Abstract

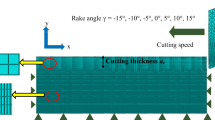

The objective of this research is to simulate the cutting edge micro-geometry in machining stainless steel (SUS-316L). This paper based on finite element method (FEM) analyzes the cutting mechanism of different cutting edge symmetry geometries (K = 1) and asymmetry geometries (K = 0.5 and K = 2), studied plastic strain and residual stress, Mises stress and distribution of temperature, and also tool-chip contact length and the effective rake angle γeff. By drag finishing prepared three kinds of cutting edge roundness with symmetry (K = 1) and asymmetry (K = 0.5 and K = 2), which is cutting test for verifying the correctness of the model through chip geometry morphology. The simulation results suggest that waterfall tools (K = 0.5) can increase stress strain and peak cutting temperature compared with other cutting edge micro-geometry. At the same time, the trumpet tools (K = 2) also have a great influence on sub-surface and surface stress distribution. Therefore, the cutting edge segment on the flank face Sα has significant the metal cutting process.

Similar content being viewed by others

Abbreviations

- K :

-

From-factor

- Sγ :

-

Cutting edge segment on the rake face

- Sα :

-

Cutting edge segment on the flank face

- Aγ :

-

Rake face

- Aα :

-

Flank face

- φ :

-

Apex angle

- r ε :

-

Edge radius of the tool (μm)

- A :

-

plastic equivalent strain in (JC) (MPa)

- B :

-

strain related constant in (JC) (MPa)

- C :

-

strain-rate sensitivity constant in (JC)

- m :

-

thermal softening exponent in (JC)

- n :

-

strain-hardening parameter in (JC)

- T m :

-

melting temperature of the work material (JC)

References

Ng E-G, El-Wardany Tahany I, Dumitrescu M, Elbestawi Mohamed A (2002) Physics-based simulation of high speed machining. Mach Sci Technol 6(3):301–329. https://doi.org/10.1081/MST-120016248

Mackerle J (1999) Finite element analysis and simulation of machining: a bibliography (1976–1996). J Mater Process Technol 5:615. https://doi.org/10.1088/0965-0393/5/6/006

Denkena B, Lucas A, Bassett E (2011) Effects of the cutting edge microgeometry on tool wear and its thermomechanical load. CIRP Ann Manuf Technol 60(1):73–76. https://doi.org/10.1016/j.cirp.2011.03.098

Tiffe M, Aßmuth R, Saelzer J, Biermann D (2019) Investigation on cutting edge preparation and FEM assisted optimization of the cutting edge micro shape for machining of nickel-base alloy. Prod Eng 13:459–467. https://doi.org/10.1007/s11740-019-00900-8

Bassett E, Köhler J, Denkena B (2012) On the honed cutting edge and its side effects during orthogonal turning operations of AISI1045 with coated WC-Co inserts. CIRP J Manuf Sci Technol 5:108–126. https://doi.org/10.1016/j.cirpj.2012.03.004

Terwey I (2011) Steigerung der Leistungsfähigkeit von Vollhartmetallwendelbohrern durch Strahlspanen. Technische Universität Dortmund

Lv DJ, Wang YG, Yu X, Chen H, Gao Y (2021) Analysis of abrasives on cutting edge preparation by drag finishing. Int J Adv Manuf Technol 119(5-6):3583–3594. https://doi.org/10.21203/rs.3.rs-669967/v1

Wyen CF (2012) Rounded cutting edges and their influence in machining titanium, vol VDI, Reihe 2. Fortschritt-Berichte Fertigungstechnik Null (685)

Denkena B, Reichstein M, Brodehl J, Lde LG (2005) Surface preparation, coating and wear performance of geometrically defined cutting Edges. In: 8th CIRP Int. Workshop on Modeling of Machining Operations, May 10–11. Chemnitz

Jiang L, Wang D (2019) Finite-element-analysis of the effect of different wiper tool edge geometries during the hard turning of AISI 4340 steel. Simul Modell Pract Theory 94:250–263. https://doi.org/10.1016/j.simpat.2019.03.006

Jin X, Altintas Y (2011) Slip-line field model of micro-cutting process with round tool edge effect. J Mater Process Technol 211(3):339–355. https://doi.org/10.1016/j.jmatprotec.2010.10.006

Molinari A, Cheriguene R, Miguelez H (2011) Numerical and analytical modeling of orthogonal cutting: the link between local variables and global contact characteristics. Int J Mech Sci 53(3):183–206. https://doi.org/10.1016/j.ijmecsci.2010.12.007

Woon KS, Rahman M, Neo KS, Liu K (2008) The effect of tool edge radius on the contact phenomenon of tool-based micromachining. Int J Mach Tools Manuf 48(12-13):1395–1407. https://doi.org/10.1016/j.ijmachtools.2008.05.001

Childs T (2006) Numerical experiments on the influence of material and other variables on plane strain continuous chip formation in metal machining. Int J Mech Sci 48(3):307–322. https://doi.org/10.1016/j.ijmecsci.2005.09.012

Krebs E, Wolf M, Biermann D, Tillmann W, Stangier D (2018) High-quality cutting edge preparation of micro milling tools using wet abrasive jet machining process. Prod Eng Res Devel 12(1):45–51

Bernard SE, Selvaganesh R, Khoshick G, Raj DS (2021) A novel contact area based analysis to study the thermo-mechanical effect of cutting edge radius using numerical and multi-sensor experimental investigation in turning. J Mater Process Technol 293:117085. https://doi.org/10.1016/j.jmatprotec.2021.117085

Maiss O, Grove T, Denkena B (2017) Influence of asymmetric cutting edge roundings on surface topography. Prod Eng Res Devel 11:383–388. https://doi.org/10.1007/s11740-017-0742-7

Schulze V, Autenrieth H, Deuchert M, Weule H (2010) Investigation of surface near residual stress states after micro-cutting by finite element simulation. CIRP Annals-Manuf Technol 59(1):117–120. https://doi.org/10.1016/j.cirp.2010.03.064

Shen Q, Liu ZQ, Hua Y, Zhao JF, Lv WY, Mohsan A (2018) Effects of cutting edge microgeometry on residual stress in orthogonal cutting of Inconel 718 by FEM. Materials 11(6):1015. https://doi.org/10.3390/ma11061015

Liu YX, Dong DA, Mathias S, Rachid M, AylinStahl J-EZ, Jin M (2021) Numerical and experimental investigation of tool geometry effect on residual stresses in orthogonal machining of Inconel 718. Simul Modell Pract Theory 106(1):102187. https://doi.org/10.1016/j.simpat.2020.102187

Denkena B, Biermann D (2014) Cutting edge geometries. CIRP Annals-Manuf Technol 63(2):631–653. https://doi.org/10.1016/j.cirp.2014.05.009

Denkena B, KHler J, Mengesha MS (2012) Influence of the cutting edge rounding on the chip formation process: Part 1. Investigation of material flow, process forces, and cutting temperature. Prod Eng 6(4-5):329–338. https://doi.org/10.1007/s11740-012-0366-x

Lv DJ, Wang YG, Yu X (2020) Effects of cutting edge radius on cutting force, tool wear, and life in milling of SUS-316L steel. Int J Adv Manuf Technol 111:2833–2844. https://doi.org/10.1007/s00170-020-06286-7

Wyen CF, Wegener K (2010) Influence of cutting edge radius on cutting forces in machining titanium. CIRP Annals - Manuf Technol 59(1):93–96. https://doi.org/10.1016/j.cirp.2010.03.056

Johnson GR, Cook WH (1983) A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. Eng Fract Mech 21:541–548

Srs A, Gla B, Tz A (2019) Finite element simulations of chip serration in titanium alloy cutting by considering material failure. Procedia CIRP 82:320–325. https://doi.org/10.1016/j.procir.2019.04.153

Bonnet C, Valiorgue F, Rech J, Claudin C, Hamdi H, Bergheau JM, Gilles P (2008) Identification of a friction model-application to the context of dry cutting of an AISI 316L austenitic stainless steel with a TiN coated carbide tool. Int J Mach Tools Manuf 48(11):1211–1223. https://doi.org/10.1016/j.ijmachtools.2008.03.011

Shashank S, Sameehan S, Joshi MV, Pantawane MR, Sangram M, Narendra B, Dahotre (2023) Multiphysics multi-scale computational framework for linking process–structure–property relationships in metal additive manufacturing: a critical review. Int Mater Rev 213:112107. https://doi.org/10.1080/09506608.2023.2169501

Li P, Chang ZY (2022) A hybrid model for turning force based on shear and extrusion deformation considering cutting-edge radius. J Manuf Processes 84:134–148. https://doi.org/10.1016/j.jmapro.2022.09.007

Özel T, Ulutan D (2012) Prediction of machining induced residual stresses in turning of titanium and nickel based alloys with experiments and finite element simulations. CIRP Annals-Manuf Technol 61(1):547–550. https://doi.org/10.1016/j.cirp.2012.03.100

Wang HSJ (2019) Feasibility study of the Ti(C7N3)-based cermet micro-mill based on dynamic fatigue behavior and modeling of the contact stress distribution on the round cutting edge. Int J Mech Sci 155:143–158. https://doi.org/10.1016/j.ijmecsci.2019.02.038

Karpat Y, Özel T (2008) Analytical and thermal modeling of high-speed machining with chamfered tools. J Manuf Sci. Eng 130(1):011001. https://doi.org/10.1115/1.2783282

Lai X, Li H, Li C, Lin Z, Ni J (2008) Modelling and analysis of micro scale milling considering size effect micro cutter edge radius and minimum chip thickness. Int J Mach Tools Manuf 48(1):1–14. https://doi.org/10.1016/j.ijmachtools.2007.08.011

Fan YH, Wang T, Hao ZP, Liu XY, Gao S, Li RL (2018) Surface residual stress in high speed cutting of superalloy Inconel 718 based on multiscale simulation. J Manuf Processes 31(1):480–493. https://doi.org/10.1016/j.jmapro.2017.12.011

Nasr M, Ng EG, Elbestawi MA (2007) Modelling the effects of tool-edge radius on residual stresses when orthogonal cutting AISI 316L. Int J Mach Tools Manuf 47(2):401–411. https://doi.org/10.1016/j.ijmachtools.2006.03.004

Acknowledgements

The authors would like to thank the Guohong Tool System (Wuxi) Co., Ltd for providing the experimental conditions and software simulation, including drag finishing and cutting experimental devices, tools, workpiece materials, and the third wave AdvantEdge software.

Author information

Authors and Affiliations

Contributions

Dejin Lv: methodology, data curation, formal analysis, writing original draft. Xin Yu: investigation, data curation. Yongguo Wang: supervision, writing — review and editing.

Corresponding author

Ethics declarations

Ethics approval

Ethics approval was not required for this research.

Consent to participate

Not applicable.

Consent for publication

The authors do agree that the copyright of this paper is transferred to Springer’s journal “The International Journal of Advanced Manufacturing Technology” when the paper is accepted for publication.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lv, D., Yu, X. & Wang, Y. Evaluation of cutting edge K-form factor in milling of 316L stainless steel: a study based on FEM. Int J Adv Manuf Technol 128, 5223–5236 (2023). https://doi.org/10.1007/s00170-023-12098-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12098-2