Abstract

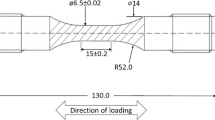

GH4169 superalloy is widely used in the manufacture of key components such as high-pressure turbine disks, turbine blades, and combustion chambers of gas turbines and aero-engines. However, mechanical and metallurgical properties of the surface layer have changed significantly on account of the cutting process, which is easy to cause fatigue failure. Therefore, surface strengthening of GH4169 superalloy subjected to ultrasonic surface rolling process (USRP) is investigated, involved with the mechanical properties and microstructure of the surface layer. The findings demonstrate that the USRP treatment reduces the surface roughness of the basis sample by 93% (from 1.17 to 0.08 µm). The USRP treatments improve the degree of the grain refinement, the number proportion of low-angle grain boundaries, and dislocation density. The depth of residual compressive stress layer and hardened layer of the samples subjected to USRP treatment are improved to 0.6 mm. Moreover, finite element models are utilized to aid in the research of the USRP treatment, especially the stress and strain fields.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Roy S, Kumar R, Anurag PA, Das RK (2018) A brief review on machining of Inconel 718. Mater Today: Proc 5(9):18664–18673

Liu YM, Wang L, Chen G, Li BB, Wang XH (2019) Investigation on ratcheting-fatigue behavior and damage mechanism of GH4169 at 650 ℃. Mat Sci Eng A-Struc 743:314–321

Zhang X-C, Li H-C, Zeng X, Tu S-T, Zhang C-C, Wang Q-Q (2017) Fatigue behavior and bilinear Coffin-Manson plots of Ni-based GH4169 alloy with different volume fractions of δ phase. Mat Sci Eng A-Struc 682:12–22

Kumar KS, Van Swygenhoven H, Suresh S (2003) Mechanical behavior of nanocrystalline metals and alloys11The Golden Jubilee Issue—selected topics in Materials science and engineering: past, present and future, edited by S. Suresh Acta Mater 51(19):5743–5774

Chai G, Forsman T, Gustavsson F (2016) Microscopic and nanoscopic study on subsurface damage and fatigue crack initiation during very high cycle fatigue. Int J Fatigue 83:288–292

Liu YG, Li MQ, Liu HJ (2017) Nanostructure and surface roughness in the processed surface layer of Ti-6Al-4V via shot peening. Mater Charact 123:83–90

Martinez SA, Sathish S, Blodgett MP, Mall S, Namjoshi S (2005) Effects of fretting fatigue on the residual stress of shot peened Ti-6Al-4V samples. Mat Sci Eng A-Struc 399(1–2):58–63

Zhou J, Sun Z, Kanoute P, Retraint D (2017) Effect of surface mechanical attrition treatment on low cycle fatigue properties of an austenitic stainless steel. Int J Fatigue 103:309–317

Li Q, Yan FK, Tao NR, Ponge D, Raabe D, Lu K (2019) Deformation compatibility between nanotwinned and recrystallized grains enhances resistance to interface cracking in cyclic loaded stainless steel. Acta Mater 165:87–98

Lei YB, Wang ZB, Xu JL, Lu K (2019) Simultaneous enhancement of stress- and strain-controlled fatigue properties in 316L stainless steel with gradient nanostructure. Acta Mater 168:133–142

Huang HW, Wang ZB, Lu J, Lu K (2015) Fatigue behaviors of AISI 316L stainless steel with a gradient nanostructured surface layer. Acta Mater 87:150–160

Majzoobi GH, Azadikhah K, Nemati J (2009) The effects of deep rolling and shot peening on fretting fatigue resistance of Aluminum-7075-T6. Mat Sci Eng A-Struc 516(1–2):235–247

Abrao AM, Denkena B, Kohler J, Breidenstein B, Morke T (2014) The influence of deep rolling on the surface integrity of AISI 1060 high carbon steel. Procedia CIRP 13:31–36. https://doi.org/10.1016/j.procir.2014.04.006

Kattoura M, Mannava SR, Qian D, Vasudevan VK (2017) Effect of laser shock peening on elevated temperature residual stress, microstructure and fatigue behavior of ATI 718Plus alloy. Int J Fatigue 104:366–378

Ye C, Suslov S, Lin D, Liao YL, Fei XL, Cheng GJ (2011) Microstructure and mechanical properties of copper subjected to cryogenic laser shock peening. J Appl Phys 110(8).

Messé OMDM, Stekovic S, Hardy MC, Rae CMF (2014) Characterization of plastic deformation induced by shot-peening in a Ni-base superalloy. JOM 66(12):2502–2515

Nagarajan B, Kumar D, Fan Z, Castagne S (2018) Effect of deep cold rolling on mechanical properties and microstructure of nickel-based superalloys. Mat Sci Eng A-Struc 728:196–207

Kumar S, Sudhakar Rao G, Chattopadhyay K, Mahobia GS, Santhi Srinivas NC, Singh V (2014) Effect of surface nanostructure on tensile behavior of superalloy IN718. Mater Design 62:76–82

Hua Y, Liu Z, Wang B, Hou X (2019) Surface modification through combination of finish turning with low plasticity burnishing and its effect on fatigue performance for Inconel 718. Surf Coat Tech 375:508–517

Zhang Y, Huang C, Liu F, Liu F, Song M, Ke L (2021) Nanocrystallization of a Ti40 cladding layer by ultrasonic impact to improve burn resistance. J Mater Res Technol 11:1331–1342

Li YG, Lian GH, Geng JW, Song CF, Chen D, Wang HW (2021) Effects of ultrasonic rolling on the surface integrity of in-situ TiB2/2024Al composite. J Mater Process Tech 293:117068

Bozdana AT, Gindy NNZ, Li H (2005) Deep cold rolling with ultrasonic vibrations - a new mechanical surface enhancement technique. Int J Mach Tool Manu 45(6):713–718

Ting W, Dongpo W, Gang L, Baoming G, Ningxia S (2008) Investigations on the nanocrystallization of 40Cr using ultrasonic surface rolling processing. Appl Surf Sci 255(5):1824–1829

Li CY, Zhu RT, Zhang XX, Huang PF, Wang X, Wang X (2020) Impact of surface ultrasonic rolling on cavitation erosion behavior of 304 stainless steel. Surf Coat Tech 383:125280

Xu XC, Liu DX, Zhang XH, Liu CS, Liu D, Zhang WC (2019) Influence of ultrasonic rolling on surface integrity and corrosion fatigue behavior of 7B50-T7751 aluminum alloy. Int J Fatigue 125:237–248

Li FQ, Zhao B, Lan SL, Feng ZB (2020) Experiment and simulation of the effect of ultrasonic rolling on the surface properties of Ti-6Al-4V. Int J Adv Manuf Tech 106(5–6):1893–1900

Liu HW, Zheng JX, Guo YL, Zhu LX (2020) Residual stresses in high-speed two-dimensional ultrasonic rolling 7050 aluminum alloy with thermal-mechanical coupling. Int J Mech Sci 186:105824

Lipson H (1957) Elements of X-ray diffraction. Contemp Phys 20(1):87–88. https://doi.org/10.1080/00107517908227805

Johnson GR, Cook WH (1985) Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng Fract Mech 21(1):31–48

Ozel T, Zeren E (2007) Finite element modeling the influence of edge roundness on the stress and temperature fields induced by high-speed machining. Int J Adv Manuf Tech 35(3–4):255–267

Pereira JM, Lerch BA (2001) Effects of heat treatment on the ballistic impact properties of Inconel 718 for jet engine fan containment applications. Int J Impact Eng 25(8):715–733

Zhou JM, Bushlya V, Peng RL, Johansson S, Avdovic P, Stahl JE (2011) Effects of tool wear on subsurface deformation of nickel-based superalloy. Procedia Eng 19:407–413

Sakai T, Belyakov A, Kaibyshev R, Miura H, Jonas JJ (2014) Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog Mater Sci 60:130–207

Yu H, Jin Y, Hu L, Wang Y (2020) Mechanical properties of the solution treated and quenched Al–Cu–Li alloy (AA2195) sheet during high strain rate deformation at room temperature. Mat Sci Eng A-Struc 793:139880

Warren A, Guo Y (2006) On the clarification of surface hardening by hard turning and grinding. J Trans North Am Manuf Res Inst SME 34:309–316

Su J, Raabe D, Li Z (2019) Hierarchical microstructure design to tune the mechanical behavior of an interstitial TRIP-TWIP high-entropy alloy. Acta Mater 163:40–54

Li Z, Wang Y, Cheng X, Li Z, Du J, Li S (2020) The effect of Ti–Mo–Nb on the microstructures and tensile properties of a Fe–Mn–Al–C austenitic steel. Mat Sci Eng A-Struc 780:139220

Zhao R, Han JQ, Liu BB, Wan M (2016) Interaction of forming temperature and grain size effect in micro/meso-scale plastic deformation of nickel-base superalloy. Mater Design 94:195–206

Hughes DA, Hansen N (1997) High angle boundaries formed by grain subdivision mechanisms. Acta Mater 45(9):3871–3886

Liu M, Li X, Zhang Y, Song C, Zhai Q (2021) Multiphase precipitation and its strengthening mechanism in a V-containing austenite-based low density steel. Intermetallics 134:107179

Gao H, Huang Y (2003) Geometrically necessary dislocation and size-dependent plasticity. Scripta Mater 48(2):113–118

Prevéy PS (2000) The effect of cold work on the thermal stability of residual compression in surface enhanced IN718. Proceedings of the 20th ASM Materials Solutions Conference & Exposition, pp 10–12

Li W, Withers PJ, Axinte D, Preuss M, Andrews P (2009) Residual stresses in face finish turning of high strength nickel-based superalloy. J Mater Process Tech 209(10):4896–4902

Acknowledgements

We thank State Key Laboratory of Metal Matrix Composites for providing USRP treatment, and we thank other members of the laboratory who made suggestions during the experimental process and the paper formation process.

Funding

The investigation was supported by National Science and Technology Major Project (Y2019-VII-0018–0160).

Author information

Authors and Affiliations

Contributions

Weiwei Yu, Qinglong An, Ming Chen, Haowei Wang and Dong Chen had designed the framework and research route of the whole work; Weiwei Yu and Jie Wu had conducted the experimental operations; Weiwei Yu had accomplished the data treatment and analysis; Weiwei Yu and Ming Chen had finished the organization and writing work of the paper; all authors discussed the results and they had revised and modified the manuscript.

Corresponding author

Ethics declarations

Ethics approval

This paper is new. Neither the entire paper nor any part of its content has been published or has been accepted elsewhere. It is not being submitted to any other journal as well.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yu, W., Wu, J., Li, Y. et al. Investigations on surface modification of nickel-based superalloy subjected to ultrasonic surface rolling process. Int J Adv Manuf Technol 129, 1473–1488 (2023). https://doi.org/10.1007/s00170-023-12299-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12299-9