Abstract

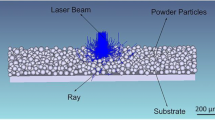

Selective laser sintering (SLS) is an attractive rapid prototyping (RP) technology capable of manufacturing parts from a variety of materials. However, the wider application of SLS has been limited, due to their accuracy. This paper presents an optimal method to determine the best processing parameter for SLS by minimizing the shrinkage. According to the nonlinear and multitudinous processing parameter feature of SLS, the theory and the algorithms of the neural network are applied for studying SLS process parameters. The process is modeled and described by neural network based on experiment. Moreover, the optimum process parameters, such as layer thickness, hatch spacing, laser power, scanning speed, work surroundings temperature, interval time, and scanning mode are obtained by adopting the genetic algorithm based on the neural network model. The optimum process parameters will be benefit for RP users in creating RP parts with a higher level of accuracy.

Similar content being viewed by others

References

Sun SH, Chiang HW, Lee MI (2007) Adaptive direct slicing of a commercial CAD model for use in rapid prototyping. Int J Adv Manuf Technol 34(13):689–701 doi:10.1007/s00170-006-0651-y

Santosa EC, Shiomia M, Osakadaa K, Laoui T (2006) Rapid manufacturing of metal components by laser forming. Int J Mach Tools Manuf 46(12–13):1459–1468

Chen X, Wang C, Ye X, Xiao Y, Huang S (2001) Direct slicing from Power SHAPE models for rapid prototyping. Int J Adv Manuf Technol 17(7):543–547 doi:10.1007/s001700170156

Li XS, Han M, Shi YS (2001) Model of shrinking and curl distortion for SLS prototypes. Chin J Mech Eng 12(8):887–889

John DW, Carl RD (1998) Advances in modeling the effects of selected parameters on the SLS process. Rapid Prototyping J 4(2):90–96 doi:10.1108/13552549810210257

Yang H-J, Huang P-J, Lee SH (2002) A study on shrinkage compensation of SLS process by using the Taguchi method.. Int J Mach Tools Manuf 42(10):1203–1212 doi:10.1016/S0890-6955(02)00070-6

Masood SH, Ratanaway W, Iovenitti P (2003) A genetic algorithm for best part orientation system for complex parts in rapid prototyping. J Mater Process Technol 139(3):110–116 doi:10.1016/S0924-0136(03)00190-0

Bai PK, Cheng J, Liu B, Wang WF (2006) Numerical simulation of temperature field during selective laser sintering of polymer-coated molybdenum powder. Trans Nonferrous Met Soc China 16(3):603–607 doi:10.1016/S1003-6326(06)60264-1

Arni RK, Gupta SK (1999) Manufacturability analysis for solid freeform fabrication. In: Proceedings of DETC 1999 ASME Design Engineering Technical conference, Vegas, NV, pp 1–12

Armillotta A, Biggioggero GF (2001) Control of prototyping surface finish through graphical simulation. In: Proceedings of the 7th ADM International conferences, Grand Hotel, Rimini, Italy, pp 17–24

Shi Y, Liu J, Huang S (2002) The research of the SLS process optimization based on the hybrid of neural network and expert system. In: Proceedings of the International Conference on Manufacturing Automation, pp 409–418

Zheng HZ, Zhang J, Lu SQ, Wang GH, Xu ZF (2006) Effect of core–shell composite particles on the sintering behavior and properties of nano-Al2O3/polystyrene composite prepared by SLS. Mater Lett 60(9–10):1219–1223 doi:10.1016/j.matlet.2005.11.003

Mehrotra P, Quaicoe JE, Venkatesan R (1996) Speed estimation of induction motor using artificial neural networks. IEEE Trans Neural Netw 6:881–886

Droogers P, Stein A, Bouma J, De BG, Keeler JD, Hartman E et al (1998) Process modeling and optimization using focused attention neural networks. ISA Trans 37(1):41–52 doi:10.1016/S0019-0578(98)00005-6

Kermani BG, Schiffman SS, Nagle HT (1999) Using neural networks and genetic algorithms to Enhance performance in an electronic nose. IEEE Trans Biomed Eng 46(4):429–450 doi:10.1109/10.752940

Xing ZY, Jia LM, Shi TY (2002) Self-tuning of controller using neural network and genetic algorithm. In: Proceedings of the 4th World Congress on Intelligent Control Automation, Shanghai, People’s Republic of China, pp 748–752

Hornik K, Stinchcombe M, White H (1989) Multilayer feedforward networks are universal approximators. Neural Netw 2(5):359–366 doi:10.1016/0893-6080(89)90020-8

Martin TH, Howard BD (2002) Neural network design. China Machine, Beijing

Luisa DV, Marco M, Luciana R (1995) Neural network architectures for industrial applications. Biosens Bioelectron 10(3):231–236

Fogel DB (1994) An introduction to simulated evolutionary optimization. IEEE Trans Neural Netw 5(1):3–14 doi:10.1109/72.265956

Painton L, Campbell J (1995) Genetic algorithms in optimization of system reliability. IEEE Trans Reliab 44(2):172–178 doi:10.1109/24.387368

Baker JE (1987) Reducing bias and inefficiency in the selection algorithm. In: Proceedings of the 2nd International Conference on Genetic Algorithms and their Application, Hillsdate, NJ, pp 14–21

Syswerda G (1989) Uniform crossover in genetic algorithms. In: Proceedings of the 3rd International Conference on Genetic Algorithms, San Mateo, CA, pp 2–9

Yasser A, Hussein SM, Ghazaly EI (2004) Modeling and optimization of microwave devices and circuits using genetic algorithms. IEEE Trans Microwave Theor Tech 52(1):329–336

Wang RJ (2005) The experiment and optimization approaches research on selective laser sintering process. Hunan University, Changsha, People’s Republic of China

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rong-Ji, W., Xin-hua, L., Qing-ding, W. et al. Optimizing process parameters for selective laser sintering based on neural network and genetic algorithm. Int J Adv Manuf Technol 42, 1035–1042 (2009). https://doi.org/10.1007/s00170-008-1669-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1669-0