Abstract

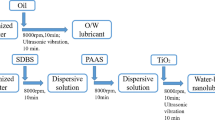

During past decades, water-based and oil-in-water (O/W) based nanolubricants with nanoparticles (NPs) as additives have been developed to replace conventional oil-based lubricants for solving contamination problems during rolling processes. The formulations of nanolubricants for rolling need to be continuously improved to provide better lubrication performance. This article reviews the formulation, physicochemical properties, and lubrication mechanisms during rolling with water-based and O/W based nanolubricants, and the effects of nanolubricants on rolling force, surface roughness and oxide skin formation during rolling are discussed. This review aims to facilitate the fundamental understanding of nanolubrication and the development of rolling lubrication technology.

Similar content being viewed by others

Data availability

All data gathered regarding this publication is presented.

Code availability

Not applicable

References

Spuzic S, Strafford KN, Subramanian C, Savage G (1994) Wear of hot rolling mill rolls: an overview. Wear 176(2):261–271

Zhang S, Che L, Liu X (2021) Modelling of deformation resistance with big data and its application in the prediction of rolling force of thick plate. Math Probl Eng 2021:1–10

Zhang S, Deng L, Zhang Q, Li Q, Hou J (2019) Modeling of rolling force of ultra-heavy plate considering the influence of deformation penetration coefficient. Int J Mech Sci 159:373–381

Zhang S, Deng L, Che L (2022) An integrated model of rolling force for extra-thick plate by combining theoretical model and neural network model. J Manuf Process 75:100–109

Fu P, Zhao J, Zhang X, Miao H, Wen Z, Kang G, Kan Q (2023) Three-dimensional tractive rolling contact analysis of functionally graded coating-substrate systems with interfacial imperfection and frictional anisotropy. Compos Struct 307:116671

Shokrani A, Dhokia V, Newman ST (2012) Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int J Mach Tools Manuf 57:83–101

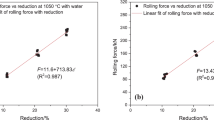

Xia WZ, Zhao JW, Wu H, Jiao SH, Jiang ZY (2016) Study on tribological property of nano-Tio 2 additive oil-in-water lubricant during hot rolling. Mater Sci Forum 874:381–386

Bao Y, Sun J, Kong L (2017) Effects of nano-SiO2 as water-based lubricant additive on surface qualities of strips after hot rolling. Tribol Int 114:257–263

Xia W, Zhao J, Wu H, Zhao X, Zhang X, Xu J, Jiang Z (2016) Effects of nano-TiO2 additive in oil-in-water lubricant on contact angle and antiscratch behavior. Tribol Trans 60(2):362–372

Xie H, Dang S, Jiang B, Xiang L, Zhou S, Sheng H, Pan F (2019) Tribological performances of SiO2/graphene combinations as water-based lubricant additives for magnesium alloy rolling. Appl Surf Sci 475:847–856

Wu H, Jia F, Li Z, Lin F, Huo M, Huang S, Jiang Z (2020) Novel water-based nanolubricant with superior tribological performance in hot steel rolling. Int J Extr Manuf 2(2):02500

Huang S, Wu H, Jiang Z, Huang H (2021) Water-based nanosuspensions: formulation, tribological property, lubrication mechanism, and applications. J Manuf Process 71:625–644

Wu H, Zhao J, Xia W, Cheng X, He A, Yun JH, Jiang Z (2017) Analysis of TiO2 nano-additive water-based lubricants in hot rolling of microalloyed steel. J Manuf Process 27:26–36

Bao YY, Sun JL, Kong LH (2017) Tribological properties and lubricating mechanism of SiO2 nanoparticles in water-based fluid. IOP Conf Ser: Mater Sci Eng 182(1):012025

He A, Huang S, Yun J-H, Wu H, Jiang Z, Stokes J, Huang H (2017) Tribological performance and lubrication mechanism of alumina nanoparticle water-based suspensions in ball-on-three-plate testing. Tribol Lett 65:1–11

Tonk R (2021) The science and technology of using nano-materials in engine oil as a lubricant additives. Mater Today: Proceedings 37:3475–3479

Kong L, Sun J, Bao Y (2017) Preparation, characterization and tribological mechanism of nanofluids. RSC Adv 7(21):12599–12609

Zhang S, Hu L, Feng D, Wang H (2013) Anti-wear and friction-reduction mechanism of Sn and Fe nanoparticles as additives of multialkylated cyclopentanes under vacuum condition. Vacuum 87:75–80

Padgurskas J, Rukuiza R, Prosyčevas I, Kreivaitis R (2013) Tribological properties of lubricant additives of Fe, Cu and Co nanoparticles. Tribol Int 60:224–232

Jason YJJ, How HG, Teoh YH, Chuah HG (2020) A study on the tribological performance of nanolubricant. Processes 8(11):1372

Kilincarslan E, Kabave Kilincarslan S, Cetin MH (2021) Evaluation of the clean nano-cutting fluid by considering the tribological performance and cost parameters. Tribol Int 157:106916

Chou R, Battez AH, Cabello JJ, Viesca JL, Osorio A, Sagastume A (2010) Tribological behavior of polyalphaolefin with the addition of nickel nanoparticles. Tribol Int 43(12):2327–2332

Abad MD, Sánchez-López JC (2013) Tribological properties of surface-modified Pd nanoparticles for electrical contacts. Wear 297(1–2):943–951

Peng DX, Kang Y, Chen SK, Shu FC, Chang YP (2010) Dispersion and tribological properties of liquid paraffin with added aluminum nanoparticles. Ind Lubrication Tribol 62(6):341–348

Wu H, Jiang C, Zhang J, Huang S, Wang L, Jiao S, Jiang Z (2019) Oxidation behaviour of steel during hot rolling by using TiO2-containing water-based nanolubricant. Oxid Metals 92(3–4):315–335

Wu C, Yang K, Chen Y, Ni J, Yao L, Li X (2021) Investigation of friction and vibration performance of lithium complex grease containing nano-particles on rolling bearing. Tribol Int 155:106761

Mohana Rao G, Dilkush S, Sudhakar I, Anil babu P (2021) Effect of cutting parameters with dry and MQL nano fluids in turning of EN-36 steel. Mater Today: Proceedings 41:1182–1187

Alghani W, Karim MSA, Bagheri S, Zaharinie T, Gulzar M (2020) Formulation, tribological performance, and characterization of base oil with ZnO, graphene, and ZnO/graphene nanoparticles additives. Materialwiss Werkstofftech 51(11):1515–1532

Mello VS, Faria EA, Alves SM, Scandian C (2020) Enhancing Cuo nanolubricant performance using dispersing agents. Tribol Int 150:106338

Sun J, Meng Y, Zhang B (2021) Tribological behaviors and lubrication mechanism of water-based MoO3 nanofluid during cold rolling process. J Manuf Process 61:518–526

Singh A, Verma N, Mamatha TG, Kumar A, Singh S, Kumar K (2021) Properties, functions and applications of commonly used lubricant additives: a review. Mater Today: Proceedings 44:5018–5022

Zhou LH, Wei XC, Ma ZJ, Mei B (2017) Anti-friction performance of FeS nanoparticle synthesized by biological method. Appl Surf Sci 407:21–28

Maritsa L, Martel S, Barros R, Bol A, Aparicio S (2021) Additivation of MoS2 nanosheets to synthetic polyalpha-olefins base oils: a theoretical study of nanolubrication. J Mol Liq 332:115881

Kong N, Zhang J, Zhang J, Li H, Wei B, Li D, Zhu H (2020) Chemical- and mechanical-induced lubrication mechanisms during hot rolling of titanium alloys using a mixed graphene-incorporating lubricant. Nanomaterials (Basel) 10(4):665

Mirzaamiri R, Akbarzadeh S, Ziaei-Rad S, Shin D-G, Kim D-E (2021) Molecular dynamics simulation and experimental investigation of tribological behavior of nanodiamonds in aqueous suspensions. Tribol Int 156:106838

Meng W, Sun J, Wang C, Wu P (2020) pH-dependent lubrication mechanism of graphene oxide aqueous lubricants on the strip surface during cold rolling. Surf Interface Anal 53(4):406–417

Tonk R (2021) The challenges and benefits of using carbon nano-tubes as friction modifier lubricant additives. Materi Today: Proceedings 37:3275–3278

Singh Y, Abd Rahim E (2020) Michelia Champaca: Sustainable novel non-edible oil as nano based bio-lubricant with tribological investigation. Fuel 282:118830

Gajrani KK, Suvin PS, Kailas SV, Mamilla RS (2019) Thermal, rheological, wettability and hard machining performance of MoS2 and CaF2 based minimum quantity hybrid nano-green cutting fluids. J Mater Process Technol 266:125–139

Ali MKA, Xianjun H, Mai L, Bicheng C, Turkson RF, Qingping C (2016) Reducing frictional power losses and improving the scuffing resistance in automotive engines using hybrid nanomaterials as nano-lubricant additives. Wear 364–365:270–281

Xie H, Wei Y, Jiang B, Tang C, Nie C (2021) Tribological properties of carbon nanotube/SiO2 combinations as water-based lubricant additives for magnesium alloy. J Market Res 12:138–149

Du S, Sun J, Wu P (2018) Preparation, characterization and lubrication performances of graphene oxide-TiO2 nanofluid in rolling strips. Carbon 140:338–351

Ghasemi S, Shanaghi A, Chu PK (2017) Nano mechanical and wear properties of multi-layer Ti/TiN coatings deposited on Al 7075 by high-vacuum magnetron sputtering. Thin Solid Films 638:96–104

Xie H, Jiang B, Liu B, Wang Q, Xu J, Pan F (2016) An investigation on the tribological performances of the SiO2/MoS2 hybrid nanofluids for magnesium alloy-steel contacts. Nanoscale Res Lett 11(1):329

Chen L, Xu H, Cui H, Zhou H, Wan H, Chen J (2017) Preparation of Cu–Ni bimetallic nanoparticles surface-capped with dodecanethiol and their tribological properties as lubricant additive. Particuology 34:89–96

Sanchez C, Chen Y, Parkinson DY, Liang H (2017) In situ probing of stress-induced nanoparticle dispersion and friction reduction in lubricating grease. Tribol Int 111:66–72

Saini V, Bijwe J, Seth S, Ramakumar SSV (2020) Role of base oils in developing extreme pressure lubricants by exploring nano-PTFE particles. Tribol Int 143:106071

Wang Y, Wan Z, Lu L, Zhang Z, Tang Y (2018) Friction and wear mechanisms of castor oil with addition of hexagonal boron nitride nanoparticles. Tribol Int 124:10–22

Wang B, Zhong Z, Qiu H, Chen D, Li W, Li S, Tu X (2020) Nano serpentine powders as lubricant additive: tribological behaviors and self-repairing performance on worn surface. Nanomaterials (Basel) 10(5):922

Dai W, Kheireddin B, Gao H, Liang H (2016) Roles of nanoparticles in oil lubrication. Tribol Int 102:88–98

Du F, Li C, Li D, Sa X, Yu Y, Li C, Wang J (2022) Research progress regarding the use of metal and metal oxide nanoparticles as lubricant additives. Lubricants 10(8)

Rabaso P, Ville F, Dassenoy F, Diaby M, Afanasiev P, Cavoret J, Le Mogne T (2014) Boundary lubrication: influence of the size and structure of inorganic fullerene-like MoS2 nanoparticles on friction and wear reduction. Wear 320:161–178

Yanan M, Jianlin S, Jiaqi H, Xudong Y, Yu P (2020) Recycling prospect and sustainable lubrication mechanism of water-based MoS2 nano-lubricant for steel cold rolling process. J Clean Prod 277:123991

Wang Y, Quinsaat JEQ, Ono T, Maeki M, Tokeshi M, Isono T, Yamamoto T (2020) Enhanced dispersion stability of gold nanoparticles by the physisorption of cyclic poly(ethylene glycol). Nat Commun 11(1):6089

Yang G, Zhang Z, Zhang S, Yu L, Zhang P, Hou Y (2013) Preparation and characterization of copper nanoparticles surface-capped by alkanethiols. Surf Interface Anal 45(11–12):1695–1701

Flores-Castañeda M, Camps E, Camacho-López M, Muhl S, García E, Figueroa M (2015) Bismuth nanoparticles synthesized by laser ablation in lubricant oils for tribological tests. J Alloy Compd 643:S67–S70

Shahnazar S, Bagheri S, Abd Hamid SB (2016) Enhancing lubricant properties by nanoparticle additives. Int J Hydrogen Energy 41(4):3153–3170

Chen S, Ding Q, Gu Y, Quan X, Ma Y, Jia Y, Tang J (2021) Study of tribological properties of fullerenol and nanodiamonds as additives in water-based lubricants for amorphous carbon (a-C) coatings. Nanomaterials (Basel) 12(1):139

Cho D-H, Kim J-S, Kwon S-H, Lee C, Lee Y-Z (2013) Evaluation of hexagonal boron nitride nano-sheets as a lubricant additive in water. Wear 302(1–2):981–986

Zhang J, Zhang Y, Zhang S, Yu L, Zhang P, Zhang Z (2013) Preparation of water-soluble lanthanum fluoride nanoparticles and evaluation of their tribological properties. Tribol Lett 52(2):305–314

Hou X, He J, Yu L, Li Z, Zhang Z, Zhang P (2014) Preparation and tribological properties of fluorosilane surface-modified lanthanum trifluoride nanoparticles as additive of fluoro silicone oil. Appl Surf Sci 316:515–523

Shen T, Wang D, Yun J, Liu Q, Liu X, Peng Z (2016) Tribological properties and tribochemical analysis of nano-cerium oxide and sulfurized isobutene in titanium complex grease. Tribol Int 93:332–346

He J, Sun J, Meng Y, Pei Y (2020) Superior lubrication performance of MoS2-Al2O3 composite nanofluid in strips hot rolling. J Manuf Process 57:312–323

Khan I, Saeed K, Khan I (2019) Nanoparticles: properties, applications and toxicities. Arab J Chem 12(7):908–931

Yao Y, Wei Y, Chen S (2015) Size effect of the surface energy density of nanoparticles. Surf Sci 636:19–24

Su Y, Gong L, Chen D (2015) An investigation on tribological properties and lubrication mechanism of graphite nanoparticles as vegetable based oil additive. J Nanomater 2015:1–7

Chen Y, Zhang Y, Zhang S, Yu L, Zhang P, Zhang Z (2013) Preparation of nickel-based nanolubricant via a facile in situ one-step route and investigation of their tribological properties. Tribol Lett 51(1):73–83

Gulzar M, Masjuki HH, Kalam MA, Varman M, Zulkifli NWM, Mufti RA, Zahid R (2016) Tribological performance of nanoparticles as lubricating oil additives. J Nanopart Res 18:1–25

Chen Y, Yang K, Lin H, Zhang F, Xiong B, Zhang H, Zhang C (2022) Important contributions of multidimensional nanoadditives on the tribofilms: from formation mechanism to tribological behaviors. Compos Part B: Engineering 234:109732

Munshi AM, Singh VN, Kumar M, Singh JP (2008) Effect of nanoparticle size on sessile droplet contact angle. J Appl Phys 103(8):084315

Lim S, Horiuchi H, Nikolov AD, Wasan D (2015) Nanofluids alter the surface wettability of solids. Langmuir 31(21):5827–5835

Wu H, Zhao J, Cheng X, Xia W, He A, Yun J-H, Jiang Z (2018) Friction and wear characteristics of TiO 2 nano-additive water-based lubricant on ferritic stainless steel. Tribol Int 117:24–38

Einat M, Kalderon R (2014) High efficiency Lifter based on the Biefeld-Brown effect. AIP Adv 4(7)

Molleman B, Hiemstra T (2018) Size and shape dependency of the surface energy of metallic nanoparticles: unifying the atomic and thermodynamic approaches. Phys Chem Chem Phys 20(31):20575–20587

Wang X-J, Zhu D-S, Yang S (2009) Investigation of pH and SDBS on enhancement of thermal conductivity in nanofluids. Chem Phys Lett 470(13):107–111

Wang B-X, Zhao Y, Zhao X-P (2007) The wettability, size effect and electrorheological activity of modified titanium oxide nanoparticles. Colloids Surf, A 295(1–3):27–33

Ahangaran F, Navarchian AH (2020) Recent advances in chemical surface modification of metal oxide nanoparticles with silane coupling agents: a review. Adv Colloid Interface Sci 286:102298

Khoshkava V, Kamal MR (2013) Effect of surface energy on dispersion and mechanical properties of polymer/nanocrystalline cellulose nanocomposites. Biomacromol 14(9):3155–3163

Alzate-Carvajal N, Basiuk EV, Meza-Laguna V, Puente-Lee I, Farías MH, Bogdanchikova N, Basiuk VA (2016) Solvent-free one-step covalent functionalization of graphene oxide and nanodiamond with amines. RSC Adv 6(114):113596–113610

Kim J, Park Y-S, Veriansyah B, Kim J-D, Lee Y-W (2008) Continuous synthesis of surface-modified metal oxide nanoparticles using supercritical methanol for highly stabilized nanofluids. Chem Mater 20(20):6301–6303

Bao YY, Sun JL, Kong LH (2017) Tribological properties and lubricating mechanism of SiO2 nanoparticles in water-based fluid. 17th Iumrs International Conference in Asia (Iumrs-Ica 2016) 182

Choi JS, An SJ (2015) The effect of ph on synthesis of nano-silica using water glass. Korean J Mater Res 25(4):209–213

Xiong S, Liang D (2022) Effect of sol process on structure and luminescent properties of nano-Mn3B7O13Cl. J Mater Res 37(13):2165–2174

Hu X, Yu Y, Hou W, Zhou J, Song L (2013) Effects of particle size and pH value on the hydrophilicity of graphene oxide. Appl Surf Sci 273:118–121

Shih CJ, Lin S, Sharma R, Strano MS, Blankschtein D (2012) Understanding the pH-dependent behavior of graphene oxide aqueous solutions: a comparative experimental and molecular dynamics simulation study. Langmuir 28(1):235–241

Xiong S, Liang D, Wu H, Lin W, Chen J, Zhang B (2021) Preparation, characterization, tribological and lubrication performances of Eu doped CaWO4 nanoparticle as anti-wear additive in water-soluble fluid for steel strip during hot rolling. Appl Surf Sci 539:148090

Xiong S, Wu H, Liang D (2022) Preparation, tribological behaviour and lubrication performances of nano-CaWO4: Eu 3+ as EP additive in water-soluble fluid for laminated copper cladding steel sheet during cold rolling. Lubr Sci 34(3):196–209

He A, Huang S, Yun J-H, Jiang Z, Stokes J, Jiao S, Huang H (2017) The pH-dependent structural and tribological behaviour of aqueous graphene oxide suspensions. Tribol Int 116:460–469

Xiong S, Liang D, Kong F (2020) Effect of pH on the tribological behavior of Eu-doped WO3 nanoparticle in water-based fluid. Tribol Lett 68:1–10

Mobarak HM, Niza Mohamad E, Masjuki HH, Kalam MA, Al Mahmud KAH, Habibullah M, Ashraful AM (2014) The prospects of biolubricants as alternatives in automotive applications. Renew Sustain Energy Rev 33:34–43

Shinkarenko A, Kligerman Y, Etsion I (2009) The effect of surface texturing in soft elasto-hydrodynamic lubrication. Tribol Int 42(2):284–292

Dearn KD, Hoskins TJ, Andrei L, Walton D (2013) Lubrication regimes in high-performance polymer spur gears. Adv Tribol 2013:1–9

Hannes D, Alfredsson B (2012) Surface initiated rolling contact fatigue based on the asperity point load mechanism—a parameter study. Wear 294–295:457–468

Qu S, Hu X, Lu F, Lai F, Liu H, Zhang Y, Li X (2021) Rolling contact fatigue properties of ultrasonic surface rolling treated 25CrNi2MoV steel under different lubricant viscosities. Int J Fatig 142:105970

Liu T, Zhou C, Gao C, Zhang Y, Yang G, Zhang P, Zhang S (2020) Preparation of Cu@SiO2 composite nanoparticle and its tribological properties as water-based lubricant additive. Lubr Sci 32(2):69–79

Wu YY, Tsui WC, Liu TC (2007) Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 262(7–8):819–825

Huo M, Wu H, Xie H, Zhao J, Su G, Jia F, Jiang Z (2020) Understanding the role of water-based nanolubricant in micro flexible rolling of aluminium. Tribol Int 151:106378

Kong L, Sun J, Bao Y (2016) Research on the physicochemical and tribological properties of nano-TiO2 in the aqueous rolling liquid. Tribol - Mater, Surfaces Interfaces 10(4):172–177

Qu J, Truhan JJ, Dai S, Luo H, Blau PJ (2006) Ionic liquids with ammonium cations as lubricants or additives. Tribol Lett 22(3):207–214

Ajithkumar JP, Anthony Xavior M (2018) Influence of nano lubrication in machining operations - a review. Mater Today: Proceedings 5(5):11185–11192

Guo J, Wang L, Liang J, Xue Q, Yan F (2009) Tribological behavior of plasma electrolytic oxidation coating on magnesium alloy with oil lubrication at elevated temperatures. J Alloy Compd 481(1–2):903–909

Wu H, Zhao J, Luo L, Huang S, Wang L, Zhang S, Jiang Z (2018) Performance evaluation and lubrication mechanism of water-based nanolubricant containing nano-TiO2in hot steel rolling. Lubricants 6(3):57

Ma L, Luo J, Zhang C, Liu S, Lu X, Guo D, Zhu T (2009) Film forming characteristics of oil-in-water emulsion with super-low oil concentration. Colloids Surf, A 340(1–3):70–76

Ma L, Xu X, Zhang C, Guo D, Luo J (2014) Reemulsification effect on the film formation of O/W emulsion. J Colloid Interface Sci 417:238–243

Luo J, Wen S, Huang P (1996) Thin film lubrication. Part I. Study on the transition between EHL and thin film lubrication using a relative optical interference intensity technique. Wear 194(1–2):107–115

Nana L, Jianlin S, Zuoxin Z, Lei X, Sang X (2015) Research of lubrication model and surface quality in cold-rolling copper alloy using O/W emulsions. Rare Metal Mater Eng 44(8):1845–1850

Xia W, Zhao J, Wu H, Zhao X, Zhang X, Xu J, Jiang Z (2018) Effects of oil-in-water based nanolubricant containing TiO2 nanoparticles in hot rolling of 304 stainless steel. J Mater Process Technol 262:149–156

Xia W, Zhao J, Wu H, Jiao S, Jiang Z (2017) Effects of oil-in-water based nanolubricant containing TiO2 nanoparticles on the tribological behaviour of oxidised high-speed steel. Tribol Int 110:77–85

Xia W, Zhao J, Jiang Z, Wu H, Jiao S, Zhang X, Zhao X (2016) A novel nano-TiO2additive oil-in-water lubricant for hot steel rolling. Materials Science Forum 861:201–206

Xia W, Zhao J, Cheng X, Sun J, Wu H, Yan Y, Jiang Z (2017) Study on growth behaviour of oxide scale and its effects on tribological property of nano-TiO2 additive oil-in-water lubricant. Wear 376–377:792–802

Wei DB, Huang JX, Zhang AW, Jiang ZY, Tieu AK, Shi X, Qu XY (2009) Study on the oxidation of stainless steels 304 and 304L in humid air and the friction during hot rolling. Wear 267(9–10):1741–1745

Xia W, Zhao J, Wu H, Jiao S, Zhao X, Zhang X, Jiang Z (2018) Analysis of oil-in-water based nanolubricant with varying mass fractions of oil and TiO2 nanoparticles. Wear 396–397:162–171

Zhang Q, Jiang ZY, Wei DB, Zhu HT, Chen ZX, Han JT, Xie GL (2013) Interface adhesion during sliding wear in cast iron after hot deformation. Wear 301(1–2):598–607

Wu H, Jia F, Zhao J, Huang S, Wang L, Jiao S, Jiang Z (2019) Effect of water-based nanolubricant containing nano-TiO2 on friction and wear behaviour of chrome steel at ambient and elevated temperatures. Wear 426–427:792–804

Berman D, Erdemir A, Sumant AV (2014) Graphene: a new emerging lubricant. Mater Today 17(1):31–42

Jiang ZY, Tang J, Sun W, Tieu AK, Wei D (2010) Analysis of tribological feature of the oxide scale in hot strip rolling. Tribol Int 43(8):1339–1345

Wu H, Kamali H, Huo M, Lin F, Huang S, Huang H, Jiang Z (2020) Eco-friendly water-based nanolubricant for industrial-scale hot steel rolling. Lubricants 8(11):96

Meng Y, Sun J, Wu P, Dong C, Yan X (2018) The role of nano-TiO2 lubricating fluid on the hot rolled surface and metallographic structure of SS41 steel. Nanomaterials (Basel) 8(2):111

Wu H, Zhao J, Xia W, Cheng X, He A, Yun JH, Jiang Z (2017) A study of the tribological behaviour of TiO2 nano-additive water-based lubricants. Tribol Int 109:398–408

Peng DX, Kang Y, Hwang RM, Shyr SS, Chang YP (2009) Tribological properties of diamond and SiO2 nanoparticles added in paraffin. Tribol Int 42(6):911–917

Raina A, Anand A (2018) Lubrication performance of synthetic oil mixed with diamond nanoparticles: effect of concentration. Mater Today: Proceedings 5(9):20588–20594

Ma L, Ma X, Xue J, Zhou C, Jiang Z, Wang T, Zhao J (2023) Study of the tribological properties of nano-TiO2 additive water-based lubricants in microrolling of ultrathin stainless steel strips. Tribol Trans 66(3):466–476

Zhao J, Mao J, Li Y, He Y, Luo J (2018) Friction-induced nano-structural evolution of graphene as a lubrication additive. Appl Surf Sci 434:21–27

Wang XL, Yin YL, Zhang GN, Wang WY, Zhao KK (2013) Study on antiwear and repairing performances about mass of nano-copper lubricating additives to 45 steel. Phys Procedia 50:466–472

Zhang C, Zhang S, Song S, Yang G, Yu L, Wu Z, Zhang P (2014) Preparation and tribological properties of surface-capped copper nanoparticle as a water-based lubricant additive. Tribol Lett 54(1):25–33

Ma L, Luo J (2015) Advances in thin film lubrication (TFL): from discovery to the aroused further researches. SCIENCE CHINA Technol Sci 58(10):1609–1616

Wang X, Xu Q, Zhang Y, Zhang F (2020) Interaction mechanism between nanoparticles and ultra-smooth surface under effect of cavitation. Precis Eng 66:464–471

Do MT, Tang Z, Kane M, de Larrard F (2009) Evolution of road-surface skid-resistance and texture due to polishing. Wear 266(5–6):574–577

Ingole S, Charanpahari A, Kakade A, Umare SS, Bhatt DV, Menghani J (2013) Tribological behavior of nano TiO2 as an additive in base oil. Wear 301(1–2):776–785

Koshy CP, Rajendrakumar PK, Thottackkad MV (2015) Evaluation of the tribological and thermo-physical properties of coconut oil added with MoS2 nanoparticles at elevated temperatures. Wear 330–331:288–308

Lee K, Hwang Y, Cheong S, Choi Y, Kwon L, Lee J, Kim SH (2009) Understanding the role of nanoparticles in nano-oil lubrication. Tribol Lett 35(2):127–131

Yadgarov L, Petrone V, Rosentsveig R, Feldman Y, Tenne R, Senatore A (2013) Tribological studies of rhenium doped fullerene-like MoS2 nanoparticles in boundary, mixed and elasto-hydrodynamic lubrication conditions. Wear 297(1–2):1103–1110

Funding

This research was supported by the National Natural Science Foundation of China (No. 51975398), the Central Government Guided Local Science and Technology Development Fund Project (Grant No. YDZJSX2021A006), and the Natural Science Foundation of Shanxi Province (Grant No. 202103021223286).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical approval

All procedures performed in studies involving human participants were in accordance with the ethical standards of the institutional and/or national research committee and with the 1964 Helsinki Declaration and its later amendments or comparable ethical standards.

Consent to participate

Informed consent was obtained from all individual participants included in the study.

Consent for publication

The participant has consented to the submission of the case report to the journal.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, L., Ma, X., Bai, S. et al. Research progress of nanolubrication for rolling process. Int J Adv Manuf Technol 129, 999–1015 (2023). https://doi.org/10.1007/s00170-023-12186-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12186-3