Abstract

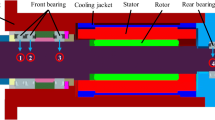

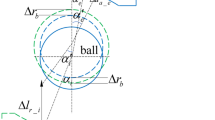

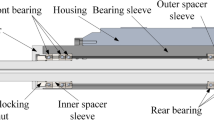

The thermal characteristics of the motorized spindle significantly affect the machining accuracy and efficiency, and many thermal models have been developed to investigate the factors that affect the spindle thermal characteristics. However, the thermomechanical coupling of the bearings with constant pressure preload is rarely considered in the present works. Thus, this paper developed a transient temperature model of motorized spindle to study the influence of the radial thermal stress on the heat generation of the constant pressure preloaded bearings. In this research, an analytical thermal stress model was established first by simplifying the components of the bearings into a rotating ring geometry to calculate the thermal stress loaded on the bearings. Meanwhile, a transient temperature model of the motorized spindle was established based on the finite element method (FEM). Then, the analytical model was integrated into the spindle transient thermal model, so that the heat generated by bearings and the motorized spindle temperature can be revised constantly, through the iterative calculation between these two models. Finally, verification experiments with different work conditions clarify that the proposed transient thermal characteristic model of the motorized spindle is valid, and the study shows that it is necessary to consider the bearing heat generation induced by the radial thermal stress when the spindle runs at a high speed.

Similar content being viewed by others

Abbreviations

- A :

-

Distance between raceway groove curvature centers (mm)

- a i/a o :

-

Semi-major axis of contact ellipse between the ball and inner/outer raceway (mm)

- B :

-

Magnetic flux density (T)

- C :

-

Electrical material constant

- c p :

-

Specific heat capacity (J/(kg·°C))

- D i/D o :

-

Bearing inner/outer nominal diameter (mm)

- d i/d o :

-

Bearing inner/outer raceway diameter (mm)

- d m :

-

Bearing pitch diameter (mm)

- D w :

-

Rolling elements diameter (mm)

- E :

-

Modulus of elasticity (MPa)

- f :

-

Magnetization frequency (Hz)

- f 0/f 1 :

-

Factor related to bearing type and lubrication method/applied force load

- F a/F r :

-

Force in axial/radial direction loaded on bearing (N)

- F cj :

-

Centrifugal force (N)

- f i/f o :

-

Ratio of bearing inner/outer raceway radius to rolling element’s diameter

- F tem :

-

Equivalent radial force loaded on rolling elements (N)

- F β :

-

Force loaded on the bearing (N)

- h :

-

Convective coefficient (W/(m2·℃))

- H ij/H oj :

-

Bearing heating in the inner/outer raceway (W)

- H si :

-

Thickness of silicon steel sheet (mm)

- I :

-

Motor winding currents (A)

- I cm :

-

Excitation current (A)

- k equ :

-

Equivalent conductivity of ring (W/(m·℃))

- k fluid :

-

Fluid thermal conductivity (W/(m·℃))

- K ij/K oj :

-

Contact stiffness between roller and outer/inner groove of bearing (Pa)

- k L/k b :

-

Grease/rolling element conductivity (W/(m·℃))

- L :

-

Hydraulic diameter

- L rotor :

-

Length of motor rotor (m)

- M :

-

Applied moment (N mm)

- M 1 :

-

Bearing friction torque due to load (N mm)

- M gj :

-

Gyroscopic moment (N mm)

- M ij/M oj :

-

Bearing friction torque in the inner/outer ring of bearing (N mm)

- M v :

-

Bearing friction torque due to lubrication (N mm)

- n :

-

Rotational speed (r/min)

- N i :

-

Shape function

- Nu:

-

Nusselt number

- P cu/P Fe :

-

Copper/iron loss (W)

- P n, P m :

-

Mechanical and magnetic loss (W)

- Pr:

-

Prandtl number

- P stator/P rotor :

-

The motor stator/rotor heating power (W)

- q :

-

Heat flux (W/m2)

- Q i/Q o :

-

Rolling element-inner/outer raceway contact normal load (N)

- r :

-

The radius of any point inside the ring (m)

- R :

-

Winding resistance (Ω)

- R cm :

-

Excitation resistance (Ω)

- Ra:

-

Rayleigh number

- R all :

-

Total resistance between bearing inner ring and outer ring (℃/W)

- R b :

-

Rolling element thermal resistance (℃/W)

- R ci/R co :

-

Grease thermal resistance (℃/W)

- Re:

-

Reynolds number

- T a :

-

Environmental temperature (℃)

- T i :

-

Node temperature (℃)

- u :

-

The radial displacement of the ring (m)

- W :

-

Bearing width (mm)

- Z :

-

Numbers of rolling elements

- ΔT :

-

Temperature rise (℃)

- Σ i/Σ o :

-

Compete elliptic integral of the second kind in the contact area between rolling element and inner/outer raceway

- \({\sigma }_{{r}_{i}\_\Delta T}^{{\text{II}}}\)/\({\sigma }_{{r}_{o}\_\Delta T}^{{\text{IV}}}\) :

-

Thermal stress on bearing inner/outer ring (Pa)

- \({\sigma }_{{r}_{i}\_0}^{{\text{II}}}\)/\({\sigma }_{{r}_{o}\_0}^{{\text{IV}}}\) :

-

Initial assembly stress on bearing inner/outer ring (Pa)

- \({\sigma }_{{r}_{i}}^{{\text{II}}}\)/\({\sigma }_{{r}_{o}}^{{\text{IV}}}\) :

-

Total stress on bearing inner/outer ring (Pa)

- ℜ i :

-

Radius of the locus of inner raceway groove curvature centers (mm)

- α :

-

Coefficient of thermal expansion

- β :

-

Ball attitude angle (°, rad)

- Γq, Γh :

-

The second/third boundary

- δ a/δ r :

-

Bearing deflection deformation in axial/radial direction (mm)

- δ ij/δ oj :

-

Normal contact deformation between rolling element and inner/outer raceway (mm)

- δ stator -rotor :

-

Gap between stator and rotor (m)

- Δψ :

-

Angular distance between rolling elements (°, rad)

- ε r/ε ϕ :

-

Radial/circumferential strain of the ring

- θ :

-

Bearing misalignment or angular deflection (°, rad)

- μ :

-

Poisson’s ratio

- μ si, μ so :

-

Friction coefficient between the rolling element and the inner/outer raceway

- μ air :

-

Friction coefficient between rotor and air

- ν 0 :

-

Kinematic viscosity of grease (Pas)

- ρ :

-

Density (kg/m3)

- ρ air :

-

Density of air (kg/m3)

- ρ ball :

-

Density of rolling elements (kg/m3)

- ρ m :

-

Rotor core density (kg/m3)

- ρ r :

-

Core resistivity (Ω m−1)

- σ r/σ ϕ :

-

Radial/circumferential stress of the ring (Pa)

- ψ j :

-

Angle of rolling elements in yz plane (°, rad)

- ω :

-

Rotational speed (rad/s)

- ω b :

-

Speed of rolling element about its own axis (rad/s)

- ω c :

-

Orbital speed of rolling elements (rad/s)

- ω si/ω so :

-

Spinning speed of the inner/outer raceway relative to the rolling elements (rad/s)

- [C] :

-

Heat capacity matrix

- [K] :

-

Heat transfer matrix

- {f} :

-

Thermal load vector

- [B] :

-

Geometry matrix

- [D] :

-

Property matrix

- L :

-

Partial differential operator

- [K] dis :

-

Stiffness matrix

- {f} dis :

-

Load vector

- g :

-

Volumetric force vector

- q b :

-

Load Vector

References

Putz M, Richter C, Regel J et al (2018) Industrial consideration of thermal issues in machine tools. Prod Eng Res Devel 12:723–736. https://doi.org/10.1007/s11740-018-0848-6

Liu H, Birembaux H, Ayed Y et al (2022) Recent advances on cryogenic assistance in drilling operation: a critical review. J Manuf Sci Eng 144:100801. https://doi.org/10.1115/1.4054518

Putz M, Richter C, Regel J et al. (2018) Industrial relevance and causes of thermal issues in machine tools. Proceedings Conference on Thermal Issues in Machine Tools, 1st edn. Wissenschaftliche Scripten, Auerbach/Vogtland: 127–139.

Weck M, McKeown P, Bonse R et al (1995) Reduction and compensation of thermal errors in machine tools. CIRP Annals 44:589–598. https://doi.org/10.1016/S0007-8506(07)60506-X

Bryan J (1990) International status of thermal error research (1990). CIRP Annals 39:645–656. https://doi.org/10.1016/S0007-8506(07)63001-7

ISO/DIS 10791–10:2021(2021) Test conditions for machining centres — part 10: evaluation of thermal distortions.

ISO 230–3. (2020) Test code for machine tools part 3: determination of thermal effects, Institution, British Standards.

Li Y, Zhao W, Lan S et al (2015) A review on spindle thermal error compensation in machine tools. Int J Mach Tools Manuf 95:20–38. https://doi.org/10.1016/j.ijmachtools.2015.04.008

Abele E, Altintas Y, Brecher C (2010) Machine tool spindle units. CIRP Ann 59:781–802. https://doi.org/10.1016/j.cirp.2010.05.002

Yan K, Hong J, Zhang J et al (2016) Thermal-deformation coupling in thermal network for transient analysis of spindle-bearing system. Int J Therm Sci 104:1–12. https://doi.org/10.1016/j.ijthermalsci.2015.12.007

Su C, Chen W (2022) An improved model of motorized spindle for forecasting temperature rise based on thermal network method. Int J Adv Manuf Technol 119:5969–5991. https://doi.org/10.1007/s00170-021-08592-0

Su C, Chen W (2021) Thermal behavior on motorized spindle considering bearing thermal deformation under oil-air lubrication. J Manuf Process 72:483–499. https://doi.org/10.1016/j.jmapro.2021.10.041

Bossmanns B, Tu JF (1999) A thermal model for high speed motorized spindles 39, Int J Mach Tools Manuf, 39(9):1345–1366. https://doi.org/10.1016/S0890-6955(99)00005-X

Liu H, Xu X, Zhang J et al (2022) The state of the art for numerical simulations of the effect of the microstructure and its evolution in the metal-cutting processes. Int J Mach Tools Manuf 177:103890. https://doi.org/10.1016/j.ijmachtools.2022.103890

Chen B, Guan X, Cai D et al (2022) Simulation on thermal characteristics of high-speed motorized spindle. Case Stud Therm Eng 35:102144. https://doi.org/10.1016/j.csite.2022.102144

Dai Y, Wang J, Li Z et al (2021) Thermal performance analysis and experimental study of high-speed motorized spindle based on the gradient descent method. Case Stud Therm Eng 26:101056. https://doi.org/10.1016/j.csite.2021.101056

Uhlmann E, Hu J (2012) Thermal modelling of a high speed motor spindle. Procedia CIRP 1:313–318. https://doi.org/10.1016/j.procir.2012.04.056

Creighton E, Honegger A, Tulsian A et al (2010) Analysis of thermal errors in a high-speed micro-milling spindle. Int J Mach Tools Manuf 50:386–393. https://doi.org/10.1016/j.ijmachtools.2009.11.002

Brecher C, Ihlenfeldt S, Neus S et al (2019) Thermal condition monitoring of a motorized milling spindle. Prod Eng Res Devel 13:539–546. https://doi.org/10.1007/s11740-019-00905-3

Liu T, Gao W, Zhang D et al (2017) Analytical modeling for thermal errors of motorized spindle unit. Int J Mach Tool Manu 112:53–70

Holkup T, Cao H, Kolář P et al (2010) Thermo-mechanical model of spindles. CIRP Ann 59:365–368. https://doi.org/10.1016/j.cirp.2010.03.021

Ma C, Yang J, Zhao L et al (2015) Simulation and experimental study on the thermally induced deformations of high-speed spindle system. Appl Therm Eng 86:251–268. https://doi.org/10.1016/j.applthermaleng.2015.04.064

Liu J, Ma C, Wang S et al (2019) Thermal-structure interaction characteristics of a high-speed spindle- bearing system. Int J Mach Tools Manuf 137:42–57. https://doi.org/10.1016/j.ijmachtools.2018.10.004

Palmgren A (1959) Ball and roller bearing engineering. SKF Industries Inc, Philadelphia

Grama SN, Mathur A, Badhe AN (2018) A model-based cooling strategy for motorized spindle to reduce thermal errors. Int J Mach Tools Manuf 132:3–16. https://doi.org/10.1016/j.ijmachtools.2018.04.004

Cuiping L, Yulong P, Ronggang N et al. (2011) Analysis of 3d static temperature field of water cooling induction motor in mini electric vehicle. Int Conf Electr Mach Syst. IEEE: 1–5. https://doi.org/10.1109/ICEMS.2011.6073618

Incropera FP, DeWitt DP, Bergman TL et al (1996) Fundamentals of heat and mass transfer. Wiley, New York

Acknowledgements

The first author would like to thank the China Scholarship Council (CSC) for financial support and the scholarship award.

Funding

This work was financially supported by the Key-Area Research and Development Program of Guangdong Province (Grant No. 2020B090927002).

Author information

Authors and Affiliations

Contributions

DS: methodology, data curation, formal analysis, writing – original draft, review and editing; YL: conceptualization, supervision, funding acquisition, writing – review and editing; WZ: conceptualization, supervision, writing – review and editing; HZ, ZN: data curation, validation, writing – review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Su, D., Li, Y., Zhao, W. et al. Modeling of the motorized spindle temperature field considering the thermos-mechanical coupling on constant pressure preloaded bearings. Int J Adv Manuf Technol 132, 1969–1988 (2024). https://doi.org/10.1007/s00170-024-13306-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13306-3