Abstract

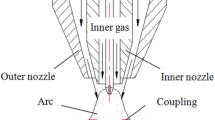

Gas-focusing TIG (GF-TIG) is developed by adding a focusing gas flow around the tungsten tip. Experimental results show that GF-TIG has advantages over conventional TIG: A larger focusing gas flow rate will enhance the arc shrinkage state and thermal pinch effect. The high-temperature cathode region size decreases, and the tungsten tip erosion degree is reduced. The arc root has a smaller diameter. The arc pressure and temperature increase with the focusing gas flow. When the focusing gas flow rate reaches 10 L/min, GF-TIG can fully penetrate the workpiece in keyhole mode, while TIG can only penetrate about half depth at the same welding current of 250A. GF-TIG is proven to highly increase penetration ability and improve welding efficiency.

Similar content being viewed by others

References

Kumar K, Kumar CS, Masanta M, Pradhan S (2022) A review on TIG welding technology variants and its effect on weld geometry. Mater Today: Proc 50:999–1004

Tsuchiya K, Kawamura H, Kalinin G (2000) Re-weldability tests of irradiated austenitic stainless steel by a TIG welding method. J Nucl Mater 283(283):1210–1214

Giridharan PK, Murugan N (2008) Optimization of pulsed GTA welding process parameters for the welding of AISI 304L stainless steel sheets. Int J Adv Manuf Technol 40(5-6):478–489

Chen JH, Hua PH, Chen PN, Chang CM, Chen MC, Wu W (2008) Characteristics of multi-element alloy cladding produced by TIG process. Mater Lett 62(15):2490–2492

Salkin JT, Beedon KW, Henon BK, Jelonek KR, Donnell DB (2004) Welding handbook, Welding Processes, vol 2, 9th edn. American Welding Society, Miami Fla

Sadek AA, Ushio M, Matsuda F (1990) Effect of rare earth metal oxide additions to tungsten electrodes. Metall Trans A 21:3221–3226

Lu FG, Tang XH, Yu HL, Yao S (2006) Numerical simulation on interaction between TIG welding arc and weld pool. Comp Mater Sci 35:458–465

Li TQ, Chen L, Zhang Y, Yang XM, Lei YC (2020) Metal flow of weld pool and keyhole evolution in gas focusing plasma arc welding. Int J Heat Mass Transf 150:119296

Liu ZM, Cui SL, Luo Z, Zhang CZ, Wang ZM, Zhang YC (2016) Plasma arc welding: process variants and its recent developments of sensing, controlling and modeling. J Manuf Process 23:315–327

Teker T, Özdemir N (2012) Weldability and joining characteristics of AISI 430/AISI 1040 steels using keyhole plasma arc welding. Int J Adv Manuf Technol 63(1-4):117–128

Sahoo A, Tripathy S (2021) Development in plasma arc welding process: a review. Mater Today: Proc 41(2):363–368

Wu CS, Wang L, Ren WJ, Zhang XY (2014) Plasma arc welding: process, sensing, control and modeling. J Manuf Process 16:74–85

Evans DM, Huang D, Mcclure JC, Nunes AC (1998) Arc efficiency of plasma arc welding. Weld J 77(2):53–58

Hessel LV (2014) Increased power density plasma arc welding. Master thesis, Delft University of Technology

Li TQ, Yang XM, Chen L, Zhang Y, Lei YC, Yan JC (2019) Arc behaviour and weld formation in gas focusing plasma arc welding. Sci Technol Weld Join 25:329–335

Liu ZM, Chen SY, Yuan X, Zuo AQ, Zhang T, Luo Z (2018) Magnetic-enhanced keyhole TIG welding process. Int J Adv Manuf Technol 99:275–285

Li DJ, Lu SP, Li DZ, Li YY (2014) Effect of structural parameters of double shielded TIG torch on the fusion zone profile for 0Cr13Ni5Mo martensitic stainless steel. J Mater Sci Technol 30(9):922–927

Manh NH, Nguyen VA, Duy HL, Akihisa M, Le VT, Ngoc TQ, Gandham B (2022) Development of a novel GTAW process for joining ultra-thin metal sheets. J Manuf Process 80:683–691

Manh NH, Le VT, Gandham B, Nguyen VH, Le DH, Van TN, Van TN (2023) Unique characteristics of the novel-GTAW process for the butt joint of ultra-thin silicon steel sheets. J Manuf Process 85:894–903

Li DJ, Lu SP, Li DZ, Li YY (2014) Principles giving high penetration under the double shielded TIG process. J Mater Sci Technol 30(2):172–178

Liu ZM, Fang YX, Cui SL, Luo Z, Liu WD, Liu ZY, Jiang Q, Yi S (2016) Stable keyhole welding process with K-TIG. J Mater Process Technol 238:65–72

Liu ZM, Wu CS, Chen MA (2012) Visualizing the influence of the process parameters on the keyhole dimensions in plasma arc welding. Meas Sci Technol 23(10):105603

Liu ZM, Wu CS, Gao JQ (2013) Vision-based observation of keyhole geometry in plasma arc welding. Int J Therm Sci 63:38–45

Yan Z, Jiang F, Huang N, Zhang S, Chen S (2019) Heat and pressure characteristics in hollow cathode centered negative pressure arc column. Appl Therm Eng 156:668–677

Tanaka M, Tashiro S (2008) Electron temperature measurement of tungsten inert gas arcs. Thin Solid Films 516(19):6628–6633

Ma SL, Gao HM, Zheng SM, Wu L (2011) Spectroscopic measurement of temperatures in pulsed TIG welding arcs. J Phys D: Appl Phys 44(40):405202

Liu ZM, Fang YX, Chen SY, Zhang T, Lv ZY, Luo Z (2019) Focusing cathode tip characteristics in cooling tungsten. Energy 167:982–993

Liu ZM, Chen SY, Cui SL, Lv ZY, Zhang T, Luo Z (2019) Experimental investigation of focusing cathode region by cooling tungsten. Int J Therm Sci 138:24–34

Bini R, Monno M, Boulos MI (2007) Effect of cathode nozzle geometry and process parameters on the energy distribution for an argon transferred arc. Plasma Chem Plasma Process 27:359–380

Funding

The authors are grateful for the financial support for this research from the National Natural Science Foundation of China (51975403, 52375373).

Author information

Authors and Affiliations

Contributions

Fei Liu performed the research, analyzed data, and wrote the paper; ZuMing Liu designed the study and revised the manuscript; WenBin Zhang performed the data processing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, F., Liu, Z. & Zhang, W. Arc characteristics and welding state in gas-focusing TIG. Int J Adv Manuf Technol 129, 5335–5346 (2023). https://doi.org/10.1007/s00170-023-12631-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12631-3