloud/)

Another approach to bibliographic analysis of research areas described in publications is text mining, which is also an option in VOSviewer software. Figure 7 shows the networks of the most common terms from the titles and abstracts of 993 publications, obtained with the assumption of a minimum frequency of 25 (242 terms). After removing common words in titles and abstracts (e.g., “effect,” “this article,” “units”), the networks were created from 127 terms. The clustering algorithm divided the research areas into five clusters (Fig. 7a), in which again four are leading: underwater welding (yellow), hardfacing and surfacing (green), health and safety topics (purple), and various aspects of fabricating and assessing the quality of welded joints (blue and red)).

2.4 Journals

The total number of journals and conference proceeding titles from which articles for analysis were collected is 396. A list of leading sources of FCAW process literature (containing at least 10 articles) is presented in Table 4. The authors choose reputable journals whose aims and scope include topics in the field of welding technologies and materials science. The most significant numerical share have journals published by Springer Nature (Welding in the World, International Journal of Advanced Manufacturing Technology, Journal of Materials Engineering and Performance and Metals and Materials International, 9.37%); American Welding Society (Welding Journal, 8.66%); Associação Brasileira de Soldagem (Soldagem & Inspeção, 4.33%); Elsevier (8.56%); MDPI (Materials and Metals journals, 4.13%); and Taylor&Francis (Science and Technology of Welding and Joining, 2.12%) publishing houses. Figure 8 shows a co-citation analysis of sources of FCAW processes literature assuming at least 3 mutual citations between journals. Networks were obtained for 61 items from 2005 to 2020 grouped under automatic settings into 9 clusters (Fig. 8a and c). From Fig. 8b, there is a trend of changing the preferred source from Welding Journal, Science and Technology of Welding and Joining (purple) to Welding in the World, Journal of Manufacturing Processes (green) and MDPI: Materials and Metals (yellow). This is primarily due to the fact that the total number of articles in the Welding in the World, Journal of Manufacturing Processes and MDPI journals has increased significantly in recent years. This also means an increase in the number of articles on FCAW and a greater share of these journals in the presented analyses. An additional factor is the availability of the journal in the Open Access formula.

Every journal and book covered by Web of Science core collection is assigned to at least one of the subject categories. Figure 9 shows the share of different categories appropriate for journals publishing articles on FCAW. Since each journal can be included up to six categories, percentages of categories do not add up to 100%. For better visibility, only categories containing more than 3% of works are included in the chart. Most of the journals with FCAW articles fall into one of four categories: Metallurgy Metallurgical Engineering (43.00%), Materials Science Multidisciplinary (37.66%), Engineering Mechanical (13.19%), and Engineering Manufacturing (11.48%).

2.5 Authors

Leading authors who have published more than 10 articles on FCAW are summarized in Table 5. The most prolific authors (over 20 articles) are JC Feng, N Guo, V. Balasubramanian, and HW Lee. It should be mentioned that the first two authors cooperate closely in publishing. In Fig. 10, the network of co-authorship among the 325 out of a total of 2134 authors is illustrated. The clustering algorithm divided the authors into six groups (Fig. 10a), while based on the density map, also six clusters of authors can be distinguished, but they are differently connected (Fig. 10c). The same data over time (yellow circles indicate recent work) is shown in Fig. 10b. Clusters basically correspond to the thematic trends indicated earlier, because usually, the authors publish works on one of the mentioned topics.

Leading FCAW documents (in terms of the absolute number of citations) are presented in Table 6. The article authored by Zhang et al. [48], describing the comparison of corrosion resistance of duplex stainless steel joints made with FCAW and GTAW processes, received the most citations (97). This is also one of the articles describing the weldability of steel by comparing FCAW with another welding process. Slightly fewer citations (95) have so far been obtained by a review article on underwater welding [49]. Another paper (91 citations) deals with health and safety issues during welding [50]. A very important indicator is also the time that the paper is available already, described by citations per year. In this case, the most frequently cited work (16.17 citations per year) is still the publication by Zhang et al. [48], and the next ones are Wang et al. [51] (12.00 citations per year) and Zhang et al. [52] (11.71 citations per year). The citation networks in this set of papers are shown in Fig. 11. It is obvious that the links between these articles indicate numerous citations in subsequent publications.

CitNetExplorer analysis conducted for the entire set of publications (993 works) is shown in Fig. 12. The oldest articles from the analyzed collection were not often cited by subsequent authors of works on this subject. This is completely consistent with the data presented in Fig. 4. It is only since 1997 that chains of citations can be noticed. In order to analyze the citation of papers in more detail, the time range was narrowed down to the years: 1999–2023 (Fig. 13) and 2009–2023 (Fig. 14). The clustering of the works in CitNetExplorer software divided them into 10 groups, among which the most numerous is the blue set (underwater welding). Particularly distinguished are the clusters: brown covering articles on health and safety, and green on hardfacing and wear problems. Works from clusters marked with other colors describe various problems of weldability of materials and quality of welded joints (e.g., diffusible hydrogen issues, properties, and fatigue strength of joints).

2.6 Countries and organizations

The analysis of Table 7, showing the most effective (over 20 works in the analyzed period) of the 57 countries from which the authors of the publication on FCAW processes come, shows that the first three places are occupied by Asian countries (China, South Korea, and India), then Brazil and the USA, followed by three European countries: Russia, Ukraine, and Poland. A smaller but significant share is held by Australia, Canada, Germany, England, and Japan. A graphical representation of this situation is shown in Fig. 15a. Bibliographic coupling for 51 out of 57 countries divided into 5 clusters is shown in Fig. 15b–d. The conclusions from the visualization analysis are consistent with the data from Table 7: still significant but a decreasing share of papers from Asian countries and an increasing number of papers from smaller and less developed countries. The interest of scientists in the FCAW method is often strongly related to the needs of local industry. Developing and developed countries, where the shipbuilding, offshore, and construction industries play an important role, are particularly frequently included in the analysis. Industry interest in the FCAW could have directly resulted in research on this method, acquiring research projects and publishing numerous articles on this topic.

Bibliometric analysis of countries of FCAW processes literature: a world map (https://www.datawrapper.de/maps/choropleth-map), b country network, c country network overlay, d country density (VOSviewer)

The analysis of the organizations to which the authors are affiliated is directly related to the country analysis. As can be seen from Table 8 and Fig. 16, the most frequently mentioned in the field of FCAW as affiliations are Chinese, Ukrainian, Korean, and Indian organizations. The most productive organizations are Harbin Institute of Technology (China), Ministry of Education Science of Ukraine, National Academy of Sciences Ukraine, and Dong-A University (South Korea). Figures 16a and b also show that the publication cooperation between the institutions clearly focuses on four Asian research centers (Korean: Dong-A University and Chinese: Harbin Institute of Technology, Tianjin University, and to a lesser extent: South China University of Technology), which makes detailed analysis difficult. Figure 16c shows an example of network enlargement for the cluster represented by Dong-A University. As can be seen, this part of the network consists of several institutions from South Korea, China, Japan, and the USA.

2.7 Funding

The largest number of articles presenting the results obtained within the projects were published by scientists from China and financed from several sources (Table 9). Subsequently, the projects were financed by Russian, Brazilian, and Korean sources. The lack of Indian and American funding agencies in this group is surprising, but this may be since publications from these two countries were published earlier and in WOS grant information indexing began in 2008.

3 Summary

The intensive development of the economy and industry would not be possible without the use of advanced welding processes. It is progressing in many directions, and the most important of which are the following: development of new and improvement of traditional consumables, invention of new manufacturing processes, finding new welding procedures improving the weldability of materials and the quality of welded joints [68,69,70,71,72,73].

The paper presents the results of complementary and unbiased bibliographic analyses of literature on FCAW processes. Nine hundred ninety-three publications from around the world extracted from the Web of Science database were used for the analysis. VOSviewer, CitNetExplorer, Biblioshiny, and other bibliographic tools were used to assess the state of knowledge and research trends and provide an outlook of the future. In addition, the paper presents networks of relations between keywords, scientists, countries, journals, and institutions (universities and national funding centers). This facilitates the search for opportunities for scientific and research cooperation and sources of funding, as well as the development of an academic career in the field of research on FCAW processes.

The publishing history of FCAW processes in WOS-indexed works began in 1965 [42]. Initially, there were only a few publications per year, then their number grew, with a significant increase over the last decade. Citations of these works show a similar development trend (Fig. 3). The vast majority (almost 92%) of the papers were published as English-language articles. Portuguese, Korean, Spanish, and Chinese languages have a relatively large share (more than 1% each). Over 78% of publications are research papers, and almost 20% are proceedings papers. There is a distinct lack of review articles. Although four such articles have been published so far, their content is focused on a very limited range of issues [36,37,38,39]. Despite decades of industrial and laboratory experience with FCAW processes, only one paper has been published in a journal specializing in publishing data articles [43]. This is a serious limitation of the possibility of using statistical techniques, including data mining, to optimize production. Despite this, a significant share of research articles is based on statistical and optimization analyses (design of experiment: Taguchi method, Plackett–Burman design, regression analysis) [74,75,76,77].

The main historical development trends (analysis of keywords and text mining of titles and abstracts in VOSviewer) are arranged into four research trends: underwater welding, hardfacing, and surfacing, aspects of making and assessing the quality of welded joints as well as health and safety. In both underwater welding and hardfacing, the FCAW process is emerging and gaining popularity. Classic FCAW-G, on the other hand, has reached or even surpassed the level of competitive methods, especially GMAW, in many applications. This is probably the reason for the apparent lack of new developments in the various welding procedures. Recently, the number of publications on health and safety has also decreased [78, 79]. The authors very often choose a methodology based on comparing the process and properties of FCAW joints with other methods, e.g., SMAW, SAW, GTAW, and GMAW [80,81,82].

Only a small percentage of journals were classified in subject areas outside the group of topics representing various aspects of materials, engineering, and metallurgy. Subject areas in the field of automatic control, physics, and chemistry account for about 18% (Fig. 9). This is due to the fact that the authors most often choose journals in the field of welding technologies and materials science (Table 4).

Despite the fact that the nature of this review does not include a detailed analysis of the content of the publication, based on the results of the citation analysis in CitNetExplorer and VOSviewer, a thematic classification of groups of articles was made. The results of this analysis are consistent with thematic analyses based on word clouds (Fig. 6d) and indicate the most current trends and urgent gaps in the state of knowledge to be filled (Table 10).

Most publishing authors are affiliated with Chinese, Indian, and Korean institutions and conduct research in such research teams limited to one country. One of the certain reasons is the financing of research on the FCAW process by institutions from these countries. There is a clear lack of broader and consequent international cooperation, although there are exceptions to this rule, such as several publications published in China-Ukraine co-authorship [83, 84].

A summary of the topic trends represented by countries, journals, and author keywords in the form of a Sankey plot (three-field plot made in Biblioshiny application) is shown in Fig. 17. It shows countries’ contribution to the relevant journals and their keyword preferences. A higher number of links among factors results in wider connection lines. A detailed analysis of the links in Fig. 17 clearly indicates the current publication trends, among which the following dominate: Chinese authors (the largest group) prefer to publish in the Journal of Materials Processing and Technology, Journal of Manufacturing Processes and Materials. However, scientists from South Korea are particularly keen on Metals and Materials International and the Korean Journal of Metals and Materials. An interesting observation is that regardless of the frequency of a given keyword, their distribution among individual journals is relatively uniform.

From the analysis of citations of the considered set of publications, authors, and countries, a picture emerges of the FCAW process, which is still in development. In some countries (large and industrially advanced Asian countries, leading Western countries, Brazil, Russia, Ukraine, and Poland), the process is extremely popular [85,86,87,88,89,90,91,92,93], and in others, it has encountered barriers to wide entry into the welded construction market. Based on the results presented in this article and the experience from the market, it can be concluded that this process is particularly well adapted to the conditions of the construction industries: marine, offshore, building, heavy civil, mining, and manufacturing [94,95,96]. In the production of large-size elements and with an appropriate production volume, the advantages of this method can be fully used, and measurable benefits can be achieved in saving time, materials, and labor, which determine the reduction of the cost of manufacturing welded structures.

Despite its contribution to presenting the state of knowledge about the FCAW process, the work has some limitations. The authors of this work have made every effort to ensure that the presented analysis results are as reliable and credible as possible. The results presented in this article have limitations resulting from several assumptions and other factors, including the following: from established search terms in the Web of Science database, limited scope of indexing of journals in the database, publishing errors when entering bibliographic data into the database. For these reasons, the presented findings may not represent all publications on FCAW. This is caused primarily by great difficulties in creating bibliometric data sets from various databases [34]. This provides a field for additional interpretation of the results of the presented analyses, and the mentioned limitations may constitute the basis for further work on the methodology and scope of bibliographic analyses. Nevertheless, the authors believe that given the study’s limitations, it is questionable whether the presented findings and conclusions would be significantly modified.

References

Tippayasam C, Taengwa C, Palomas J, Siripongsakul T, Thaweechai T, Kaewvilai A (2023) Effects of flux-cored arc welding technology on microstructure and wear resistance of Fe-Cr-C hardfacing alloy. Mater Today Commun 35:105569

Pańcikiewicz K (2021) Preliminary process and microstructure examination of flux-cored wire arc additive manufactured 18Ni-12Co-4Mo-Ti maraging steel. Materials 14(21):6725

Al-Mendwi KA, Doos QM (2023) Selection of welding process to large scale project on site by QFD and multi criteria methods. AIP Conference Proceedings 2651:1

Gomes JHF, Costa SC, Paiva AP, Balestrassi PP (2012) Mathematical modeling of weld bead geometry, quality, and productivity for stainless steel claddings deposited by FCAW. J Mater Eng Perform 21:1862–1872

Alvarães CP, Madalena FCA, Souza LFGD, Jorge JCF, Araújo LS, Mendes MC (2019) Performance of the INCONEL 625 alloy weld overlay obtained by FCAW process. Matéria (Rio de Janeiro) 24(1): e–12290

Moreno JS, Conde FF, Correa CA, Barbosa LH, da Silva EP, Avila J, ... Pinto HC (2022) Pulsed FCAW of martensitic stainless clads onto mild steel: microstructure, hardness, and residual stresses. Materials 15(8):2715

Guo N, Zhang X, Fu Y, Luo W, Chen H, He JL (2023) A novel strategy to prevent hydrogen charging via spontaneously molten-slag-covering droplet transfer mode in underwater wet FCAW. Mater Design 226:111636

Liu S, Ji H, Zhao W, Hu C, Wang J, Li H, ... Lei Y (2022) Evaluation of arc signals, microstructure and mechanical properties in ultrasonic-frequency pulse underwater wet welding process with Q345 steel. Metals 12(12):2119

Amaral EC, Jácome-Carrascal JL, Moreno-Uribe AM, Bracarense AQ (2021) Influence of the formulation of a flux-cored wire on the microstructure and hardness of welded metal. J Phys: Conf Ser 2118(1):012010

Parshin S, Levchenko A, Wang P, Maystro A (2021) Mathematical analysis of the influence of the flux-cored wire chemical composition on the electrical parameters and quality in the underwater wet cutting. Adv Mater Sci 21(1):77–89

Cai C, Xie J, Wang H, Chen H (2022) Welding characteristics and mechanical property of rotating laser welding-brazing of aluminum alloy to steel. Opt Laser Technol 151:107989

Mutașcu D, Karancsi O, Mitelea I, Crăciunescu CM, Buzdugan D, Uțu ID (2023) Pulsed TIG cladding of a highly carbon-, chromium-, molybdenum-, niobium-, tungsten-and vanadium-alloyed flux-cored wire electrode on duplex stainless steel X2CrNiMoN 22-5-3. Materials 16(13):4557

Schwab S, Selin R, Voron M (2023) Welding materials for TIG welding, surfacing, and WAAM technology of titanium alloys. Weld World 67(4):981–986

Wang M, Fang N, Sun L, Wu P, Huang R, Xu K, ... Long W (2023) Study of the microstructure and properties of the butt joint of laser-welded titanium alloy with flux-cored wire. Metals 13(2):369

Afkari MZ, Hastuty S, Barrinaya MA, Awwaluddin M, Anwar MS, Sunnardianto GK, Mahmuddin F (2023) Analysis of voltage, current density, and welding speed of flux core arc welding on the hardness and micro-structure of high strength low alloy (ASTM A572). Key Eng Mater 948:33–39

De Paz RR, Famadico GP, Ortiz AMJ, Tanap RCF, Tayactac RG, Ang EB, ... Honra J (2023) Analysis on the industrial applications of flux cored arc welding on an international scale. In 2023 14th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT) (pp. 135–142). IEEE

Fitriyus G, Zulkarnain Z, Istana B, Nasution AK (2023) Comparative study on welding characteristics of FCAW and SMAW welded ASTM A106 Grade B based on ASME standard. AIP Conference Proceedings 2601(1)

Świerczyńska A (2019) Effect of storage conditions of rutile flux cored welding wires on properties of welds. Adv Mater Sci 19(4):46–56

Świerczyńska A, Landowski M (2020) Plasticity of bead-on-plate welds made with the use of stored flux-cored wires for offshore applications. Materials 13(17):3888

Harwig DD, Longenecker DP, Cruz JH (1999) Effects of welding parameters and electrode atmospheric exposure on the diffusible hydrogen content of gas shielded flux cored arc welds. Weld J 78:314-s

Dhanistha WL, Pratikno H, Maharani SDP, Satrio D (2023) Comparative analysis of welding mechanical properties FCAW welding joint of A36 and A53. IOP Conf Ser: Earth Environ Sci 1198(1):012035

Świerczyńska A, Łabanowski J, Michalska J, Fydrych D (2017) Corrosion behavior of hydrogen charged super duplex stainless steel welded joints. Mater Corros 68(10):1037–1045

Wolski A, Świerczyńska A, Lentka G, Fydrych D (2023) Storage of high-strength steel flux-cored welding wires in urbanized areas. Int J Precis Eng Manuf-Green Technol 1–16 (In Press)

Bembenek M, Prysyazhnyuk P, Shihab T, Machnik R, Ivanov O, Ropyak L (2022) Microstructure and wear characterization of the Fe-Mo-BC—based hardfacing alloys deposited by flux-cored arc welding. Materials 15(14):5074

Fydrych D, Świerczyńska A, Tomków J (2014) Diffusible hydrogen control in flux cored arc welding process. Key Eng Mater 597:171–178

Zhang Z, Craciun S, van der Mee V (2021) All-positional flux cored wire with lower trace element contents and improved ambient temperature toughness for welding P91 steels. Weld World 65(10):1859–1869

Wang J, Li C, Wang D, Di X (2023) Effect of microalloying with Nb and/or V on the microstructure and mechanical properties of GPa grade deposited metals. Weld World 1–16

Tenni B, Brochu M, Godin S, Thibault D (2021) Shielding gas and inclusion content effects on impact toughness and tensile properties of 410NiMo steel welds. Weld J 100:52–62

Singh VK, Singh P, Karmakar M, Leta J, Mayr P (2021) The journal coverage of Web of Science, Scopus and Dimensions: a comparative analysis. Scientometrics 126:5113–5142

Van Eck NJ, Waltman L (2017) Citation-based clustering of publications using CitNetExplorer and VOSviewer. Scientometrics 111:1053–1070

Van Eck NJ, Waltman L (2014) CitNetExplorer: A new software tool for analyzing and visualizing citation networks. J Informet 8(4):802–823

Yan H, Ma M, Wu Y, Fan H, Dong C (2022) Overview and analysis of the text mining applications in the construction industry. Heliyon 8(12):e12088

Catumba BD, Sales MB, Borges PT, Ribeiro Filho MN, Lopes AAS, de Sousa Rios MA, ... dos Santos JCS (2023) Sustainability and challenges in hydrogen production: an advanced bibliometric analysis. Int J Hydrogen Energy 48(22):7975–7992

Aria M, Cuccurullo C (2017) bibliometrix: An R-tool for comprehensive science mapping analysis. J Informet 11(4):959–975

Dzogbewu TC, Amoah N, Jnr SA, Fianko SK, de Beer DJ (2023) Multi-material additive manufacturing of electronics components: a bibliometric analysis. Results Eng 19:101318

Westin EM (2022) Hot cracking in duplex stainless steel weldments—a review. Welding World 66(8):1483–1499

Taube F (2013) Manganese in occupational arc welding fumes—aspects on physiochemical properties, with focus on solubility. Ann Occup Hyg 57(1):6–25

Bajic D, Vladimirovich Kuzmenko G, Samardžić I (2013) Welding of rails with new technology of arc welding. Metalurgija 52(3):399–402

Aloraier A, Al-Mazrouee A, Price JWH, Shehata T (2010) Weld repair practices without post weld heat treatment for ferritic alloys and their consequences on residual stresses: a review. Int J Press Vessels Pip 87(4):127–133

Zhang B, Ahmad W, Ahmad A, Aslam F, Joyklad P (2022) A scientometric analysis approach to analyze the present research on recycled aggregate concrete. J Build Eng 46:103679

Asghar R, Khan MA, Alyousef R, Javed MF, Ali M (2023) Promoting the green construction: scientometric review on the mechanical and structural performance of geopolymer concrete. Constr Build Mater 368:130502

Lee RH (1965) Flux-cored wire for welding of steel. Weld J 44(5):387

Lagares ML Jr, Silva GC, Caldeira L (2020) Fusion zone microstructure image dataset of the flux-cored and shielded metal arc welding processes. Data Brief 33:106353

Pandita R, Singh S (2022) A study of distribution and growth of open access research journals across the world. Publ Res Q 38(1):131–149

Perianes-Rodríguez A, Olmeda-Gómez C (2019) Effects of journal choice on the visibility of scientific publications: a comparison between subscription-based and full Open Access models. Scientometrics 121(3):1737–1752

Kulevicz RA, Porfirio GEDO, de Oliveira OS, Zavala Zavala AA, Silva BAD, Constantino M (2020) Influence of sustainability reports on social and environmental issues: bibliometric analysis and the word cloud approach. Environ Rev 28(4):380–386

de Sousa FDB (2022) A simplified bibliometric mapping and analysis about sustainable polymers. Mater Today: Proceedings 49:2025–2033

Zhang Z, Jing H, Xu L, Han Y, Zhao L, Zhang J (2017) Influence of microstructure and elemental partitioning on pitting corrosion resistance of duplex stainless steel welding joints. Appl Surf Sci 394:297–314

Rowe M, Liu S (2001) Recent developments in underwater wet welding. Sci Technol Weld Joining 6(6):387–396

Lehnert M, Pesch B, Lotz A, Pelzer J, Kendzia B, Gawrych K, ... Weldox Study Group (2012) Exposure to inhalable, respirable, and ultrafine particles in welding fume. Ann Occup Hyg 56(5):557-567

Wang Y, Kannan R, Li L (2016) Characterization of as-welded microstructure of heat-affected zone in modified 9Cr–1Mo–V–Nb steel weldment. Mater Charact 118:225–234

Zhang Z, Jing H, Xu L, Han Y, Zhao L (2016) Investigation on microstructure evolution and properties of duplex stainless steel joint multi-pass welded by using different methods. Mater Des 109:670–685

Coronado JJ, Caicedo HF, Gómez AL (2009) The effects of welding processes on abrasive wear resistance for hardfacing deposits. Tribol Int 42(5):745–749

Thibault D, Bocher P, Thomas M (2009) Residual stress and microstructure in welds of 13% Cr–4% Ni martensitic stainless steel. J Mater Process Technol 209(4):2195–2202

Palani PK, Murugan N (2007) Optimization of weld bead geometry for stainless steel claddings deposited by FCAW. J Mater Process Technol 190(1–3):291–299

Kannan T, Murugan N (2006) Effect of flux cored arc welding process parameters on duplex stainless steel clad quality. J Mater Process Technol 176(1–3):230–239

Katherasan D, Elias JV, Sathiya P, Haq AN (2014) Simulation and parameter optimization of flux cored arc welding using artificial neural network and particle swarm optimization algorithm. J Intell Manuf 25:67–76

Qi X, Jia Z, Yang Q, Yang Y (2011) Effects of vanadium additive on structure property and tribological performance of high chromium cast iron hardfacing metal. Surf Coat Technol 205(23–24):5510–5514

Jenkins NT, Pierce WMG, Eagar TW (2005) Particle size distribution of gas metal and flux cored arc welding fumes. Welding J 84(10):156–163

Świerczyńska A, Fydrych D, Rogalski G (2017) Diffusible hydrogen management in underwater wet self-shielded flux cored arc welding. Int J Hydrogen Energy 42(38):24532–24540

Magudeeswaran G, Balasubramanian V, Reddy GM, Balasubramanian TS (2008) Effect of welding processes and consumables on tensile and impact properties of high strength quenched and tempered steel joints. J Iron Steel Res Int 15(6):87–94

Reddy GM, Mohandas T, Papukutty KK (1998) Effect of welding process on the ballistic performance of high-strength low-alloy steel weldments. J Mater Process Technol 74(1–3):27–35

Sun QJ, Cheng WQ, Liu YB, Wang JF, Cai CW, Feng JC (2016) Microstructure and mechanical properties of ultrasonic assisted underwater wet welding joints. Mater Des 103:63–70

Jia C, Zhang T, Maksimov SY, Yuan X (2013) Spectroscopic analysis of the arc plasma of underwater wet flux-cored arc welding. J Mater Process Technol 213(8):1370–1377

Zhang Y, Jia C, Zhao B, Hu J, Wu C (2016) Heat input and metal transfer influences on the weld geometry and microstructure during underwater wet FCAW. J Mater Process Technol 238:373–382

Magudeeswaran G, Balasubramanian V, Reddy GM (2008) Hydrogen induced cold cracking studies on armour grade high strength, quenched and tempered steel weldments. Int J Hydrogen Energy 33(7):1897–1908

Palani PK, Murugan N (2006) Development of mathematical models for prediction of weld bead geometry in cladding by flux cored arc welding. Int J Adv Manuf Technol 30:669–676

Bhoskar A, Kalyankar V, Deshmukh D (2023) Metallurgical characterisation of multi-track Stellite 6 coating on SS316L substrate. Can Metall Q 62(4):665–677

Kalyankar V, Bhoskar A (2021) Influence of torch oscillation on the microstructure of Colmonoy 6 overlay deposition on SS304 substrate with PTA welding process. Metall Res Technol 118(4):406

Lopes JG, Rocha P, Santana DA, Shen J, Maawad E, Schell N, ... Oliveira JP (2023) Impact of arc‐based welding on the microstructure evolution and mechanical properties in newly developed Cr29. 7Co29. 7Ni35. 4Al4Ti1. 2 multi‐principal element alloy. Adv Eng Mater

Shen J, Agrawal P, Rodrigues TA, Lopes JG, Schell N, He J, ... Oliveira JP (2023) Microstructure evolution and mechanical properties in a gas tungsten arc welded Fe42Mn28Co10Cr15Si5 metastable high entropy alloy. Mater Sci Eng: A 867:144722

Kalyankar V, Bhoskar A, Deshmukh D, Patil S (2022) On the performance of metallurgical behaviour of Stellite 6 cladding deposited on SS316L substrate with PTAW process. Can Metall Q 61(2):130–144

Shen J, Gonçalves R, Choi YT, Lopes JG, Yang J, Schell N, ... Oliveira JP (2022) Microstructure and mechanical properties of gas metal arc welded CoCrFeMnNi joints using a 410 stainless steel filler metal. Mater Sci Eng: A 857:144025

Trembach B, Grin A, Turchanin M, Makarenko N, Markov O, Trembach I (2021) Application of Taguchi method and ANOVA analysis for optimization of process parameters and exothermic addition (CuO-Al) introduction in the core filler during self-shielded flux-cored arc welding. Int J Adv Manuf Technol 114(3):1099–1118

Kordas P, Bęczkowski R, Gucwa M, Winczek J (2019) Application of design of experiment to a FCAW process. MATEC Web Conf 254:01009

Gribkov EP, Malyhin SO, Hurkovskaya SS, Berezshnaya EV, Merezhko DV (2022) Mathematical modelling, study and computer-aided design of flux-cored wire rolling in round gauges. Int J Adv Manuf Technol 119(7–8):4249–4263

Costa PS, Altamirano-Guerrero G, Ochoa-Palacios RM, Resendiz-Flores EO, Guía-Hernández LA, Ramirez-Luna LE (2022) Optimization of welding parameters in underwater wet FCAW on a structural steel using support vector regression and sequential quadratic programming. Int J Adv Manuf Technol 121(5–6):4225–4236

Westin EM, McCarrick S, Laundry-Mottiar L, Wei Z, Biesinger MC, Barker I, ... Hedberg YS (2021) New weldable 316L stainless flux-cored wires with reduced Cr (VI) fume emissions: part 1—health aspects of particle composition and release of metals. Weld World 65:2319–2337

Vats V, Melton G, Islam M, Krishnan VV (2023) FTIR spectroscopy as a convenient tool for detection and identification of airborne Cr (VI) compounds arising from arc welding fumes. J Hazard Mater 448:130862

Pereira DHDM, Pereira DHDM, Rolim TL, Ferreira RAS (2020) Residual stress analysis using CPD method in ASTM A131 AH36 steel multipass welding by SMAW and FCAW processes. Soldagem Inspeção 25:e2513

Świerczyńska A, Fydrych D, Landowski M, Rogalski G, Łabanowski J (2020) Hydrogen embrittlement of X2CrNiMoCuN25-6-3 super duplex stainless steel welded joints under cathodic protection. Constr Build Mater 238:117697

Feng C, Su M, Xu L, Zhao L, Han Y (2023) Estimation of fatigue life of welded structures incorporating importance analysis of influence factors: a data-driven approach. Eng Fract Mech 281:109103

Yang J, Xu S, Jia C, Han Y, Maksymov S, Wu C (2023) A novel 3D numerical model coupling droplet transfer and arc behaviors for underwater FCAW. Int J Therm Sci 184:107906

Guo N, Du Y, Maksimov S, Feng J, Yin Z, Krazhanovskyi D, Fu Y (2018) Study of metal transfer control in underwater wet FCAW using pulsed wire feed method. Weld World 62:87–94

Maurya AK, Pandey C, Chhibber R (2021) Dissimilar welding of duplex stainless steel with Ni alloys: a review. Int J Press Vessels Pip 192:104439

Nellikode S, Manladan SM, Jo I, Jung SJ, Kim IC, Park H, ... Park YD (2023) Effect of microstructural heterogeneities on variability in low-temperature impact toughness in multi-pass weld metal of 420 MPa offshore engineering steel. Weld World 67(7):1679–1693

Winczek J, Gucwa M, Mičian M, Koňár R, Parzych S (2019) The evaluation of the wear mechanism of high-carbon hardfacing layers. Arch Metall Mater 64(3):1111–1115

Chen J, Xie W, Liu R, Wei Y (2022) Microstructure and wear resistance of Fe-based hardfacing layer prepared by flux-cored wire feeding MAG welding process. Weld World 66(2):175–185

Pessoa ECP, Liu S (2021) The state of the art of underwater wet welding practice: Part 1. Weld J 100(4):132–141

Balakrishnan M, Leitão C, Craveiro D, Rodrigues DM, Santiago A, da Silva LS, Subramanian C (2022) Post fire tensile properties of S355 J2 structural steel welded connections for construction industrial applications. Metall Res Technol 119(5):511

de Sousa JMS, Gil GS, dos Santos Barbosa M, Garcia DN, Lobato MQ, Machado PC (2023) Tribological performance under abrasive wear of Fe-Cr-C+ Nb coating deposited by FCAW process. Wear 523:204824

Hariprasath P, Sivaraj P, Balasubramanian V, Pilli S, Sridhar K (2023) Evaluation of high cycle fatigue behavior of flux cored arc welded naval grade DMR249 A grade steel joints for ship hull structures. Forces Mech 11:100189

Burger S, Zinke M, Jüttner S (2021) Hot cracking tendency of flux-cored arc welding with flux-cored wires of types Ni 6625. Weld World 65:381–392

Rhode M, Nietzke J, Richter T, Mente T, Mayr P, Nitsche A (2023) Hydrogen effect on mechanical properties and cracking of creep-resistant 9% Cr P92 steel and P91 weld metal. Weld World 67(1):183–194

Meszaros K, Rana A, Henein H, Dias M (2023) Abrasion resistance and hardness evaluation of FCAW-S hard-facing following elevated temperature exposure. Wear 523:204759

Braun M, Kahl A, Willems T, Seidel M, Fischer C, Ehlers S (2021) Guidance for material selection based on static and dynamic mechanical properties at sub-zero temperatures. J Offshore Mech Arct Eng 143(4):041704

Funding

Parts of this paper have been supported by the National Research, Development and Innovation Office – NKFIH, OTKA PD 138729 (B. Varbai). Parts of this paper have been supported by Gdańsk University of Technology, DEC-18/2021/IDUB/I.3.3 grant under the ARGENTUM TRIGGERING RESEARCH GRANTS—“Excellence Initiative—Research University” (A. Świerczyńska).

Author information

Authors and Affiliations

Contributions

AŚ: conceptualization, methodology, formal analysis, writing original draft, writing—review and editing, visualization, project administration, funding acquisition.

BV: conceptualization, methodology, formal analysis, writing original draft, visualization, funding acquisition.

CP: conceptualization, methodology, formal analysis, writing original draft.

DF: conceptualization, methodology, formal analysis, writing original draft, writing—review and editing, visualization, supervision.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Świerczyńska, A., Varbai, B., Pandey, C. et al. Exploring the trends in flux-cored arc welding: scientometric analysis approach. Int J Adv Manuf Technol 130, 87–110 (2024). https://doi.org/10.1007/s00170-023-12682-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12682-6