Abstract

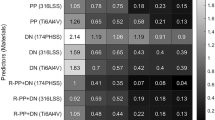

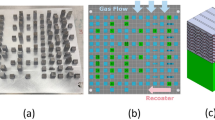

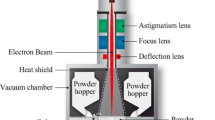

The laser powder bed fusion (LPBF) process is commonly used in additive manufacturing (AM) to produce integrated parts from metallic powder. However, this process can result porosity in fabricated components due to gas bubbles or lack of fusion. In this study, four different methods (response surface methodology, artificial neural network, fuzzy logic, and adaptive-network-based fuzzy inference system (ANFIS)) were employed to predict the correlation between process parameters and porosity levels in AlSi10Mg alloy produced by the LPBF process. The ANFIS method utilizes fuzzy rules and artificial neural networks to predict the impact of process parameters, such as island size, hatch space, scan speed, and laser power on porosity levels. The results shows that the laser power and scan speed have a significant effect on the volume of porosity, while the influence of island size and hatch space were slighter in the LPBF process of AlSi10Mg alloy. Furthermore, the ANFIS model demonstrates an excellent fitting parameter with an R2 value of more than 0.99 for the total data and an RMSE of about 0.67 for the output. This result indicates that the ANFIS method is the best model among all the methods tested in accurately predicting the process target. The success of the ANFIS method in this study suggests that it is a robust and reliable technique for predicting porosity levels in the LPBF process.

Similar content being viewed by others

References

Wang L-Z, Wang S, Wu J-J (2017) Experimental investigation on densification behavior and surface roughness of AlSi10Mg powders produced by selective laser melting. Opt Laser Technol 96:88–96

Li W et al (2016) Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: microstructure evolution, mechanical properties and fracture mechanism. Mater Sci Eng, A 663:116–125

Cáceres C, Davidson C, Griffiths J (1995) The deformation and fracture behaviour of an Al Si Mg casting alloy. Mater Sci Eng, A 197(2):171–179

Tradowsky U, White J, Ward R, Read N, Reimers W, Attallah M (2016) Selective laser melting of AlSi10Mg: influence of post-processing on the microstructural and tensile properties development. Mater Des 105:212–222

Wang L, Liu Y, Chang S (2016) Fabrication of spherical AlSi10Mg powders by radio frequency plasma spheroidization. Metall and Mater Trans A 47(5):2444–2453

Shafaie M, Khademi M, Sarparast M, Zhang H (2022) Modified GTN parameters calibration in additive manufacturing of Ti-6Al-4 V alloy: a hybrid ANN-PSO approach. Int J Adv Manuf Technol 123(11):4385–4398

Sadeghi E, Karimi P, Esmaeilizadeh R, Berto F, Shao S, Moverare J, ... Shamsaei N (2022) A state-of-the-art review on fatigue performance of powder bed fusion-built alloy 718. Prog Mater Sci 133:101066

Thijs L, Kempen K, Kruth J-P, Van Humbeeck J (2013) Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater 61(5):1809–1819

Mohsen Sarparast MS, Babakan AM et al (2023) Investigation of ANN structure on predicting the fracture behavior of additively manufactured Ti-6Al-4V alloys https://doi.org/10.21203/rs.3.rs-2488963/v1

Elahinia M, Moghaddam NS, Andani MT, Amerinatanzi A, Bimber BA, Hamilton RF (2016) Fabrication of NiTi through additive manufacturing: a review. Prog Mater Sci 83:630–663

Schneider J, Shamsaei N, Shao S, Ghiaasiaan R, Guo S, McGill P, Belcher T (2022) Microstructure and properties of additively manufactured metal alloys. In: metal additive manufacturing for propulsion applications. American institute of aeronautics and astronautics, Inc, Reston, VA, pp 237–306

Spears TG, Gold SA (2016) In-process sensing in selective laser melting (SLM) additive manufacturing. Integr Mater Manuf Innov 5(1):16–40

Kempen K, Thijs L, Yasa E, Badrossamay M, Verheecke W, Kruth JP (2011) Process optimization and microstructural analysis for selective laser melting of AlSi10Mg. In: 2011 International Solid Freeform Fabrication Symposium. University of Texas at Austin

Buchbinder D, Schleifenbaum H, Heidrich S, Meiners W, Bültmann J (2011) High power selective laser melting (HP SLM) of aluminum parts. Phys Procedia 12:271–278

Rao H, Giet S, Yang K, Wu X, Davies CH (2016) The influence of processing parameters on aluminium alloy A357 manufactured by selective laser melting. Mater Des 109:334–346

Liu A, Chua CK, Leong KF (2010) Properties of test coupons fabricated by selective laser melting. Key Eng Mater 447:780–784

Calignano F, Manfredi D, Ambrosio E, Iuliano L, Fino P (2013) Influence of process parameters on surface roughness of aluminum parts produced by DMLS. Int J Adv Manuf Technol 67(9):2743–2751

Wu H et al (2021) Selective laser melted AlSi10Mg alloy under melting mode transition: microstructure evolution, nanomechanical behaviors and tensile properties. J Alloy Compd 873:159823

Read N, Wang W, Essa K, Attallah MM (2015) Selective laser melting of AlSi10Mg alloy: process optimisation and mechanical properties development. Mater Des 1980–2015(65):417–424

Kempen K, Thijs L, Van Humbeeck J, Kruth J-P (2015) Processing AlSi10Mg by selective laser melting: parameter optimisation and material characterisation. Mater Sci Technol 31(8):917–923

Behvar A, Eftekhary H, Cheraghi A, Adazbeh M (2018) Microscopic illustration of zinc evaporation and ZnO nanowire production during brass alloy sintering. Int J Eng Technol 10(4):932–941

Zhao L, Macías JGS, Douillard T, Li Z, Simar A (2021) Unveiling damage sites and fracture path in laser powder bed fusion AlSi10Mg: comparison between horizontal and vertical loading directions. Mater Sci Eng, A 807:140845

Xiong Z, Liu S, Li S, Shi Y, Yang Y, Misra R (2019) Role of melt pool boundary condition in determining the mechanical properties of selective laser melting AlSi10Mg alloy. Mater Sci Eng, A 740:148–156

Li X et al (2021) Effect of construction angles on microstructure and mechanical properties of AlSi10Mg alloy fabricated by selective laser melting. J Alloy Compd 881:160459

Quintana MJ, Temple AJ, Harlow DG, Collins PC (2022) On the prediction of uniaxial tensile behavior beyond the yield point of wrought and additively manufactured Ti-6Al-4V. Integrating Materials and Manufacturing Innovation 11(3):327–338

Ahmadianfar I, Shirvani-Hosseini S, He J, Samadi-Koucheksaraee A, Yaseen ZM (2022) An improved adaptive neuro fuzzy inference system model using conjoined metaheuristic algorithms for electrical conductivity prediction. Sci Rep 12(1):1–34

Khaimovich A, Balyakin A, Oleynik M, Meshkov A, Smelov V (2022) Optimization of process parameters for powder bed fusion additive manufacturing using a linear programming method: a conceptual framework. Metals 12(11):1976

Xia C, Pan Z, Polden J, Li H, Xu Y, Chen S (2022) Modelling and prediction of surface roughness in wire arc additive manufacturing using machine learning. J Intell Manuf 33(5):1467–1482

Jang J-S (1993) ANFIS: adaptive-network-based fuzzy inference system. IEEE Trans Syst Man Cybern 23(3):665–685

Chigilipalli BK, Veeramani A (2022) An experimental investigation and neuro-fuzzy modeling to ascertain metal deposition parameters for the wire arc additive manufacturing of Incoloy 825. CIRP J Manuf Sci Technol 38:386–400

Sai T, Pathak VK, Srivastava AK (2020) Modeling and optimization of fused deposition modeling (FDM) process through printing PLA implants using adaptive neuro-fuzzy inference system (ANFIS) model and whale optimization algorithm. J Braz Soc Mech Sci Eng 42(12):1–19

Biswas A, Roy SS (2023) An adaptive neuro-fuzzy-based methodology for prediction of surface roughness in wire arc additive manufacturing. In Recent Trends in Product Design and Intelligent Manufacturing Systems: Springer, pp 739–747

Rong-Ji W, Xin-Hua L, Qing-Ding W, Lingling W (2009) Optimizing process parameters for selective laser sintering based on neural network and genetic algorithm. Int J Adv Manuf Technol 42(11):1035–1042

Garg A, Lam JSL, Savalani M (2015) A new computational intelligence approach in formulation of functional relationship of open porosity of the additive manufacturing process. Int J Adv Manuf Technol 80(1):555–565

Garg A, Lam JSL (2015) Measurement of environmental aspect of 3-D printing process using soft computing methods. Measurement 75:210–217

Krishnan M et al (2014) On the effect of process parameters on properties of AlSi10Mg parts produced by DMLS. Rapid Prototyp J 20(6):449–458

Sarparast M, Ghoreishi M, Jahangirpoor T, Tahmasbi V (2019) Modelling and optimisation of temperature and force behaviour in high-speed bone drilling. Biotechnol Biotechnol Equip 33(1):1616–1625

Abdollahzadeh M et al (2022) Estimating the density of deep eutectic solvents applying supervised machine learning techniques. Sci Rep 12(1):4954

Pujol J (2007) The solution of nonlinear inverse problems and the Levenberg-Marquardt method. Geophysics 72(4):W1–W16

Paermentier B, Debruyne D, Talemi R (2021) A machine learning based sensitivity analysis of the GTN damage parameters for dynamic fracture propagation in X70 pipeline steel. Int J Fract 227(1):111–132

Shafaie M, Biglari FR, Keneshlou M, Gharib AR (2023) Blank shape optimization in sheet metal processing using a hybrid fuzzy-sensitivity method. Int J Comput Integr Manuf 36(4):511–523

Dolatabadi M, Mehrabpour M, Esfandyari M, Alidadi H, Davoudi M (2018) Modeling of simultaneous adsorption of dye and metal ion by sawdust from aqueous solution using of ANN and ANFIS. Chemom Intell Lab Syst 181:72–78

. MATLAB (2019) 9.6. 0.1072779 (R2019a). The MathWorks Inc.: Natick

Rajurkar S, Verma NK (2017) Developing deep fuzzy network with Takagi Sugeno fuzzy inference system. In: 2017 IEEE International Conference on Fuzzy Systems (FUZZ-IEEE). IEEE, pp 1–6

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Babakan, A.M., Davoodi, M., Shafaie, M. et al. Predictive modeling of porosity in AlSi10Mg alloy fabricated by laser powder bed fusion: A comparative study with RSM, ANN, FL, and ANFIS. Int J Adv Manuf Technol 129, 1097–1108 (2023). https://doi.org/10.1007/s00170-023-12333-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12333-w