Abstract

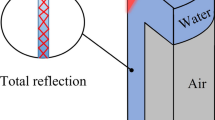

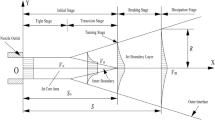

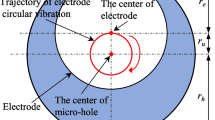

In order to understand the transmission mode of laser in water jet–guided laser (WJGL) after entering blind holes, the flow characteristics of water jet in blind holes and the formation process of WJGL processing blind holes were studied. Firstly, the flow characteristics of water jets in blind holes under different water jet and blind hole conditions were studied through numerical simulation, including water jet diameter d (0–300 μm), hole diameter D (0–300 μm), and water jet velocity v (0–200 m/s). Secondly, single-point drilling experiments with different processing times (2–40 s) were conducted using WJGL technology to characterize the formation process of blind holes. Finally, the transmission mode of laser in blind holes and formation process mechanism of blind hole processed by WJGL were analyzed. The simulation results indicate that the process of water jet entering the blind hole can be divided into incident stage, rebound stage, and stable stage. The transmission of water jet in blind holes is influenced by D/d and v. When D/d is greater than 2.3, the water jet can stably transmit to the bottom of the blind hole. Taking 75 m/s and 150 m/s as the change points, as v increases, the stable transmission length of the water jet first decreases, then remains unchanged, and then increases. The experimental results indicate that with the increase of processing time, the formation process of blind holes undergoes rapid drilling stage, uniform reaming stage, bottom reaming stage, and stable stage. Under experimental conditions, the depth of blind holes first increases and then stabilizes with increasing processing time. The maximum depth of blind holes processed by WJGL is 720 μm. This article reveals the flow pattern of micro water jets in blind holes and the factors that affect their stable transmission for the first time. From the perspective of the guiding effect of water jets on laser, it is revealed that laser propagates along a straight line in a blind hole. The simulation and experimental results have guiding significance for improving the application of WJGL technology in blind hole processing.

Similar content being viewed by others

References

Kruusing A (2004) Underwater and water-assisted laser processing: part 1—general features, steam cleaning and shock processing. Opt Lasers Eng 41(2):307–327. https://doi.org/10.1016/S0143-8166(02)00142-2

Deng C, Yeo H, Ki H (2020) Electrodynamic simulation of laser beam propagation in waterjet-guided laser processing. Opt Express 28(8):11128. https://doi.org/10.1364/OE.389497

Zhang Y, Qiao H, Zhao J et al (2022) Research on water jet-guided laser micro-hole machining of 6061 aluminum alloy. Int J Adv Manuf Technol 118(1-2):1–13. https://doi.org/10.1007/s00170-021-07104-4

Anjum A, Shaikh A (2023) Experimental and analytical modeling for channel profile using CO2 laser considering Gaussian beam distribution. J Eng Res 11(2):100035. https://doi.org/10.1016/j.jer.2023.100035

Qiao H, Cao Z, Cui J et al (2021) Experimental study on water jet guided laser micro-machining of mono-crystalline silicon. Opt Laser Technol 140(4):107057. https://doi.org/10.1016/j.optlastec.2021.107057

Perrottet D, Spiegel A, Amorosi S et al (2005) GaAs-wafer dicing using the water jet guided laser. In: Synova SA, De la Dent-d’Oche C (eds) 2005 International Conference on Compound Semiconductor Manufacturing Technology: Digest of Papers, April 11-14, 2005, New Orleans, LA (US). 1024 Ecublens, Switzerland, pp 305–307 10.1.1.546.7618

Bruckert F, Beyer E, Morris T et al (2012) Tailor cutting of crystalline solar cells by laser micro jet®. In: Proceedings of SPIE - High Power Laser Materials Processing: Lasers, Beam Delivery, Diagnostics, and Applications. January 21, 2012, San Francisco, CA(US), vol 8239, pp 19–26. https://doi.org/10.1117/12.906397

Nilsson T, Wagner F, Housh R et al (2004) Scribing of GaN wafer for white LED by water jet guided laser. In: Synova SA, De la Dent-d’Oche C (eds) Light-emitting diodes: research, manufacturing, and applications VIII, January 27-28, 2004, San Jose, CA(US), vol 5366. CH-1024 Ecublens, Switzerland, pp 200–206. https://doi.org/10.1117/12.529012

Li CF, Johnson DB, Kovacevic R (2003) Modeling of waterjet guided laser grooving of silicon. Int J Mach Tools Manuf 43(9):925–936. https://doi.org/10.1016/S0890-6955(03)00063-4

Yang L, Wang M, Wang Y (2010) Research on water-jet guided laser micromachining of 65-Mn steel. Int J Abras Technol 3(4):338–353. https://doi.org/10.1504/IJAT.2010.036966

Zhang Y, Qiao H, Zhao J et al (2020) Numerical simulation of water jet–guided laser micromachining of CFRP. Mater Today Commun 25:101456. https://doi.org/10.1016/j.mtcomm.2020.101456

Wei M, Liu Y, Liu Z et al (2018) Investigation on the stability of capillary waterjet as the optical waveguide influenced by cavitation. In: 2018 IEEE 8th International Conference on Underwater System Technology: Theory and Applications (USYS), December 1-3, 2018. IEEE, Hubei, China. New York, pp 1–5. https://doi.org/10.1109/USYS.2018.8778876

Ng YK, Guannan D (2015) The stability of 30-μm-diameter water jet for jet-guided laser machining. Int J Adv Manuf Technol 78(5-8):939–946. https://doi.org/10.1007/s00170-014-6692-8

Liu X, Lienhard JH, Lombara JS (1991) Convective heat transfer by impingement of circular liquid jets. J Heat Transf 113(3):571–582. https://doi.org/10.1115/1.2910604

Couty P, Wanger F, Hoffmann P (2004) Laser coupling with a multimode water-jet waveguide. Opt Eng 44(6):068001. https://doi.org/10.1117/1.1928280

Zhang Y, Qiao H, Zhao J et al (2023) Research on the influence of the jet flow regime in the kerf on the cutting surface accuracy in WJGL. Mater Today Commun:105503. https://doi.org/10.1016/j.mtcomm.2023.105503

Luo Y, Liu Y, Zhang D et al (2014) Influence of morphology for drag reduction effect of sharkskin surface. J Mech Med Biol 14(02):1450029. https://doi.org/10.1142/s0219519414500298

Zhang D, Luo Y, Xiang L et al (2011) Numerical simulation and experimental study of drag-reducing surface of a real shark skin. J Hydrodyn 23(2):8. https://doi.org/10.1016/S1001-6058(10)60105-9

Zhu G, Kou J, Yao B et al (2019) Thermodynamically consistent modelling of two-phase flows with moving contact line and soluble surfactants. J Fluid Mech 879:327–359. https://doi.org/10.1017/jfm.2019.664

Zuckerman N, Lior N (2006) Jet Impingement heat transfer: physics, correlations, and numerical modeling. Adv Heat Tran 39(06):565–631. https://doi.org/10.1016/S0065-2717(06)39006-5

Subasi L, Diboine J, Gunaydin A et al (2021) Water jet guided laser microdrilling of aerospace alloys: correlation of material properties to process time and quality. J Laser Appl 33(1):012015. https://doi.org/10.2351/7.0000302

Marimuthu S, Smith B (2021) Water-jet guided laser drilling of thermal barrier coated aerospace alloy. Int J Adv Manuf Technol 113(4). https://doi.org/10.1007/s00170-020-06584-0

Spiegel A, Vago N, Wagner F (2004) High efficiency Raman scattering in micrometer-sized water jets. Opt Eng 43(2):450–454. https://doi.org/10.1117/1.1634292

Anjum A, Shaikh AA, Tiwari N (2023) Comparative assessment of the developed algorithm with the soft computing algorithm for the laser machined depth. Infrared Phys Technol 129:104545. https://doi.org/10.1016/j.infrared.2023.104545

Ferrucci M, Ametova E (2021) Charting the course towards dimensional measurement traceability by X-ray computed tomography. Meas Sci Technol 32(9):092001. https://doi.org/10.1088/1361-6501/abf058

Withers PJ, Bouman C, Carmignato S et al (2021) X-ray computed tomography. Nat Rev Methods Primers 1:18. https://doi.org/10.1038/s43586-021-00015-4

Funding

This work was sponsored by the National Key Research and Development Project (No. 2022YFB4601600), National Natural Science Foundation of China (51875558), and Liaoning Revitalization Talents Program (No.XLYC1803036).

Author information

Authors and Affiliations

Contributions

Jinsheng Liang: summarization of the experiments and writing original paper. Hongchao Qiao: comment and revision for the paper. Jibin Zhao: formulations of the problem. Zhihe Cao and Yinuo Zhang: measurements of experiment data. Shunshan Wang: preparation of samples

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liang, J., Qiao, H., Zhao, J. et al. Study on fluid flow characteristics and laser transmission mode of water jet–guided laser processing in blind hole. Int J Adv Manuf Technol 129, 1717–1730 (2023). https://doi.org/10.1007/s00170-023-12391-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12391-0