Abstract

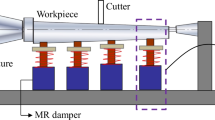

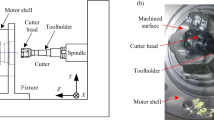

Cantilever parts are extensively used in aerospace applications. However, machining vibrations readily arise under the action of cutting forces due to the poor fixed stiffness of cantilever parts mounted on large structures, compromising working accuracy and efficiency. To address the shortcomings of traditional special vibration suppression fixtures including lengthy development cycles, high costs and limited universality, a mobile robot-assisted clamping system was proposed to fulfill the vibration suppression requirements of diverse cantilever parts on large structures. Furthermore, to analyze the vibration responses under different clamping states, a workpiece-fixture dynamics model incorporating the mobile robot-assisted clamping system is established using the transfer matrix method for multibody systems (MSTMM). Then, the effects of different clamping states on cantilevered part vibration are explored using acceleration responses as the metric. Finally, the effectiveness of the vibration suppression method and the accuracy of the dynamics model are validated through experiment and simulation. This work provides a solution for vibration suppression and optimal clamping states selection of different cantilever parts.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Zhou X, Zhang DH, Luo M, Wu BH (2015) Chatter stability prediction in four-axis milling of aero-engine casings with bull-nose end mill. Chin J Aeronaut 28:1766–1773

Yang Y, Zhang WH, Ma YC, Wan M (2016) Chatter prediction for the peripheral milling of thin-walled workpieces with curved surfaces. Int J Mach Tool Manuf 109:36–48

Moradi H, Vossoughi G, Behzad M, Movahhedy MR (2015) Vibration absorber design to suppress regenerative chatter in nonlinear milling process: application for machining of cantilever plates. Appl Math Model 39:600–620

Li B, Cui GY, Tian W, Liao WH (2022) Vibration suppression of an industrial robot with AGV in drilling applications by configuration optimization. Appl Math Model 112:614–631

Shamoto E, Mori T, Nishimura K, Hiramatsu T, Kurata Y (2010) Suppression of regenerative chatter vibration in simultaneous double-sided milling of flexible plates by speed difference. CIRP Ann-Manuf Technol 59:387–390

Khorshidi K, Rezaei E, Ghadimi AA, Pagoli M (2015) Active vibration control of circular plates coupled with piezoelectric layers excited by plane sound wave. Appl Math Model 39:1217–1228

Fei JX, Lin B, Xiao JL, Ding M, Yan S, Zhang XF, Zhang J (2018) Investigation of moving fixture on deformation suppression during milling process of thin-walled structures. J Manuf Process 32:403–411

Yuan H, Wan M, Yang Y (2019) Design of a tunable mass damper for mitigating vibrations in milling of cylindrical parts. Chin J Aeronaut 32:748–758

Kono I, Miyamoto T, Utsumi K, Nishikawa K, Onozuka H, Hirai J, Sugita N (2017) Study on machining vibration suppression with multiple tuned mass dampers: vibration control for long fin machining. Int J Auto Tech-Jpn 11:206–214

Qin P, Liu YA, Wang M, Zhang YL (2021) Milling vibration control of semiconical shell workpiece with multiple distribution tuned mass dampers. Int J Adv Manuf Technol 115:2175–2190

Kolluru K, Axinte D, Becker A (2013) A solution for minimising vibrations in milling of thin walled casings by applying dampers to workpiece surface. CIRP Ann-Manuf Technol 62:415–418

Christian M, Hans CS, Philip K, Christian B, Simon-Markus K, Jörg W, Wolfgang H (2017) Machining of large scaled CFRP-Parts with mobile CNC-based robotic system in aerospace industry. Procedia Manuf 14:17–29

Smith S, Wilhelm R, Dutterer B, Cherukuri H, Goel G (2012) Sacrificial structure preforms for thin part machining. CIRP Ann-Manuf Technol 61:379–382

Slamani M, Gauthier S, Chatelain J-F (2015) A study of the combined effects of machining parameters on cutting force components during high speed robotic trimming of CFRPs. Measurement 59:268–283

Kaliński Krzysztof J, Mazur Michał R, Galewski Marek A (2013) The optimal spindle speed map for reduction of chatter vibration during milling of bow thruster blade. Solid State Commun 198:686–691

Zhang XM, Ding H (2013) Note on a novel method for machining parameters optimization in a chatter-free milling process. Int J Mach Tool Manuf 72:11–15

Wang H, Zhang KY, Wu DB, Yu T, Yu J, Liao YP (2021) Analysis and optimization of the machining fixture system stiffness for near-net-shaped aero-engine blade. Int J Adv Manuf Technol 113:3509–3523

Luo M, Zhang XF, Zhang DH, Wu BH (2015) On-line compressor blade stiffness enhancement in multi-axis machining process. IFAC-PapersOnline 48:664–667

Atsushi M, Hiroaki N, Nils K, Daisuke K (2018) Influence of contact condition between flexible plate and passive pivot support on machining vibration. Procedia CIRP 77:557–560

Zeng SS, Wan XJ, Li WL, Yin ZP, Xiong YL (2012) A novel approach to fixture design on suppressing machining vibration of flexible workpiece. Int J Mach Tool Manuf 58:29–43

Raghu A, Melkote SN (2004) Analysis of the effects of fixture clamping sequence on part location errors. Int J Mach Tool Manuf 44:373–382

Wan X, Zhang Y, Huang X (2013) Investigation of influence of fixture layout on dynamic response of thin-wall multi-framed work-piece in machining. Int J Mach Tool Manuf 75:87–99

Wang SY, Song QH, Liu ZQ (2019) Vibration suppression of thin-walled workpiece milling using a time-space varying PD control method via piezoelectric actuator. Int J Adv Manuf Technol 105:2843–2856

Nagamatsu S, Shiraishi T (2021) Semi-active vibration suppression of a structure by a shear-type damper using magnetorheological grease. In: Oberst S, Halkon B, Ji J, Brown T (eds) Vibr Eng Sustain Future. Springer, Cham, pp 241–247

Ma JJ, Zhang DH, Wu BH, Luo M, Chen B (2016) Vibration suppression of thin-walled workpiece machining considering external damping properties based on magnetorheological fluids flexible fixture. Chin J Aeronaut 29:1074–1083

Sallese L, Grossi N, Tsahalis J, Scippa A, Campatelli G (2016) Intelligent fixtures for active chatter control in milling. Procedia CIRP 55:176–181

Li YG, Liu CQ, Hao XZ, Gao JX, Maropoulos PG (2015) Responsive fixture design using dynamic product inspection and monitoring technologies for the precision machining of large-scale aerospace parts. CIRP Ann-Manuf Technol 64:173–176

Li B, Tian W, Zhang CF, Hua FF, Cui GY, Li YF (2022) Positioning error compensation of an industrial robot using neural networks and experimental study. Chin J Aeronaut 35:346–360

Cui GY, Li B, Tian W, Liao WH, Zhao W (2022) Dynamic modeling and vibration prediction of an industrial robot in manufacturing. Appl Math Model 105:114–136

Rui XT, Wang XP, Zhou QB, Zhang JS (2019) Transfer matrix method for multibody systems (Rui method) and its applications. Sci China Technol Sci 62:712–720

Rui XT, Zhang JS, Wang X, Rong B, He B, Jin Z (2022) Multibody system transfer matrix method: the past, the present, and the future. Int J Mech Syst Dyn 2:3–26

Funding

This work was co-supported by the National Natural Science Foundation of China (Nos. 52005254, 52075256 and U22A20204), and the Fundamental Research Funds for the Central Universities (No. NT2022016).

Author information

Authors and Affiliations

Contributions

Pinzhang Wang: experiments design, dynamics modeling, data analysis, writing—original draft. Wei Tian: experiments design, data analysis, writing—reviewing and editing. Bo Li: investigation, supervision, reviewing and editing.

Corresponding authors

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

We confirm that this work is original and has not been published elsewhere, nor is it currently under consideration for publication elsewhere. All the authors listed have agreed to publish the manuscript that is enclosed.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

The transfer equation of the state vector \({\boldsymbol{\rm Z}}_{r,O}\) with respect to \({{\varvec{Z}}}_{r,I}\) is defined as

where \({{\varvec{U}}}_{r}\) is the transfer matrices of the rigid body, it is expressed as

where

where \({\widetilde{{\varvec{l}}}}_{CO}={\widetilde{{\varvec{l}}}}_{IO}-{\widetilde{{\varvec{l}}}}_{IC}\), I and O are the input and output end respectively, C is the center of mass, and \({\widetilde{{\varvec{l}}}}_{PQ}\) is the coordinate matrices of point Q relative to P. \({{\varvec{J}}}_{I}\) is the moment of inertia with respect to I, m is the mass of the body, \(\omega\) is the system natural frequency.

The transfer equation and the geometric relationship between multiple input ends are

where the transfer matrix \({{\varvec{U}}}_{\mathrm{13,1}}\) is consistent with the form of \({{\varvec{U}}}_{r}\) in Eq. (13), the transfer matrices of the output end with respect to input ends n (\(n=\mathrm{2,3},4\)) are represented as

The geometrical relationship of the first end with respect to itself is

The additional geometrical equations describing geometrical relationships between the first and nth \(\left(n=2,3,4\right)\) input ends can be expressed as

The transfer matrix of workpiece 31 can be obtained according to the above method.

The transfer matrix of spatial elastic hinge is

where v = 1, 3, 4, 6, 7, 9, 10, 12, 14, 16, 18, 20, 22, 24, 26, 28, 30, 32, and

in which \({K}_{v,x},{K}_{v,y}\), and \({K}_{v,z}\) donate the stiffnesses of springs in the \(x,y\), and \(z\) directions, respectively. Moreover, \({K}_{v,x}{\prime},{K}_{v,y}{\prime}\), and \({K}_{v,z}{\prime}\) are the torsional stiffnesses of rotary springs about the \(x,y\), and \(z\) directions, respectively.

According to the automatic deduction, the main transfer equation is established as follows

where \({{\varvec{Z}}}_{k,0}\) reprintings the state vector of the output end of element k, and

where \({{\varvec{U}}}_{i}\) is the transfer matrix corresponding to the element i, \({{\varvec{U}}}_{31,30}\) and \({{\varvec{U}}}_{31,32}\) are the transfer matrices of workpiece 31 with respect to input ends 30 and 32, \({{\varvec{U}}}_{13,3}\),\({{\varvec{U}}}_{13,6}\),\({{\varvec{U}}}_{13,9}\) and \({{\varvec{U}}}_{13,12}\) are the transfer matrices of AGV 13 with respect to input ends 3, 6, 9, and 12.

Furthermore, the coordinate transformation matrices are

where \({\theta }_{k}\) is the angle of the joint k, and

The elements with multiple input ends in the ARGW system include workpiece 31 and vehicle body 13, so system geometric equations can be found as

where \({{\varvec{O}}}_{6\times 1}\) denotes a 6 × 1 zero column matrix, and the parameters in Eq. (25) can be expressed as.

where

where \({l}_{io}\) represents the displacement matrix of the input point end o relative to first input end i, \({\widetilde{{\varvec{l}}}}_{io}\) refers to the skew-symmetric matrix of \({{\varvec{l}}}_{io}\). In this paper, i includes 13, and 31, o is the corresponding 3, 6, 9, 12, and 30, 32.

Combing the system main transfer equation Eq. (18) and the system geometric equations Eq. (25), the system overall transfer equation can be obtained as

Furthermore

Appendix 2. Calculation of the dynamic equation

The form of the coefficients in the overall dynamic equations are

And the augmented eigenvector of the kth model is defined as

The damping \({\varvec{C}}=2\zeta \omega {\varvec{M}}\), where \(\zeta\) is the modal damping ratio. According to the orthogonality of the augmented eigenvectors, the relation between M, K, and the augmented eigenvector \({{\varvec{V}}}^{j}\) is satisfied

where \({M}^{j}\) and \({K}^{j}={({\omega }^{j})}^{2}{M}^{j}\) are the jth-order modal mass and stiffness, respectively. Only when k = j, \({\delta }_{k,j}=1\), in other situations, \({\delta }_{k,j}=0\).

Appendix 3. Parameters in the simulation

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, P., Tian, W. & Li, B. Machining vibration suppression of cantilever parts of aerospace structure using robot-assisted clamping system. Int J Adv Manuf Technol 128, 4103–4121 (2023). https://doi.org/10.1007/s00170-023-12090-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12090-w