Abstract

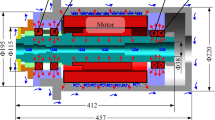

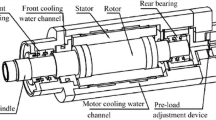

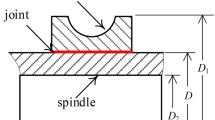

In order to investigate the thermal variations of axial static stiffness of motorized spindle unit, a thermal modeling method of spindle axial static stiffness is established by combining the numerical simulation technology with analytical method. Firstly, based on a thermoelastic ring cylinder model and the Hertz contact theory, the analytical model of temperature rise–axial static stiffness thermal variation effect of spindle-angular contact ball bearing system is constructed; then, the spindle structural thermal model considering its coolant heat transfer is obtained by using the finite element heat–fluid–solid coupling simulation technology, to solve temperature rises of spindle bearings. Based on them, the Bushing element is used to analyze the stiffness of the bearing assembly in the thermal–structural coupling simulation modeling of motorized spindle unit and thus to simulate the thermal variation effects of spindle axial static stiffness. Ultimately, the variation tendencies of the spindle axial static stiffness under various thermal conditions are analyzed by using this model, and the obtained results are compared with their corresponding test data. The comparisons show that this modeling method can accurately predict the thermal variation tendencies of axial static stiffness during spindle operations. Then the temperature rises of spindle structure can cause its axial static stiffness to harden, which is associated with the thermal increase of bearing preload. The conclusions have the guiding significance for thermal balance design and optimization of spindle structure.

Similar content being viewed by others

Data availability

The data generated or analyzed in this study are available.

Abbreviations

- α :

-

Thermal expansion coefficient (K−1)

- μ :

-

Poisson’s ratio

- r i/r o :

-

Elastomer radius of inner ring/outer ring (m)

- ω :

-

Angular velocity (rad/s)

- Δt :

-

Structural temperature rise (℃)

- E :

-

Elastic modulus (Pa)

- ρ :

-

Density (Kg/m3)

- P 1/P 2/P 3 :

-

Compressive stress of inner ring/outer ring/end face of circular cylinder (Pa)

- z 0 :

-

Thickness of circular cylinder (m)

- \({D}_{\mathrm{BO}}^{\mathrm{I\_1}}/{D}_{\mathrm{BO}}^{\mathrm{I\_2}}/{D}_{\mathrm{BO}}^{\mathrm{I\_3}}\) :

-

Outer diameter I_1/2/3 of angular contact ball bearing (m)

- \({D}_{\mathrm{BI}}^{\mathrm{III\_1}{\prime}}/{D}_{\mathrm{BI}}^{\mathrm{III\_2}{\prime}}/{D}_{\mathrm{BI}}^{\mathrm{III\_3}{\prime}}\) :

-

Inner diameter III_1'/2'/3' of angular contact ball bearing (m)

- A :

-

Curvature center distance (m)

- \({D}_{\mathrm{BO}}^{\mathrm{I}}/{D}_{\mathrm{BO}}^{\mathrm{II}}/{D}_{\mathrm{BO}}^{\mathrm{III}}\) :

-

Outer diameter I/II/III of angular contact ball bearing (m)

- \({D}_{\mathrm{BI}}^{\mathrm{I}}/{D}_{\mathrm{BI}}^{\mathrm{II}}/{D}_{\mathrm{BI}}^{\mathrm{III}}\) :

-

Inner diameter I/II/III of angular contact ball bearing (m)

- \({I}_{\mathrm{BO}}/{I}_{\mathrm{BI}}\) :

-

Interference fit value of outer ring/inner ring (m)

- \({\mu }_{\mathrm{BO\_}t}^{\mathrm{II\_hou}}/{\mu }_{\mathrm{BO\_}t}^{\mathrm{II\_bea}}\) :

-

Displacement of edge II_hou/II_bea of outer ring of angular contact ball bearing (m)

- E b/E spa/E h :

-

Elastic modulus of angular contact ball bearing/bearing spacer/housing (Pa)

- \({l}_{\mathrm{O}}^{\mathrm{hou}}/{l}_{\mathrm{I}}^{\mathrm{spi}}\) :

-

Length of bearing housing/shaft matched with bearing (m)

- \({l}_{\mathrm{O}}^{{\mathrm{be}}\mathrm{a\_a2}}/{l}_{\mathrm{O}}^{\mathrm{bea\_21}}{l}_{\mathrm{O}}^{\mathrm{bea\_1d}}\) :

-

Outer diameter bea_a2/bea_21/bea_1d of angular contact ball bearing (m)

- \({w}_{{\mathrm{O}}\_t}^{\mathrm{hou}}\) :

-

Displacement of bearing housing (m)

- \({w}_{{\mathrm{O}}\_t}^{\mathrm{spa\_1}}/{w}_{{\mathrm{O}}\_t}^{\mathrm{spa\_2}}\) :

-

Displacement of bearing spacer 1/2 (m)

- \({w}_{{\mathrm{O}}\_t}^{\mathrm{bea\_a2}}/{w}_{{\mathrm{O}}\_t}^{\mathrm{bea\_21}}/{w}_{{\mathrm{O}}\_t}^{\mathrm{bea\_1d}}\) :

-

Displacement of bearing a2/21/1d (m)

- I AO :

-

Axial interference fit value of angular contact ball bearing (m)

- α b/α spa/α h :

-

Thermal expansion coefficient of bearing/bearing spacer/housing (K−1)

- D w :

-

Bearing roller diameter (m)

- \({f}_{\mathrm{i\_}t}/{f}_{\mathrm{o\_}t}\) :

-

Curvature coefficient of inner/outer raceway of bearing

- α t :

-

Contact angle of bearing (°)

- ρ t :

-

Radius of curvature (m−1)

- d m_ t :

-

Bearing pitch diameter (m)

- \({\delta }_{t}^{*}\) :

-

Normal approach quantity of bearing rolling element

- K n :

-

Bearing stiffness coefficient

- Q h :

-

Normal load (N)

- F a_ t :

-

Thermally induced axial preload (N)

- Z :

-

Number of bearing rolling elements

- P 0 :

-

Motor input power (W)

- U/I :

-

Rated voltage/current of motor (V/A)

- ΔP :

-

Motor power loss (W)

- η :

-

Motor efficiency

- H r/H s/H s :

-

Heat generation of motor rotor/stator/bearing (W/m3)

- n :

-

Spindle rotating speed (RPM)

- M 0/M 1 :

-

Bearing frictional torque for lubricant viscosity/applied force load (Nmm)

- f 0/f 1 :

-

Factor related to bearing type and lubrication method/applied force load

- ν 0 :

-

Kinematics viscosity of lubricant (mm2/s)

- F β :

-

Applied force load onto bearing (N)

- h a :

-

Coefficient of convection heat transfer (W/(m2K))

- Nu a :

-

Nusselt number

- λ a :

-

Thermal conductivity of air (W/(m•K))

- d e :

-

Diameter of spindle part (m)

- R e a/P r a :

-

Reynolds number/Prandtl number of air

- V a :

-

Flow velocity of air (m/s)

- ν a :

-

Kinematics viscosity of air (m2/s)

- c a :

-

Specific heat capacity of air (J/(kg•°C))

- μ a :

-

Dynamic viscosity coefficient of air (Pa•s)

References

Matsubara A, Yamazaki T, Ikenaga S (2013) Non-contact measurement of spindle stiffness by using magnetic loading device. Int J Mach Tools and Manuf 71:20–25. https://doi.org/10.1016/j.ijmachtools.2013.04.003

Abele E, Altintas Y, Brecher C (2010) Machine tool spindle units. CIRP Ann Manuf Technol 59(2):781–802. https://doi.org/10.1016/j.cirp.2010.05.002

Fang CG, You WC, Huo DH (2022) Investigations of the static and dynamic characteristics of the precision hydrostatic spindle with mid-thrust bearing under different loads. P I Mech Eng Part J-J Eng 236(4):732–747. https://doi.org/10.1177/13506501211023618

Xi ST, Cao HR, Chen XF (2019) Dynamic modeling of spindle bearing system and vibration response investigation. Mech Syst Signal Process 114:486–511. https://doi.org/10.1016/j.ymssp.2018.05.028

Miao HH, Li CY, Wang CY, Xu MT, Zhang YM (2021) The vibration analysis of the CNC vertical milling machine spindle system considering nonlinear and nonsmooth bearing restoring force. Mech Syst Signal Process 161:1–21. https://doi.org/10.1016/j.ymssp.2021.107970

Du WT, Wang LM, Shao YM (2023) A semi-analytical dynamics method for spindle radial throw in boring process. J Manuf Process 96:110–124. https://doi.org/10.1016/j.jmapro.2023.04.04

Zhang XH, Chen XM, Yan K, Chen XH, Zhu YS, Hong J (2023) Transient thermal properties investigation for precision bearing-spindle system considering fixed-position preload and lubricant viscosity-temperature effect. J Manuf Process 96:41–53. https://doi.org/10.1016/j.jmapro.2023.04.010

Kato M, Kono D, Kakinuma Y (2022) Dynamical characteristic validation of motorized CFRP spindle unit based on receptance coupling. Mech Syst Signal Process 173:1–19. https://doi.org/10.1016/j.ymssp.2022.109028

Li BJ, Cao HJ, Yang X, Jafar S, Zeng D (2018) Thermal energy balance control model of motorized spindle system enabling high-speed dry hobbing process. J Manuf Process 35:29–39. https://doi.org/10.1016/j.jmapro.2018.07.010

Su CA, Chen WF (2021) Thermal behavior on motorized spindle considering bearing thermal deformation under oil-air lubrication. J Manuf Process 72:483–499. https://doi.org/10.1016/j.jmapro.2021.10.041

Fedorynenko D, Kirigaya R, Nakao Y (2020) Dynamic characteristics of spindle with water-lubricated hydrostatic bearings for ultra-precision machine tools. Precis Eng 62:187–196. https://doi.org/10.1016/j.precisioneng.2020.02.003

Li YF, Zhang YJ, Zhao YQ, Shi XJ (2021) Thermal-mechanical coupling calculation method for deformation error of motorized spindle of machine tool. Eng Fail Anal 128:1–15. https://doi.org/10.1016/j.engfailanal.2021.105597

Liu L, Lu LH, Yu KC, Gao Q, Zhao H, Chen WQ (2022) A steady modeling method to study the effect of fluid–structure interaction on the thrust stiffness of an aerostatic spindle. Eng Appl Comp Fluid 16:453–468. https://doi.org/10.1080/19942060.2021.2024452

Cheng YN, Zhang XP, Zhang GX, Jiang WQ, Li BW (2022) Thermal error analysis and modeling for high-speed motorized spindles based on LSTM-CNN. Int J Adv Manuf Technol 121:3243–3257. https://doi.org/10.1007/s00170-022-09563-9

Zhou CJ, Qu ZF, Hu B, Li SB (2021) Thermal network model and experimental validation for a motorized spindle including thermal–mechanical coupling effect. Int J Adv Manuf Technol 115:487–501. https://doi.org/10.1007/s00170-021-07221-0

Li WT, Huang B, Bi ZB (2004) Theoretical analysis and application of thermal stress. Electric Power Press, China

Bian W, Wang ZH, Yuan JT, Xu WW (2016) Thermo-mechanical analysis of angular contact ball bearing. J Mech Sci and Technol 30(1):297–306. https://doi.org/10.1007/s12206-015-1233-4

Harris T, Kotzalas M (2009) Analysis of rolling bearing (volume I): essential concepts of bearing technology. Machine Industry Press, Beijing

Luo JW, Luo TY (2009) Analysis, calculation and application of rolling bearing. Machine Industry Press, Beijing

Liu T, Gao WG, Zhang DW, Zhang YF, Chang WF, Liang CM, Tian YL (2017) Analytical modeling for thermal errors of motorized spindle unit. Int J Mach Tools Manuf 112:53–70. https://doi.org/10.1016/j.ijmachtools.2016.09.008

Xu M, Jiang SY, Cai Y (2007) An improved thermal model for machine tool bearings. Int J Mach Tools Manuf 47(1):53–62. https://doi.org/10.1016/j.ijmachtools.2006.02.018

Ramesh R, Mannan M, Poo A (2000) Error compensation in machine tools—a review: part I: geometric, cutting-force induced and fixture-dependent errors. Int J Mach Tools Manuf 40(9):1235–1256

Grama S, Mathur A, Badhe A (2018) A model-based cooling strategy for motorized spindle to reduce thermal errors. Int J Mach Tools Manuf 132:3–16. https://doi.org/10.1016/j.ijmachtools.2018.04.004

Li Y, Zhao WH, Lan SH, Ni J, Wu WW, Lu BH (2015) A review on spindle thermal error compensation in machine tools. Int J Mach Tools Manuf 95:20–38. https://doi.org/10.1016/j.ijmachtools.2015.04.008

Li DX, Feng PF, Zhang JF, Wu ZJ, Yu DW (2014) Calculation method of convective heat transfer coefficients for thermal simulation of a spindle system based on RBF neural network. Int J Adv Manuf Technol 70(5–8):1445–1454. https://doi.org/10.1007/s00170-013-5386-y

Funding

This study was supported by the National Natural Science Foundation of China (grant number 52005152); the Natural Science Foundation of Hebei, China (grant number E2021202117), and the Basic Research Fund Project of Hebei University of Technology (grant number JBKYTD2202).

Author information

Authors and Affiliations

Contributions

T.L. is the main contributor to this paper. T.L. proposed and described the idea of thermal modeling method of spindle axial static stiffness by combining numerical simulation technology with analytical method and then performed all theoretical derivations in this study. Critically, he finished the handwriting of the manuscript as a whole. H.X. constructed the experimental platform and finished verification experiments for the proposed thermal modeling method of spindle axial static stiffness in this study. Y.Z. designed the logical structure of the whole manuscript and then finished all data analyses about experimental and simulation results. L.Z. finished all the numerical simulations about spindle structural thermal behaviors in this study. Z.J. completed the programming of numerical simulation and analytical models. Z.D. gave crucial comments onto this study for improving its technical route.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

All authors consent to participate in the author team of this submitted manuscript.

Consent for publication

The submitted manuscript is approved by all its authors for publication.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, T., Xu, H., Zhang, Y. et al. Thermal effect modeling of axial static stiffness of motorized spindle unit. Int J Adv Manuf Technol 129, 1455–1471 (2023). https://doi.org/10.1007/s00170-023-12347-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12347-4